Functionalized styrene-maleic anhydride copolymer/silicon dioxide composite fiber membrane material and preparation method thereof

A composite fiber membrane and maleic anhydride technology, applied in chemical instruments and methods, separation methods, fiber chemical characteristics, etc., can solve the problems of oil-water separation efficiency decline, easy fouling, membrane easy pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

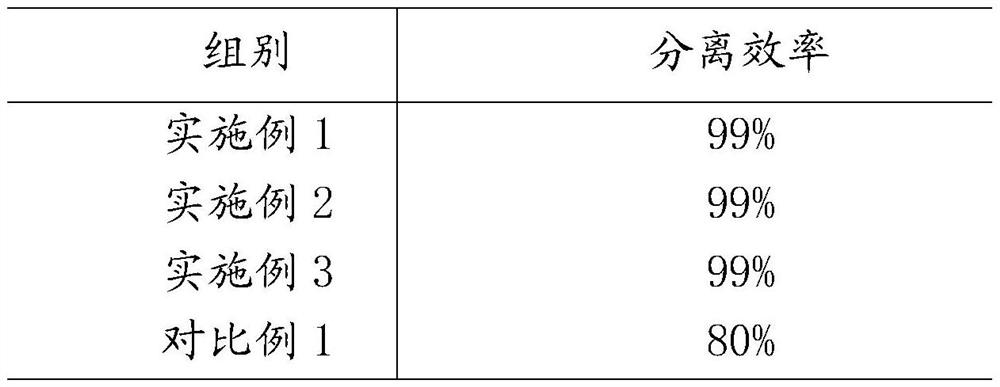

Embodiment 1

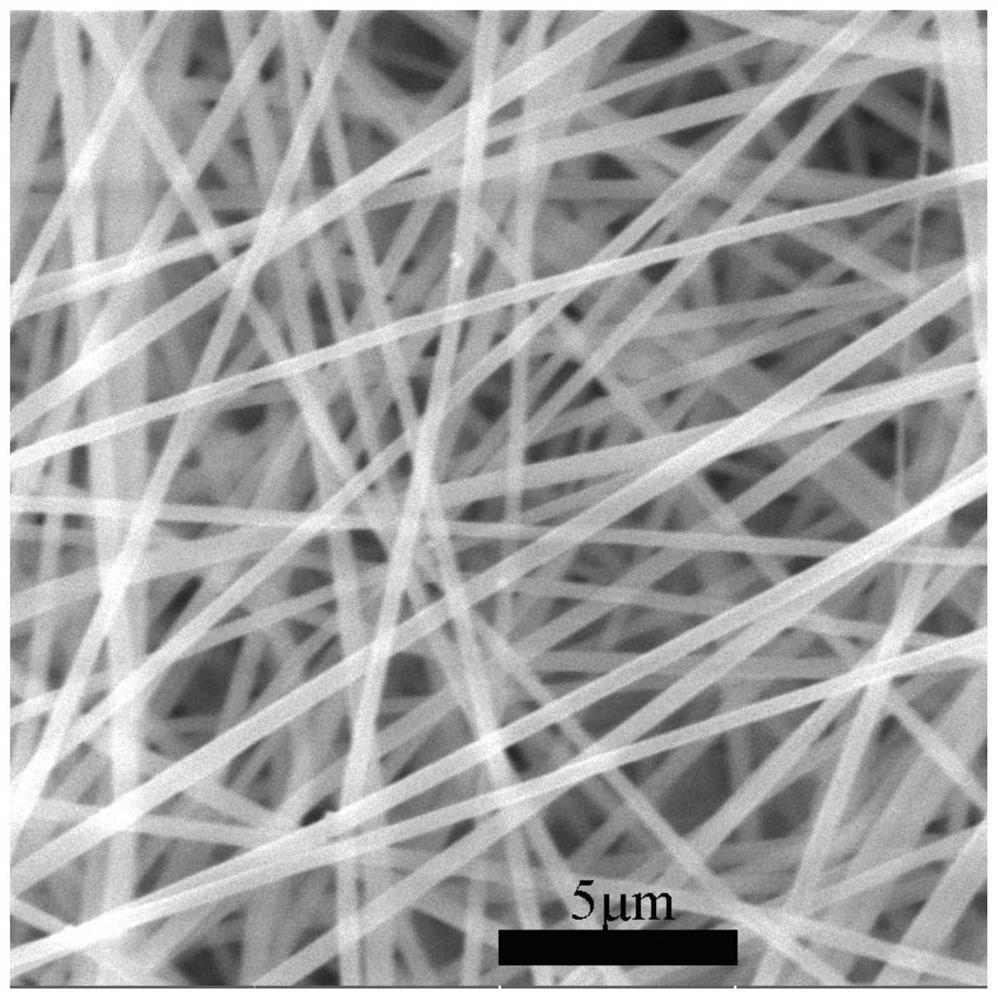

[0032] A kind of preparation method of styrene-maleic anhydride copolymer / silicon dioxide composite fiber membrane material, concrete steps are as follows:

[0033] 1) Add 0.21g of silane coupling agent monomer YDH-151 and 100ml of toluene into a three-necked flask, dissolve 4.9g of maleic anhydride in 20ml of toluene, slowly add it dropwise to the three-necked flask, and simultaneously add 9.8g of styrene and 0.01 g azobisisobutyronitrile AIBN mixture, after the dropwise addition, react at a constant temperature at 75° C. for 1 hour, then raise the temperature to 80° C., react at a constant temperature for 1 hour, and after the reaction is completed, f-PSMA is obtained by suction filtration.

[0034] 2) Disperse 0.3g of nano-silica in 11ml of DMF, sonicate at 30°C for 1.5h, add 3g of f-PSMA to dissolve it, and obtain an electrospinning solution with a mass concentration of 0.3g / ml.

[0035] 3) The spinning liquid is electrospun at a voltage of 20KV, the distance between the e...

Embodiment 2

[0038] A kind of preparation method of styrene-maleic anhydride copolymer / silicon dioxide composite fiber membrane material, concrete steps are as follows: concrete steps are as follows:

[0039]1) Add 0.5g of silane coupling agent monomer YDH-151 and 100ml of toluene into a three-necked flask, dissolve 4.9g of maleic anhydride in 20ml of toluene, slowly add it dropwise to the three-necked flask, and simultaneously add 4.9g of styrene and 0.02 The mixture of g AIBN was reacted at 75° C. for 1 hour at a constant temperature after the dropwise addition, and then heated to 85° C. for 2 hours at a constant temperature. After the reaction was completed, f-PSMA was obtained by suction filtration.

[0040] 2) Disperse 0.2g of nano-silica in 8ml of DMF, sonicate at 30°C for 1.5h, add 3g of f-PSMA to dissolve it, and obtain an electrospinning solution with a mass concentration of 0.4g / ml.

[0041] 3) The spinning liquid is electrospun at a voltage of 17KV, the distance between the elec...

Embodiment 3

[0043] A kind of preparation method of styrene-maleic anhydride copolymer / silicon dioxide composite fiber membrane material, concrete steps are as follows:

[0044] 1) Add 1.0g of silane coupling agent monomer YDH-151 and 100ml of toluene into a three-necked flask, dissolve 4.9g of maleic anhydride in 20ml of toluene, slowly add it dropwise to the three-necked flask, and simultaneously add 9.8g of styrene and 0.03 The mixture of g AIBN was reacted at 75° C. for 1 hour at a constant temperature after the dropwise addition, and then heated to 85° C. for 3 hours at a constant temperature. After the reaction was completed, f-PSMA was obtained by suction filtration.

[0045] 2) Disperse 0.2g of nano-silica in 8.4ml of DMF, sonicate at 30°C for 1.5h, add 4g of f-PSMA to dissolve it, and obtain an electrospinning solution with a mass concentration of 0.5g / ml.

[0046] 3) The spinning liquid is electrospun at a voltage of 15KV, the distance between the electrospinning needle and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com