Preparation and use of phenylethylene block copolymer micro-nano microsphere

A technology of styrene blocks and nano-microspheres, which is applied in coatings, textiles, papermaking, and fiber treatment, etc. It can solve the problems of difficult control of microsphere size, time-consuming and labor-intensive, difficult to enlarge, etc., and achieves simple and easy operation. The effect of reducing production costs and reducing cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Microspheres prepared after exposure to 2% star-shaped styrene-butadiene triblock polymer precipitant for 1 h

[0029] Accurately weigh 0.04 g of star-shaped styrene-butadiene triblock polymer, add toluene solvent to 2.0 g, and dissolve under stirring. Pour an appropriate amount of precipitant methanol into the jar, and seal it tightly for a while. Put the clean glass piece into the above-mentioned jar with methanol vapor atmosphere, and drop 5 drops of the polymer solution on the glass piece, and then seal the jar again. After standing still for 1 h, the glass slides were taken out and observed under a microscope.

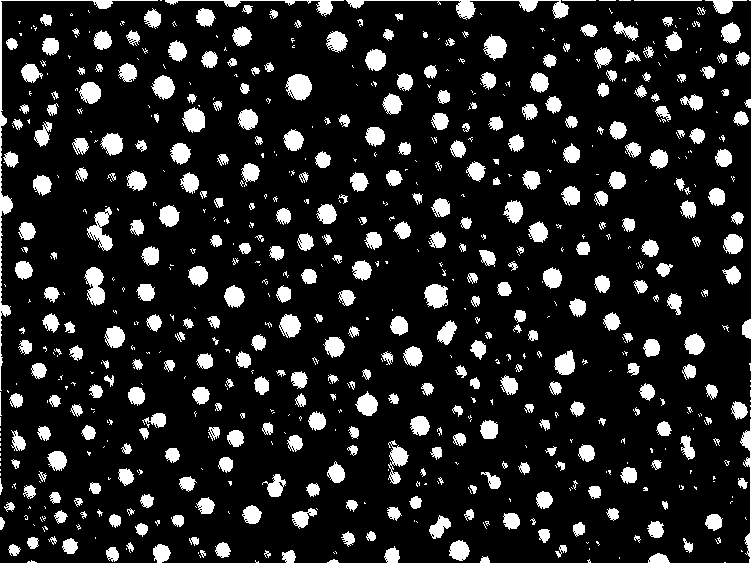

[0030] The scanning electron micrographs of the prepared star-shaped styrene-butadiene triblock copolymer microspheres are shown in figure 1 , the particle size distribution diagram of the prepared star-shaped styrene-butadiene triblock copolymer microspheres is shown in Figure 5 .

Embodiment 2

[0031] Example 2: Microspheres prepared after the concentration of 1% linear styrene-butadiene diblock polymer precipitation agent exposed for 50min

[0032] Accurately weigh 0.03 g of linear styrene-butadiene diblock polymer, add toluene solvent to 3.0 g, and dissolve under stirring. Pour an appropriate amount of precipitant methanol into the jar, and seal it tightly for a while. Put the clean glass piece into the above-mentioned jar with methanol vapor atmosphere, spread 0.1 ml of the polymer solution evenly on the glass piece, and seal the jar again. After standing still for 50min, take out the glass piece and observe it under a microscope.

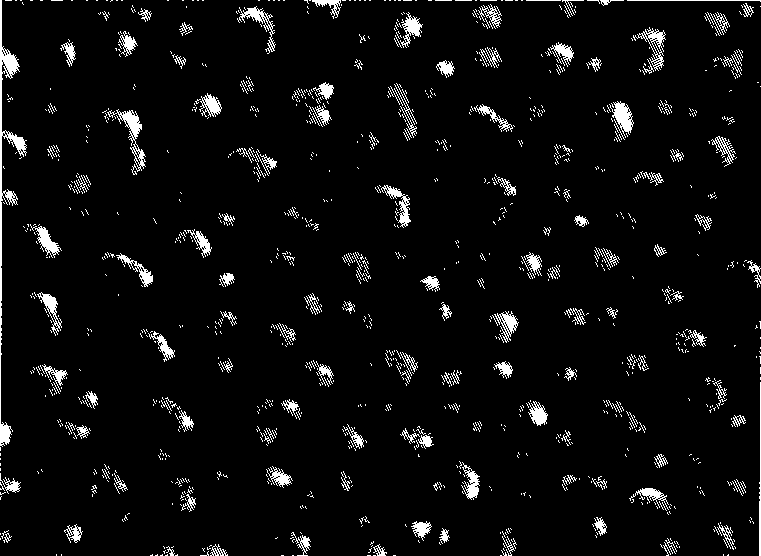

[0033] The scanning electron micrographs of the prepared linear styrene-butadiene diblock copolymer microspheres are shown in figure 2 .

Embodiment 3

[0034] Example 3: Microspheres prepared after the concentration of 1% linear styrene-butadiene triblock polymer precipitant exposed for 30min

[0035]Accurately weigh 0.03 g of linear styrene-butadiene triblock polymer, add solvent cyclohexane to 3.0 g, and dissolve under stirring. Pour an appropriate amount of precipitant acetone into the jar, and seal it tightly for a while. Put the clean glass piece into the above-mentioned jar with acetone vapor atmosphere, spread 0.1 ml of the polymer solution evenly on the glass piece, and seal the jar again. After standing still for 30min, take out the glass slide and observe under the microscope.

[0036] The scanning electron micrographs of the prepared linear styrene-butadiene triblock copolymer microspheres are shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com