Super-hydrophilic and underwater super-oleophobic oil-water separation mesh film and preparation method thereof

An oil-water separation omentum and underwater super-oleophobic technology, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of poor water resistance of the omentum, achieve large water flux, low energy consumption, and membrane The effect of slow flux decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

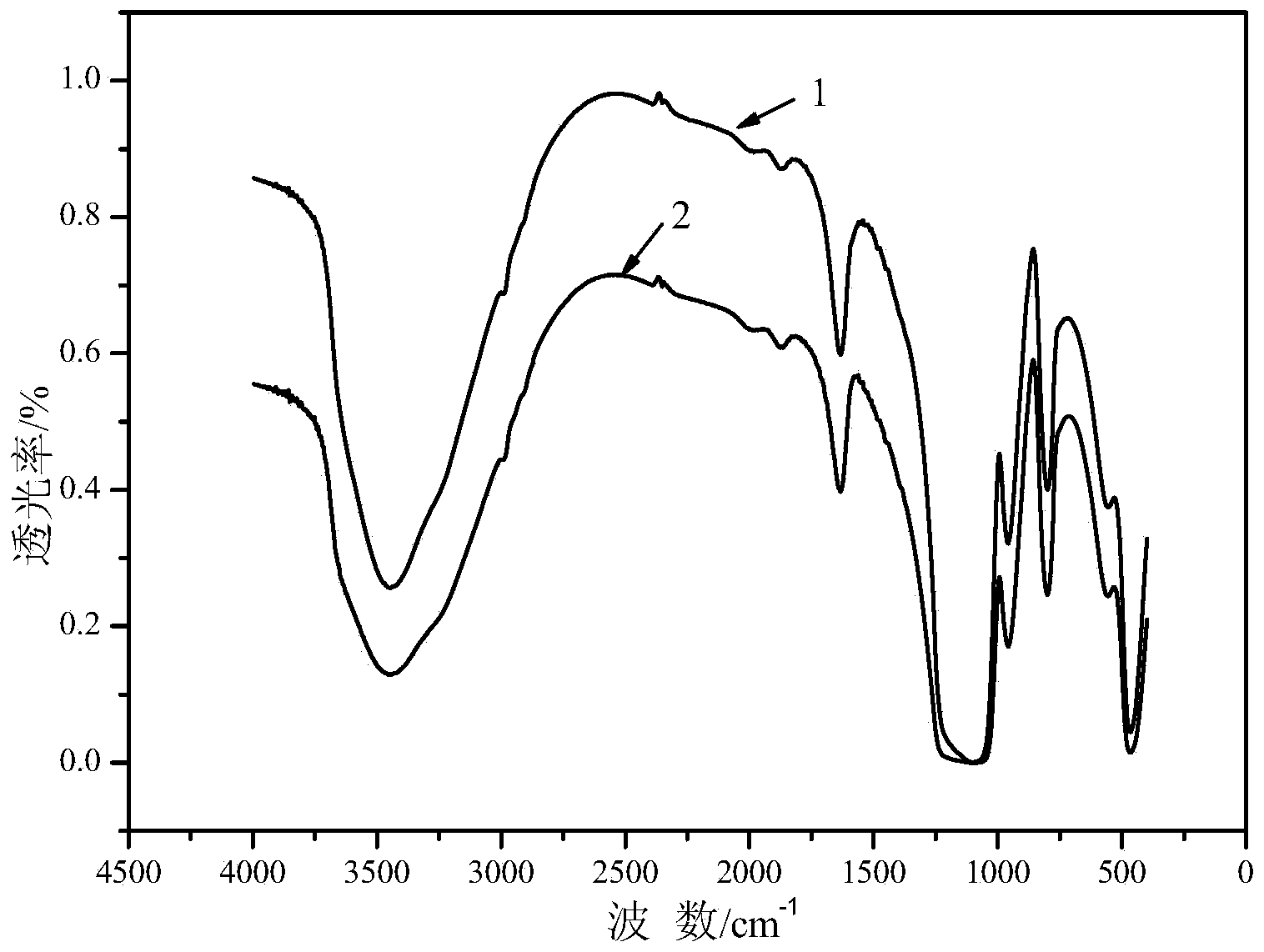

Method used

Image

Examples

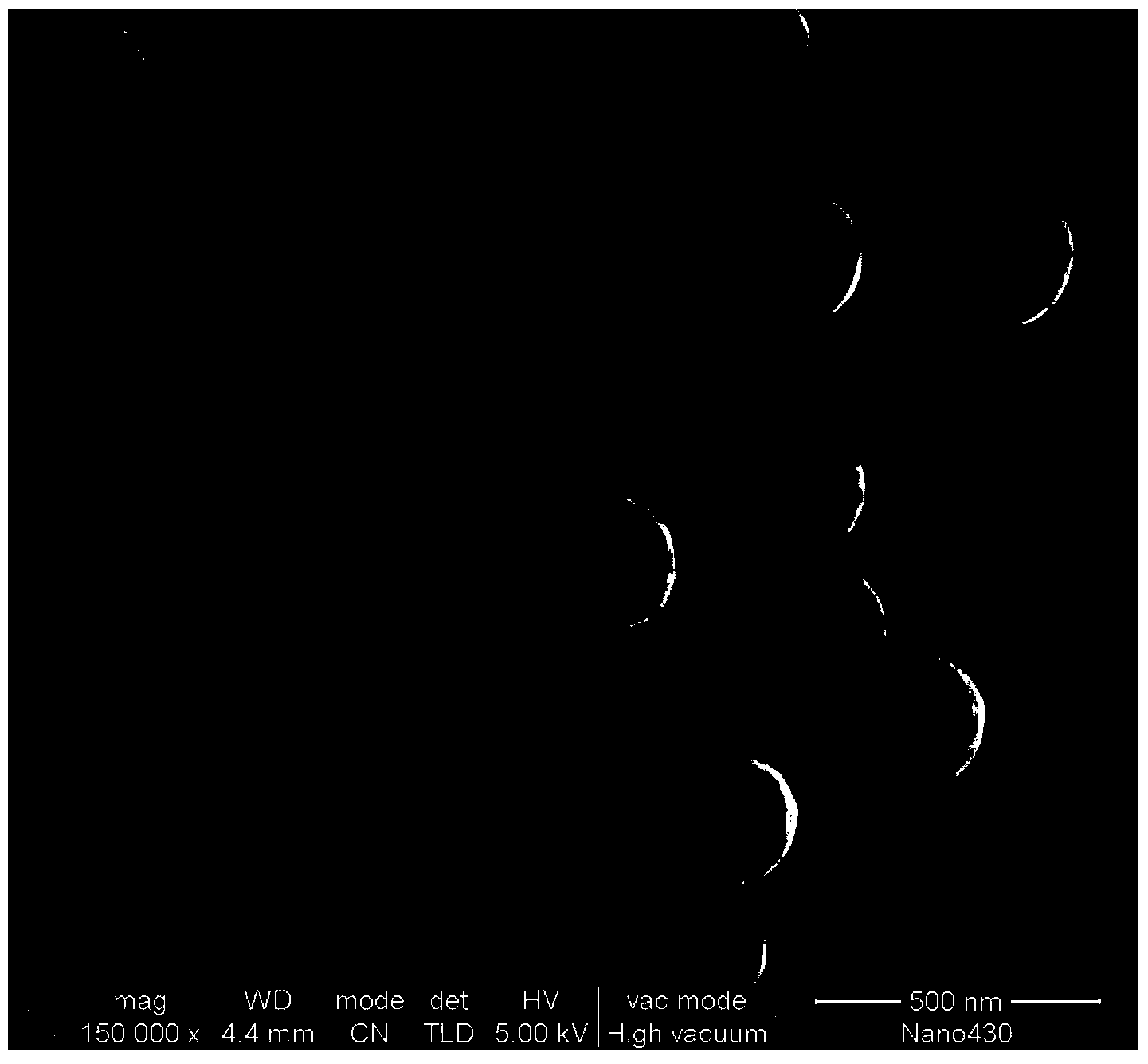

Embodiment 1

[0033] (1) Put a piece of 15×15mm 2 The 300-mesh stainless steel wire mesh was immersed in distilled water, ethanol or acetone, and distilled water in order, respectively, and ultrasonically cleaned at 150W and 40KHz for 8min, and hung up to dry at room temperature;

[0034] (2) Preparation of seed emulsion, in a 250ml four-necked flask, add 100g deionized water and 0.0252g SDBS, stir and gradually heat up to 90°C, then add 0.4g sodium persulfate, 0.45g acrylic acid and 4.4g styrene Add the mixture at one time, stir evenly, keep warm after 1 hour of reaction;

[0035] (3) For the preparation of nuclear latex particles, add 120 g of deionized water, 122 g of styrene, and 6 g of dodecanethiol into a 1000 ml four-neck flask, stir and heat to 85 ° C, and slowly add the above seed emulsion within 1 hour;

[0036] (4) Preparation of core-shell latex particles. In the solution containing the above-mentioned core latex particles, add 120g of deionized water and 1.056g of sodium persulf...

Embodiment 2

[0044] (1) Put a piece of 15×15mm 2 The 100-mesh copper wire mesh was immersed in distilled water, ethanol, and distilled water in order, respectively, cleaned at 100W and 20KHz for 10min, and hung up to dry at room temperature;

[0045] (2) Preparation of seed emulsion, in a 250ml four-necked flask, add 50g deionized water and 0.0126g SDBS, mix and stir and gradually heat up to 85°C, then add 0.2g sodium persulfate, 0.225g methacrylic acid and 2.2g benzene The mixture composed of ethylene is added at one time, stirred evenly, and kept warm after reacting for 1 hour;

[0046] (3) For the preparation of nuclear latex particles, add 100g of deionized water, 100g of styrene, and 3g of mercaptoethanol into a 1000ml four-neck flask, stir and heat to 85°C, and slowly add the above seed emulsion within 1h;

[0047] (4) Preparation of core-shell latex particles. In the solution containing the above-mentioned core latex particles, add 100g deionized water and 0.8g sodium persulfate mi...

Embodiment 3

[0055] (1) Put a piece of 15×15mm 2 The 200-mesh aluminum wire mesh was immersed in distilled water, ethanol or acetone, and distilled water in order, respectively, and ultrasonically cleaned at 150W and 40KHz for 10min, and hung up to dry at room temperature;

[0056] (2) Preparation of seed emulsion, in a 250ml four-necked flask, add 100g deionized water and 0.0252g SDBS, mix and stir and gradually heat up to 90°C, then add 0.4 sodium persulfate, 0.45g acrylic acid and 4.4g styrene Add the mixture at one time, stir evenly, keep warm after 1 hour of reaction;

[0057] (3) For the preparation of nuclear latex particles, add 120 g of deionized water, 122 g of styrene, and 6 g of dodecanethiol into a 1000 ml four-neck flask, stir and heat to 85 ° C, and slowly add the above seed emulsion within 1 hour;

[0058] (4) Preparation of core-shell latex particles. In the solution containing the above-mentioned core latex particles, add 120g of deionized water and 1.056g of sodium pers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com