Patents

Literature

129results about How to "Suitable for large-scale mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

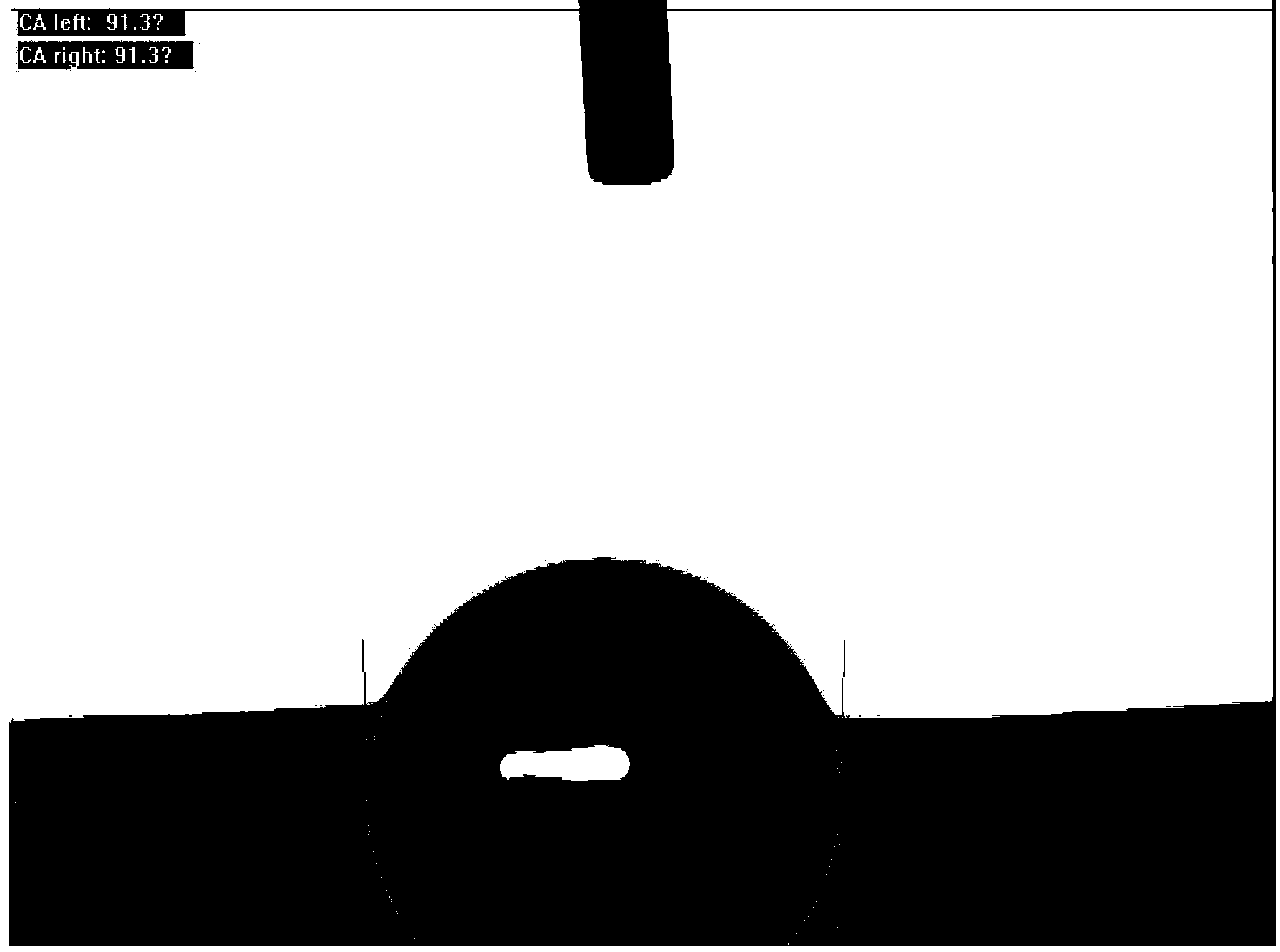

Super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane, and preparation method and application thereof

InactiveCN103316507AHas super oleophobic propertiesLow costFatty/oily/floating substances removal devicesLiquid separationHydrophilic polymersSewage

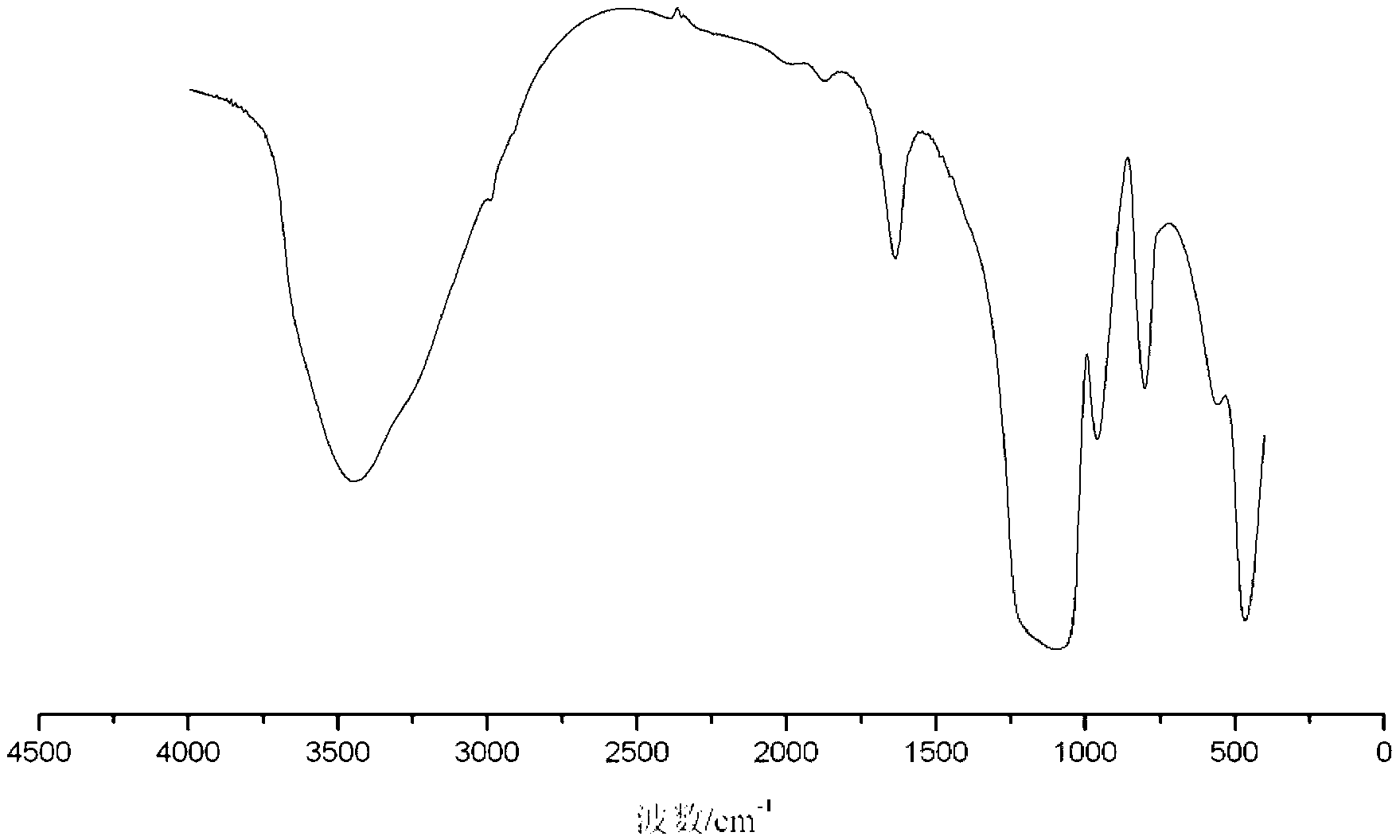

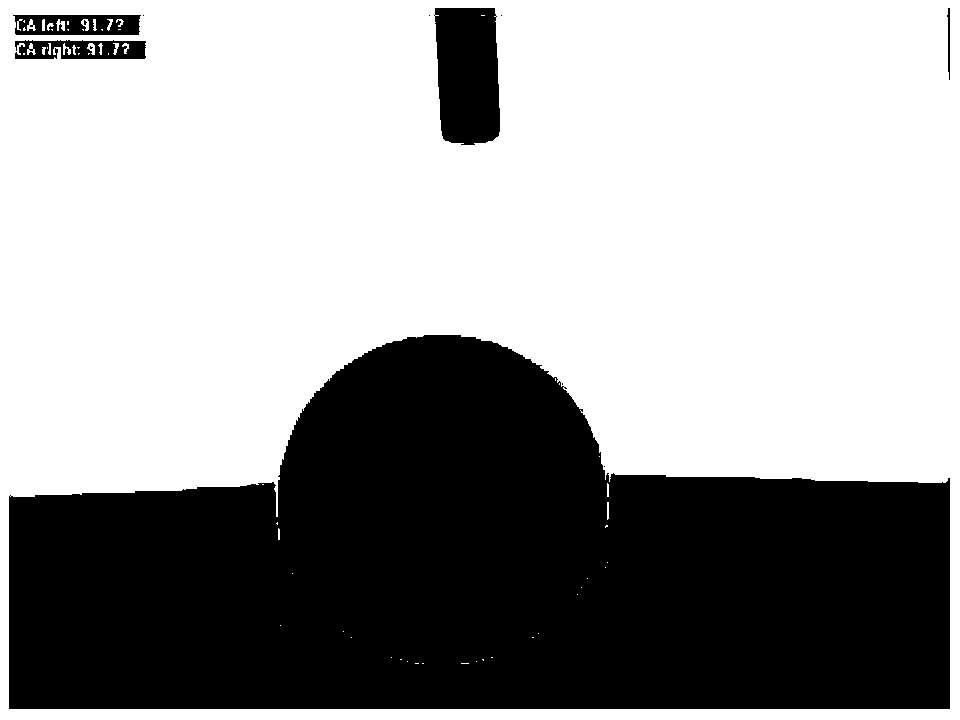

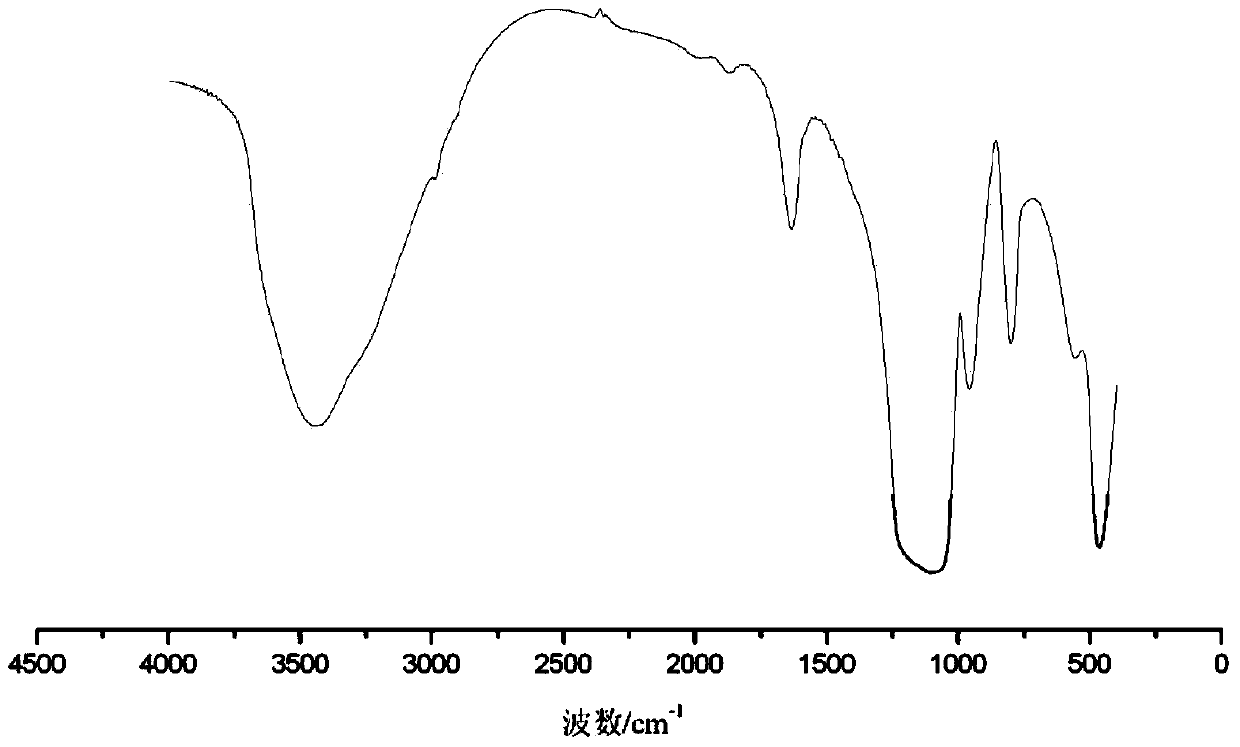

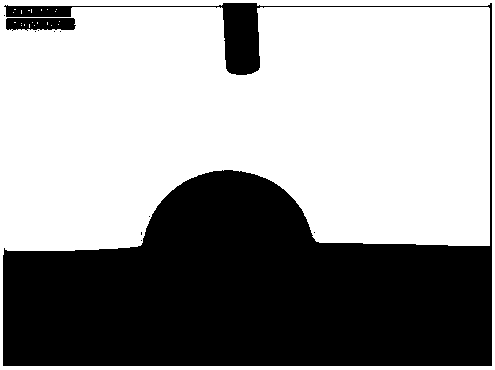

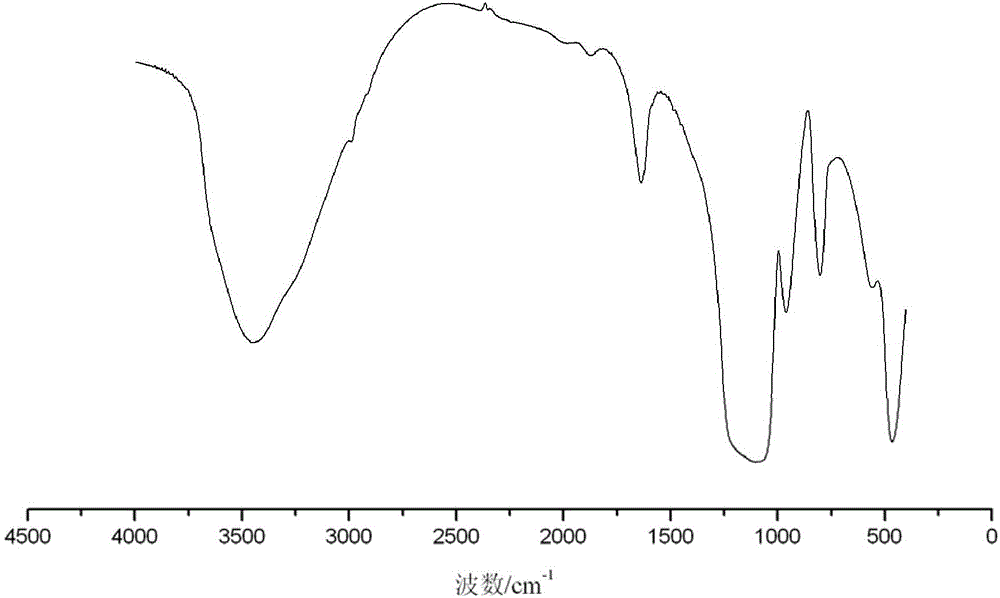

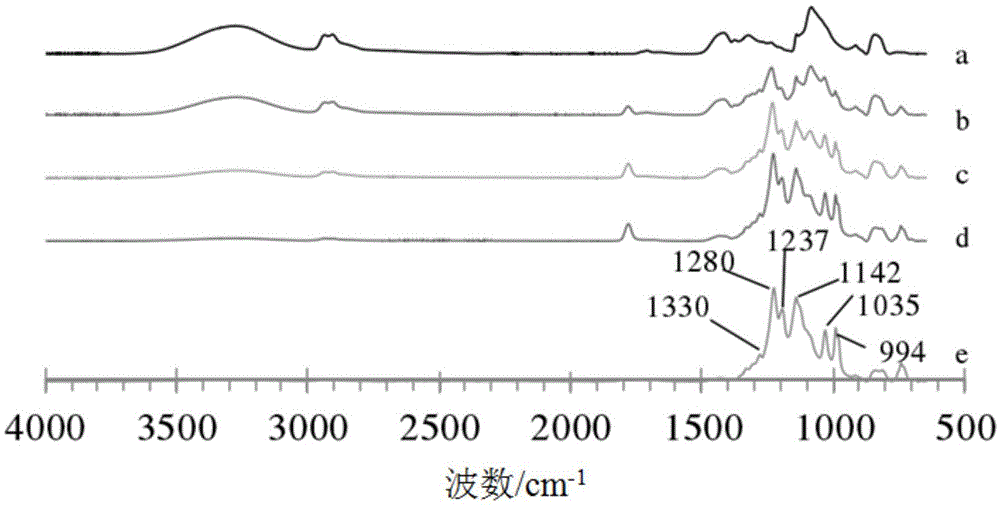

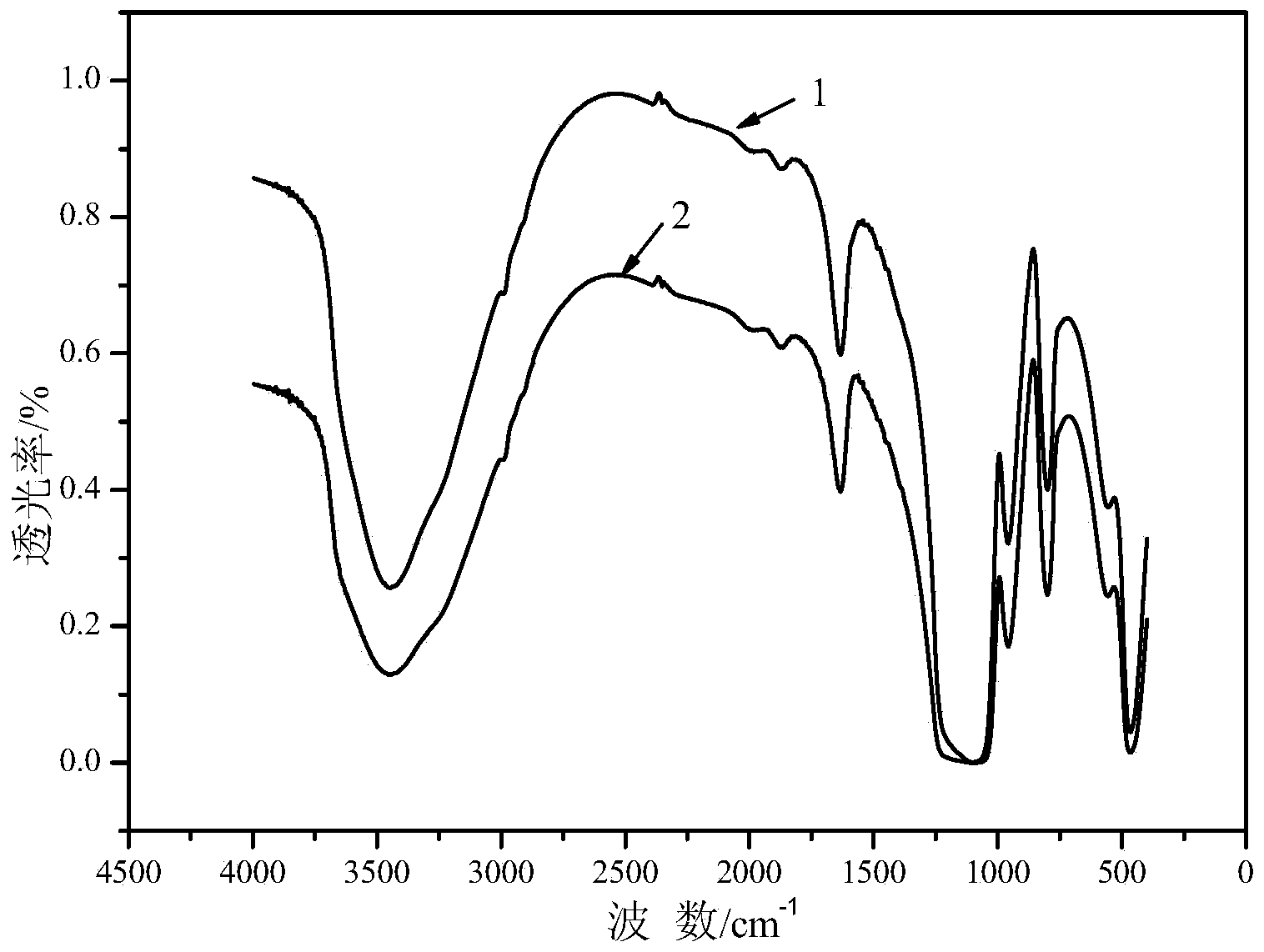

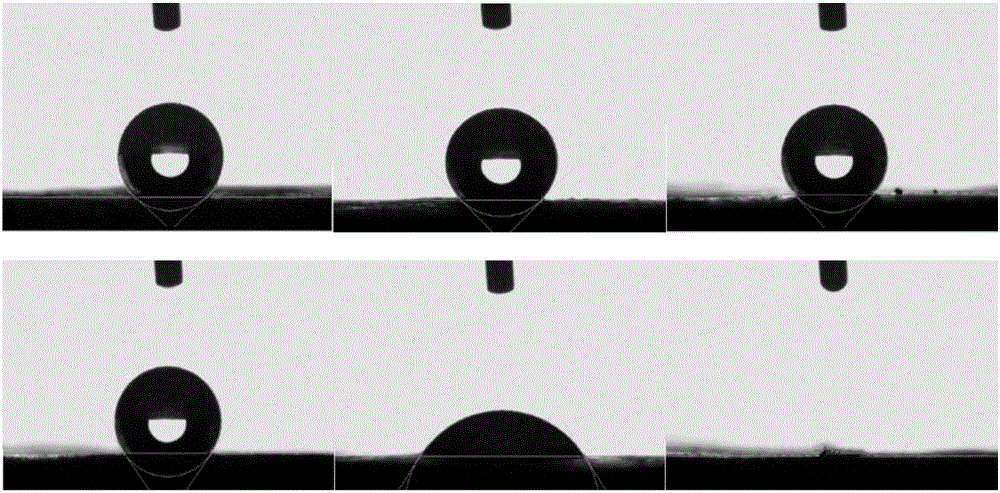

The invention discloses a super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane, and a preparation method and an application thereof. According to the method, fabric mesh with a specification of 100-300 meshes is subjected to ultrasonic cleaning, and is air-dried under normal temperature; a hydrophilic polymer water-sensitive agent and a cross-linking agent are dissolved in water according to a ratio of 1:9-9:1; the mixture is well mixed by magnetic stirring, such that a solution with a concentration of 1-99% is prepared; nano-sol is prepared with a sol-gel method; the solution and the nano-sol are prepared into a mixed solution with a concentration of 1-99%, and the solution is well dispersed through ultrasonic dispersion; the mesh is soaked in the mixed solution and is vertically lifted, or the mesh is directly sprayed by using a high-pressure spraying gun; and the mesh is bake-dried, such that the super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane is obtained. Contact angles of the super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane with water and oil in air are both 0 DEG, and the membrane is super-hydrophilic. Under water, the contact angle of the membrane with oil drops is larger than 150 DEG, and the membrane has an oil drop low adhesion characteristic. The mesh membrane provided by the invention can be used in oil-water mixture separation and oil-containing sewage processing.

Owner:SOUTH CHINA UNIV OF TECH

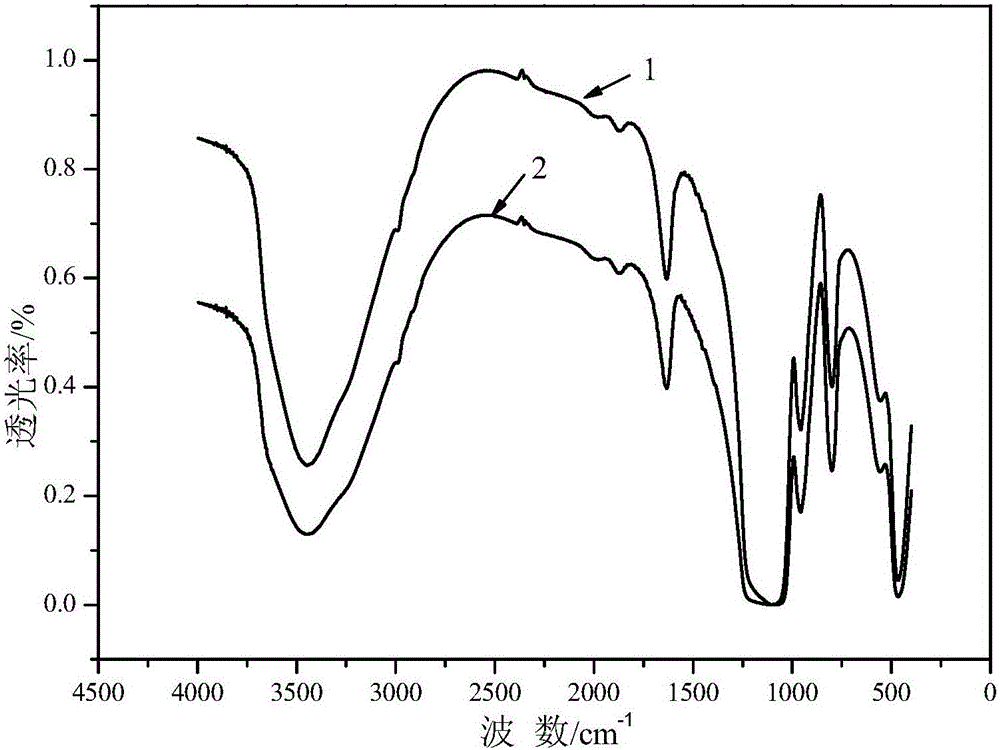

Oxidized graphene-modified super-hydrophilic super-oleophobic oil-water separation film and preparation method and application thereof

InactiveCN103623709AImproved swelling resistance and mechanical propertiesLow costSemi-permeable membranesFatty/oily/floating substances removal devicesCvd grapheneHydrophilic polymers

The invention discloses an oxidized graphene-modified super-hydrophilic super-oleophobic oil-water separation film and a preparation method and application thereof. The method comprises the following steps: mixing a hydrophilic polymer water-sensitive agent and a cross-linking film-forming agent according to a ratio of 1:9-9:1, dissolving the mixture and nano-silica sol in water according to a mass ratio of 1:9-9:1, magnetically stirring uniformly to prepare a 1-99% solution, adding 0.5-1 percent of oxidized graphen as an inorganic cross-linking agent, and ultrasonically and uniformly dispersing; ultrasonically cleaning a fabric silk screen with the particle size of 100-300 meshes, drying at normal temperature, forming a film on the silk screen in a spraying, dip-coating or spinning manner, drying and cross-linking, thus obtaining the hydrophilic and underwater super-oleophobic oil-water separation film. The oil-water separation film has excellent swelling resistance and mechanical property after graphene cross-linking modification, has a contact angle of 0 degree with both water and oil in air and has high super-hydrophilic property; the film has a contact angle of 150 degrees with oil drops under the water and has the low-adhesion characteristic to oil drops. The film can be applied to separation of oil-water mixtures and treatment of oil-containing sewage.

Owner:SOUTH CHINA UNIV OF TECH

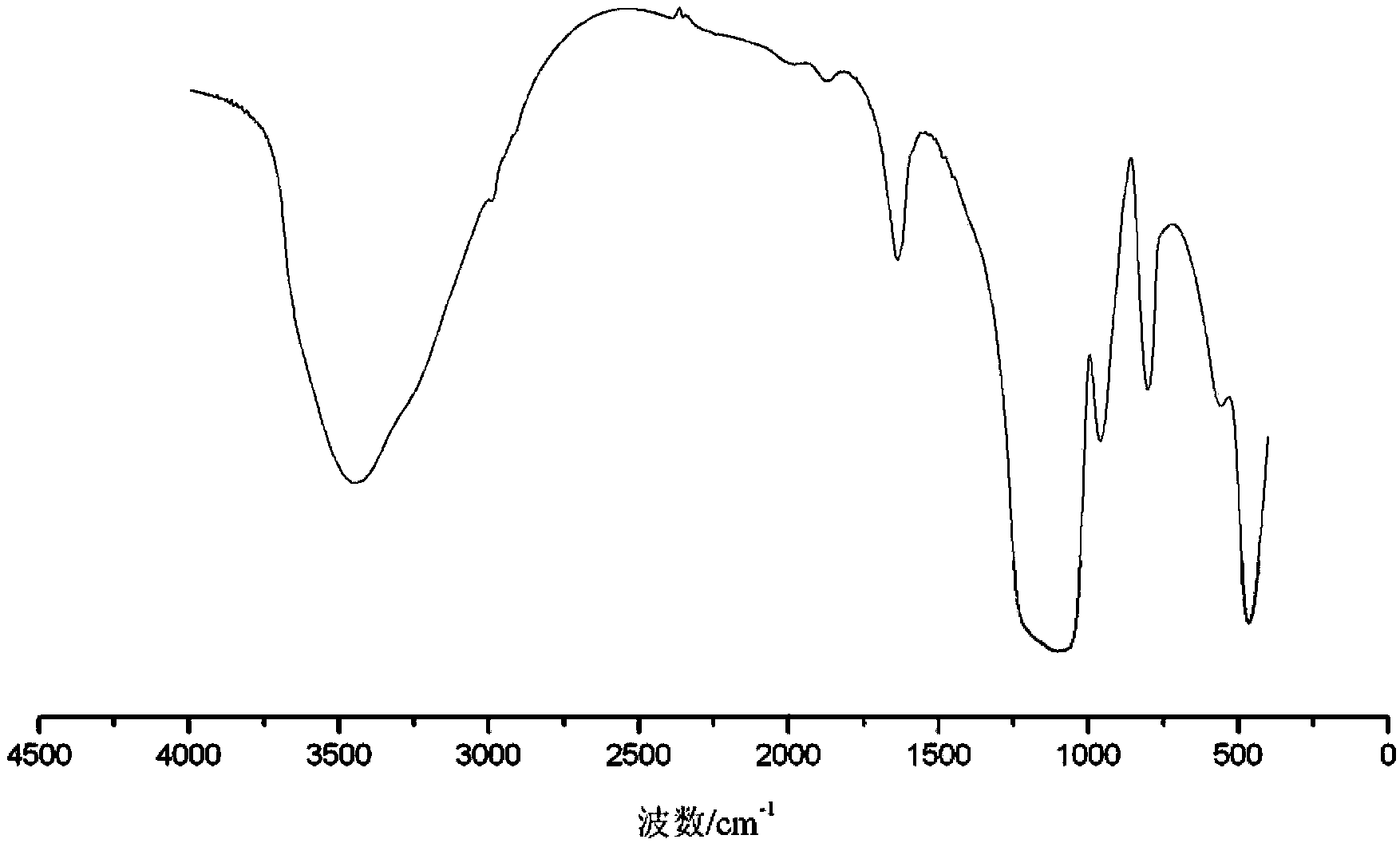

Hydrophilic oleophobic polymer and preparation method thereof, and application thereof in humidity response oil and water separating membrane

InactiveCN103601826AGood water and solvent resistanceLow costSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCarboxylationSewage

The invention discloses a hydrophilic oleophobic polymer and preparation method thereof, and application thereof in humidity response oil and water separating membrane. The preparation of the hydrophilic oleophobic polymer comprises the following steps: carrying out an esterification reaction of polyvinyl alcohol and perfluorocarboxylic acid or firstly carrying out a carboxylation of polyvinyl alcohol and then a neutralization reaction of the intermediate product and perfluorotertiary amine. When the product is used, a fabric silk screen is cleaned with ultrasonic sound; 10-50 parts of hydrophilic oleophobic polymer, 50-500 parts of nanometer sol, 1-5 parts of cross-linking agents and 1-5 parts of catalysts are dispersed uniformly; the mixed liquor is dip-coated or spray-coated on the surface of the membrane, and after drying and crosslinking, the humidity response super-hydrophilic and super-oleophobic oil and water separating net membrane. According to the invention, hydrophilic groups are distributed surrounding the hydrophobic chain segment on the surface of the net membrane with humidity responsiveness, and contact angle in the air of the product to water is reduced to 0 degree from more than 90 degrees, and the contact angle in air and water of the product to oil is above 150 degrees, so the product has a low adherence characteristic of droplet. The net membrane is used for separating oil and water mixture and processing oil-containing sewage.

Owner:SOUTH CHINA UNIV OF TECH

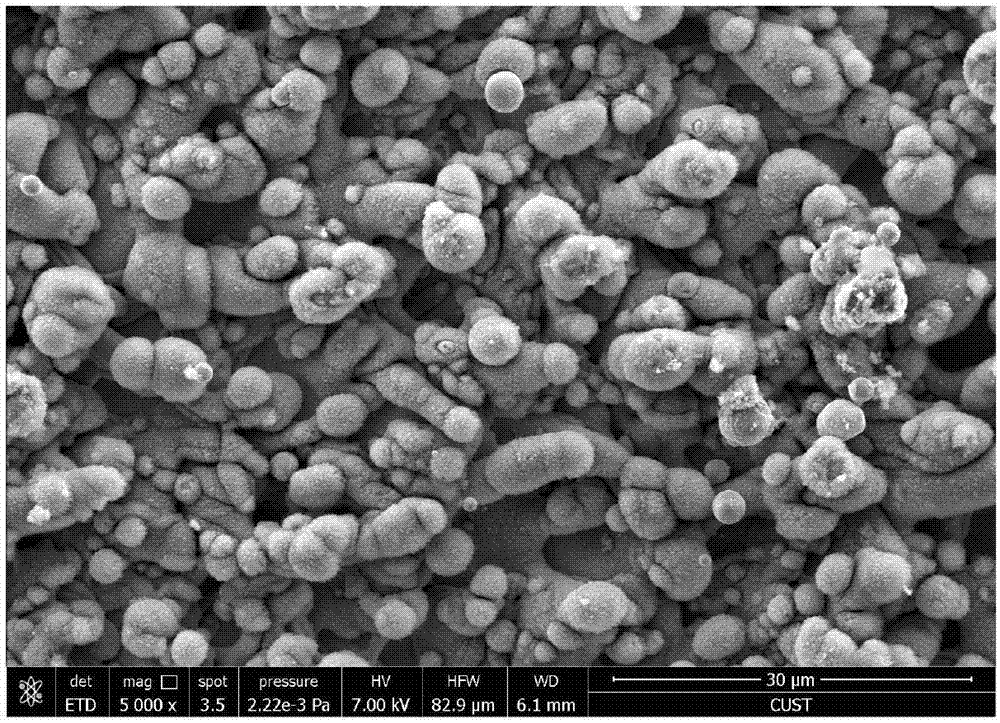

Super-hydrophilic and underwater super-oleophobic oil-water separation mesh film and preparation method thereof

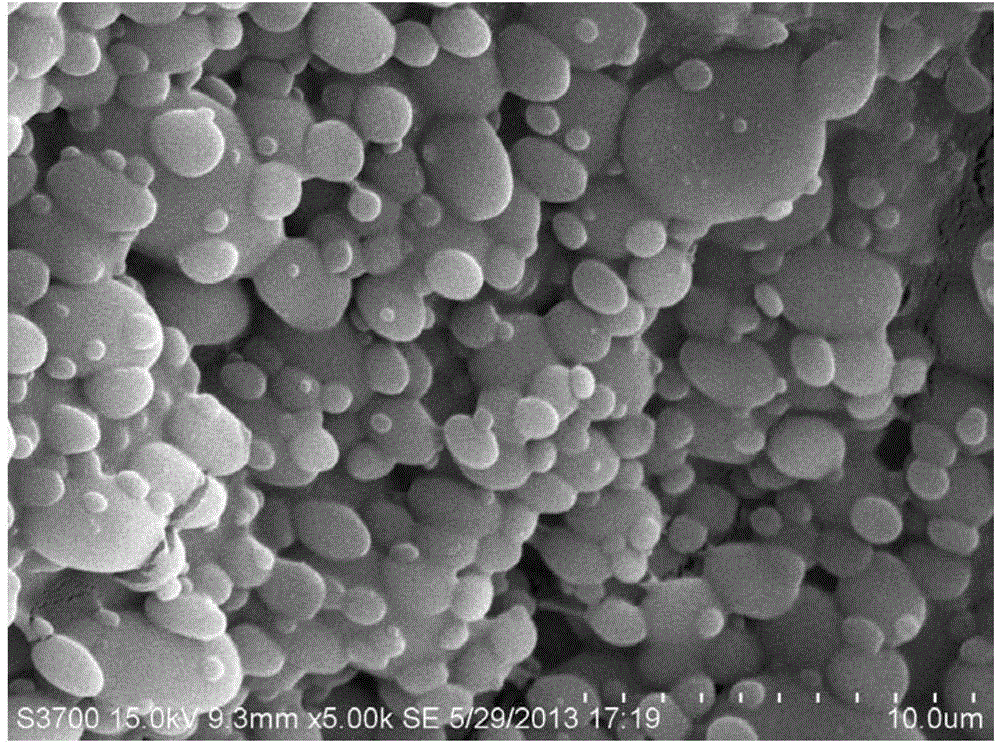

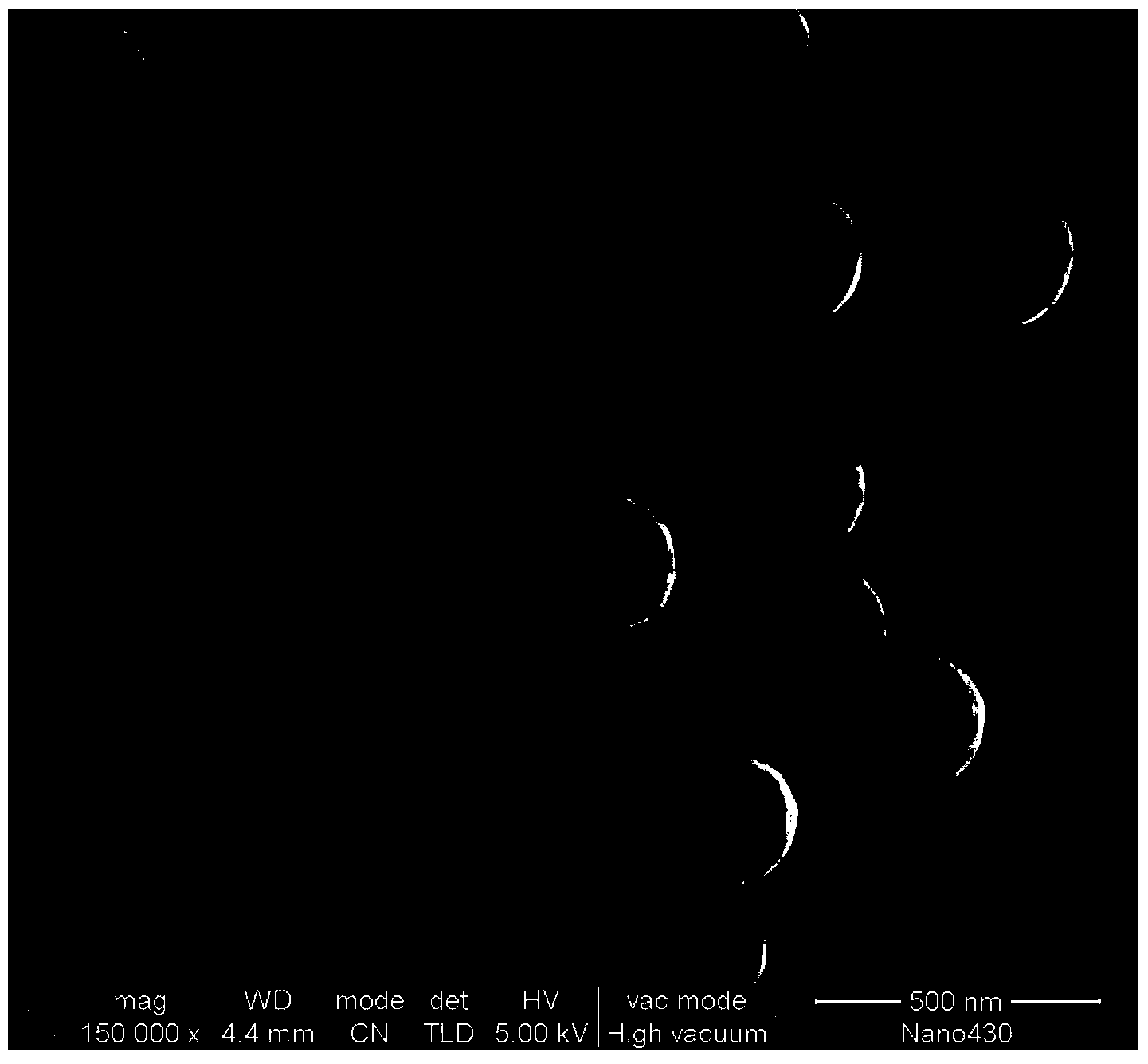

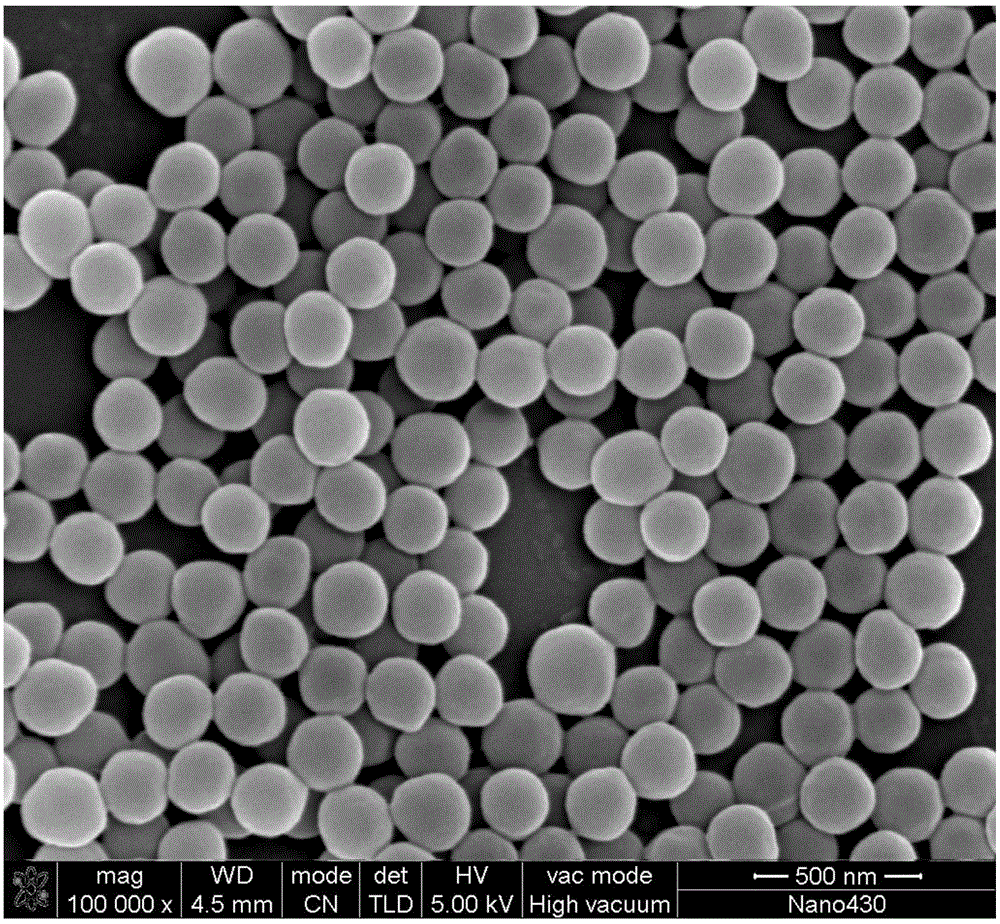

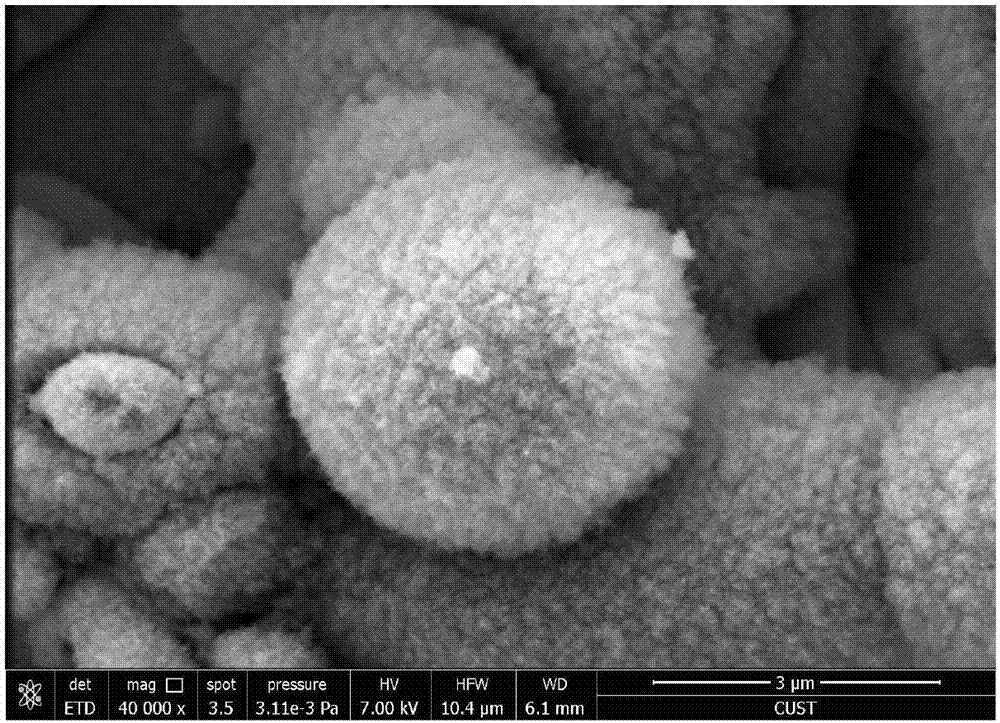

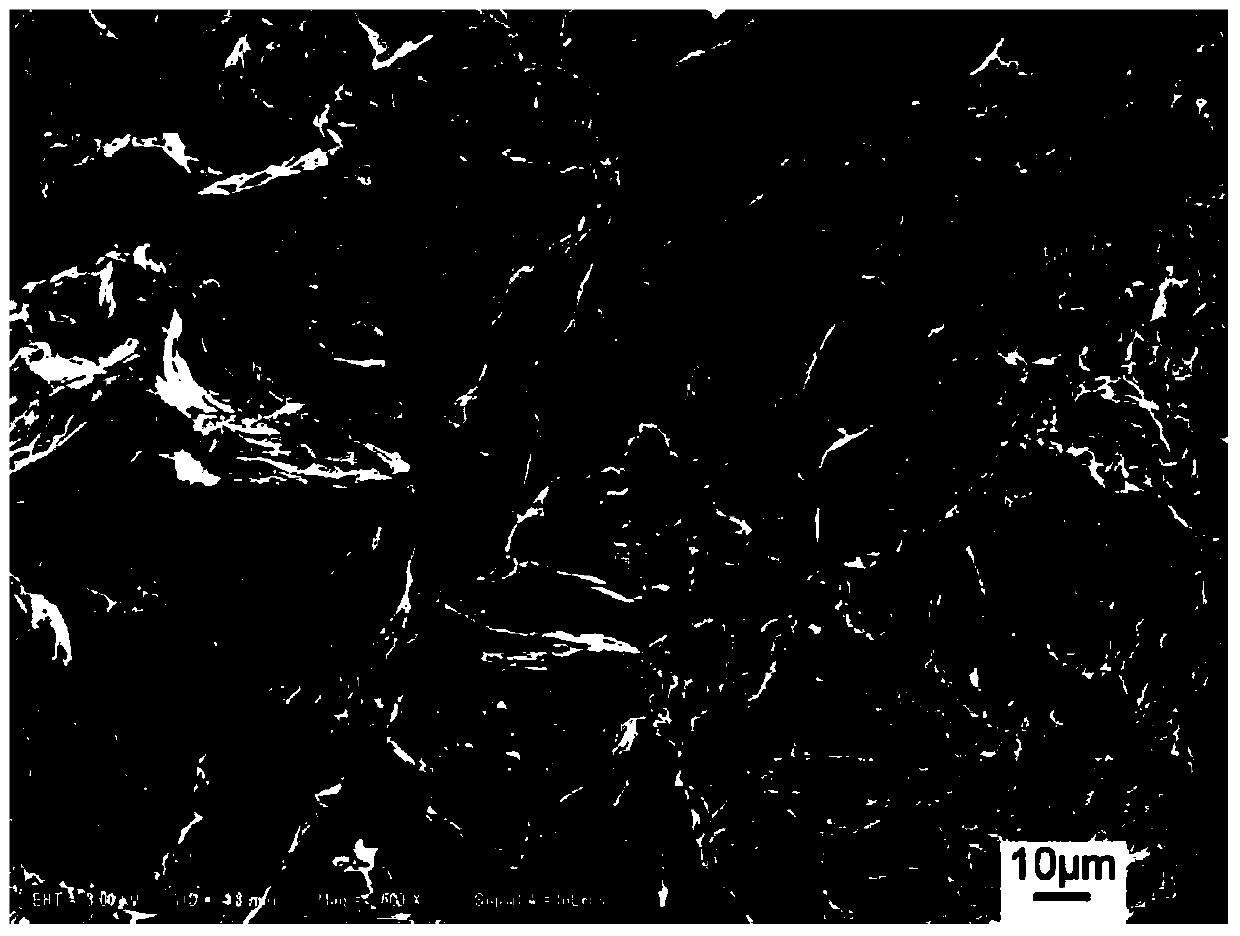

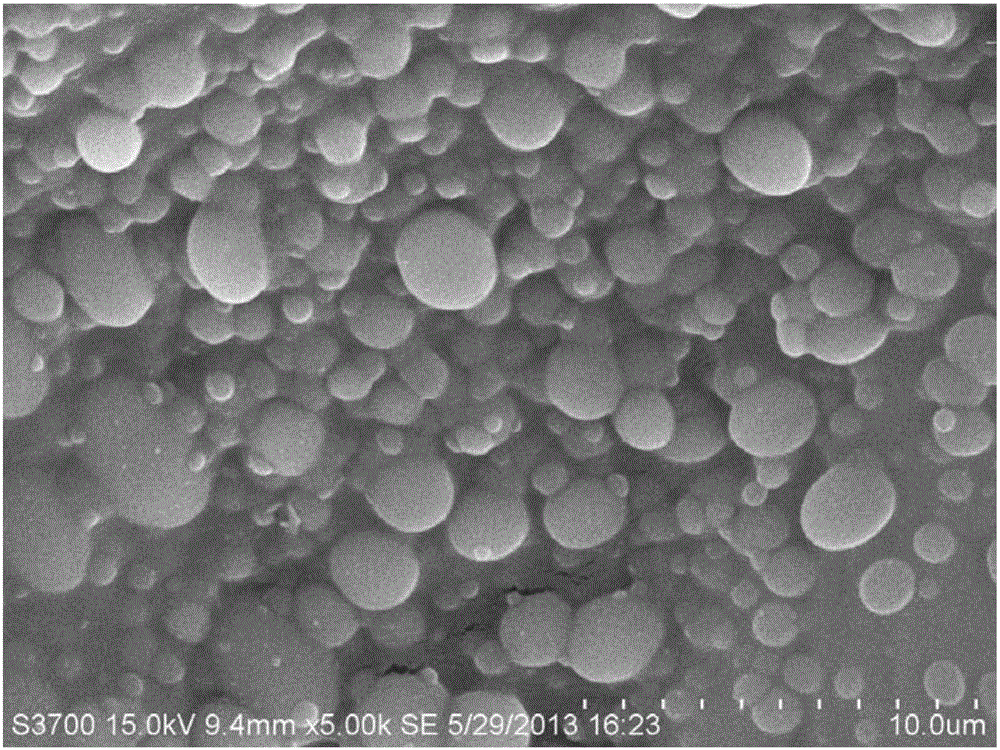

InactiveCN103893999AHas super oleophobic propertiesLow costLiquid separationMicro nanoPolymer science

The invention discloses a super-hydrophilic and underwater super-oleophobic oil-water separation mesh film and a preparation method thereof. The method comprises the following steps: ultrasonically cleaning a fabric silk screen and airing at normal temperature; preparing polymer emulsion particle microspheres of which the particle size distribution is 100-500nm and the surface is rich in carboxyl salt by adopting an emulsion polymerization, and preparing nano-silica sol by adopting a sol-gel method; preparing hydrophilic emulsion particles and the nano sol into a mixed solution and performing uniformly ultrasonic dispersion; immersing the silk screen into the mixed solution, vertically lifting up, or directly spraying by adopting a high-pressure spray gun, and drying to obtain the super-hydrophilic and underwater super-oleophobic oil-water separation mesh film. The surface of the oil-water separation mesh film has a spherical rough micro-nano binary structure, contact angles with water and oil in air are 0 degree, and the oil-water separation mesh film has the super hydrophilicity. A contact angle with oil drops under water is larger than 150 degrees, and the oil-water separation mesh film has low adhesion properties on the oil drops. The mesh film can be applied to separating oil water mixtures and treating oily sewage.

Owner:SOUTH CHINA UNIV OF TECH

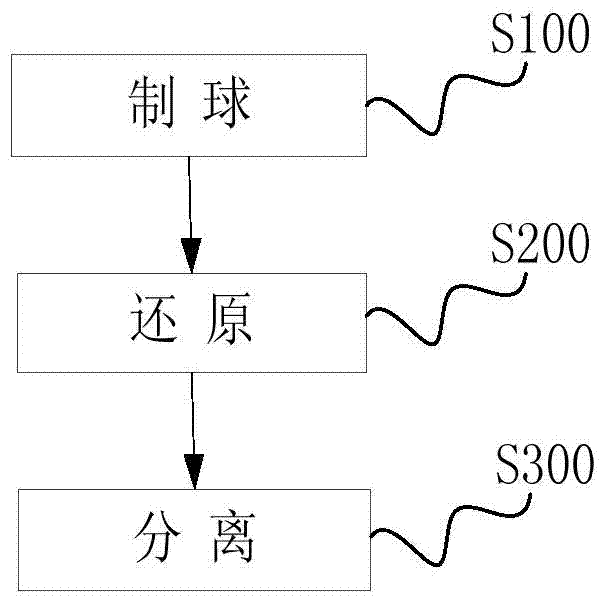

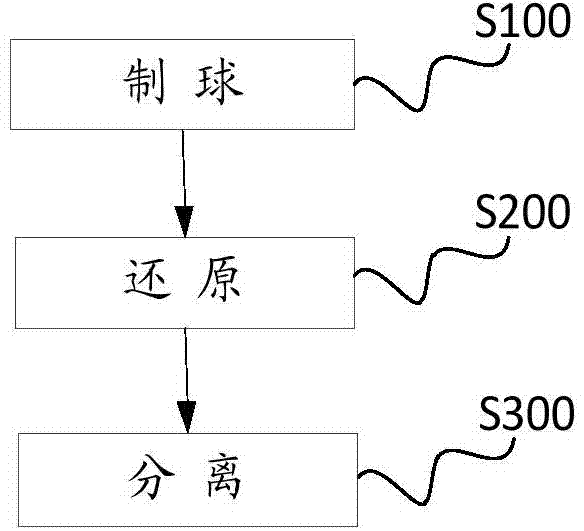

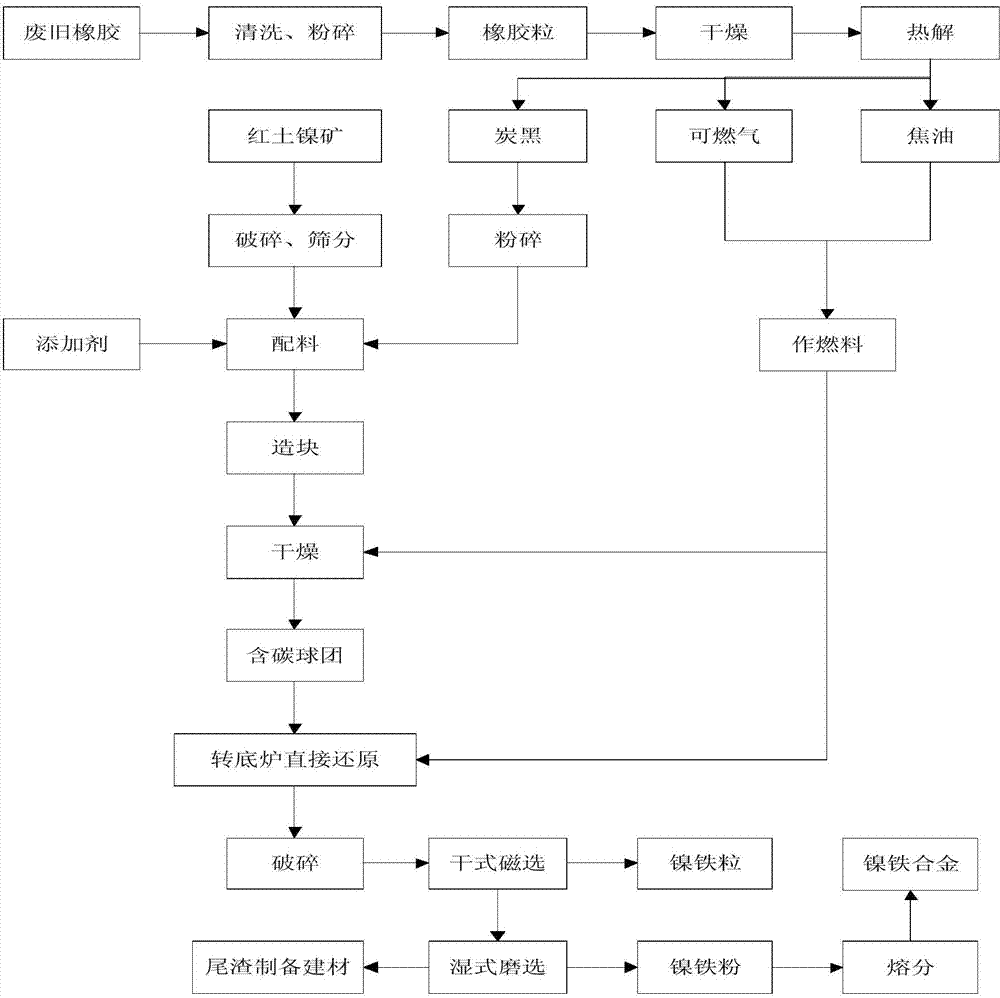

Treatment method of laterite-nickel ore

ActiveCN103667742AEffectively madeImproving the Efficiency of Reduction Roasting Laterite Nickel OreHearth type furnacesSlagHearth

The invention discloses a smelting method of laterite-nickel ore. The method comprises the following steps: pelleting laterite-nickel ore, carbon black and additives; carrying out reducing roasting on the laterite-nickel ore pellets in a heat-accumulation rotary hearth furnace to obtain metalized pellets; and carrying out slag-iron separation on the metalized pellets to obtain nickel iron and tailings. The method can be effectively utilized to prepare the nickel iron product.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

UV cured super-hydrophilic and underwater super-oleophobic oil-water separation membrane, its preparation method and application thereof

InactiveCN103357276AGood hydrophilic effectGood anti-oil adhesion effectSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPhotoinitiatorSol-gel

The invention discloses a UV cured super-hydrophilic and underwater super-oleophobic oil-water separation membrane, its preparation method and an application thereof. The preparation method comprises the following steps: carrying out ultrasonic cleaning on a fabric silk screen; preparing nano sol by a sol-gel method, mixing 10-50 parts of a single-function UV cured oligomer, 60-80 parts of a bi-functional UV cured oligomer, 10-20 parts of multifunctional UV cured oligomer, 200-500 parts of silica sol, 1-5 parts of a waterborne photoinitiator and 1-5 parts of an emulsifier, and uniformly dispersing; coating a mixed liquor on the surface of a membrane by a dip-coating or spray process, drying, and carrying out UV curing to obtain a product. The surface of the oil-water separation membrane has a hydrophilic polymer molecular brush structure based on the micro-nano dual structure. The contact angle of the membrane to water and oil is 0 degree in the air, and the membrane has super-hydrophilicity. The contact angle of the membrane to oil drops is greater than 150 degrees underwater, and the membrane has low adherence to oil drops. The membrane provided by the invention can be used in separation of an oil-water mixture and treatment of oily sewage.

Owner:SOUTH CHINA UNIV OF TECH

Superhydrophilic and superoleophobic oil-water separation membrane with humidity responsiveness as well as preparation method and application of oil-water separation membrane

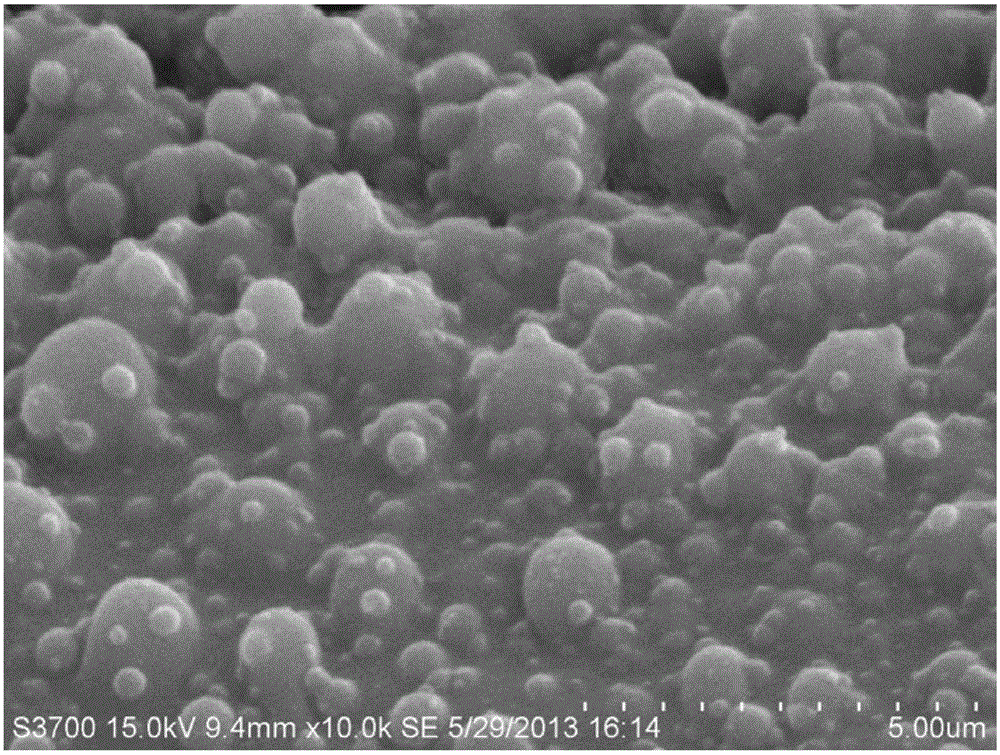

ActiveCN105148563AReduce energy consumptionLow costSemi-permeable membranesFatty/oily/floating substances removal devicesWater basedMicro nano

The invention belongs to the technical field of preparation of oil-water separation membranes and discloses a superhydrophilic and superoleophobic oil-water separation membrane with humidity responsiveness as well as a preparation method and an application of the oil-water separation membrane in oily sewage treatment and oil-water separation. The oil-water separation membrane is prepared with the method comprising the following steps: inorganic nanoparticles are prepared, subjected to oleophobic modification through a perfluoroalkyl siloxane solution and mixed with a prepared hydrophilic coating, and a hybrid hydrophilic coating is obtained; a silk screen is coated with a UV cured water-based anticorrosive coating with a dip coating or spray coating method, and an anticorrosive base coat membrane is obtained; the anticorrosive base coat membrane is coated with the hybrid hydrophilic coating with the dip coating or spray coating method, dried and cured, a micro-nano coarse structure is constructed, and the superhydrophilic and superoleophobic oil-water separation membrane with humidity responsiveness is obtained. The separation membrane has an initial contact angle with water in air being 150 degrees, the angle is reduced to 0 degree within 10-30 min, and the separation membrane has a contact angle with oil drops either in air or underwater being larger than 150 degrees all along.

Owner:SOUTH CHINA AGRI UNIV

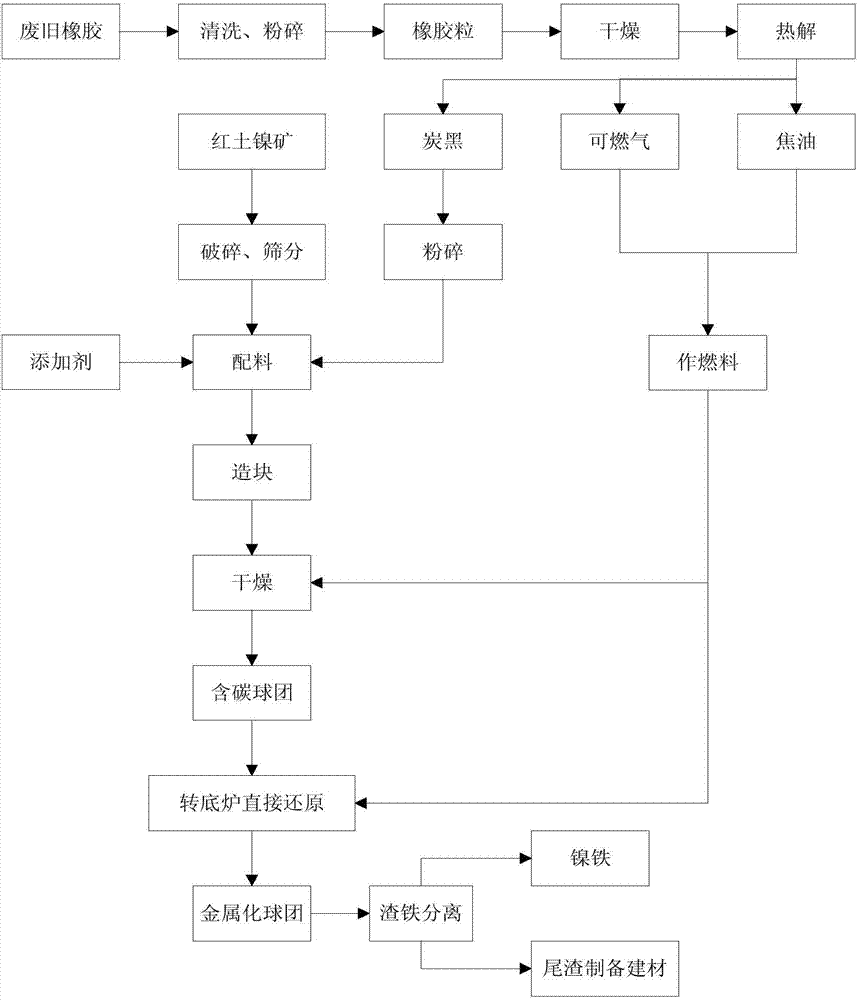

Treatment method of laterite-nickel ore

The invention discloses a treatment method of laterite-nickel ore. The method comprises the following steps: pelleting laterite-nickel ore, a reducer and additives to obtain laterite-nickel ore pellets; carrying out reducing roasting on the laterite-nickel ore pellets in a heat-accumulation rotary hearth furnace to obtain metalized pellets; carrying out crushing and dry magnetic separation on the metalized pellets to obtain nickel iron granules and first tailings; and carrying out wet grinding and wet magnetic separation on the first tailings to obtain nickel iron powder and second tailings, wherein the reducer is carbon black prepared from rubber. The method can be effectively utilized to prepare the nickel iron product.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

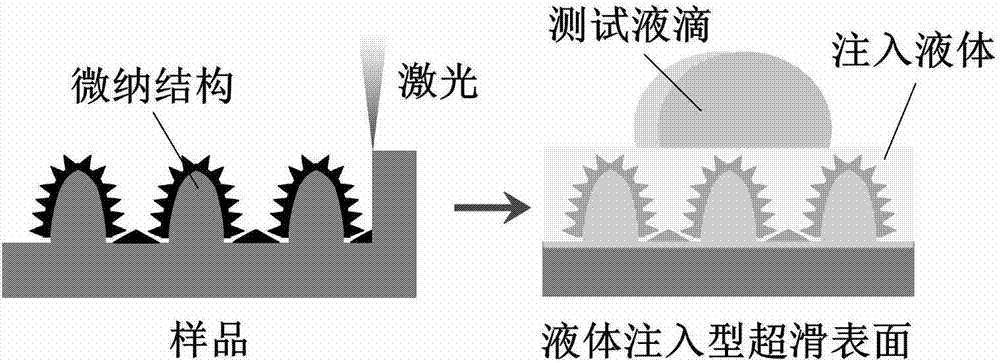

Liquid injection type super smooth surface and laser precision micro-fabrication method thereof

InactiveCN106865487ASimple processEasy to operateDecorative surface effectsChemical vapor deposition coatingRetention timePollution

The invention relates to a liquid injection type super smooth surface and a laser precision micro-fabrication method thereof, and belongs to the technical field of functional materials. The liquid injection type super smooth surface takes a metal as a substrate; firstly, a micro-nano composite structure is prepared on the metal surface by means of laser etching; after that, a super-hydrophobic surface is obtained by baking, and then injected liquid covers the super-hydrophobic surface to obtain the liquid injection type super smooth surface. Test droplets include water droplets, acid solutions, alkali solutions, lake water, sea water, serum, glycerin and ketchup. The liquid injection type super smooth surface provided by the invention has very small frictional resistance, and can very easily slide off the surface and reduce the retention time and probability of the water droplets and other test liquid on the surface. The laser precision micro-fabrication method of the liquid injection type super smooth surface provided by the invention adopts the laser precision machining technology to prepare the micro-nano composite structure on the metal surface, the technological process is simple and easy to operate, no other chemical additives are needed, and there is no toxic side effect and pollution, so that the laser precision micro-fabrication method is suitable for large-scale and mass production.

Owner:CHANGCHUN UNIV OF SCI & TECH

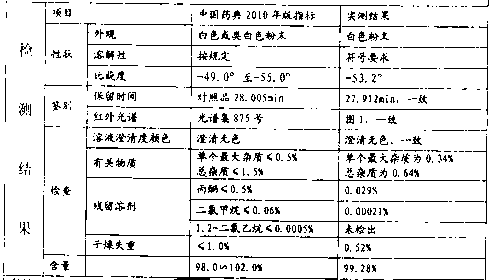

Method for extracting paclitaxel from taxus chinensis branch and leaf

ActiveCN103172598AImprove performanceReduce extraction costsOrganic chemistryFiltrationGradient elution

The invention relates to a method for extracting paclitaxel from taxus chinensis branches and leaves, and the method comprises the following steps of: (1) soaking 1000 kg of pulverized taxus chinensis branches and leaves by using 5 m<3> of methanol, and filtering; (2) decoloring filter liquor; (3) decompressing and concentrating a decolored solution, and extracting; (4) degreasing and dewaxing extract liquor, crystallizing, depositing, filtering, and drying to obtain a primary product; (5) removing impurities contained in the primary product in a silicagel column, carrying out gradient elution, collecting paclitaxel-containing elution flows, and decompressing and concentrating to obtain a crude product; (6) stirring the crude product into silica gel, packing, carrying out gradient elution, collecting the paclitaxel-containing elution flows, and decompressing and concentrating to obtain a semi-finished product; (7) dissolving the semi-finished product, adding petroleum ether, standing, filtering, and drying to obtain a semi-finished product with the content more than or equal to 30%; (8) removing the impurities contained in the semi-finished product obtained from the step (7) in a silicagel column, carrying out gradient elution, collecting the paclitaxel-containing elution flows, and decompressing and concentrating to obtain a semi-finished product with the content more than or equal to 95%; and (9) dissolving the semi-finished product obtained from the step (8), filtering, adding normal hexane, standing, carrying out suction filtration; and drying to obtain a finished product with the content more than or equal to 99%.

Owner:SICHUAN XIANGGUANG AGRI TECH DEV

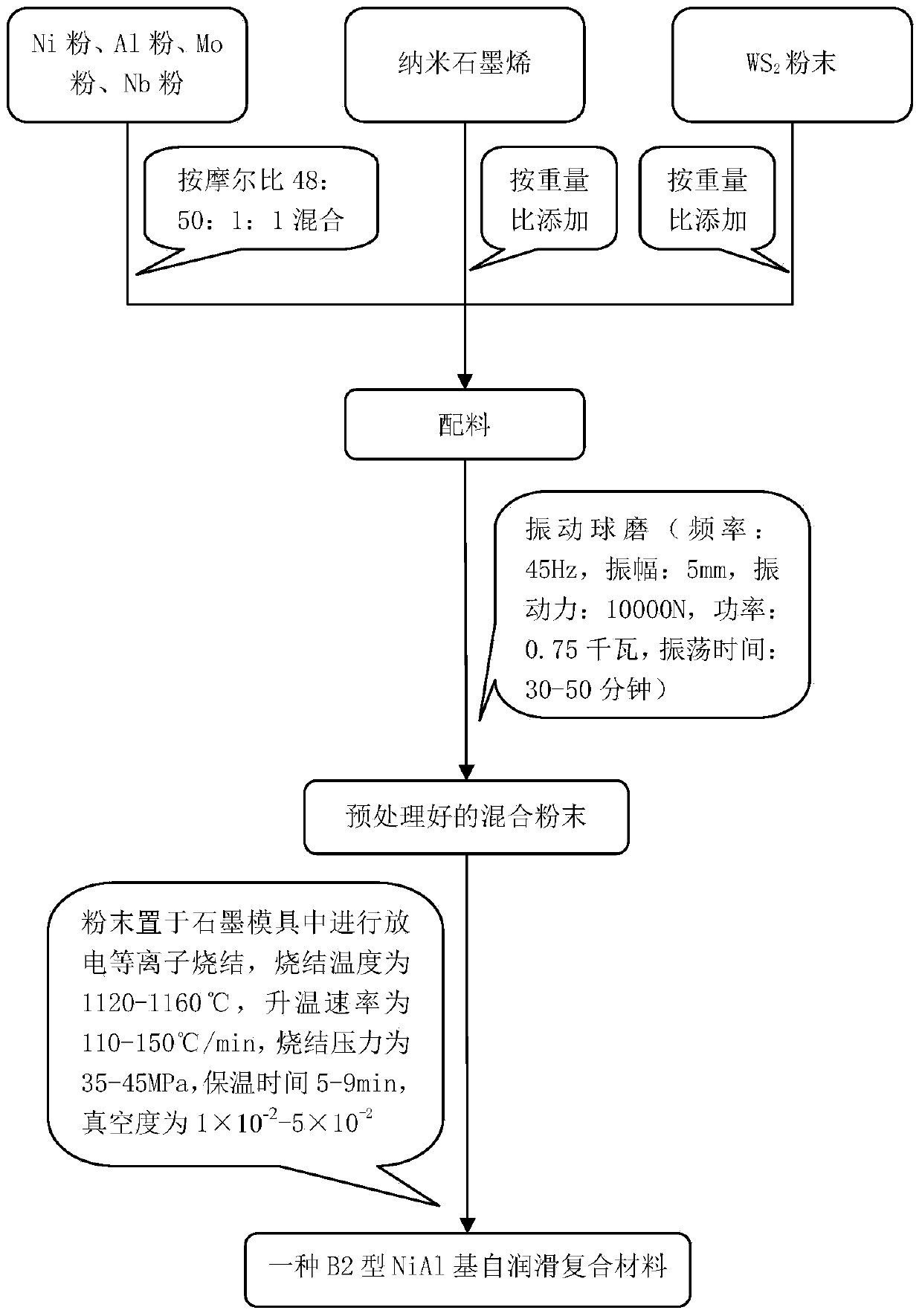

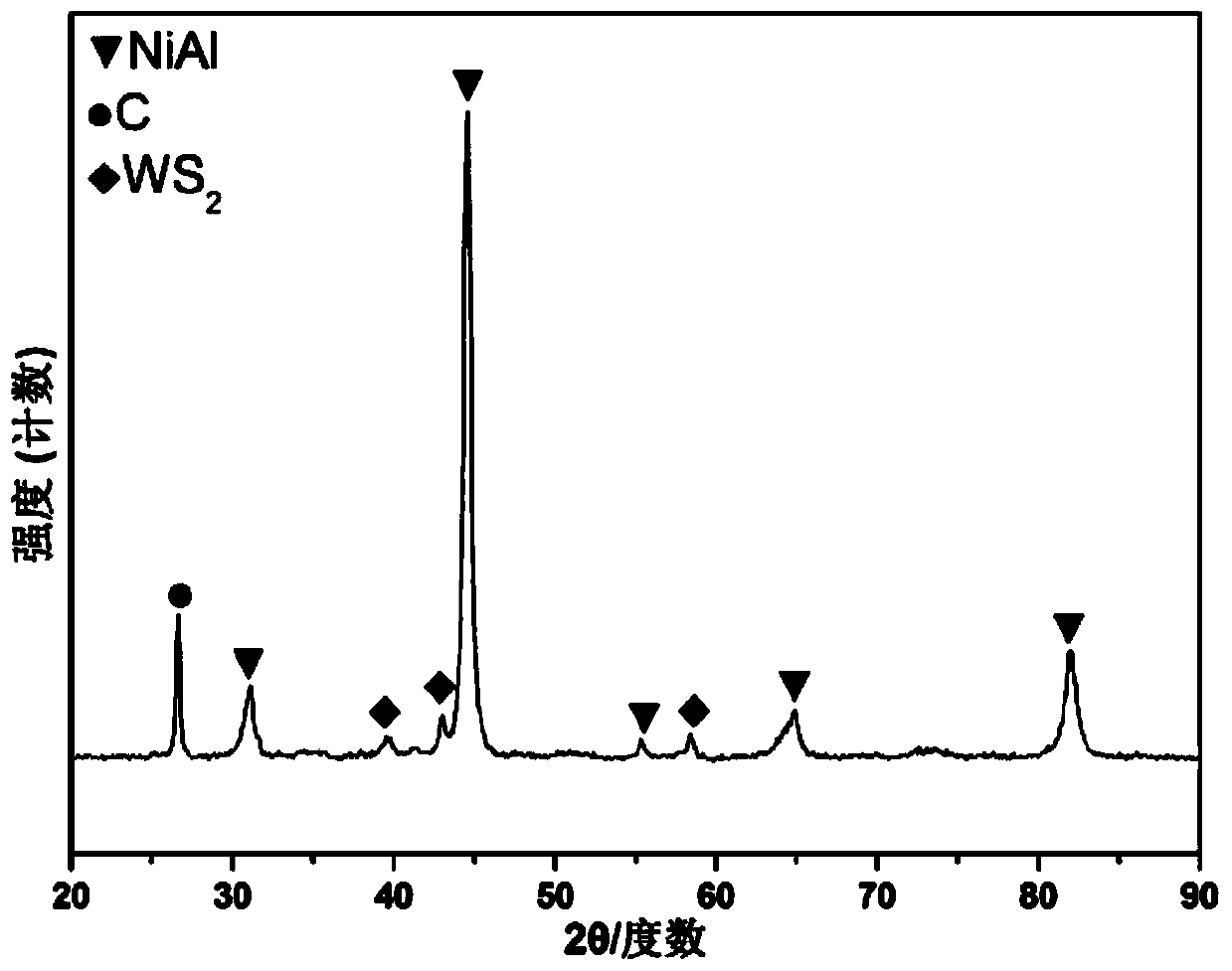

B2 type NiAl-based self-lubricating composite materials and preparing method thereof

The invention provides B2 type NiAl-based self-lubricating composite materials and a preparing method thereof. The method comprises the following steps that (1) Ni powder, Al powder, Mo powder, Nb powder, nano grapheme and WS2 powder are selected according to proportion, and ingredients are obtained; (2) the ingredients are placed in a vibration ball mill for dry grinding, the inner wall of a vibration ball milling tank is made of Teflon, vibration frequency is 45 Hz, amplitude is 5 mm, vibration force is 10000 N, vibration time is 30 minutes-50 minutes, and preprocessed mixed powder is obtained; and (3) the preprocessed mixed powder is placed in a graphite mould with the inner diameter of 20 mm, and then under the vacuum condition, a spark plasma sintering method is used for the B2 type NiAl-based self-lubricating composite materials. The self-lubricating composite materials obtained through the method are high in purity and good in compactness and have good tribology performance. In addition, through the spark plasma sintering method, sintering temperature is lowered, sintering time is shortened, the steps are simple and convenient to achieve, and large-scale batch production can be well achieved.

Owner:重庆三木汽车部件有限公司

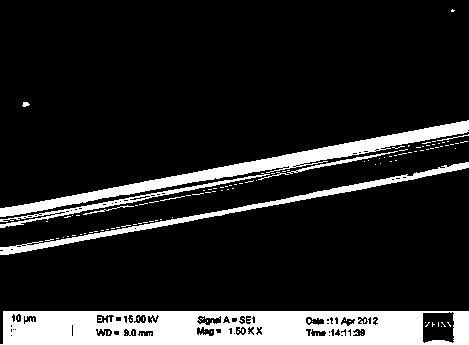

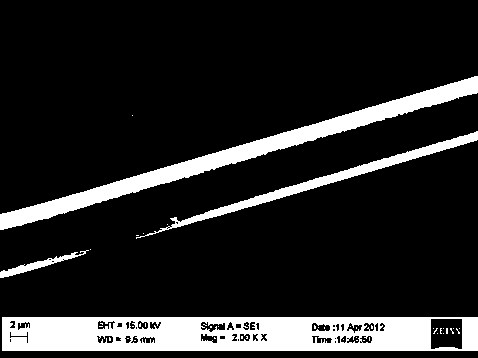

Water-based epoxy emulsion type carbon fiber sizing agent and preparation method thereof

The invention relates to a water-based epoxy emulsion type carbon fiber sizing agent and a preparation method thereof. The water-based epoxy emulsion type carbon fiber sizing agent comprises the following components in percentage by weight: 15%-35% of epoxide resin, 5%-20% of surface active agent, 0.1%-0.5% of lubricating agent, 0.1%-0.5% defoaming agent and 55%-65% of deionized water. According to the water-based epoxy emulsion type carbon fiber sizing agent and the preparation method thereof, no volatile organic compound is added, so that the harm to production equipment and operators in preparation and application processes of the sizing agent is greatly reduced, and the environment protection is facilitated. The water-based epoxy emulsion type carbon fiber sizing agent and the preparation method thereof which are disclosed by the invention have the advantages of simple emulsifying process, safety in operation, low requirement on the production equipment, easiness for raw material obtaining, low price and suitability for large-scale production.

Owner:HENGSHEN

Super-hydrophilic and underwater super-oleophobic oil-water separation membrane with chemical resistance as well as preparation and application of oil-water separation membrane

ActiveCN105056770AGood hydrophilic effectGood anti-oil adhesion effectSemi-permeable membranesLiquid separationUV curingOligomer

The invention belongs to the technical field of preparation of oil-water separation membranes and discloses a super-hydrophilic and underwater super-oleophobic oil-water separation membrane with chemical resistance as well as a preparation method and an application of the oil-water separation membrane. The oil-water separation membrane is prepared with a method comprising steps as follows: nano-sol is prepared and mixed with mono-functional UV (ultraviolet)-curable oligomer, a dual-functional UV-curable oligomer and a poly-functional UV-curable oligomer, and a UV-curable water-based coating is obtained; a screen mesh is coated with the UV-curable water-based anticorrosive coating with a dip coating method or a spray coating method, UV curing is performed after drying, and an anticorrosive base-coated mesh membrane is obtained; the anticorrosive base-coated mesh membrane is coated with the UV-curable water-based coating with the dip coating method or the spray coating method, drying and UV curing are performed, and the super-hydrophilic and underwater super-oleophobic oil-water separation membrane with chemical resistance is obtained. The oil-water separation membrane has contact angles of zero with water and oil in air, has a contact angle larger than 150 degrees with oil drops underwater, and can be applied to separation of an oil-water mixture and treatment of oily sewage.

Owner:SOUTH CHINA AGRI UNIV

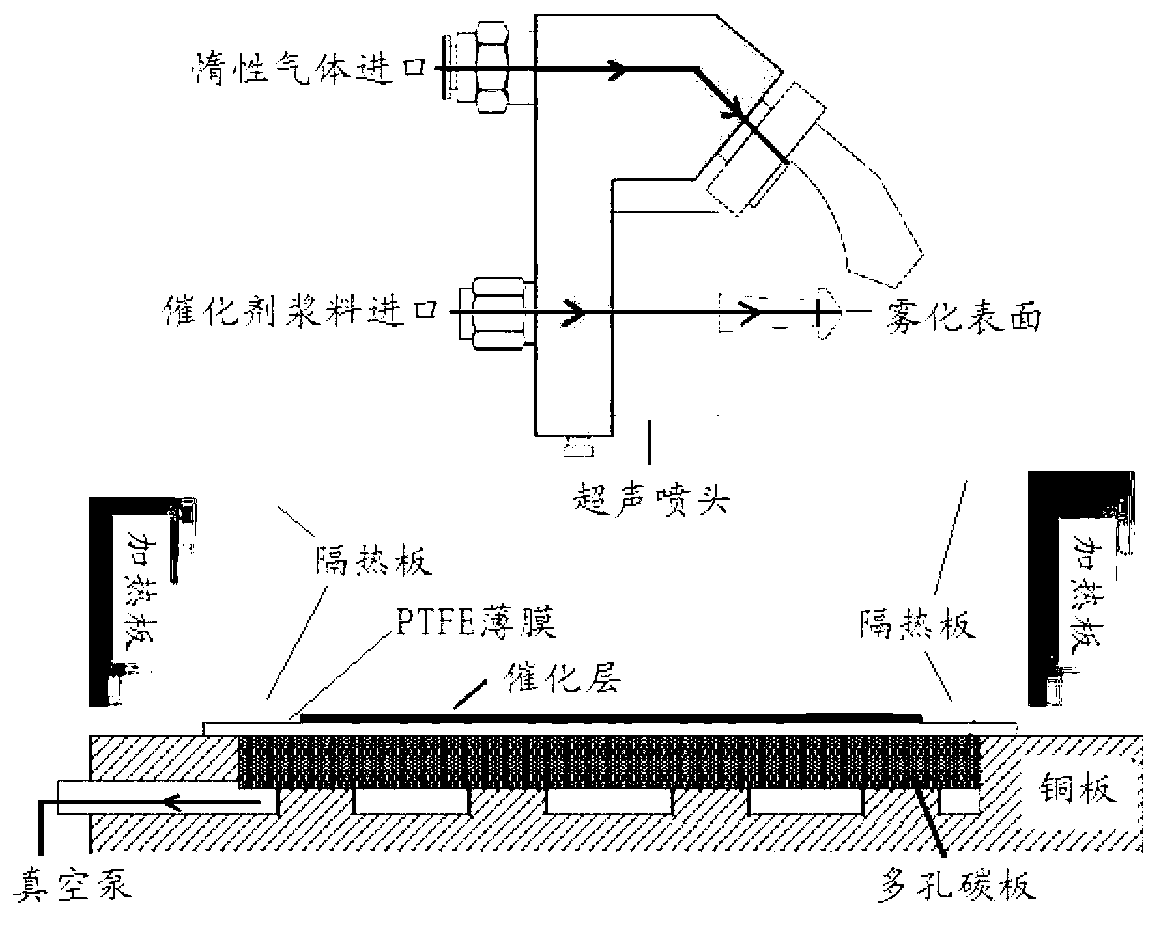

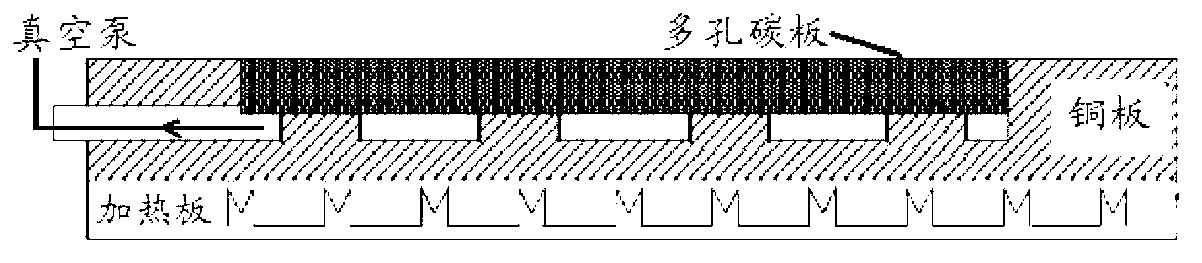

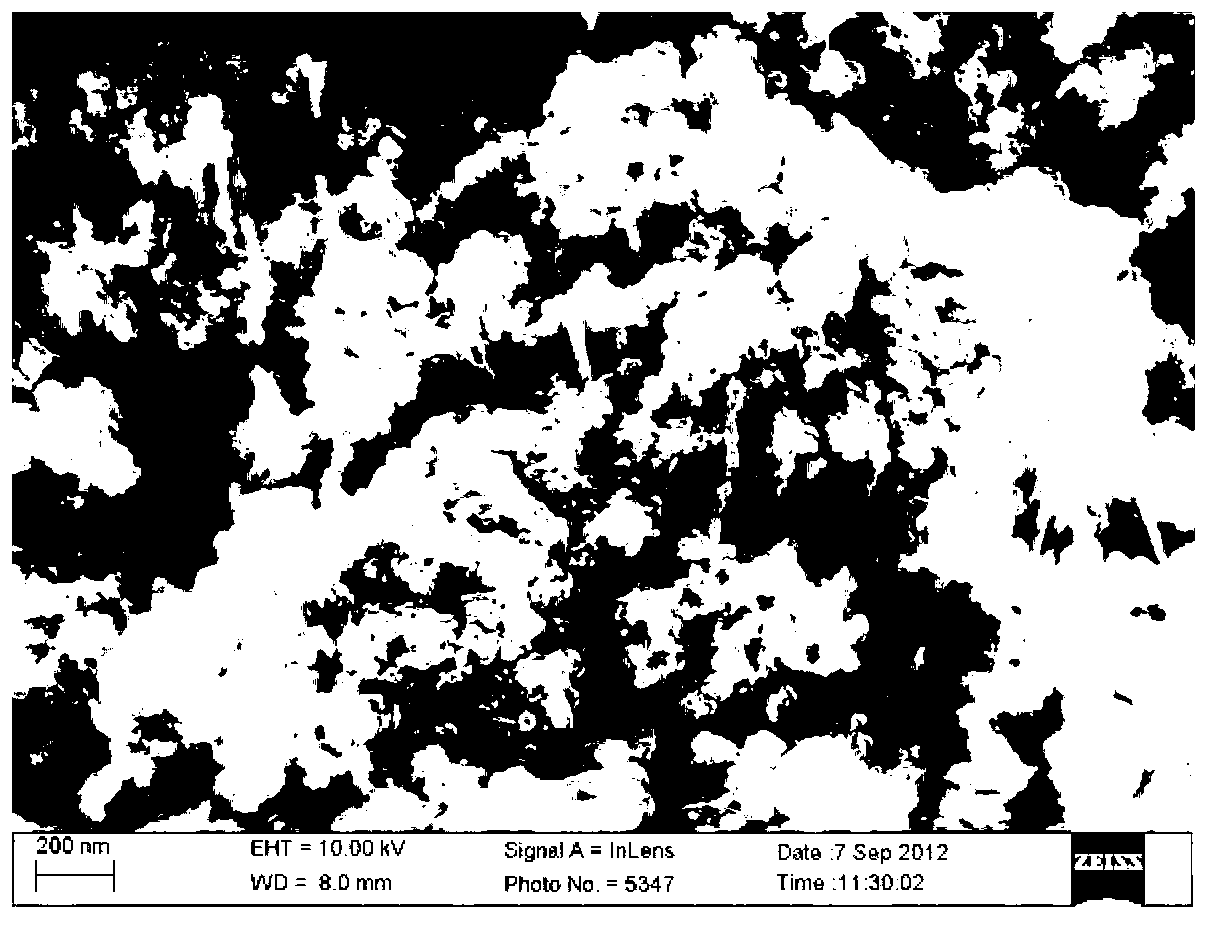

Method for preparing high-efficiency membrane electrode of direct methanol fuel cell

InactiveCN103000912AGuaranteed continuitySimple manufacturing processCell electrodesPtru catalystNanowire

The invention discloses a method for preparing a high-efficiency membrane electrode of a direct methanol fuel cell and belongs to the structure of a high-efficiency membrane electrode component of the direct methanol fuel cell and the technical field of manufacturing of structures of high-efficiency membrane electrode components. A proton exchange membrane is adopted as an electrolyte membrane by the membrane electrode, a platinum-ruthenium black catalyst and a platinum black catalyst are respectively adopted as a cathode catalyst and an anode catalyst, isopropyl alcohol and redistilled water are adopted as dispersing agents. During preparation, an ultrasound spray-coating technology is applied in a temperature field, the agglomeration morphology of catalyst particles is adjusted by the adjustment on factors such as ingredient proportioning and preparation environments of catalyst slurry, a proton channel with a nano wire structure is prepared in a catalytic layer, so that a continuous proton channel is established effectively in the microstructure of the prepared membrane electrode, the internal resistance of the cell is reduced, the electrochemical surface area of the electrode is increased, and therefore, the efficiency of the catalytic layer of the membrane electrode is improved.

Owner:UNIV OF SCI & TECH BEIJING

Continuous method for preparing high dispersion nano oxide powder by jet coprecipitation

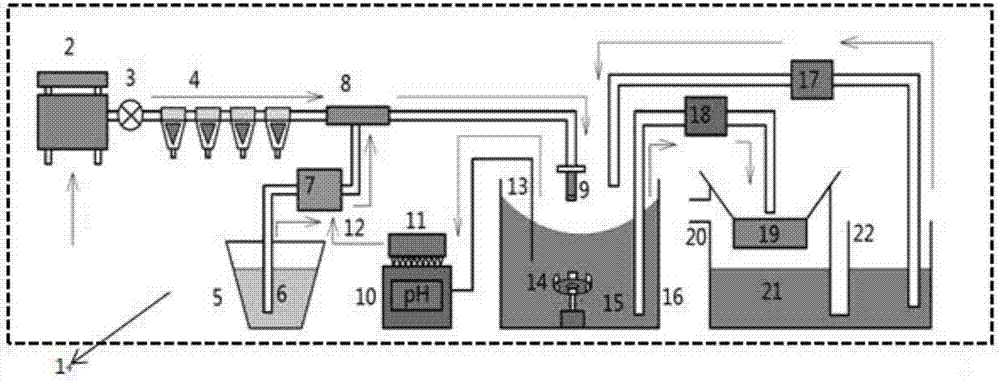

The invention discloses a continuous method for preparing high dispersion nano oxide powder by jet coprecipitation, and the method is characterized in that: in the precipitation process, drying process and calcination process of nano oxide powder preparation, by use of a jet coprecipitation continuous device (1), precursor continuous preparation and solid-liquid separation can be realized. The method can effectively solve the problems of uneven precursor distribution and powder aggregation and the like during the preparation of the nano oxide powder, and greatly improves the automation degree in the reaction process, the continuous precipitation process and solid liquid separation are realized, and the method has the advantages of simple equipment, high efficiency, controllable process and high yield.

Owner:XUZHOU NORMAL UNIVERSITY

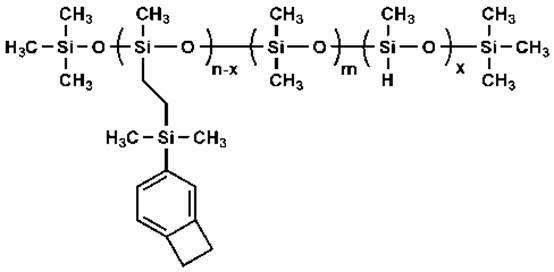

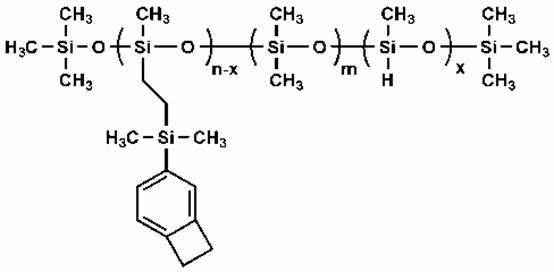

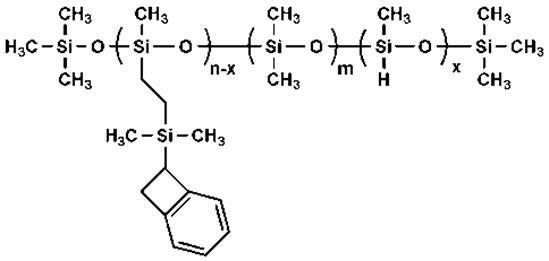

Benzocyclobutene silicone oil resin and preparation method thereof

InactiveCN102516547AImprove mechanicsGood thermal propertiesOther chemical processesMethyl benzenePlatinum catalyst

The invention discloses dimethyl-4-benzocyclobutene silicon-based vinyl-grafted modified hydrogen-containing silicone oil shown as a formula (IV) and a preparation method thereof. The preparation method of benzocyclobutene silicone oil resin comprises the following steps of: putting solvent-toluene-diluted hydrogen-containing silicone oil and 4-(1,1-dimethyl-1-vinyl) silicon benzocyclobutene intoa reactor, adding a platinum catalyst after being protected by N2, and stirring and carrying out reaction for 20-40 hours at the reaction temperature of 60-90 DEG C; and adding triphenylphosphine, heating to reflux for 3 hours, cooling, filtering, adding methanol and mixing after a filtrate is concentrated, carrying out precipitation, filtering, carrying out repeated precipitation on solids for 1-2 times by using methanol, and then, drying to obtain a product. The product, i.e. benzocyclobutene silicone oil resin, has excellent thermal properties, mechanical properties, electrical properties and film forming properties and has wide development and application prospects in fields, such as microelectronics industry, aerospace and national defense and the like.

Owner:BEICHUAN RUIHUI SCI & TECH CO LTD

Barbecue chilli powder seasoning and making method thereof

InactiveCN102754806APrevent odor from evaporatingEfficient use ofFood preparationCapsicum annuumGARLIC POWDER

The invention discloses a barbecue chilli powder seasoning and a making method thereof. In the aspects of formula and content, the barbecue chilli powder seasoning is prepared by taking chilli as a main material and garlic powder, pepper, anise, peanut, dried ginger, cardamun, black pepper and other various spices as auxiliary materials through the steps of stir-frying, low-temperature crushing, blending, stirring for uniformity, sterilizing, inspecting, packaging and sealing. The barbecue chilli powder seasoning has aromatic odor and warm nature and integrates essences of various spices, and a process is simple and is easy to master.

Owner:岳杰

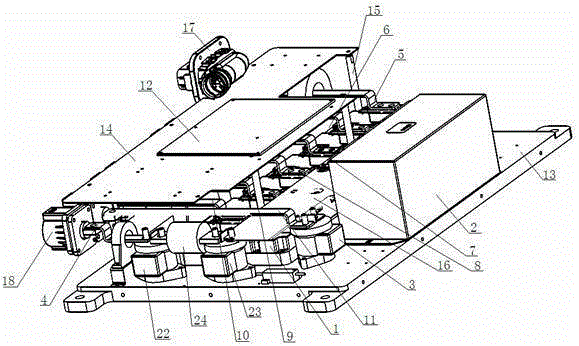

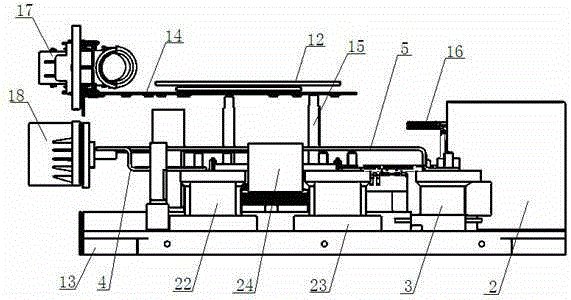

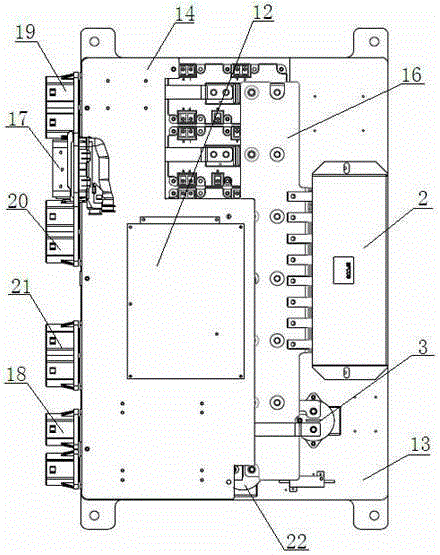

Internal layout structure of switched reluctance machine controller of electric vehicle

InactiveCN105207540ASimple structureCompact layoutElectronic commutation motor controlCapacitanceElectric machinery

The invention provides an internal layout structure of a switched reluctance machine controller of an electric vehicle. The internal layout structure comprises a high-voltage part, a low-voltage part and a radiator base (13). The high-voltage part comprises an IGBT module (1), a thin-film capacitor (2), a high-voltage copper bar and a pre-charge contactor (3). The high-voltage copper bar comprises a copper bar positive electrode (4), a copper bar U positive electrode (5), a copper bar U negative electrode (6), a copper bar V positive electrode (7), a copper bar V negative electrode (8), a copper bar W positive electrode (9), a copper bar W negative electrode (10) and a copper bar negative electrode (11). The low-voltage part comprises a low-voltage main control board (12) and a low-voltage connector (17). The low-voltage connector (17) is connected with the low-voltage main control board (12), the high-voltage part is arranged on the radiator base (13), and the low-voltage part is arranged above the high-voltage part. The hierarchical design of the high-voltage part and the low-voltage part is adopted in the longitudinal direction, and the internal layout structure is simple, compact in layout structure, high in system reliability and suitable for large-scale batch production.

Owner:DONGFENG COMML VEHICLE CO LTD

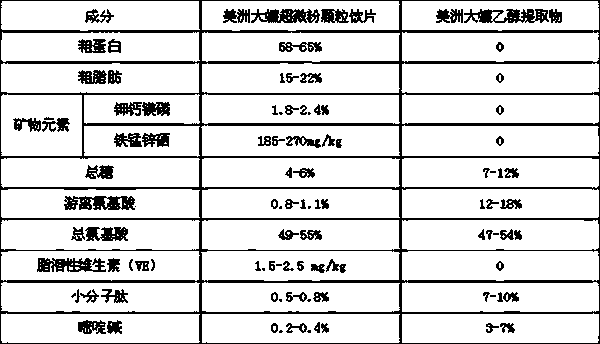

Preparation method of periplaneta americana superfine-grinding granulate piece

InactiveCN103919813AKeep natural propertiesEasy to takeAnthropod material medical ingredientsDigestive systemHigh volume manufacturingMedicine

The invention relates to a preparation method of a traditional Chinese medicine piece, and in particular relates to a preparation method of a periplaneta americana superfine-grinding granulate piece. The preparation method mainly comprises the steps of fasting, catching and killing, drying, degreasing, superfine grinding, mixing, pelletizing, completely mixing, and packing by quantity, etc. The preparation method has the advantages that any excipient, binding agent and other auxiliary materials are not added, the natural characteristics of the traditional Chinese medicine are kept in a hundred percent, the advantages of the traditional Chinese medicine are remained, and a patient is convenient to take; the process is regular, the parameters are easy to detect and control, and large-scale and mass production is easily carried out; petroleum ether with boiling range of 60 to 90 DEG C is used as a degreasing solvent, which is high in volatility, nontoxic and easy to remove; in addition, petroleum ether is reusable, so that the resource is saved.

Owner:KUNMING SINOWAY NATURAL PHARMA

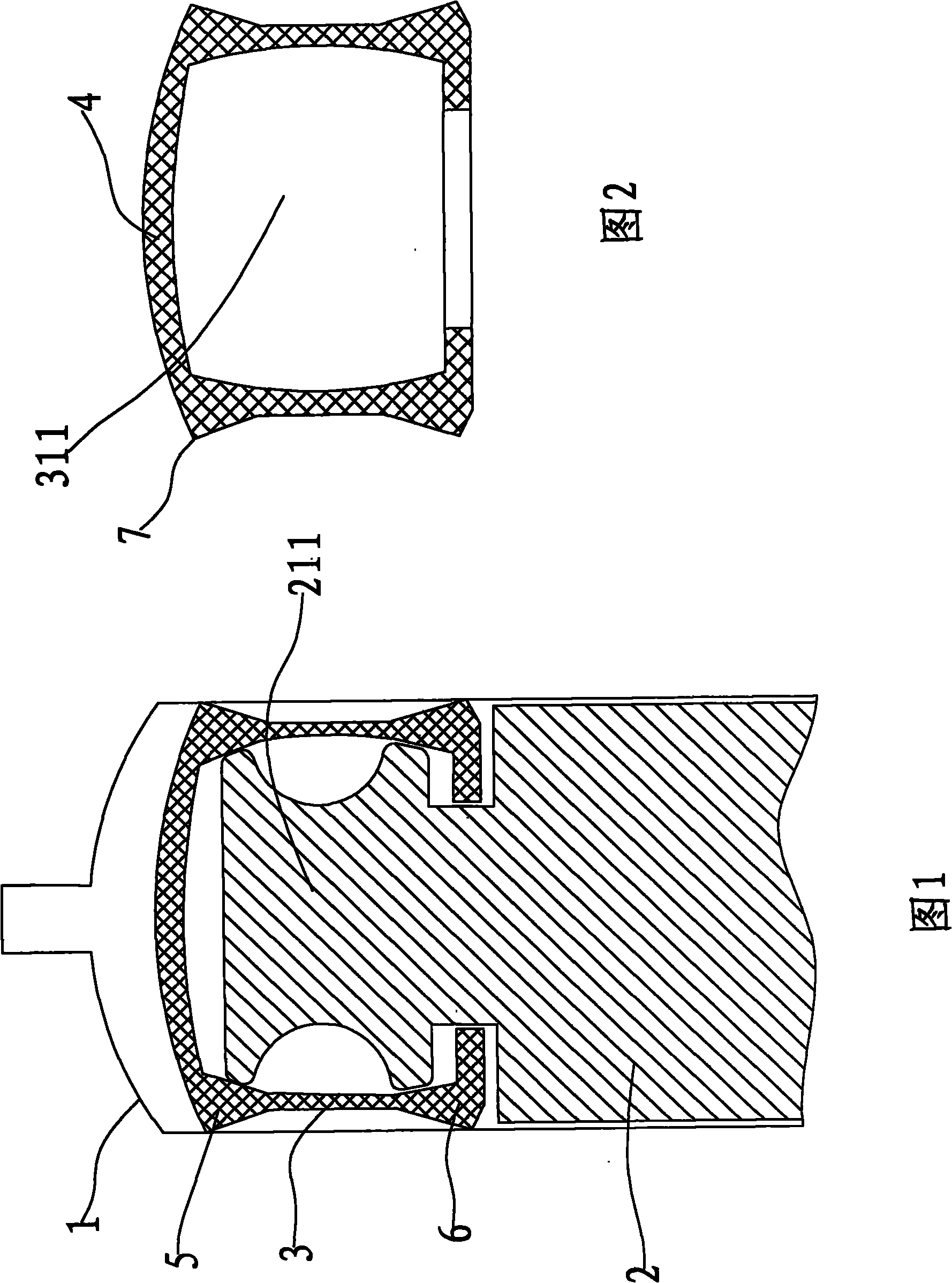

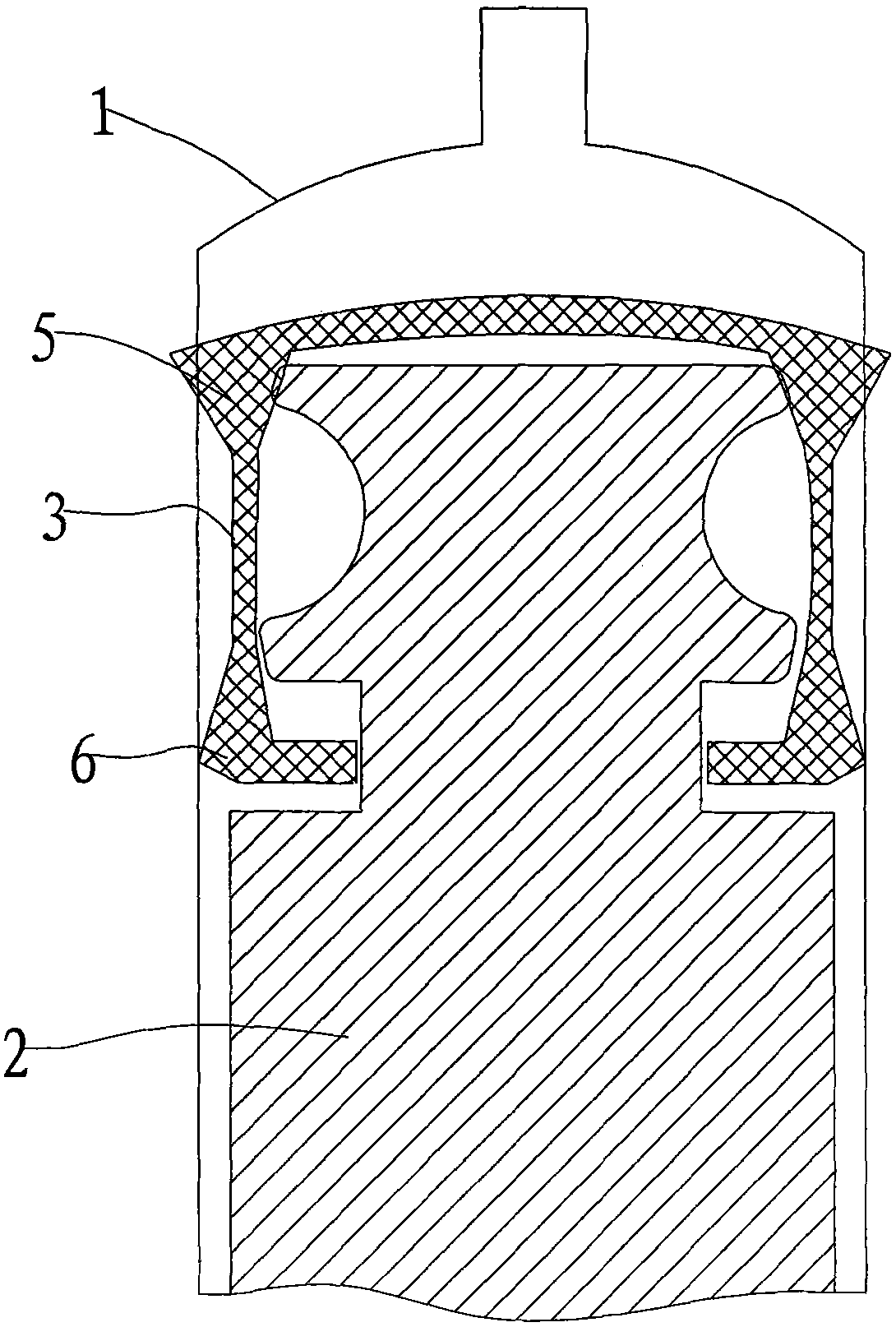

Novel low-resistance injector

The invention relates to a novel low-resistance injector. The novel low-resistance injector comprises a syringe, a push rod and a rubber plug, wherein the push rod consists of a main body and a mounting head which is used for mounting the rubber plug; a cavity for accommodating the mounting head is reserved in the rubber plug; the cavity of the rubber plug has a big middle part and two small ends along the axial direction of the push rod; the diameters of the upper and lower heads of the mounting head are a little bigger than those of the two heads of the cavity; after the rubber plug is arranged on the push rod, space is reserved between the mounting head and the rubber plug in the axial direction, so that the rubber plug can slide backwards and forwards relative to the push rod along the axial direction of the push rod; the top part of the rubber top slightly arches upwards to form a hogback; two sealing rings are integrally formed on the outer circumference of the rubber plug; and the section of each sealing ring has a triangular shape, so that the four corners on the outside of the longitudinal section of the rubber plug have angular shapes. The injector adopts the structure and the frictional resistance is reduced to 0.05 Newton, so that the aims of low resistance and high sealing property are fulfilled. The practice shows that the low-resistance injector products have the advantages of simple production process, reject ratio lower than 1 / 10,000 and suitability for large-scale batch production.

Owner:余利荣

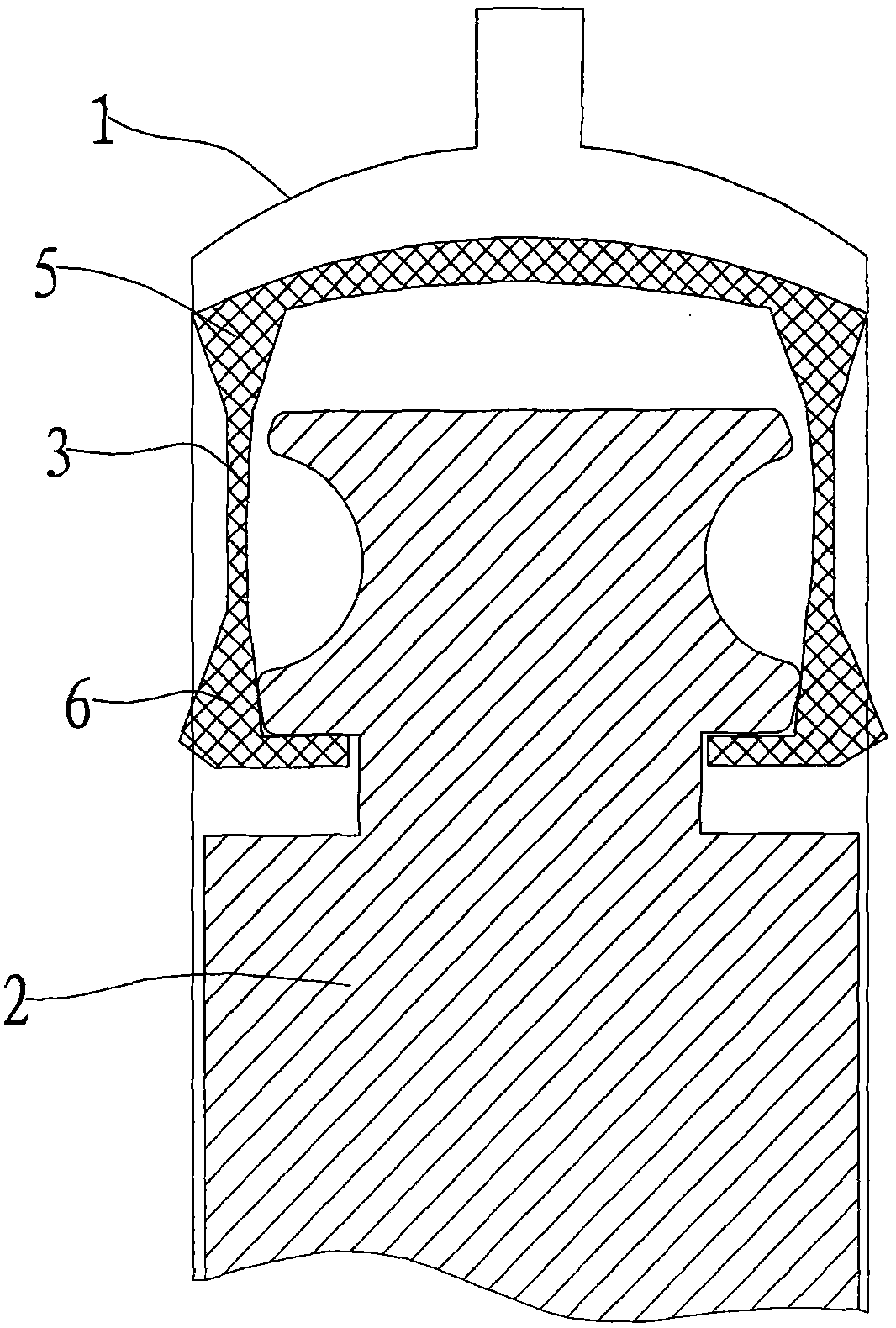

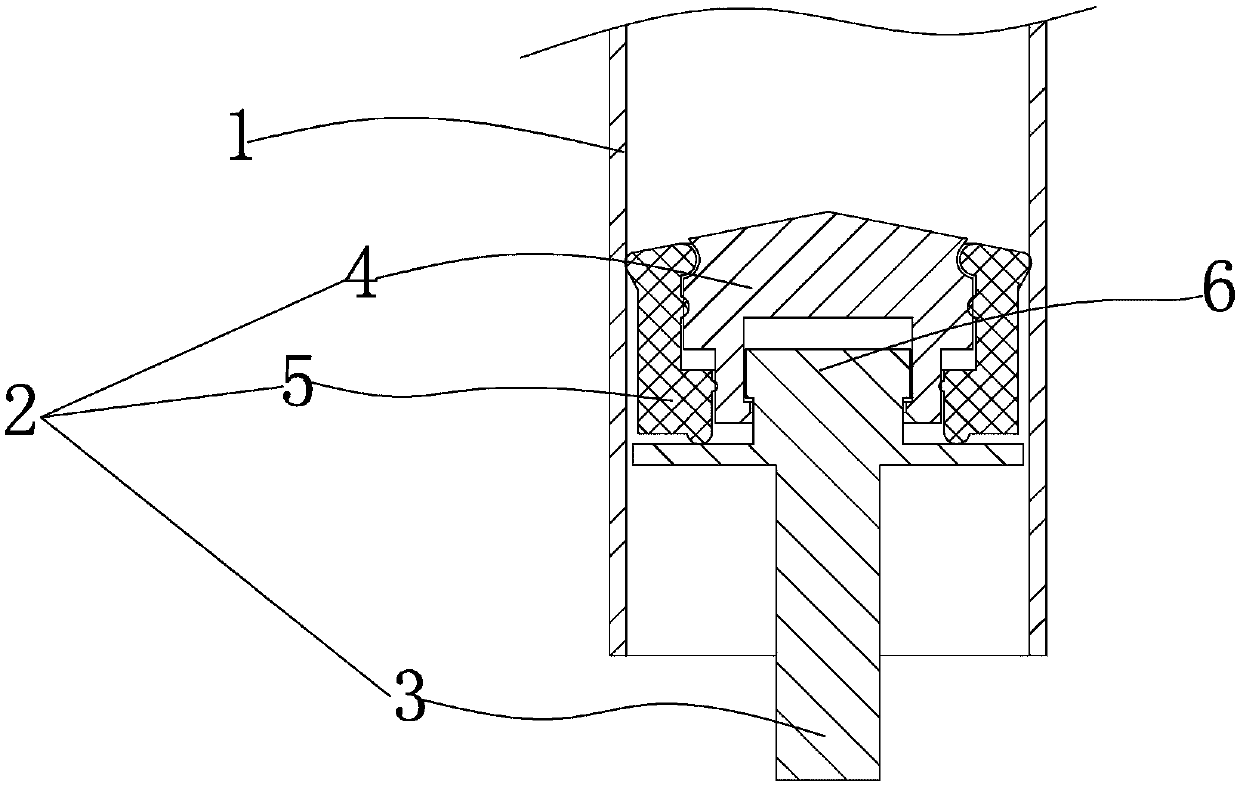

Improved low-resistance injector

ActiveCN105498048AGuaranteed sealing performanceImprove sealingIntravenous devicesLow-resistance syringeTop cap

An improved low-resistance injector comprises a needle cylinder and a piston. The improved low-resistance injector is characterized in that the piston is composed of a push rod, a top cap and a rubber plug. The top cap is installed on an installation head at the front end of the push rod. The top cap is sleeved with the rubber plug. A push plate is formed at the portion, below the rubber plug, of the push rod. The top cap is provided with an inner cavity for containing the installation head of the push rod. In the initial state, a gap is reserved between the top cap and the top end of the installation head, and correspondingly, a gap is reserved between the bottom of the top cap and the push plate of the push rod. An upper shoulder is arranged on the top cap. A lower shoulder corresponding to the upper shoulder is arranged inside the rubber plug. In the initial state, the gap is reserved between the upper shoulder and the lower shoulder. An inner adjustment sealing ring is integrally formed on the inner circumferential face of the upper portion of the rubber plug. A semicircular groove where the inner adjustment sealing ring can be embedded is formed in the outer circumferential face of the top cap correspondingly. An outer sealing ring is integrally formed on the outer circumferential face of the upper portion of the rubber plug.

Owner:余利荣

Crisp fish production method

The present invention relates to food producing process, and is especially the production process of crisp fish. The crisp fish product is produced with fresh fish and through the steps of pre-treatment, steaming at 97-100 deg.c for 1-8 hr, cooling, sterilizing and packing. The crisp fish has its bone eatable, intact appearance, beautiful color, and nutritious components well maintained, and the production process has short period and high efficiency and is suitable for large scale production.

Owner:屈金彪

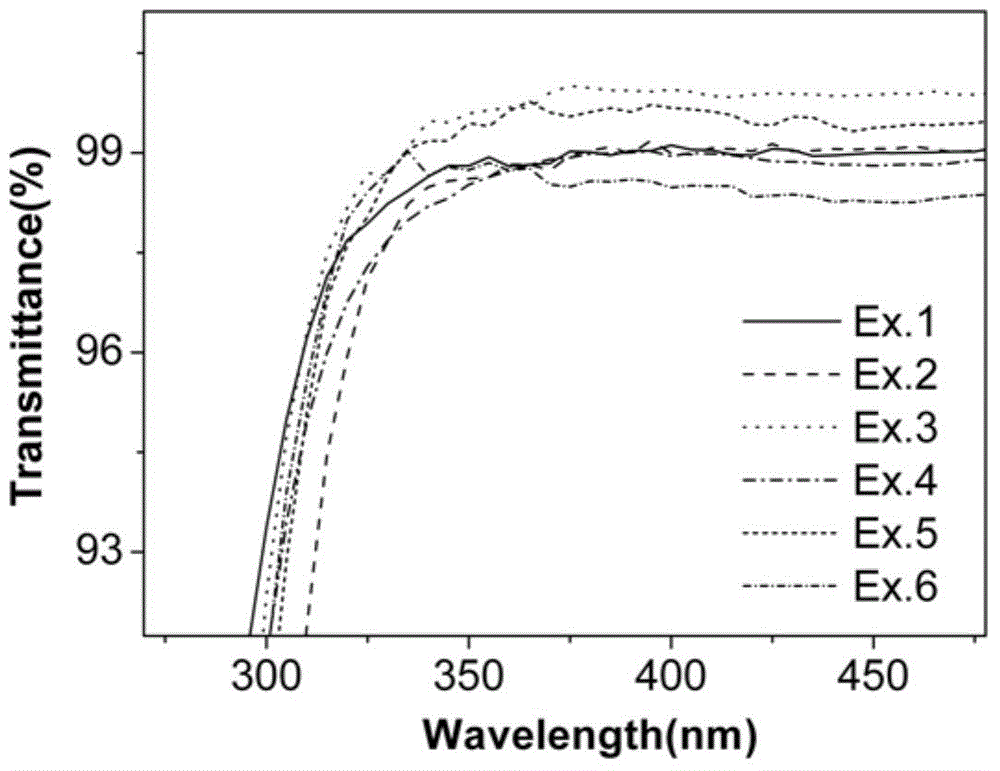

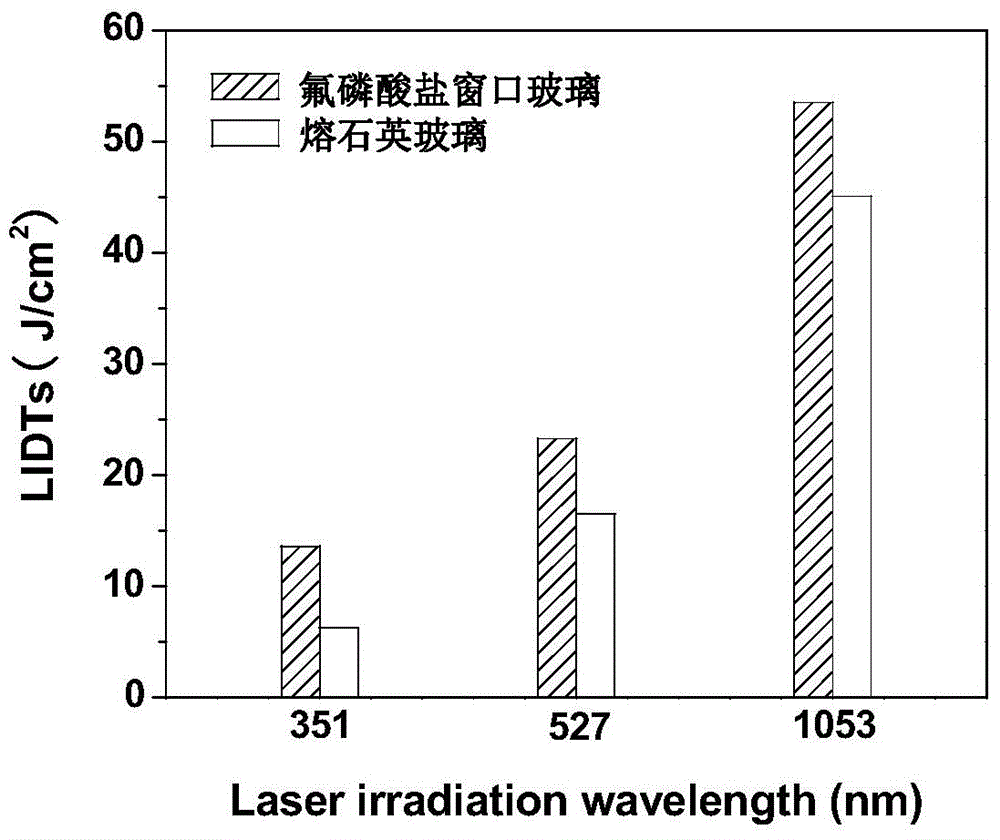

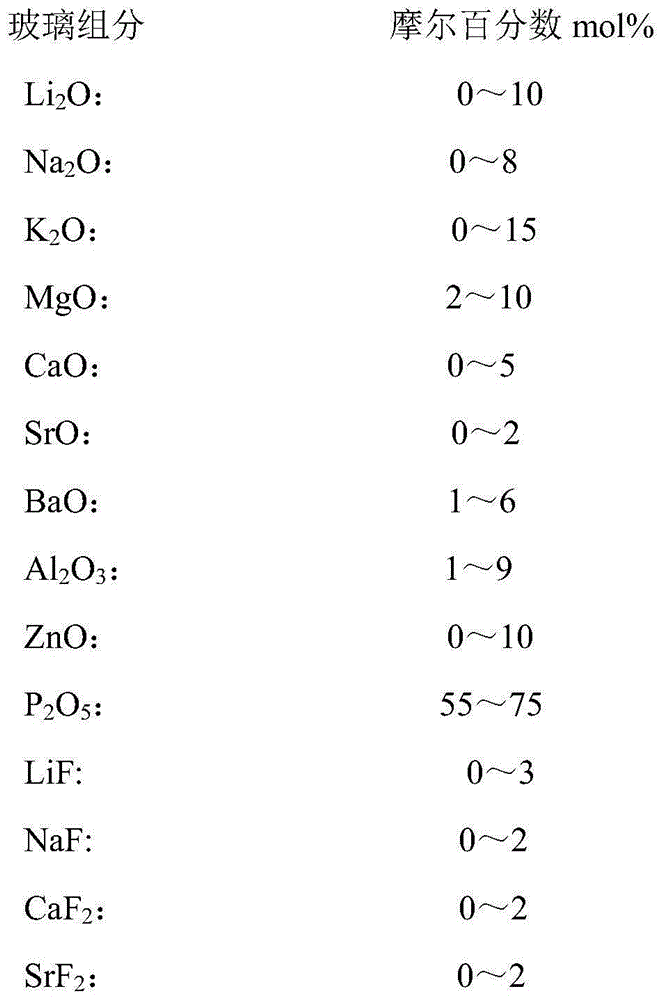

Ultraviolet-transmittance and high-damage-threshold fluoride phosphate laser glass and preparation method thereof

ActiveCN105000801AGood spectral transmission performanceHigh resistance to laser damage thresholdGlass furnace apparatusGlass shaping apparatusHigh power lasersHigh energy

The invention provides high-damage-threshold fluoride phosphate laser glass as a material for preparing an ultraviolet-transmittance window, and a preparation method of the high-damage-threshold fluoride phosphate laser glass. The preparation method comprises the steps of adopting an alkali metal oxide, an alkaline earth metal oxide, alumina, zinc oxide and phosphoric pentoxide as main raw materials, adding a small amount of rare earth fluoride, molding and preparing glass pressing blanks based on the drip injection method after the treatments of high-temperature melting, clarification and homogenizing, and finally obtaining the high-damage-threshold fluoride phosphate laser glass material through the annealing treatment. The fused quartz material can be replaced by the above glass material for preparing lenses, plane windows, prisms and other optical components applied to high-energy and high-power laser systems. In this way, the laser-induced damage problems of ultraviolet optical components made of the fused quartz material in existing high-energy and high-power laser systems can be solved. The load output capability of a laser is further improved. Therefore, the above material can be used for preparing the ultraviolet-transmittance optical components of high-power lasers for laser-driven inertial confinement fusion experiments.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

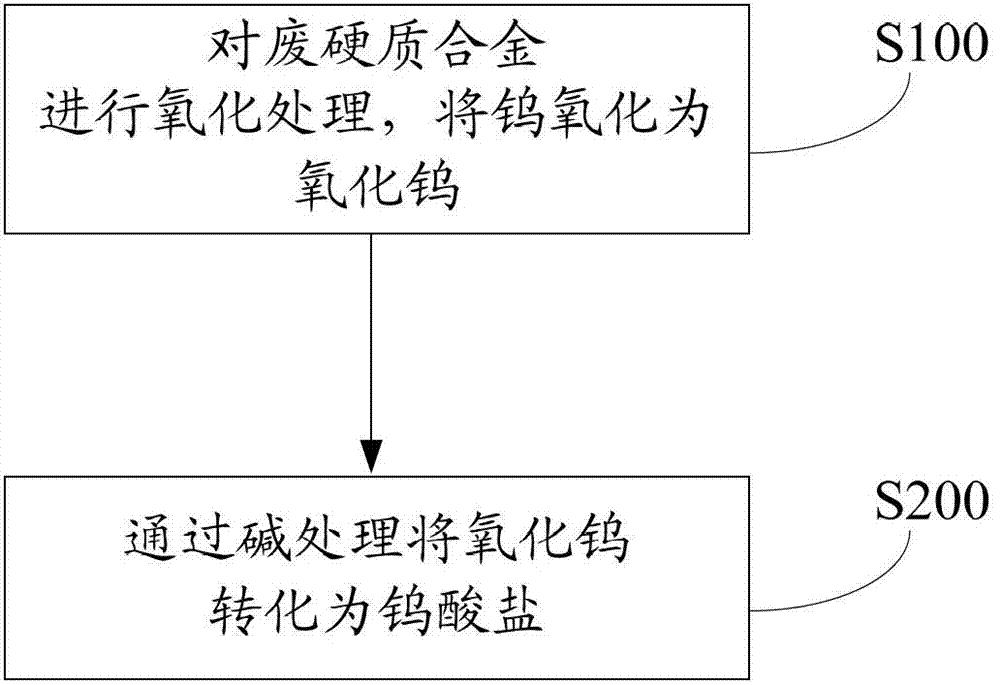

Method for treating waste hard alloy

InactiveCN102925692AHigh recycling valueImprove oxidation efficiencyProcess efficiency improvementCemented carbideTungstate

The invention provides a method for treating waste hard alloy. The method comprises the following steps of: oxidizing the waste hard alloy to convert tungsten into tungsten oxide; and reacting the oxidized waste hard alloy with alkali to convert the tungsten oxide into tungstate. By the method, the waste hard alloy can be effectively treated.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

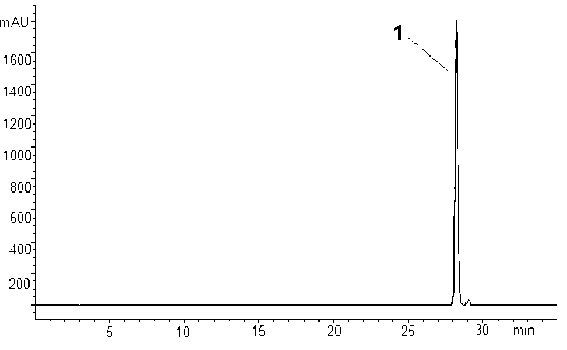

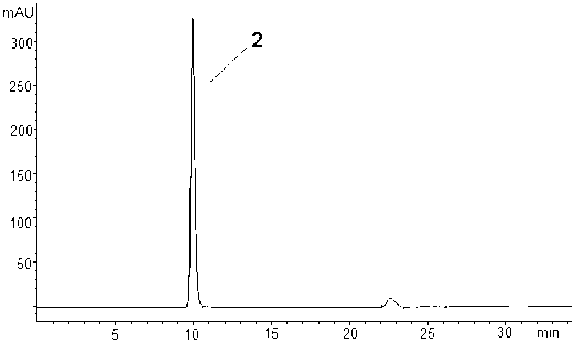

Method for quickly separating and preparing high-purity deoxyrhapontin and rhapontin

ActiveCN102702283AClear chemical structureHigh puritySugar derivativesSugar derivatives preparationStationary phaseMethanol water

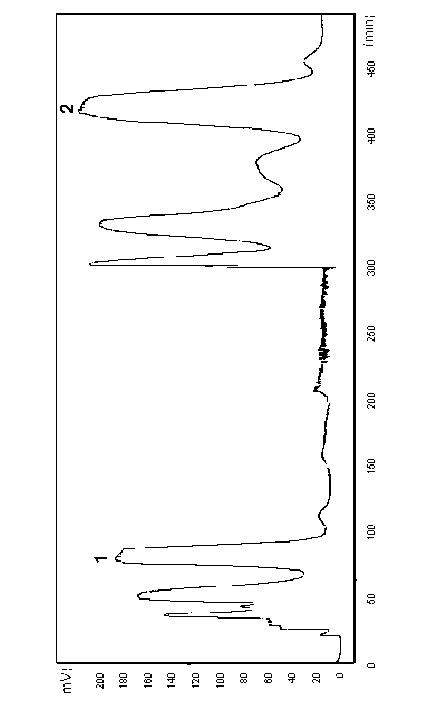

The invention relates to a method for quickly separating and preparing high-purity deoxyrhapontin and rhapontin. The method comprises the following steps of: (1) cutting or grinding the dry root or rhizome of the wild or cultivated rhubarb plant to obtain the extraction raw material; (2) performing alcohol extraction and drying of the extraction raw material to obtain an extract; (3) mixing four solvents of methanol, water, n-butyl alcohol and chloroform; shaking, standing for layering and collecting the upper-phase solvent and the lower-phase solvent; and performing ultrasonic treatment of the upper-phase solvent and the lower-phase solvent to obtain a stationary phase and a mobile phase; (4) dissolving the extract in the mobile phase to obtain a sample injection solution; (5) sequentially pumping the stationary phase and the mobile phase into a separation tube of a high-speed counter-current chromatographic apparatus, and injecting the sample injection solution into a sample injection ring of the high-speed counter-current chromatographic apparatus; (6) collecting the effluent liquid A in the time range from 70min to 100min, and drying the effluent liquid A to obtain deoxyrhapontin; (7) reversely rotating the separation tube; and (8) collecting the effluent liquid B in the time range from 400min to 450min, and drying the effluent liquid B to obtain rhapontin. The method provided by the invention is simple to operate and facilitates the industrial production.

Owner:PUREDIA LTD

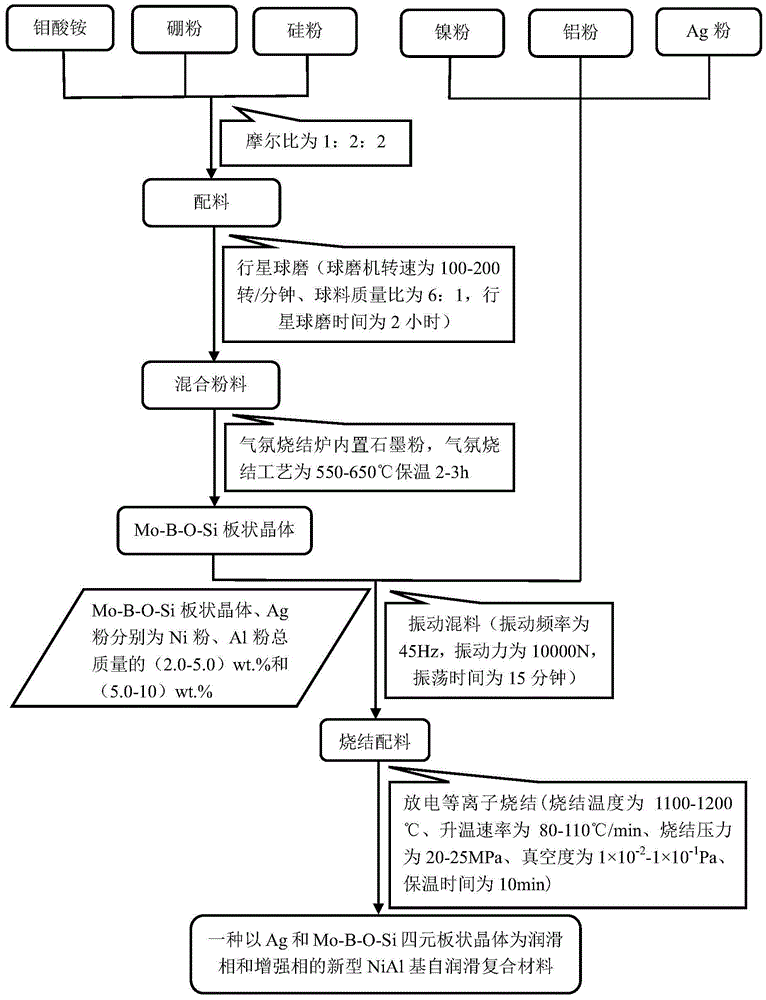

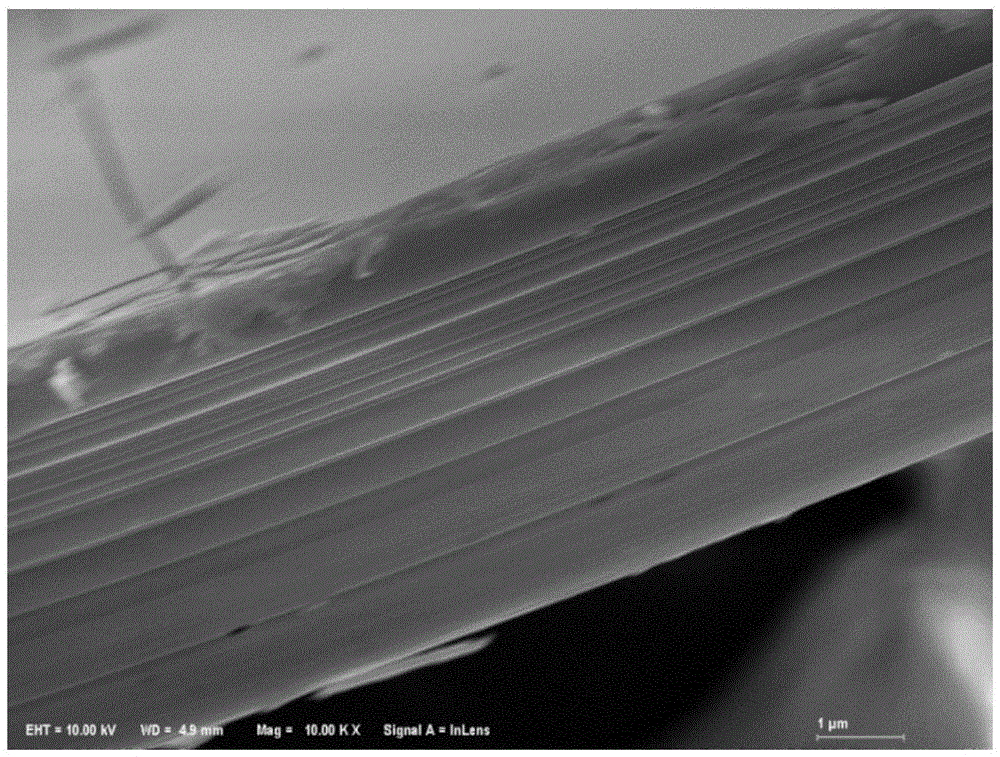

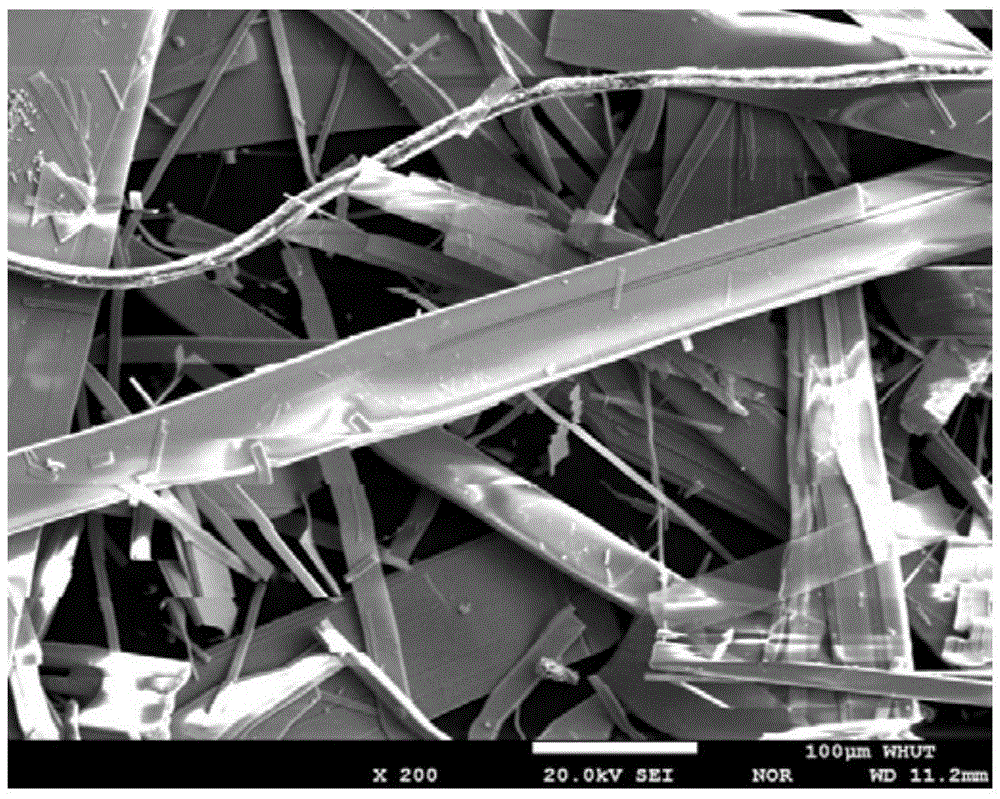

Novel NiAl-based self-lubricating material using Ag and Mo-B-O-Si four-element platy crystal as composite lubricating phase and reinforcing phase and preparation method of novel NiAl-based self-lubricating material

The invention relates to a novel NiAl-based self-lubricating material using Ag and Mo-B-O-Si four-element platy crystals as a composite lubricating phase and a reinforcing phase and a preparation method of the novel NiAl-based self-lubricating material. The preparation method includes following steps: preparing the Mo-B-O-Si four-element platy crystals; selecting Ni powder and Al powder according to a molar ratio of Ni:Al=1:1, selecting the Mo-B-O-Si four-element platy crystals and Ag powder, and mixing the Mo-B-O-Si four-element platy crystals with the Ni powder, the Al powder and the Ag powder to obtain an ingredient; disposing the ingredient in a vibration mixing machine for dry mixing to obtain a sintered ingredient; subjecting the sintered ingredient to discharging plasma sintering to obtain the novel NiAl-based self-lubricating material. The self-lubricating material is low in friction coefficient and wear rate in the process of friction and wear and has excellent tribological performance, the preparation method is simple and novel, and process parameters are easy to control in the preparation process.

Owner:WUHAN UNIV OF TECH

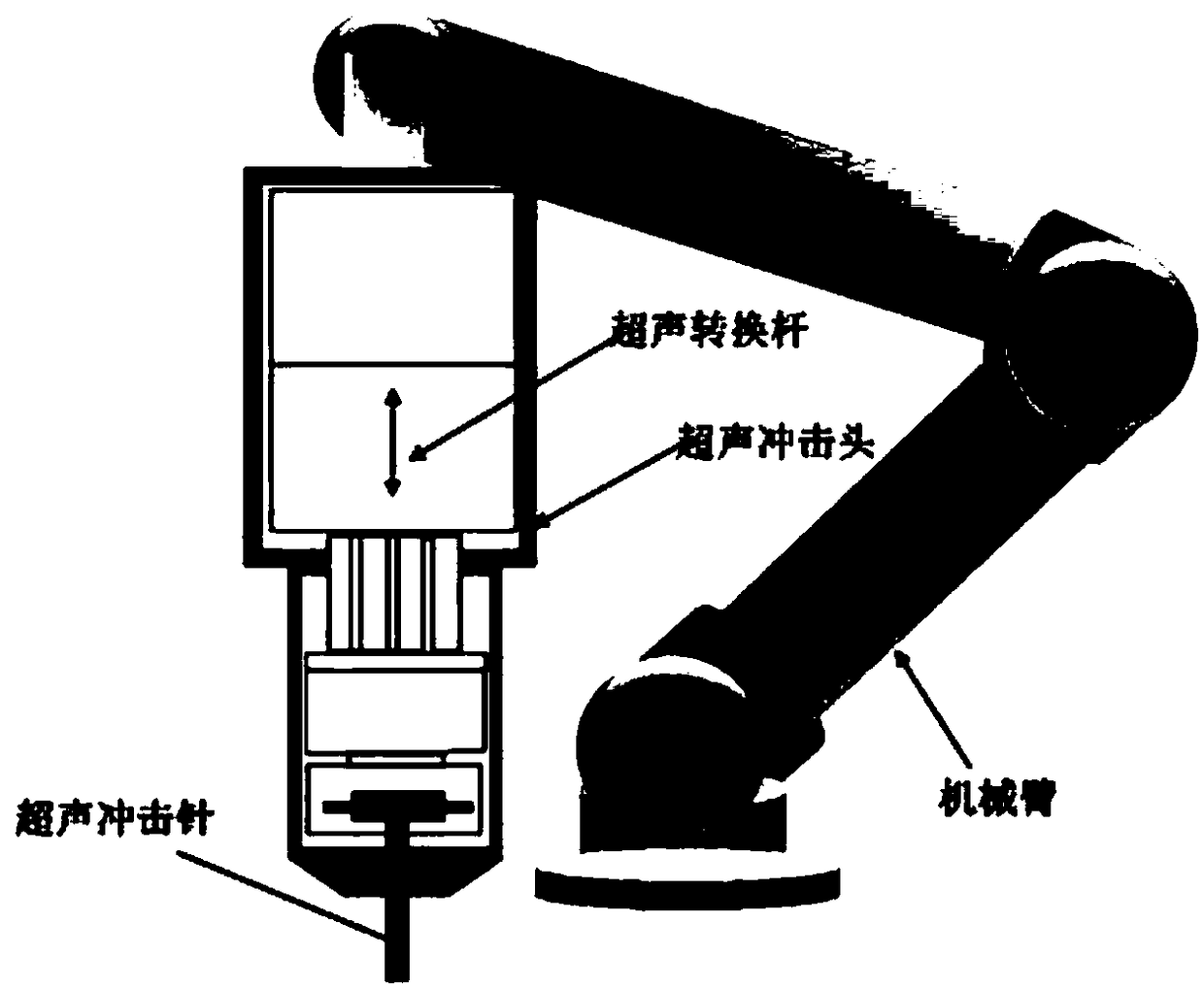

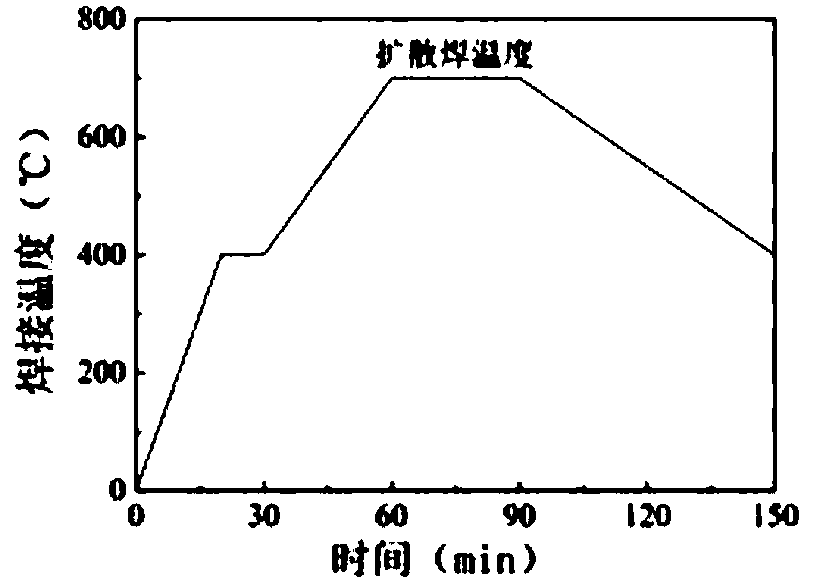

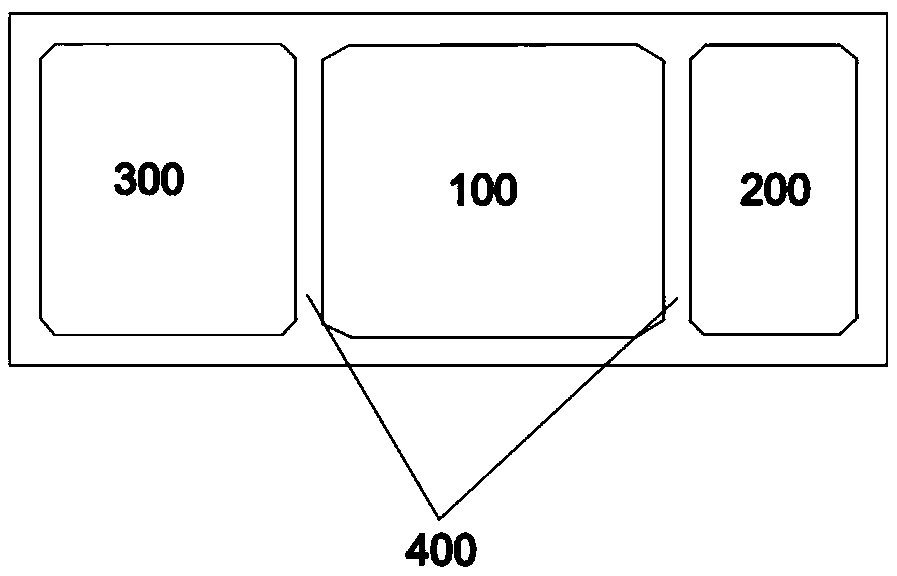

Ultrasonic impact surface modification auxiliary titanium alloy diffusion connection method

ActiveCN109423587AReduce energy consumptionRealize green and energy-saving weldingSurface modificationAtomic diffusion

The invention discloses an ultrasonic impact surface modification auxiliary titanium alloy diffusion connection method. According to the method, ultrasonic impact is conducted on the surface of a titanium alloy plate, the titanium alloy plate is heated and diffused, so that joints can be tightly combined, and the high-strength connection of a titanium alloy is realized. According to the method, agrain refinement layer is obtained through ultrasonic impact surface modification, the atomic diffusion rate is increased, diffusion connection parameters of the titanium alloy are reduced, and low-temperature diffusion connection of the titanium alloy is realized; and the method is simple and convenient to operate, good in adaptability, high in repeatability, green and energy-saving, and can greatly improve the industrial production efficiency.

Owner:TIANJIN UNIV

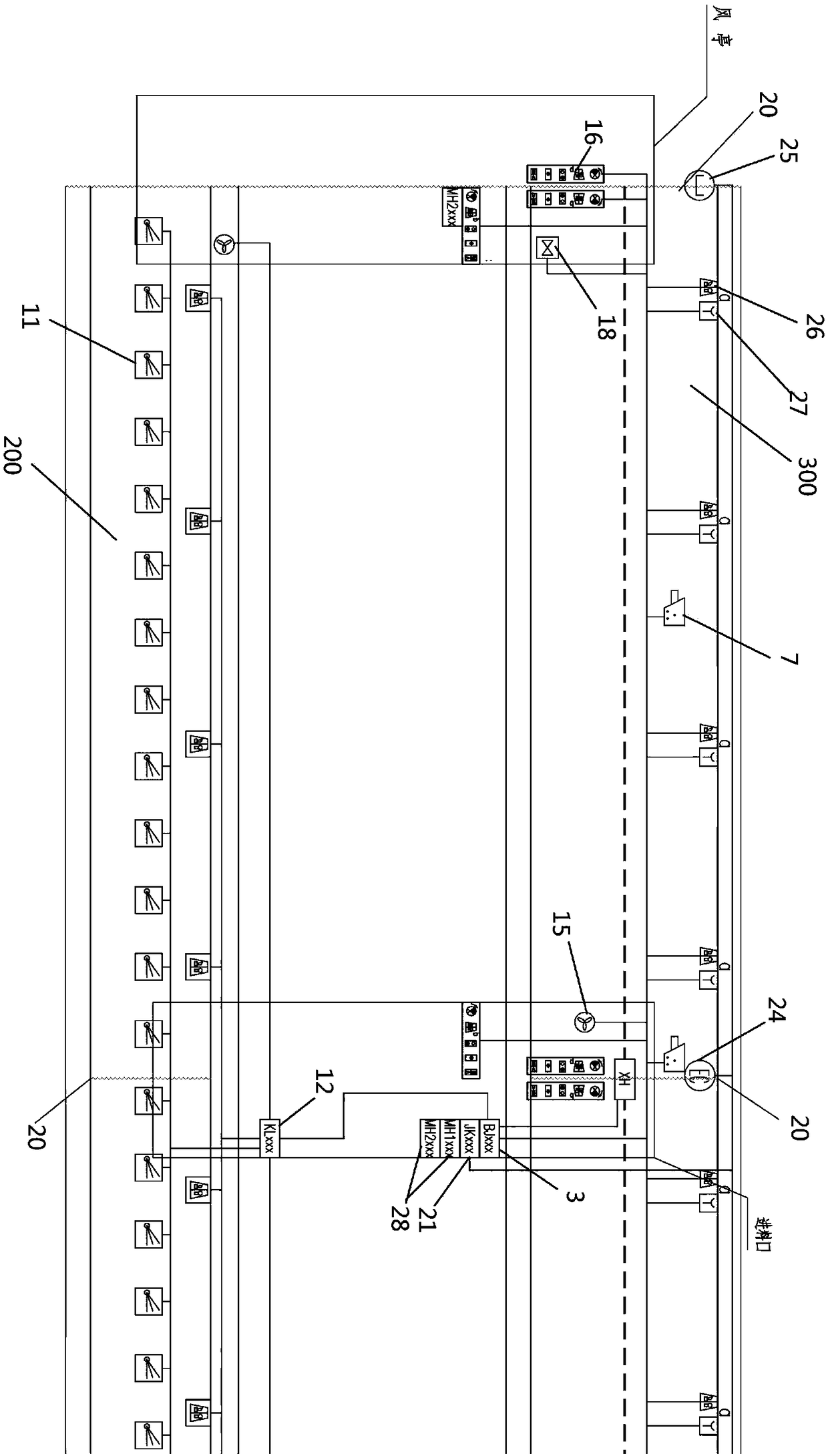

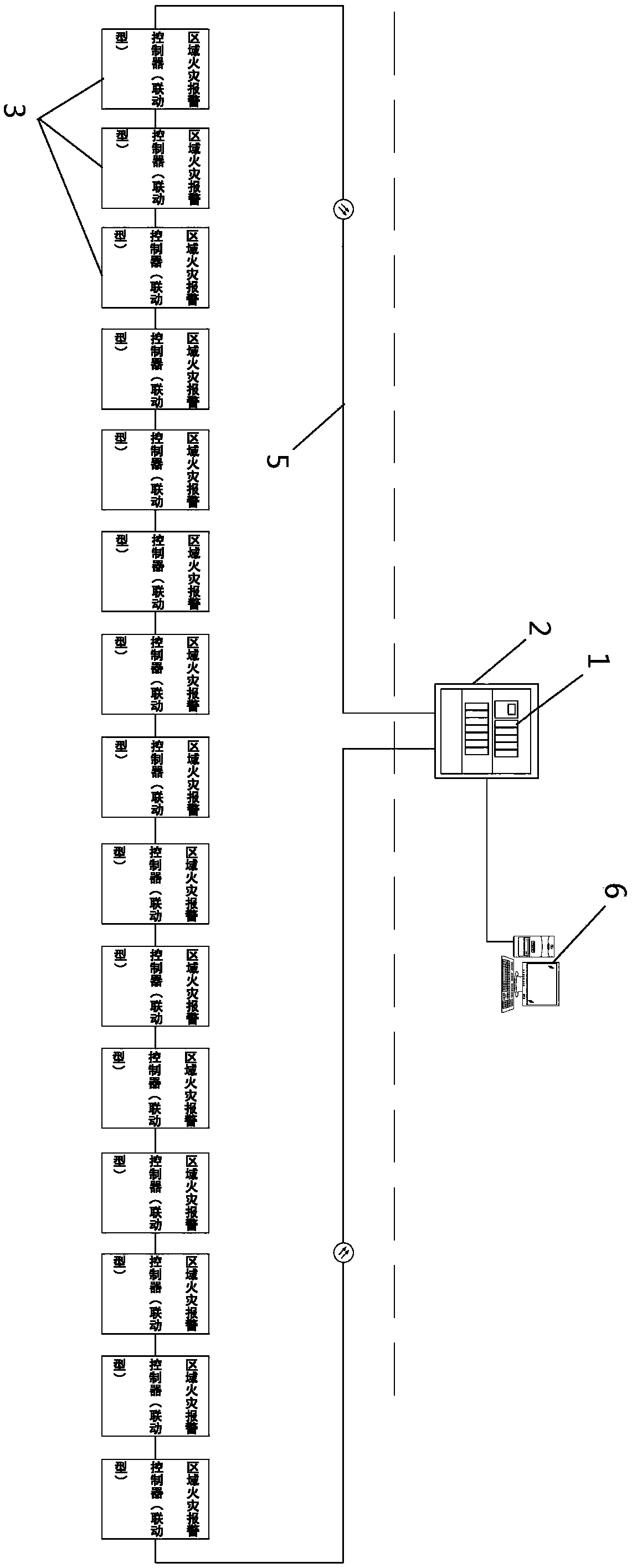

Comprehensive pipe gallery fire treatment system

PendingCN109173130AImprove construction efficiencyImprove quality controlFire rescueFire alarm radiation actuationFire detectorFire risk

The invention discloses a comprehensive pipe gallery fire treatment system which comprises a fire alarm linked main machine, a fire detector, a regional fire alarm controller, a fire extinguishing controller and a fire extinguishing device. The fire detector is arranged in a comprehensive pipe gallery for detecting whether a fire happens or not; the regional fire alarm controller is separately connected to the fire alarm linked main machine and the fire detector for receiving a fire signal sent by the fire detector and sending the fire signal to the fire alarm linked main machine; the fire extinguishing controller is connected to the fire alarm linked main machine; the fire extinguishing device is connected to the fire extinguishing controller and is arranged in the comprehensive pipe gallery; and the fire alarm linked main machine receives the fire signal and starts the fire extinguishing controller, and the fire extinguishing controller controls the fire extinguishing device to startto extinguish the fire. The system can monitor the fire dangerous omen in the comprehensive pipe gallery for treating the fire behavior at a first time, so that the fire risk is extinguished to the maximum extent, spread of the fire behavior is controlled effectively when the fire happens, and the economical loss is reduced.

Owner:中铁一局集团厦门建设工程有限公司 +2

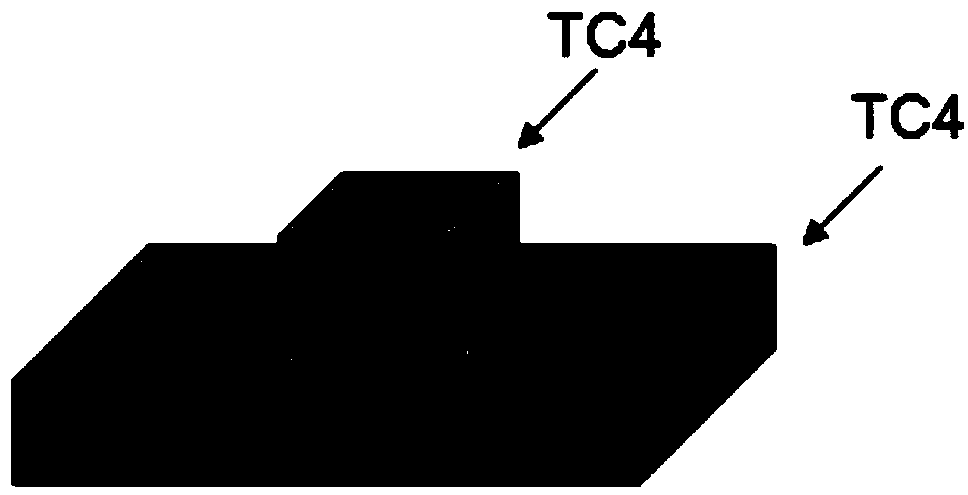

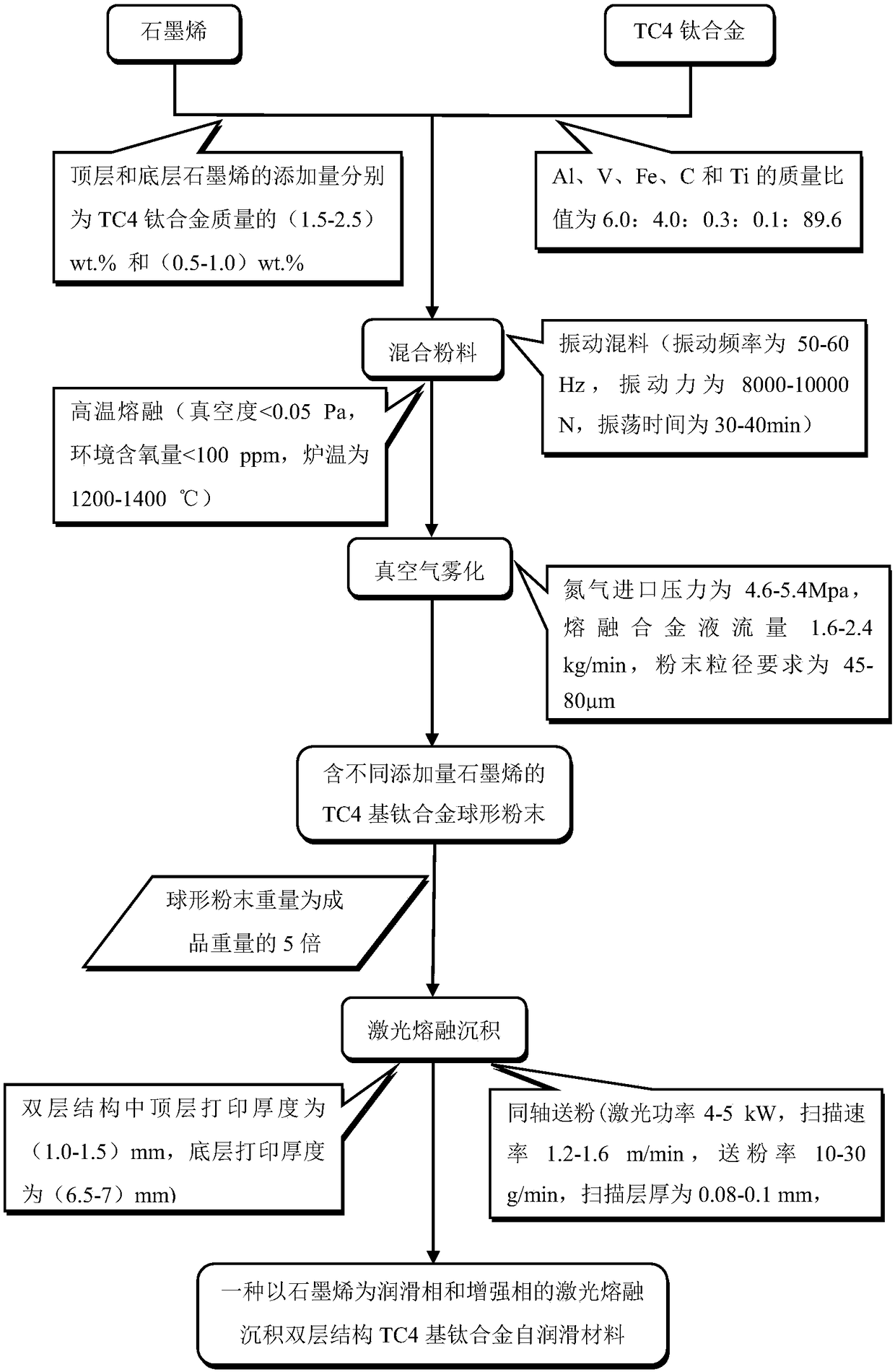

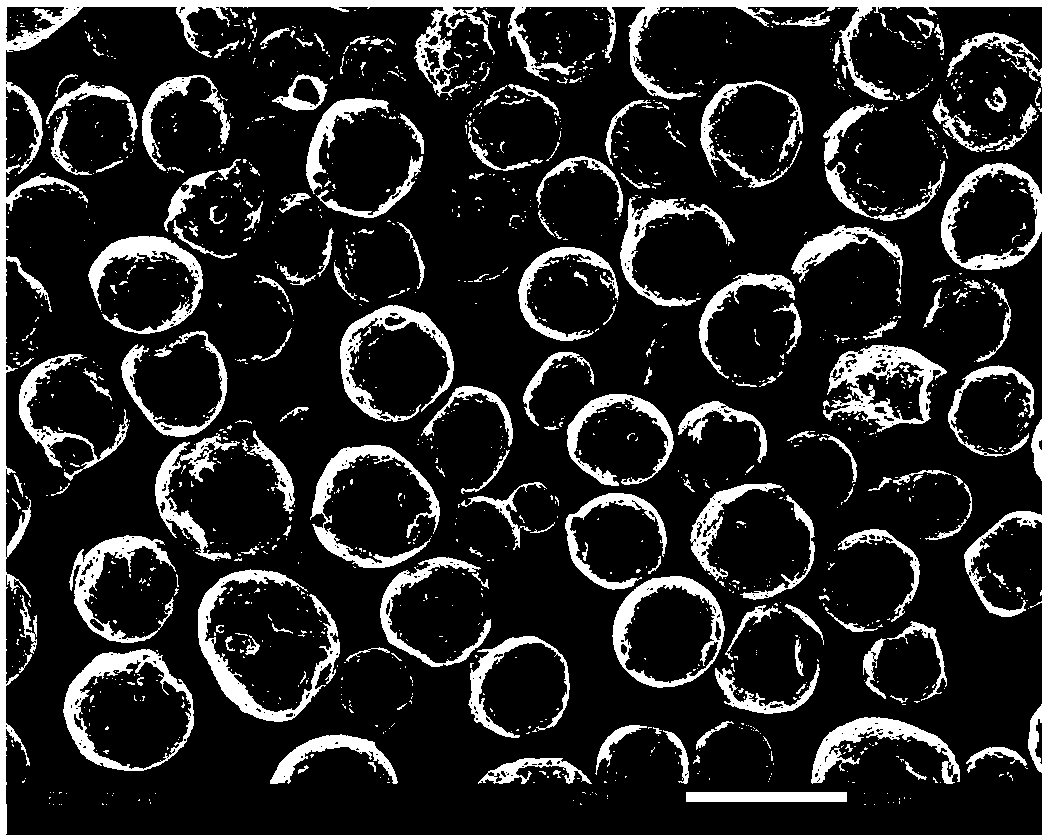

Bilayer structure TC4-base titanium alloy self-lubricating material and preparation method thereof

ActiveCN108188393AReduce dosageImprove anti-friction performanceAdditive manufacturingIncreasing energy efficiencyTitaniumWear resistance

The invention relates to a bilayer structure TC4-base titanium alloy self-lubricating material. TC4 titanium alloy is used as a base material, graphene is used as a lubrication phase and a reinforcement phase, and the processes of vibration material mixing, high-temperature melting, vacuum gas atomization and laser melting deposition are sequentially executed to prepare the TC4-base titanium alloyself-lubricating material with the top layer and the bottom layer including different adding amounts of the graphene. According to the self-lubricating material, the graphene is arranged into a TC4 titanium alloy matrix by means of graded distribution in-situ composite, and the friction coefficient and attrition rate of the obtained self-lubricating material in the frictional wearing process arelow. Compared with a self-lubricating material with the lubrication phase and the reinforcement phase being evenly distributed, the properties of antifriction and wearing resistance can be better achieved more rapidly, and the precious lubrication phase and reinforcement phase graphene can be reduced. Moreover, the technological parameters can be controlled easily in the preparation process, and it is of great significance to improving the tribological property of the self-lubricating material and industrialized application of the self-lubricating material.

Owner:WUHAN UNIV OF TECH

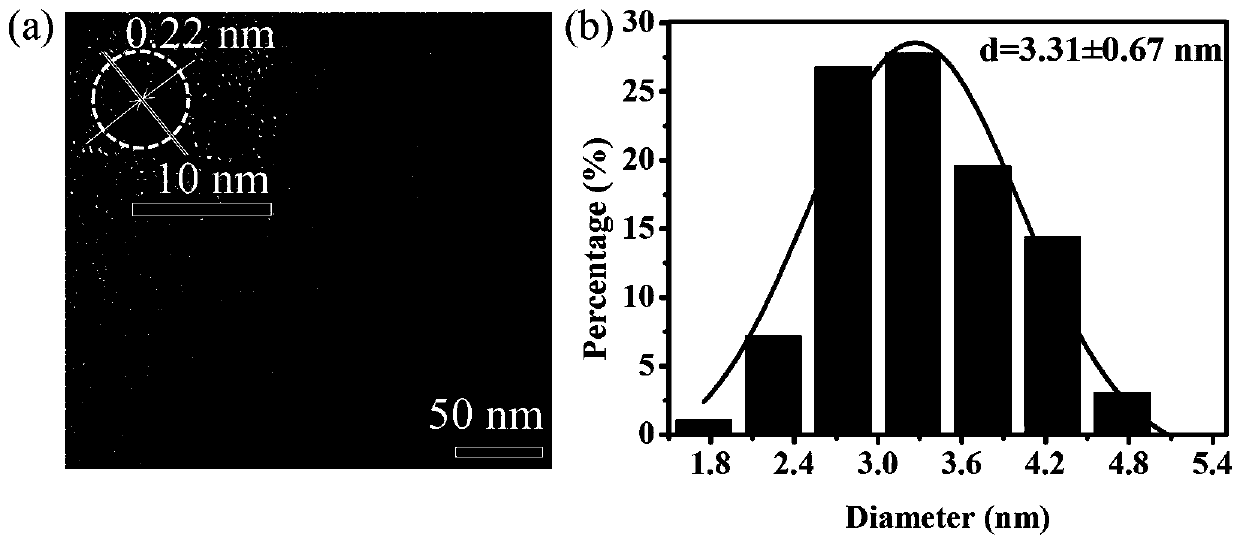

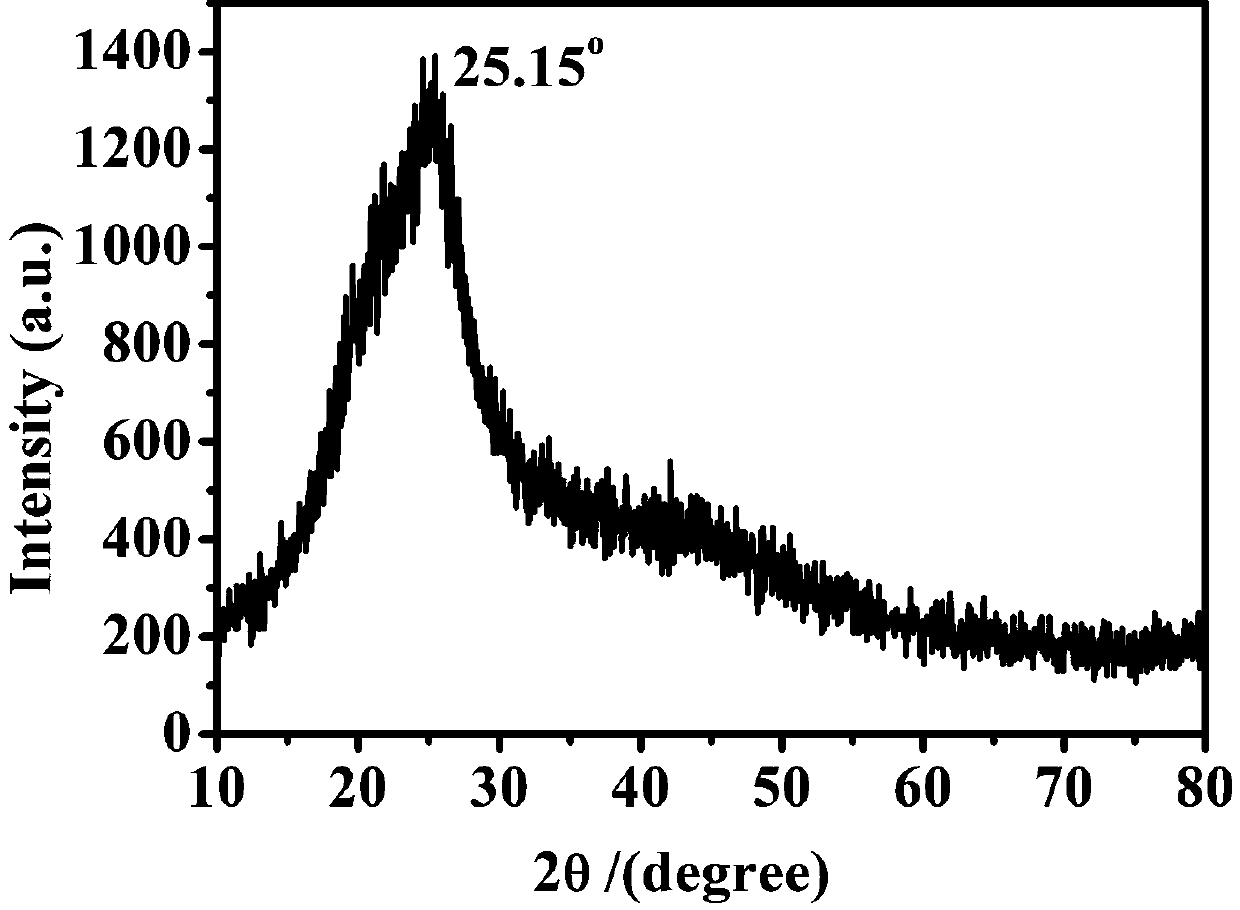

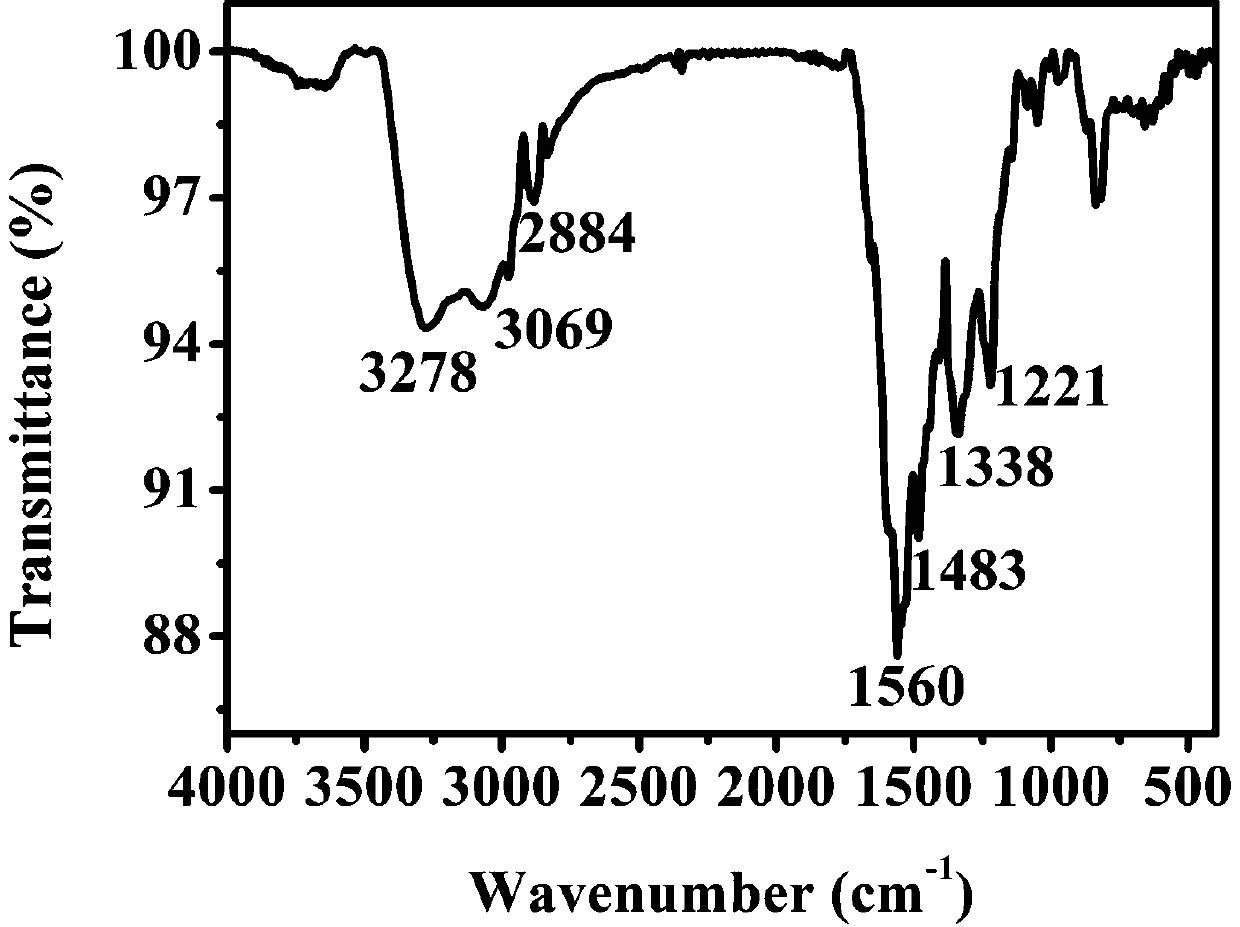

Green fluorescent carbon quantum dot with high yield and high fluorescent quantum yield, and preparation method thereof

InactiveCN110562957AHigh fluorescence quantum yieldSolve commercial application problemsNanoopticsNano-carbonQuantum yieldEthylenediamine

The invention relates to a green fluorescent carbon quantum dot and a preparation method thereof. The green fluorescent carbon quantum dot is prepared through a solvothermal technology by taking 2,7-dihydroxynaphthalene as a carbon source, hydrogen peroxide as an oxidizing agent, ethylenediamine as a nitrogen doping agent and anhydrous ethanol as a solvent. The green fluorescent carbon quantum dotprepared by the method has a high yield and a high fluorescent quantum yield, and can be used for preparing warm white LEDs suitable for indoor illumination as a phosphor.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com