Material and preparation method for ph-controlled transition from superamphiphobic to superhydrophobic/superlipophilic

A super-hydrophobic and super-amphiphobic technology, applied in separation methods, chemical instruments and methods, immiscible liquid separation, etc., can solve problems affecting oil-water separation performance, achieve excellent oil-water separation performance, strong practicability, and preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with accompanying drawing.

[0069] 1. Synthesis of materials with pH-controlled transition from superamphiphobic to superhydrophobic / superlipophilic

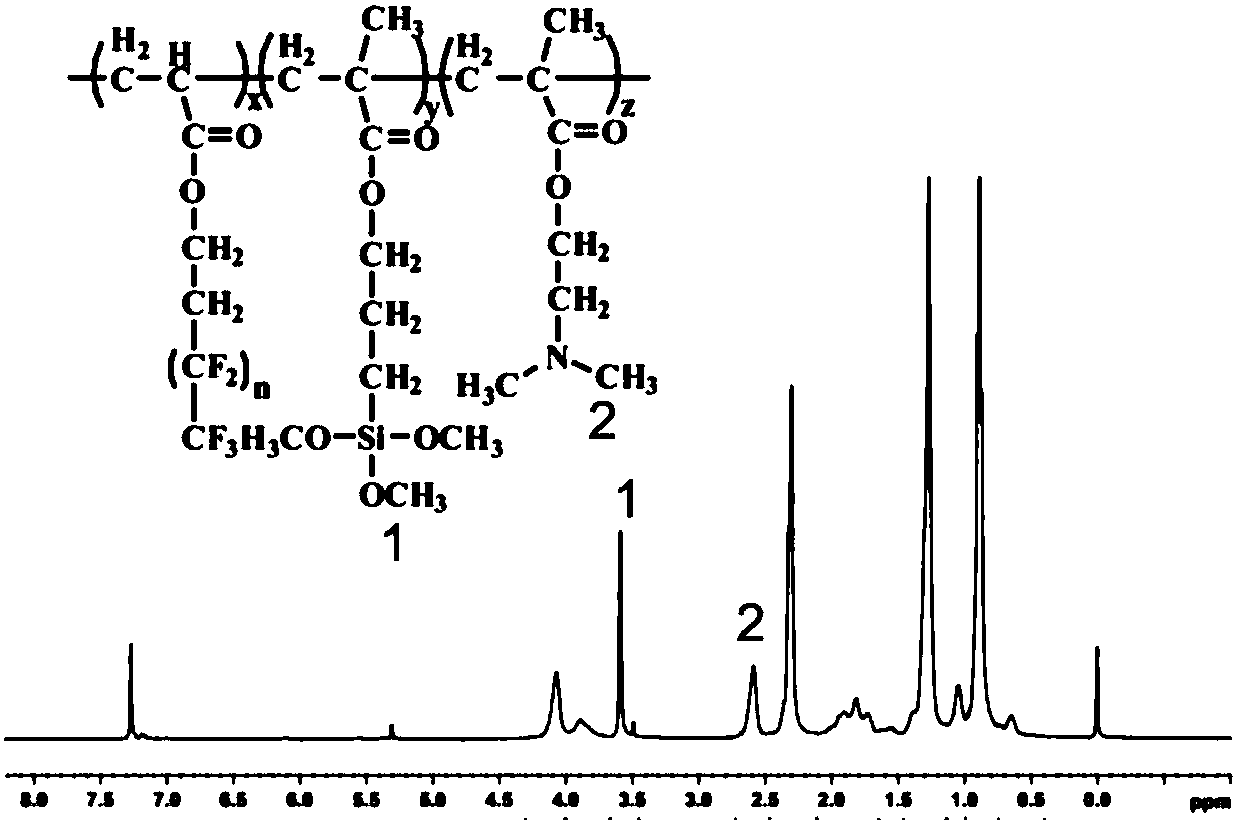

[0070] 1. Synthesis of Fluorinated Copolymers

[0071] Weigh a certain amount of reactant perfluoroalkyl ethyl acrylate, 3-(methacryloyloxy)propyltrimethoxysilane and dimethylaminoethyl methacrylate according to the molar ratio: 8:1:16 , into a 100mL three-necked flask, methyl isobutyl ketone was added as a reaction solvent, and then an appropriate amount (wt=0.5% of the total mass of the substance) of the initiator azobisisobutyronitrile (AIBN) was added, and then nitrogen gas was introduced for 30 minutes, The air was removed, then the temperature was raised to 65°C, and the reaction was carried out for 18 hours. After the reaction is completed, the above solution is precipitated with a large amount of n-hexane, and the obtained precipitate is a flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com