Superhydrophilic and superoleophobic oil-water separation membrane with humidity responsiveness as well as preparation method and application of oil-water separation membrane

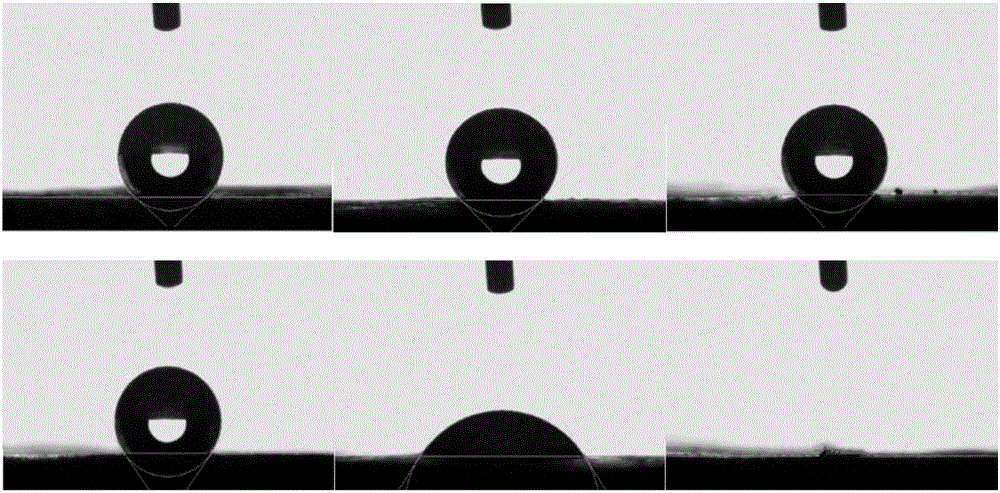

A super-oleophobic, responsive technology, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve the problems of high price, low yield, complicated preparation process, etc., and achieve the effect of good fouling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] (1) Put a piece of 15×15mm 2 The 300 mesh stainless steel wire mesh was immersed in distilled water, ethanol or acetone, and distilled water in order, respectively, and ultrasonically cleaned at 150W and 40KHz for 8 minutes, and hung up to dry at room temperature.

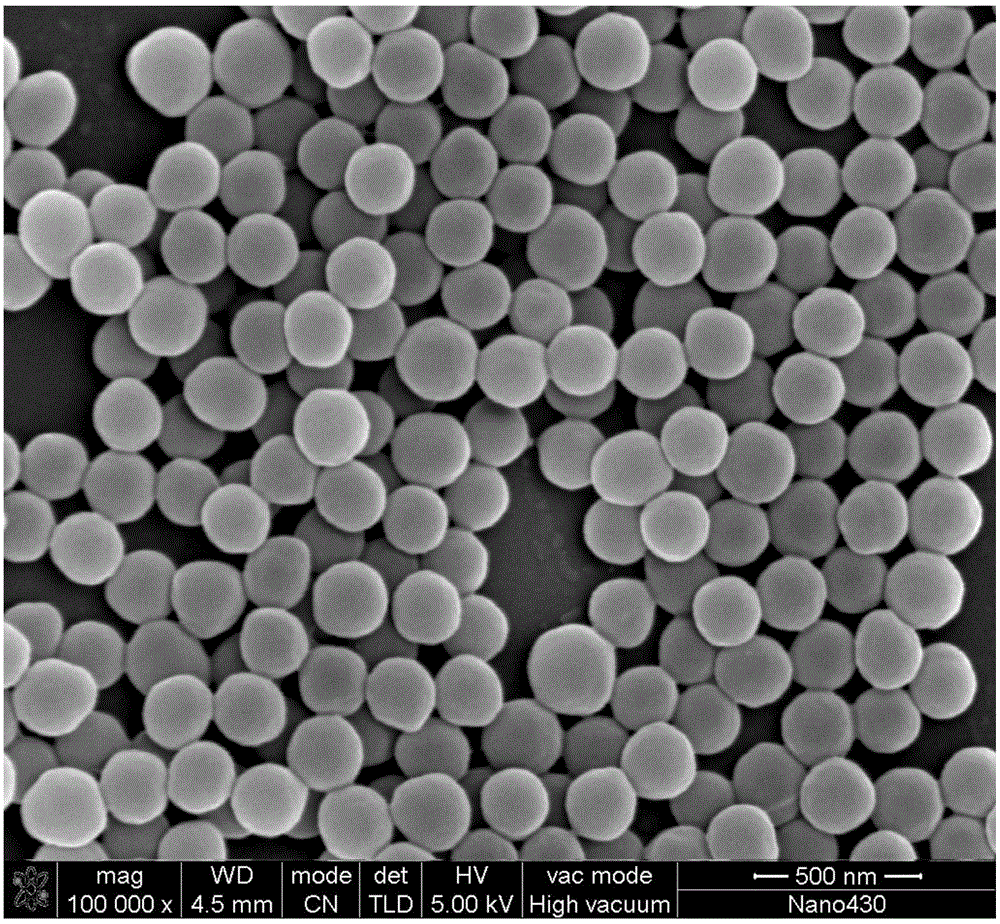

[0077] (2) Add 50g of tetraethoxysilane, 100g of absolute ethanol, and 20g of deionized water into a four-necked flask, heat it in a constant temperature water bath at 35°C and stir constantly. After stirring, weigh 0.5g of 25% by mass Ammonia water was added to 30 g of deionized water, dropped into a four-necked flask with a constant flow pump at a rate of 1 mL / min, and discharged after being kept for 4 hours to prepare nano silica sol with a particle size of about 20 nm, and the mass content of nano particles was 20%.

[0078] (3) Add 30 g of a 10% isopropanol solution of heptafluorodecyltriethoxysilane to the four-necked flask in step (2), and keep it for 5 hours to prepare an oleophobic modified nano silica so...

Embodiment 2

[0086] (1) Put a piece of 15×15mm 2 The 100 mesh copper wire mesh was immersed in distilled water, ethanol, and distilled water in order, and washed at 100W and 20KHz for 10 minutes, and hung up to dry at room temperature.

[0087] (2) Add 50g of tetraethoxysilane, 100g of absolute ethanol and 20g of deionized water into a four-necked flask, heat it in a constant temperature water bath at 80°C and stir continuously. After stirring is uniform, weigh 0.5g of 25% mass concentration Hydrochloric acid was added to 30 g of deionized water, dropped into a four-necked flask with a constant flow pump at a speed of 1 mL / min, and discharged after being kept for 4 hours to prepare nano silica sol with a particle size of about 500 nm, and the mass content of nano particles was 35%.

[0088] (3) Add 50 g of a 1% tetrahydrofuran solution of tridecafluorooctyltriethoxysilane to the four-necked flask in step (2), and keep it for 5 hours to prepare an oleophobic modified nano silica sol.

[0089] (4) ...

Embodiment 3

[0095] (1) Put a piece of 15×15mm 2 The 200 mesh aluminum wire mesh was immersed in distilled water, ethanol or acetone, and distilled water in order, respectively, and ultrasonically cleaned at 150W and 40KHz for 10 minutes, and hung up to dry at room temperature.

[0096] (2) Add 50g of tetramethoxysilane, 100g of absolute ethanol, and 20g of deionized water into a four-necked flask, heat it in a constant temperature water bath at 35°C and stir continuously. After stirring is uniform, weigh 0.5g of 25% by mass Sodium bicarbonate was added to 30 g of deionized water, dropped into a four-necked flask with a constant flow pump at a speed of 1.5 mL / min, and after holding for 5 hours, the material was discharged to prepare nano silica sol with a particle size of about 200 nm.

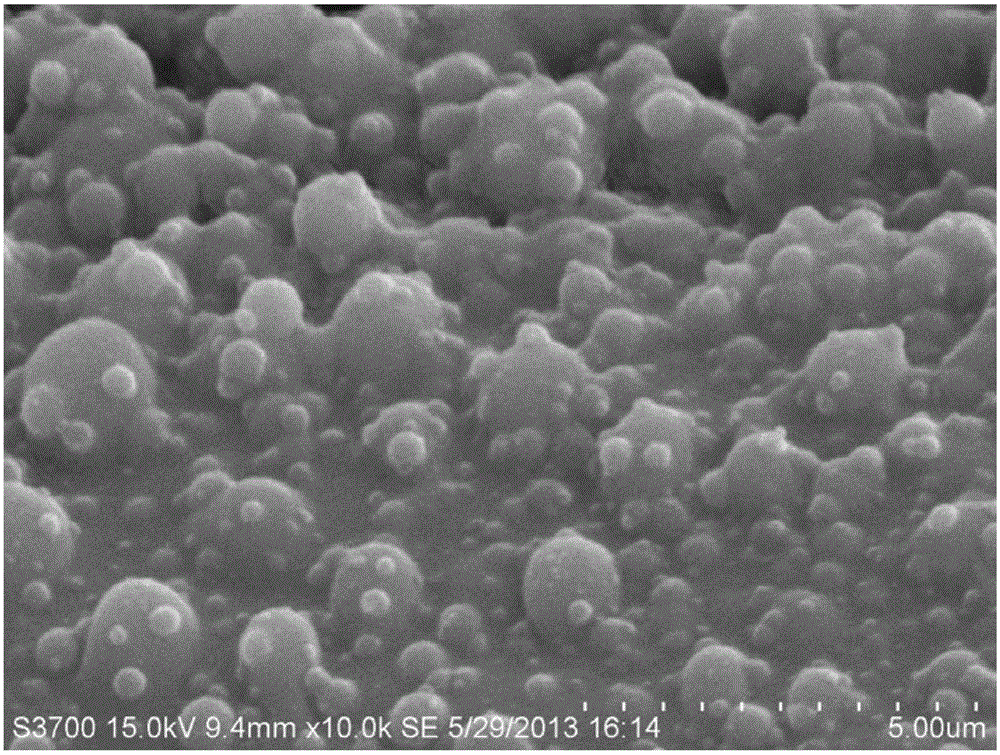

[0097] (3) In the four-necked flask in step (2), add 40g of a 1% isopropanol solution of pentafluorononyltriethoxysilane and keep it for 5 hours to prepare an oleophobic modified nano silica sol. Hitachi S-3700...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com