Water-based epoxy emulsion type carbon fiber sizing agent and preparation method thereof

A water-based epoxy emulsion and carbon fiber technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of volatile organic compounds that threaten human health, unfavorable large-scale production and cost control, and cannot realize large-scale application. , to achieve the effect of environmental protection, improvement and mass production, and low requirements for production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of the water-based epoxy emulsion type carbon fiber sizing agent, comprising the following production steps:

[0031] a. Add epoxy resin with a mass percentage of 15% to 35% into the flask, and raise the temperature of the flask to 85 to 90°C;

[0032] b. After the above-mentioned epoxy resin is completely softened, turn on the mixer for stirring. After 60-90 minutes, add 5%-20% surfactant by mass percentage, 0.1%-0.5% lubricant by mass percentage and 0.1%-0.5% by mass percentage to the flask. % defoamer, continue to use the mixer to stir for more than 120 minutes;

[0033] c. Afterwards, the flask was cooled to 65°C and the stirring rate was increased to more than 1500 rpm;

[0034] d. Slowly add deionized water with a mass percentage of 55% to 65% to the flask, and the water-based epoxy emulsion sizing agent is obtained after the addition is completed within 180-240 minutes.

Embodiment 1

[0036] A water-based epoxy emulsion type carbon fiber sizing agent, the mass percentage of its components is: 35% epoxy resin; 5% surfactant; 0.5% lubricant; 0.5% defoamer; 60% deionized water.

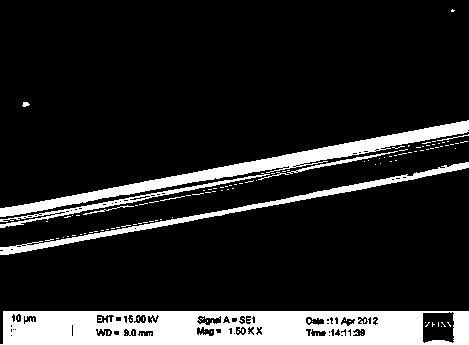

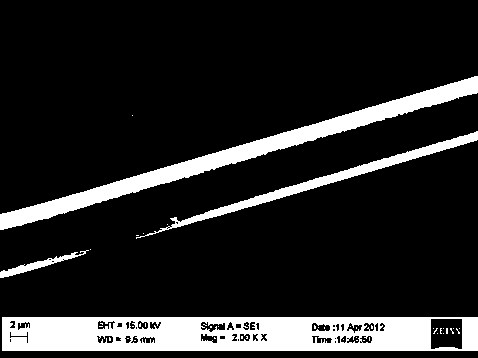

[0037] Preparation of sizing agent: put 240g of epoxy resin E51 and 360g of bisphenol A type epoxy resin E20 into a 3000mL four-neck flask equipped with a stirrer, a thermometer and a deionized water inlet tube, raise the temperature to 85-90°C, and wait for the bisphenol Start stirring after the A-type epoxy resin E20 is completely softened, add 32g alkylphenol polyoxyethylene ether NP-40, 32g alkylphenol polyoxyethylene ether NP-50, 8.63g polyethylene glycol stearate after 60 minutes and 8.63g of silicone water-based antifoaming agent BYK-022, continue to stir for 120 minutes, cool down to 65°C and increase the stirring speed to 1500 rpm, slowly add 1000g of deionized water dropwise, and complete the addition within 180 minutes to obtain water-based Epoxy emulsion sizing agent i...

Embodiment 2

[0040] A water-based epoxy emulsion type carbon fiber sizing agent, the mass percentage of its components is: epoxy resin 35%; surfactant 5%; lubricant 0.49%; defoamer 0.49%; deionized water 59%.

[0041] Preparation of sizing agent: Weigh 600g DOW-331 and 600g DOW-661 and place them in a 5000mL four-necked flask equipped with a mechanical stirrer, a thermometer and a deionized water inlet tube, raise the temperature to 85-90°C, and wait until the DOW-661 is completely softened Start stirring, add 60g of alkylphenol polyoxyethylene ether NP-40, 60g of alkylphenol polyoxyethylene ether NP-50, 16.53g of polyethylene glycol stearate and 16.53g of silicone water-based defoamer after 80 minutes , continue to stir for 150 minutes, lower the temperature to 65°C and increase the stirring rate to 1600 rpm, slowly add 2000g of deionized water dropwise, preferably within 240 minutes, to obtain 3361.4g of water-based epoxy emulsion sizing agent, test its The particle size is 268±4.815...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com