Patents

Literature

64results about How to "Improve oil-water separation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

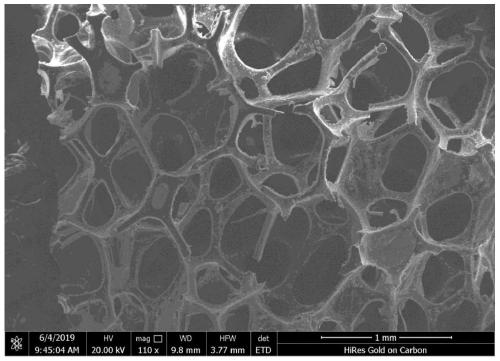

Preparation method of oil-water separation material

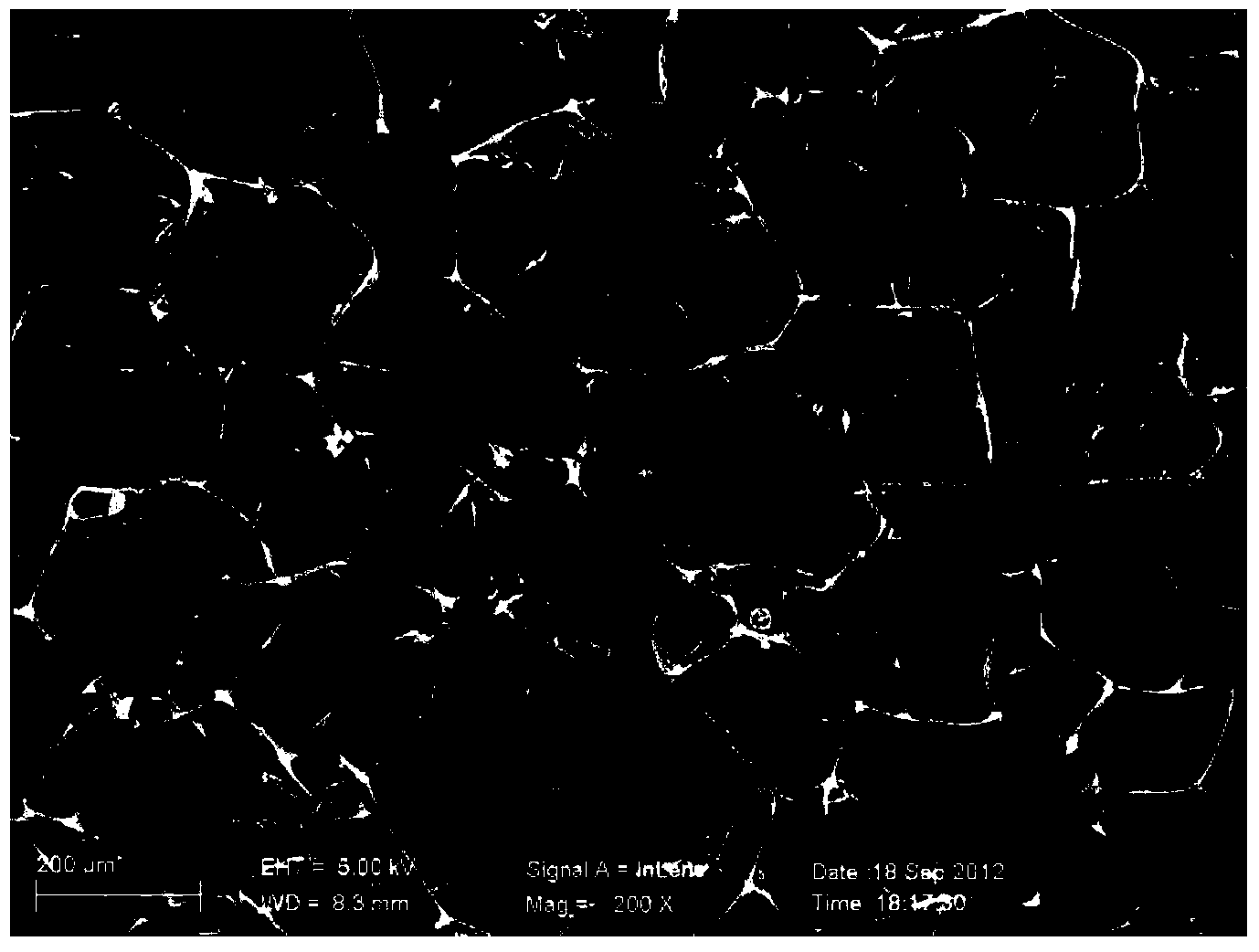

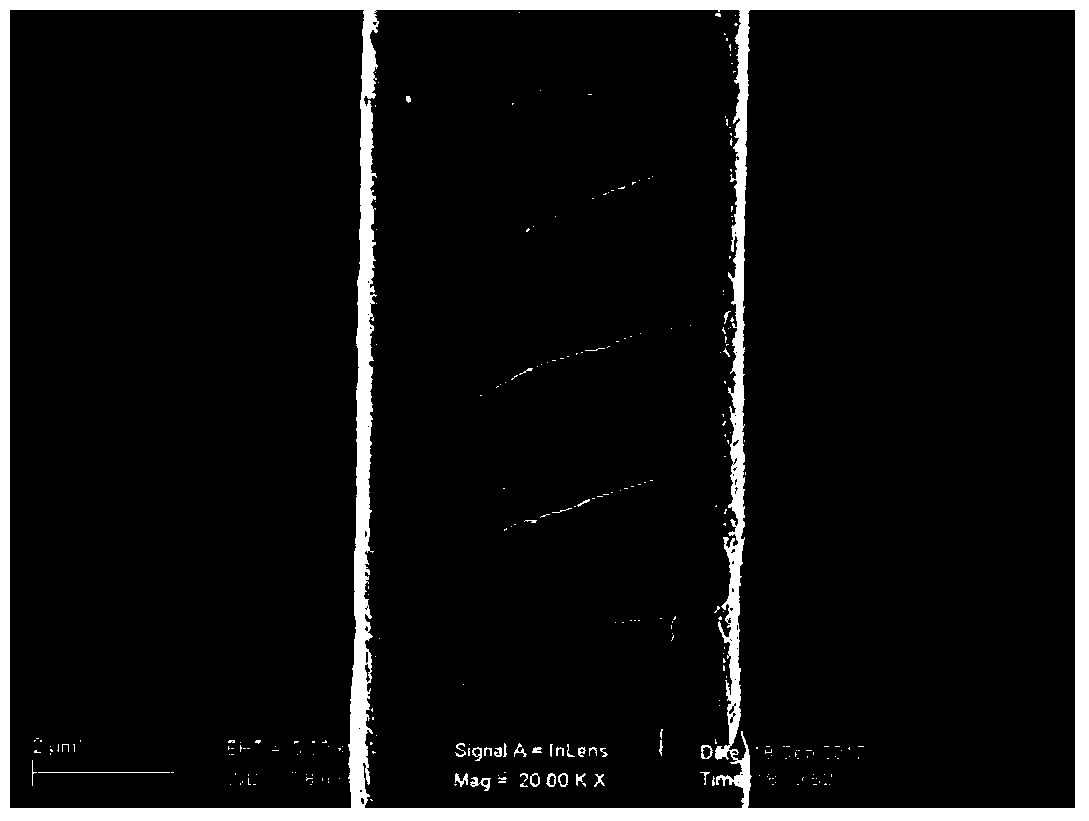

ActiveCN103626171AImprove oil-water separation effectEasy to separateGrapheneLiquid separationSeparation technologyMechanical stability

The invention provides a preparation method of an oil-water separation material, which comprises the following steps: soaking a sponge material in a graphene oxide solution, taking out the obtained sponge material and centrifuging the sponge material, so that a graphene oxide coated sponge material is obtained; and carrying out a reduction reaction on the graphene oxide coated sponge material under the action of a reducing agent so as to obtain the oil-water separation material. The oil-water separation material prepared by using the method provided by the invention is a reduced graphene oxide coated sponge material, is coated with a graphene layer uniformly and tightly and has good rebound resilience and mechanical stability, and the reduced graphene oxide layer provides good hydrophobicity and lipophilicity, therefore, the preparation method disclosed by the invention can be applied to oil-water separation technologies.

Owner:UNIV OF SCI & TECH OF CHINA

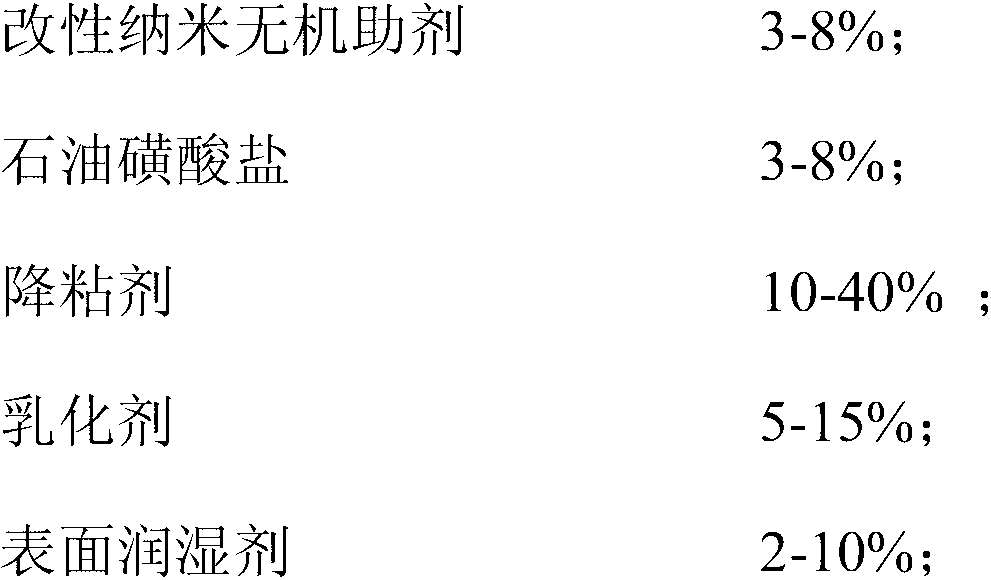

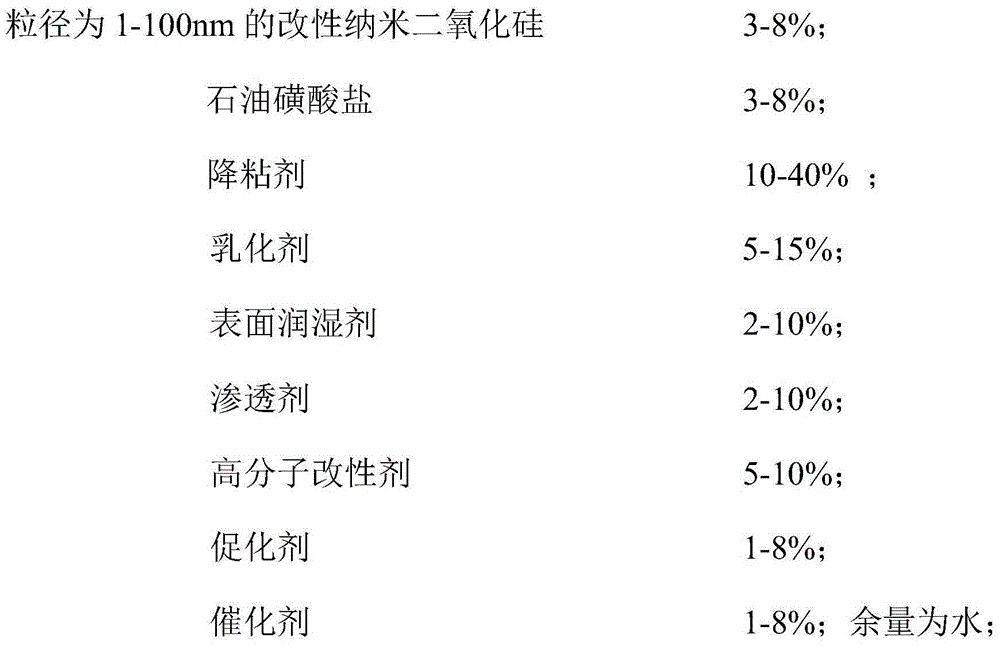

Nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery and preparation method thereof

ActiveCN103320110AGood viscosity reductionReduce dosageDrilling compositionSalt resistanceTemperature resistance

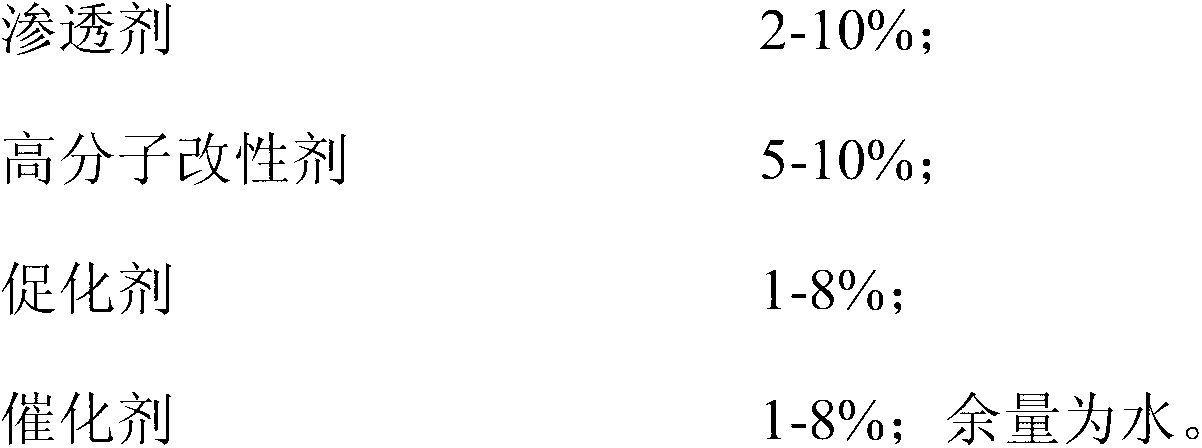

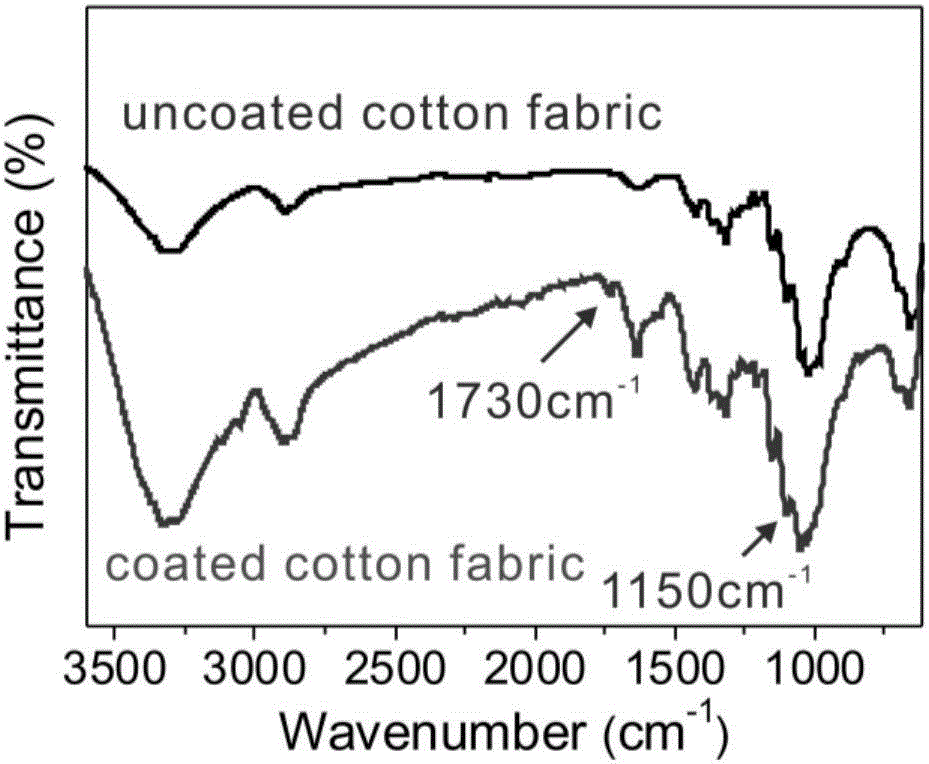

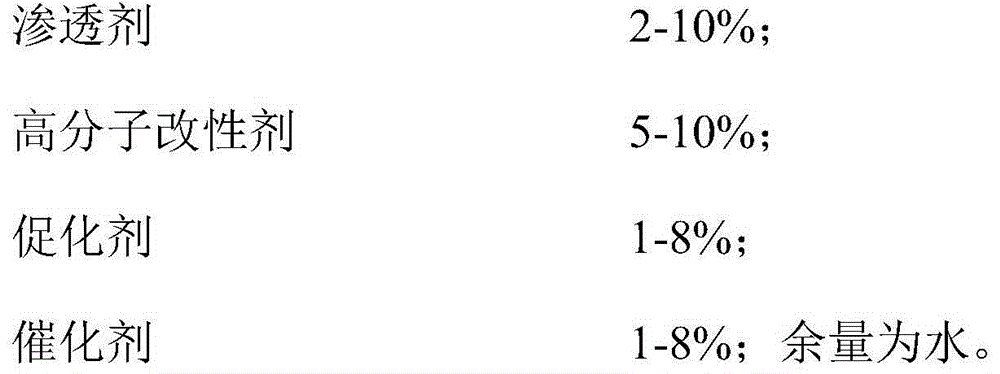

The invention discloses a nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery. The nano composite high-temperature-resistant extraction aid is prepared from 3-8 weight percent of modified nano-silica, 3-8 weight percent of petroleum sulfonate, 10-40 weight percent of a viscosity reducer, 5-15 weight percent of an emulsifier, 2-10 weight percent of a surface wetting agent, 2-10 weight percent of a penetrating agent, 5-10 weight percent of a high polymer modifier, 1-8 weight percent of a catalyst and the balance of water. The preparation method comprises the following steps: polymerizing the petroleum sulfonate, viscosity reducer, a promoting agent and the catalyst at the temperature of 60-150 DEG C for 2-6 hours according to a ratio, adding the modified nano inorganic aid, and uniformly mixing; and finally, adding the emulsifier, surface wetting agent, penetrating agent, high polymer modifier and water according to the ratio, and mixing for 1-2 hours. The nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery has high high-temperature resistance and excellent emulsification and salt resistance, the production efficiency can be greatly improved, and the recovery rate is reduced.

Owner:GUNGHO CHARGE TIANJIN REFINED PETROLEUM TECH DEV

Material changed from super-amphiphilic to super-hydrophobic/super-oleophylic by virtue of pH control and preparation method thereof

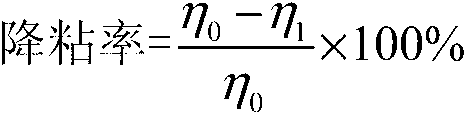

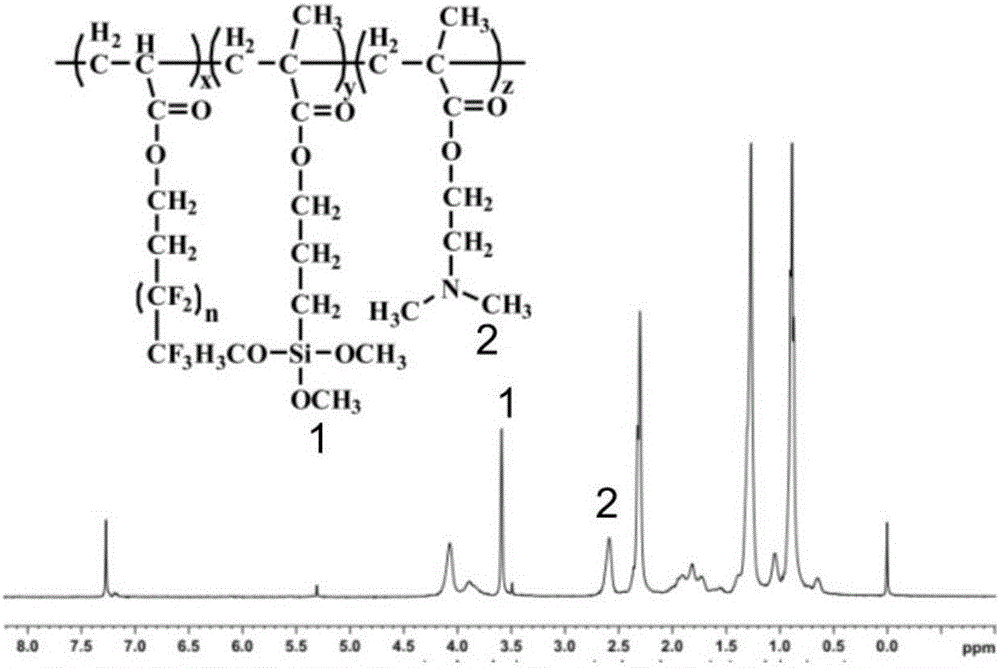

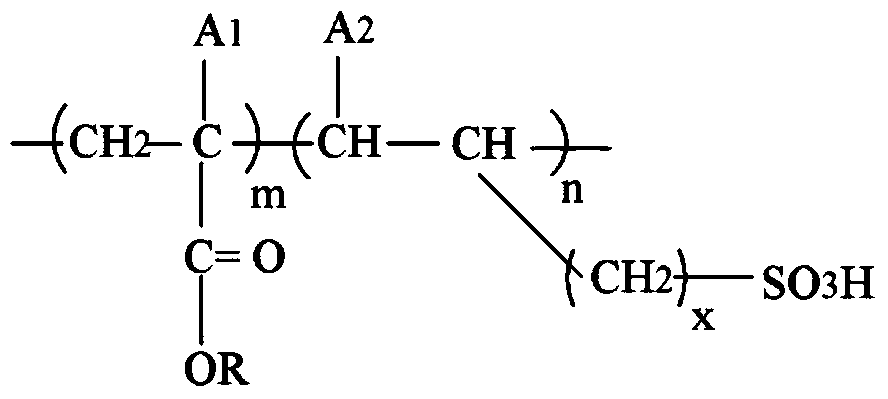

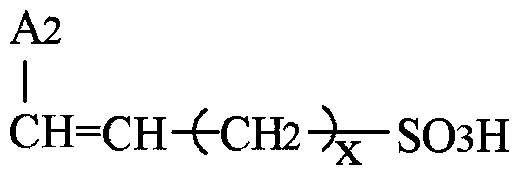

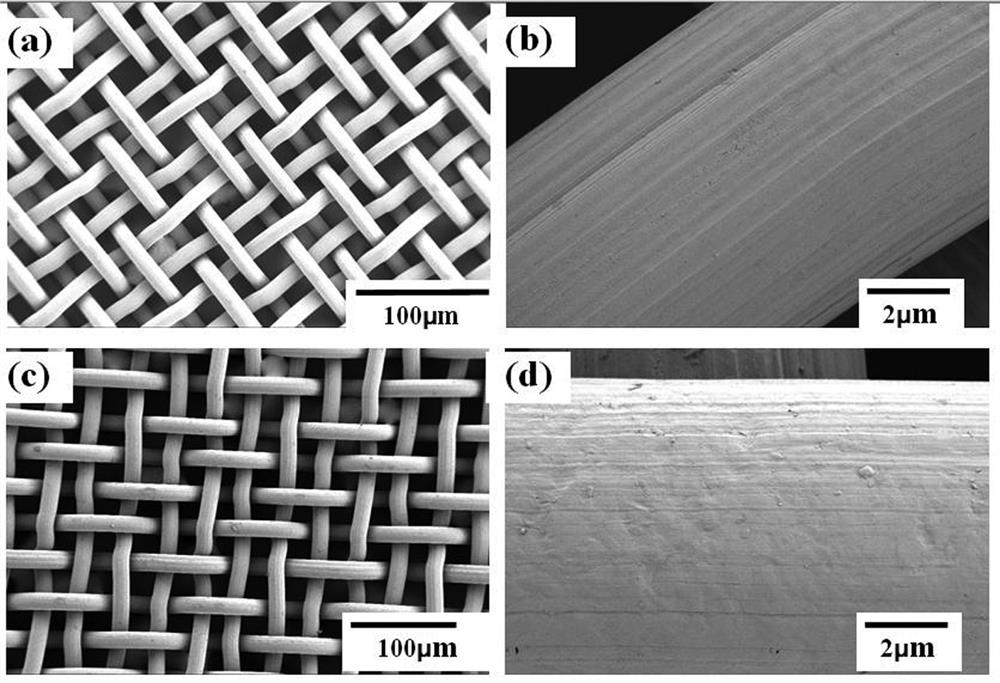

ActiveCN106632829AHas super oleophobic propertiesEasy to cleanNon-miscible liquid separationChemical structureAfter treatment

The invention discloses a material changed from super-amphiphilic to super-hydrophobic / super-oleophylic by virtue of pH control and a preparation method thereof. The preparation method comprises the following steps: adding perfluorooctyl iodide modified silicon dioxide nano-particles into a solvent, adding a copolymer after uniform dispersion, mixing the materials uniformly to form a mixed solution, immerging a base material in the mixed solution for a period of time, and performing after-treatment to obtain the material changed from super-amphiphilic to super-hydrophobic / super-oleophylic by virtue of pH control. The chemical structural formula of the copolymer is shown in the specification. By adopting the material disclosed by the invention, the material can be changed from super-amphiphilic to super-hydrophobic / super-oleophylic by virtue of pH control so as to ensure that the material has self-cleaning performance before the use of oil-water separation, and has super-hydrophobic / super-oleophylic separation performance during the use of oil-water separation.

Owner:山东动向化学有限公司

Modified nano-silica, PVDF micro-filtration membrane and application of PVDF micro-filtration membrane

ActiveCN107200848AImproved wettabilityImprove stabilityFatty/oily/floating substances removal devicesUltrafiltrationFiltration membraneIce water

The invention discloses modified nano-silica, a PVDF micro-filtration membrane and application of the PVDF micro-filtration membrane. A preparation method of the modified nano-silica comprises the following steps: at first, enabling reaction between nano-silica and an amino silane coupling agent to prepare aminated silica; adding paraffin to prepare paraffin balls of which the surfaces are covered with aminated silica; adding an acid capture agent, and dripping brominated alkyl acyl bromide or brominated alkyl acyl chloride under an ice-water bath condition to obtain a silica initiator; adding a monomer, cuprous bromide and aglucon, and enabling reaction to obtain polymer-grafted silica; and dispersing the product in an alpha-methoxy-omega-carboxyl polyethylene glycol solution, and performing stirring for reaction to obtain the modified nano-silica. Polymer chain segments, easily miscible with PVDF, on the surfaces of the modified nano-silica can fix the nano-silica particles after film forming, so that the stability of a micro-nanostructure on the surface of a film is enhanced, and the hydrophilic modified micro-filtration membrane has very good durability.

Owner:SUZHOU UNIV OF SCI & TECH

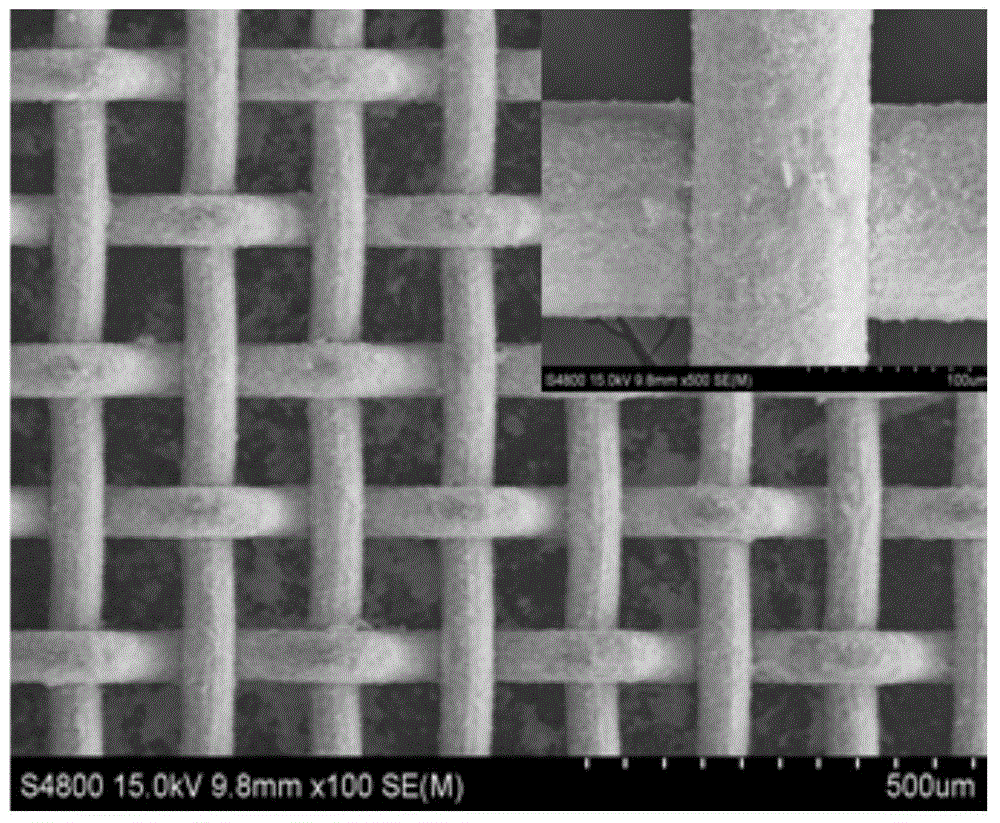

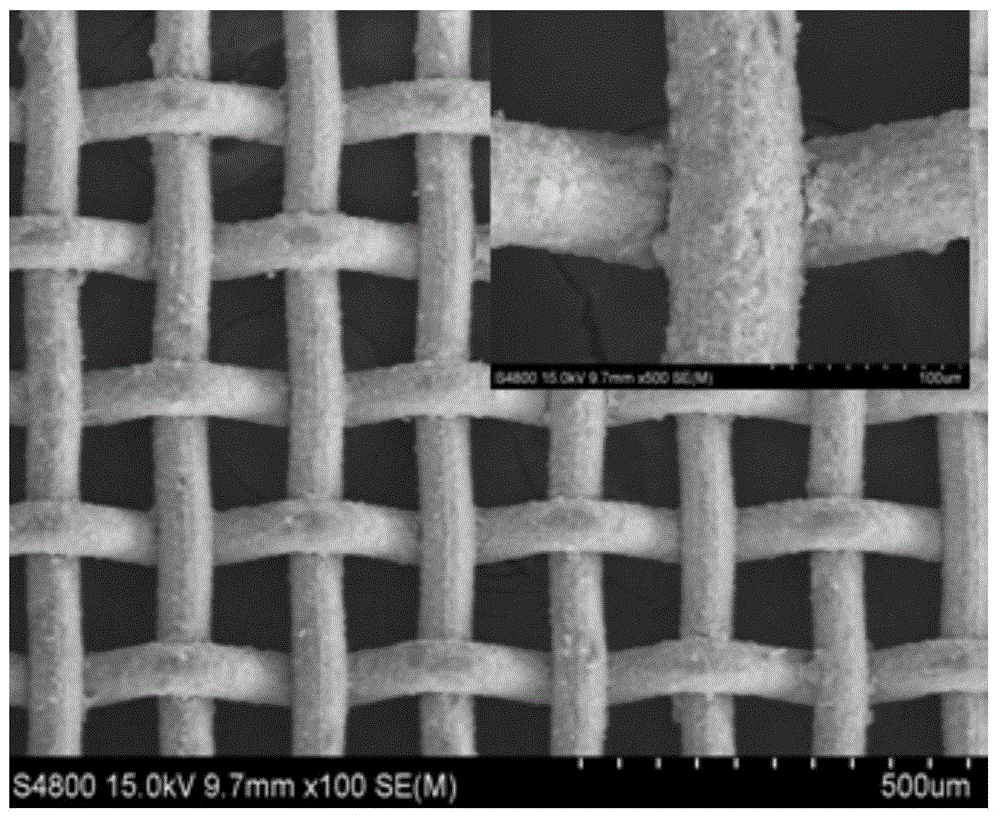

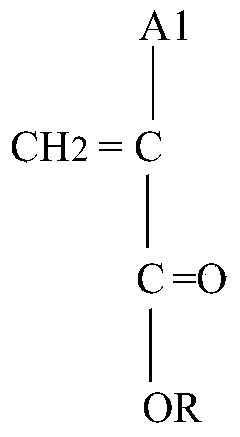

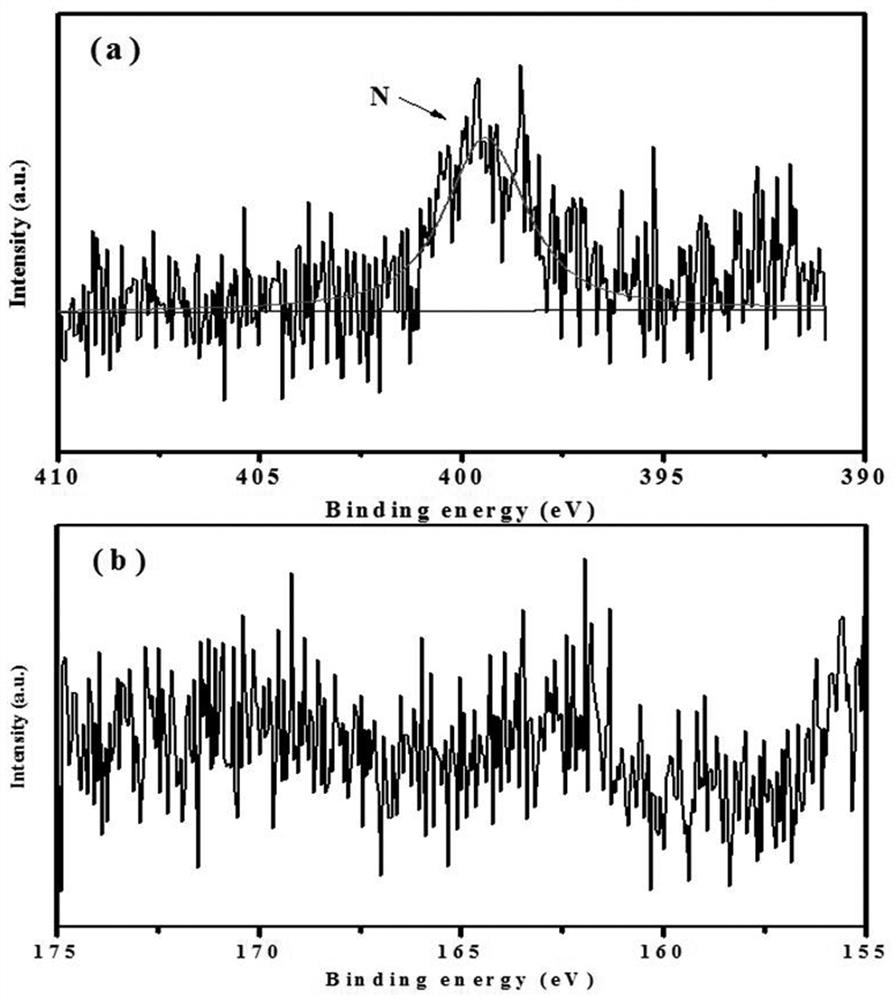

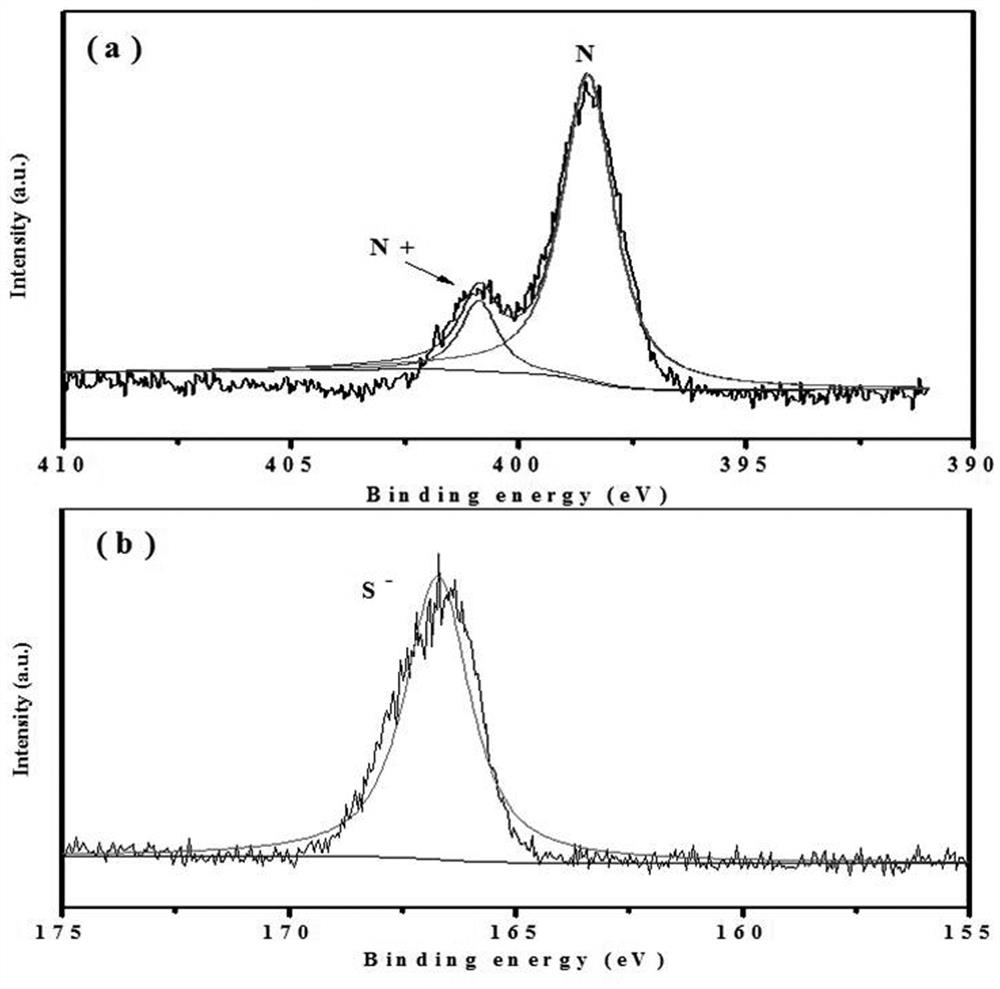

Method for coating surface of underwater oleophobic net film with nano-material

InactiveCN104888496ALow costImprove surface hydrophilicityFatty/oily/floating substances removal devicesLiquid separationWire gauzeNitrogen gas

The invention provides a method for coating the surface of an underwater oleophobic net film with a nano-material. The method comprises the following steps of carrying out chemical etching on a cleaned and dried stainless wire net film by a chemical etching agent, carrying out ultrasonic cleaning and drying, immersing the stainless wire net film in a cation precipitating agent solution so that chemical modification is realized, taking out the stainless wire net film, carrying out washing by deionized water, carrying out blow-drying by a nitrogen flow, immersing the stainless wire net film in a silicon dioxide dispersion liquid of graphene oxide so that a coating process is realized, taking out the treated stainless wire net film, carrying out washing by deionized water, repeating chemical modification-coating processes multiple times to obtain a coated stainless wire net film, carrying out drying, carrying out calcination at a temperature of 500-550 DEG C in a nitrogen protective atmosphere for 3-4h and carrying out cooling to obtain the stainless wire net film finished product. The method is carried out at a normal temperature, has simple processes and a low cost, utilizes an etching agent and a modified agent with low environment pollution and does not cause secondary pollution. The stainless wire net film has strong corrosion resistance, substantial oil-water separation effects, a long service life and good escherichia coli inhibition effects.

Owner:JIANGSU UNIV

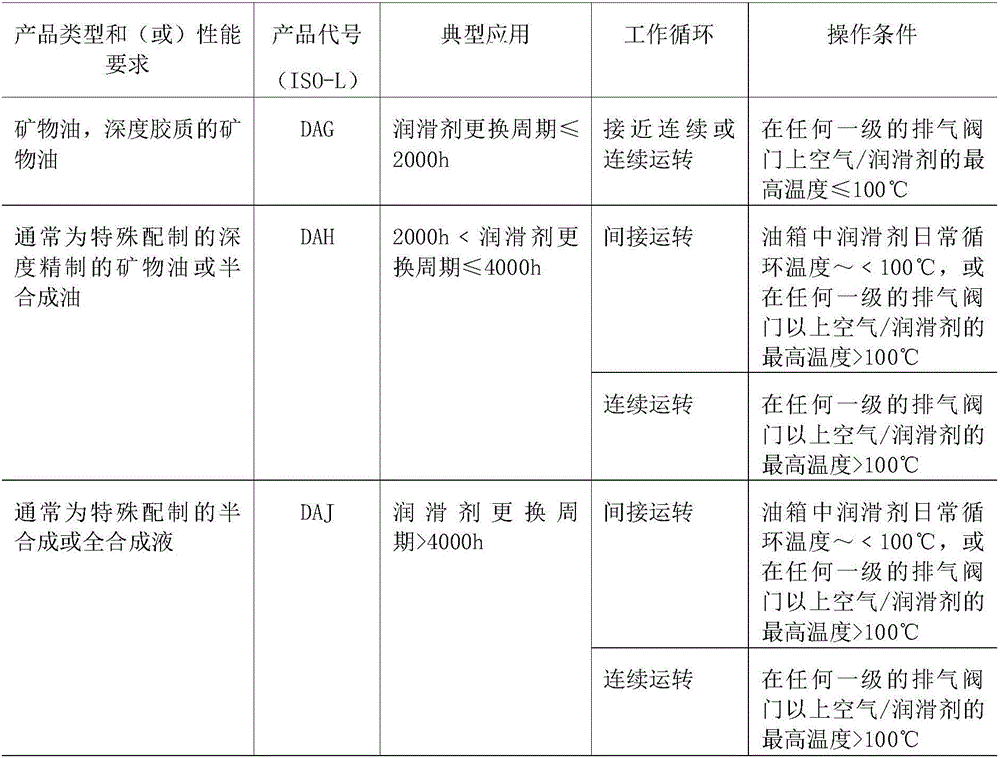

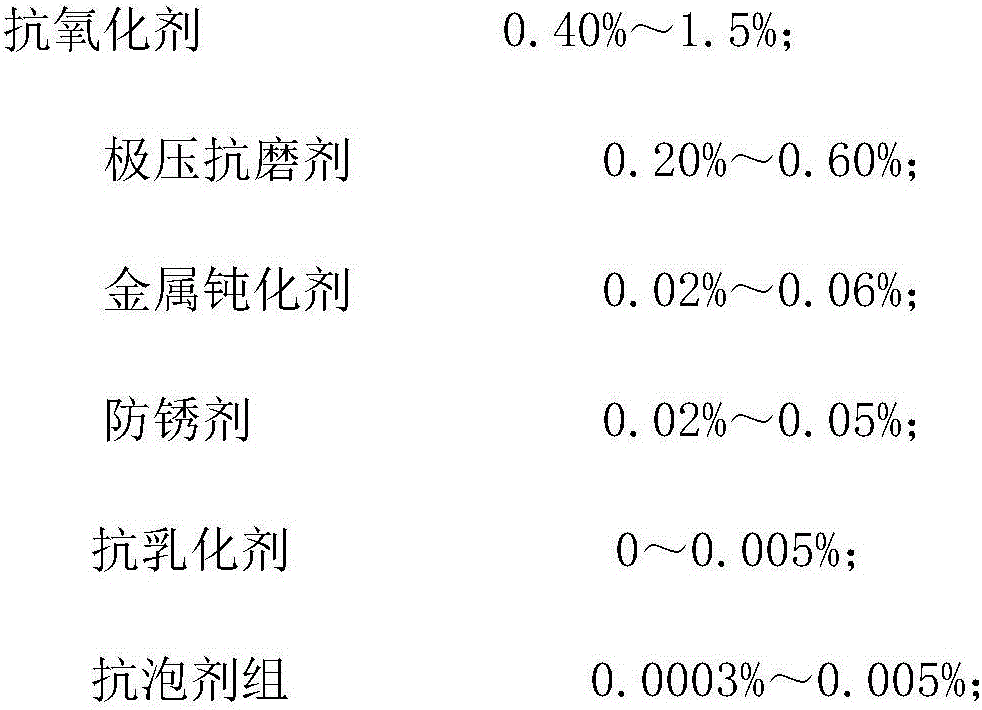

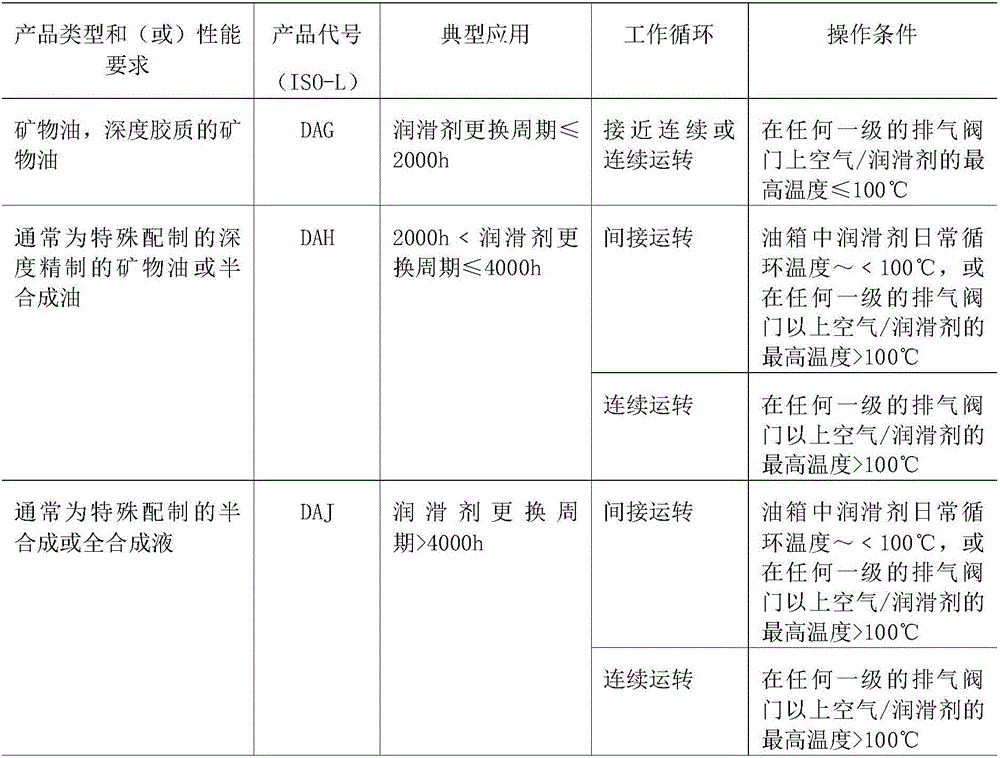

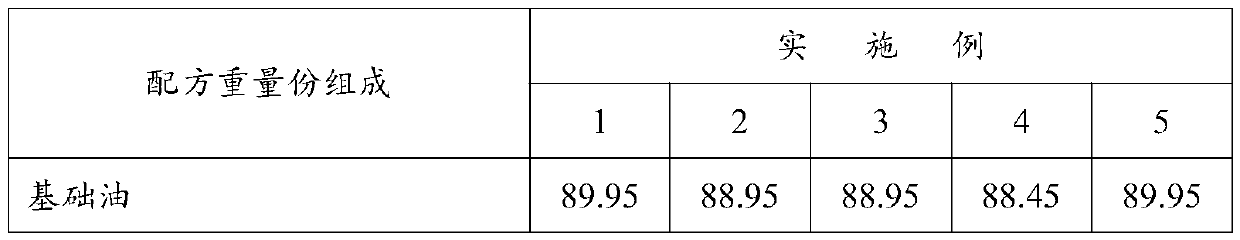

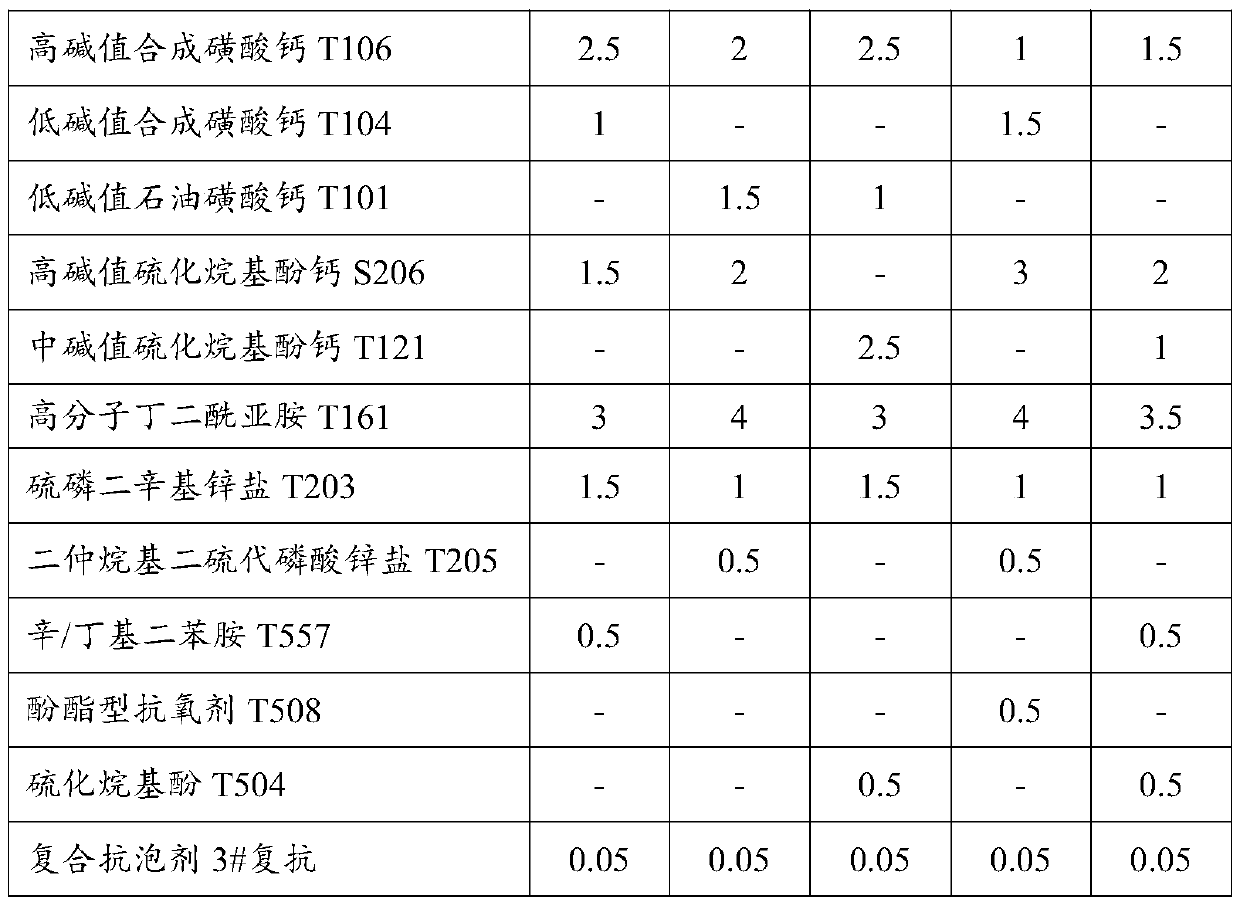

Long-life oil jet rotary air compressor oil composition

InactiveCN106433936AGood antioxidant propertiesImprove antioxidant capacityAdditivesAir compressorMotor oil

The invention discloses long-life oil jet rotary air compressor oil composition. The composition is prepared from components shown in the specification in percentage by mass.

Owner:ZHEJIANG OCEAN UNIV

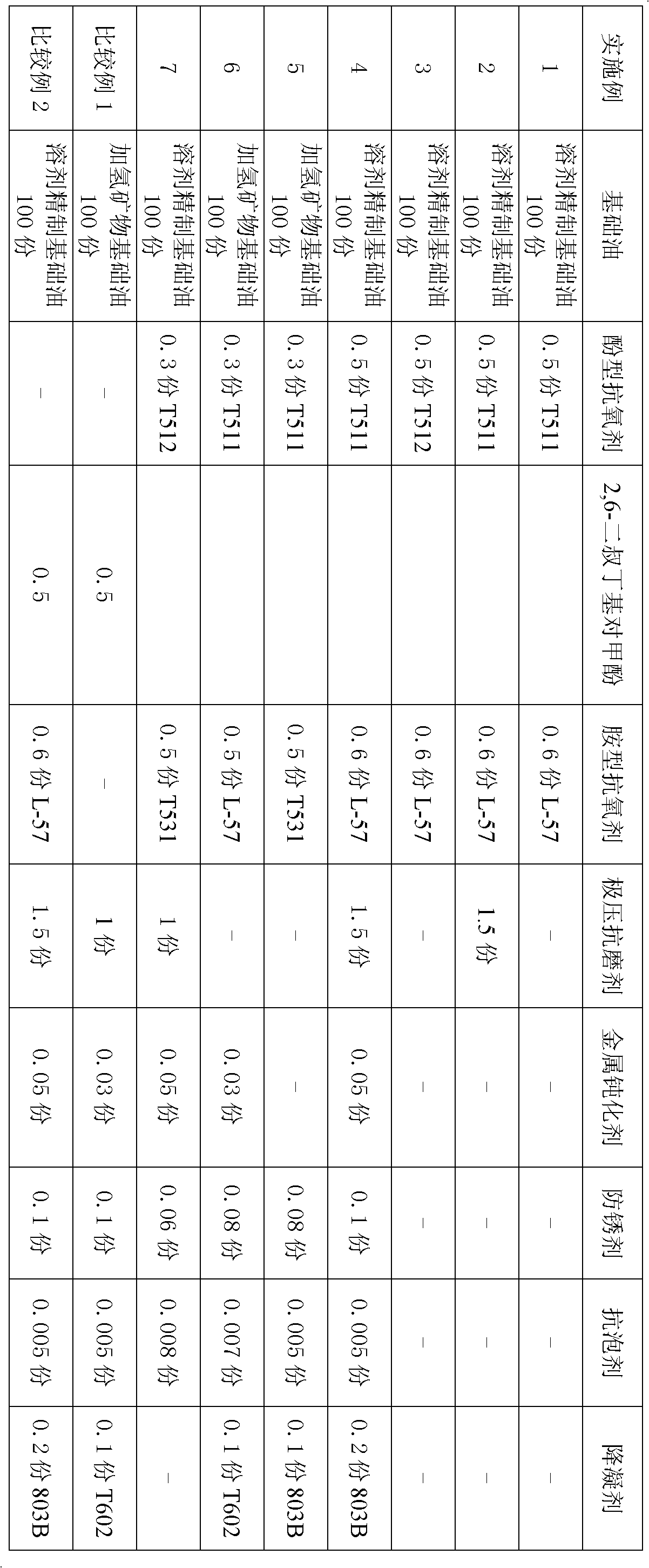

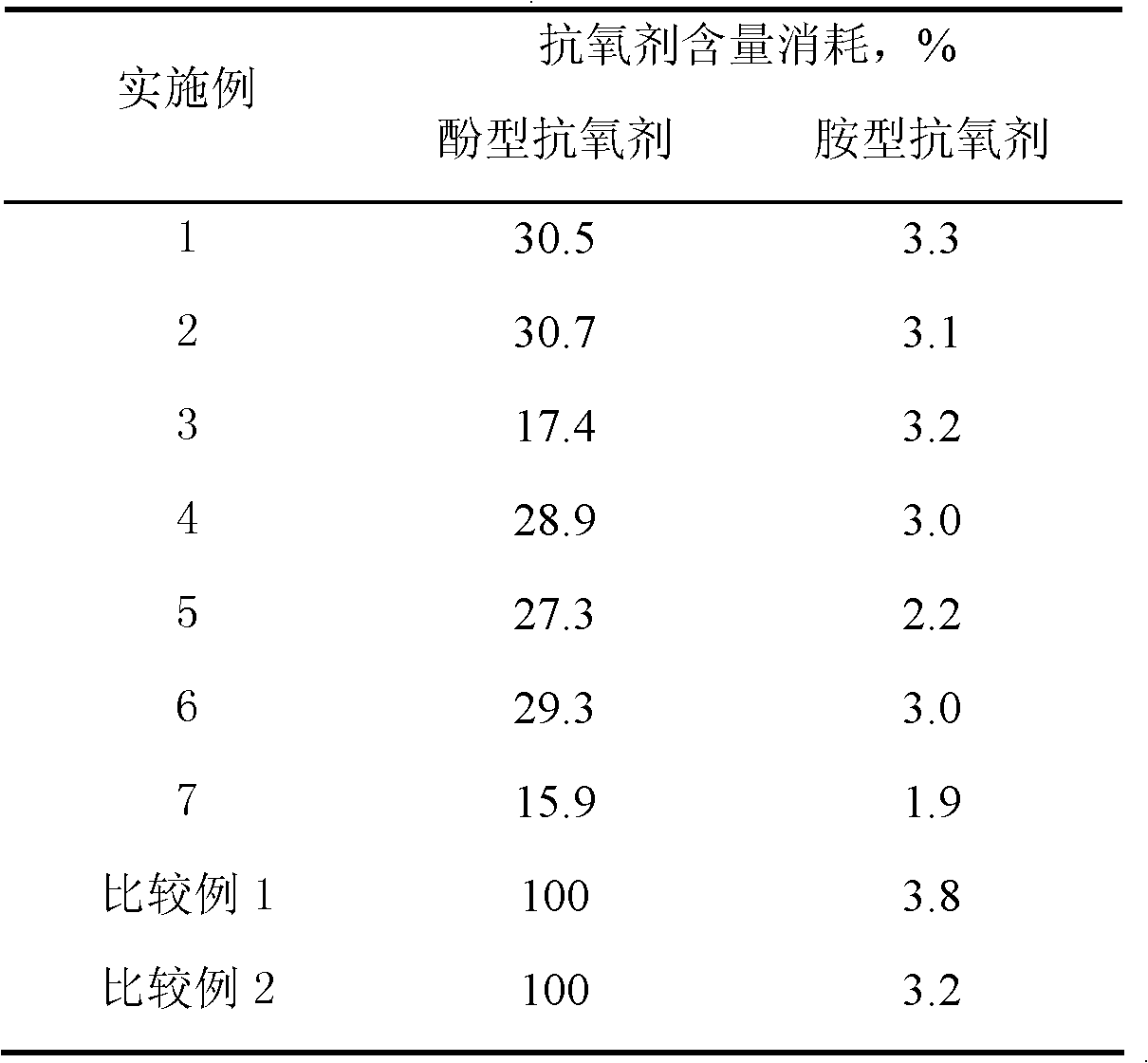

Screw-type ammonia compressor oil composite

InactiveCN103031188AImprove Oxidation StabilityGood viscosity and temperatureAdditivesPropanoic acidTert butyl phenol

The invention relates to a screw-type ammonia compressor oil composite, which mainly solves the technical problems of poor resistance to oxidation and short oil product service life of the screw-type ammonia compressor oil composite under the condition that cuprammonia is mixed with ammonia in the prior art. The screw-type ammonia compressor oil composite comprises the following ingredients in parts by weight: 100 parts of mineral base oil and 0.01-2 parts of antioxygen, wherein the antioxygen consists of phenol-type antioxygen and ammonia-type antioxygen; the phenol-type antioxygen is selected from at least one of 4,4-methylenebis (2,6- di-tert-butyl phenol), 3,5-di-tert-butyl-4-hydroxy phenyl acrylic ester or quadri[beta(3,5-di-tert-butyl-4-hydroxy phenyl) propionic acid] pentaerythritol ester; and the ammonia-type antioxygen is selected from at least one of phenyl-alpha-naphthylamine, alkylating phenyl-alpha-naphthylamine and octyl butyl diphenylamine or alkylating diphenylamine. According to the technical scheme, the problem is favorably solved, and the technical scheme can be used for the industrial production of the screw-type ammonia compressor oil composite.

Owner:CHINA PETROLEUM & CHEM CORP

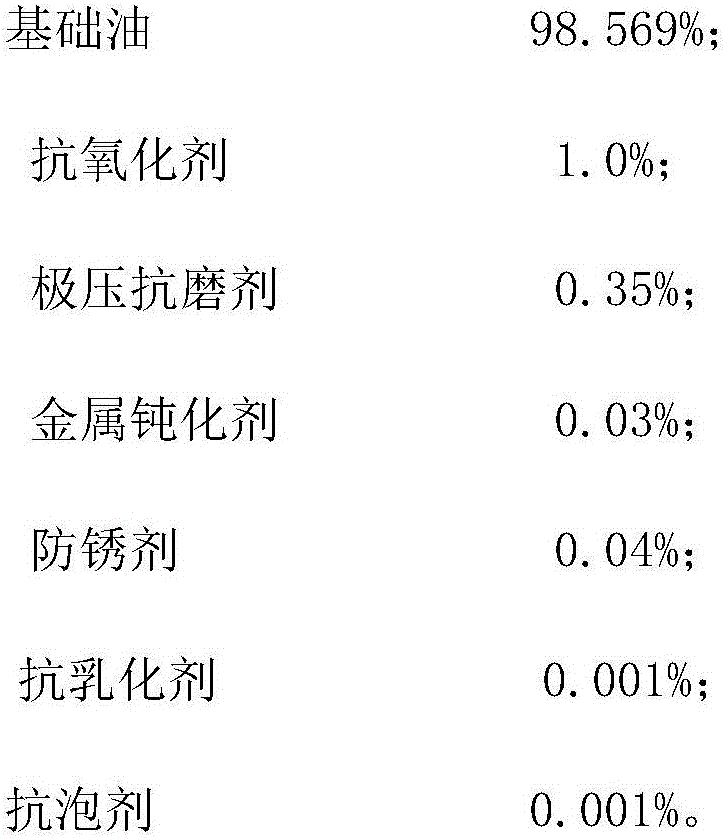

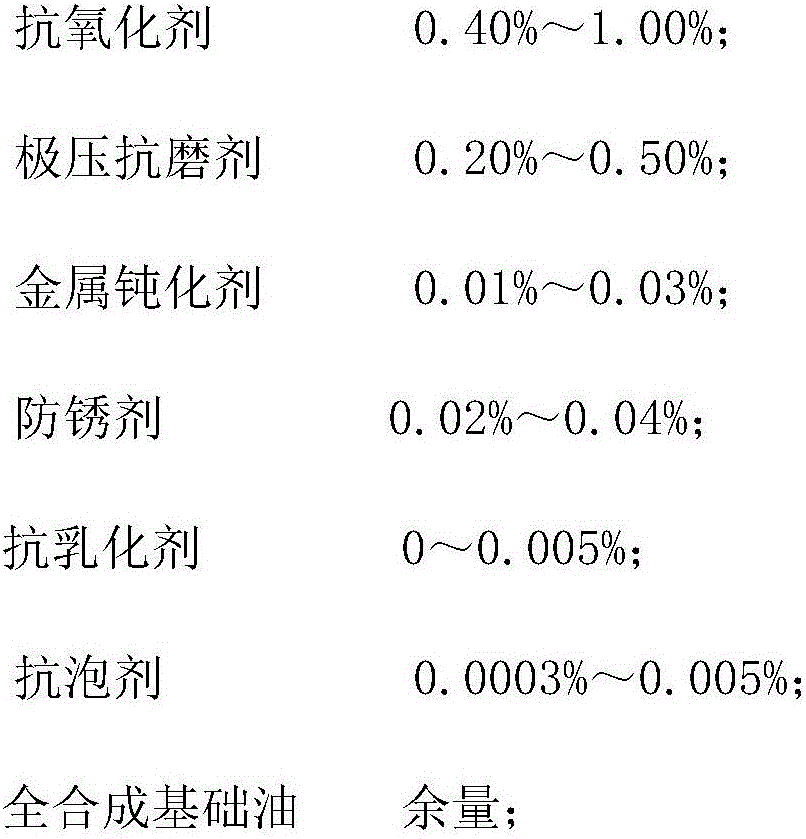

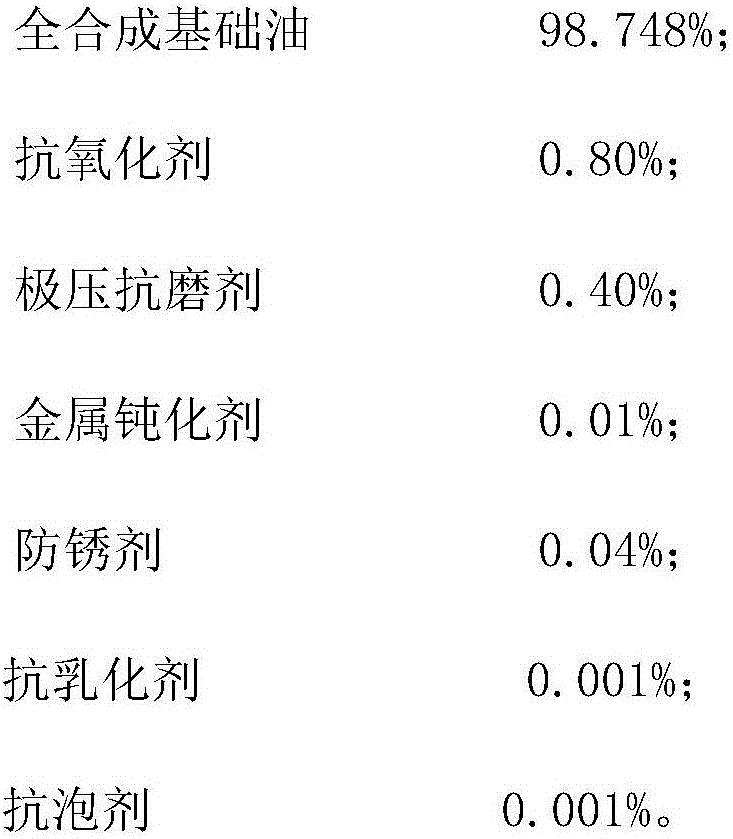

Totally-synthesized DAJ heavy-load screw air compressor oil composition

InactiveCN106433937AImprove antioxidant capacityImprove oil-water separation effectAdditivesEngineeringHeavy load

The invention discloses totally-synthesized DAJ heavy-load screw air compressor oil composition. The composition is prepared from components shown in the specification in percentage by mass.

Owner:ZHEJIANG OCEAN UNIV

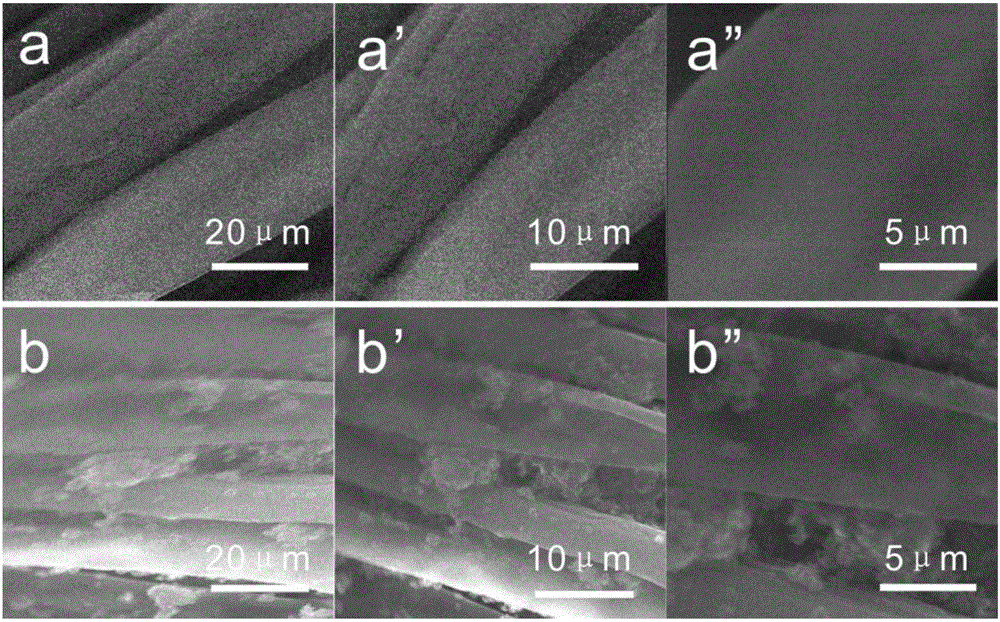

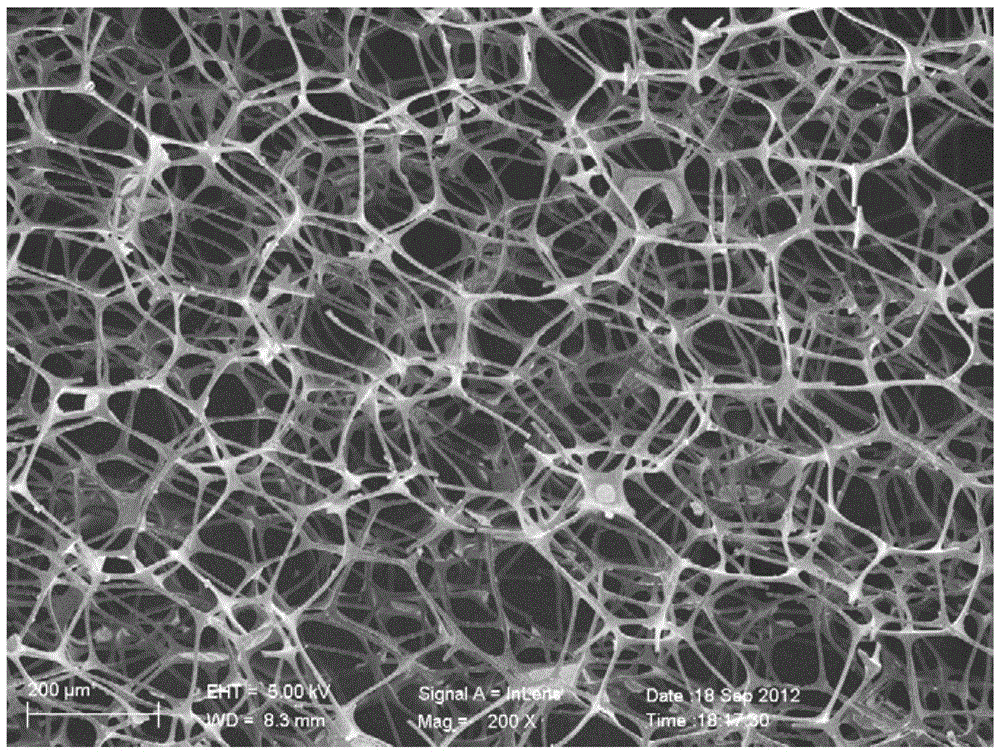

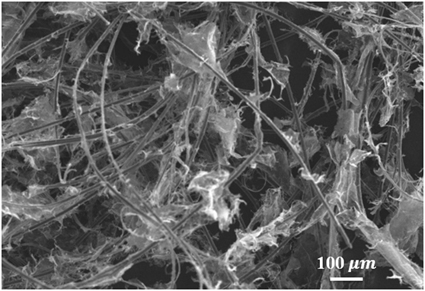

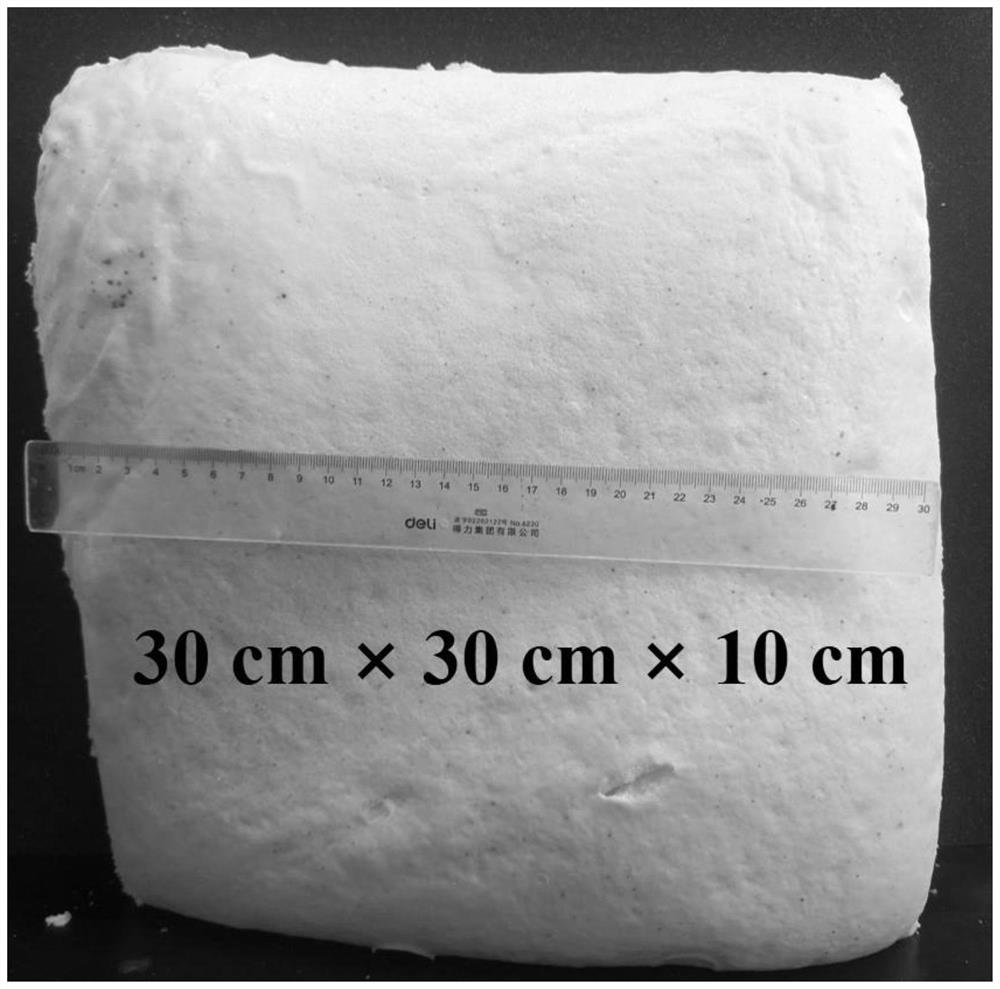

Super-oleophylic and super-hydrophobic sponge for oil-water separation, and preparation method and application of super-oleophylic and super-hydrophobic sponge

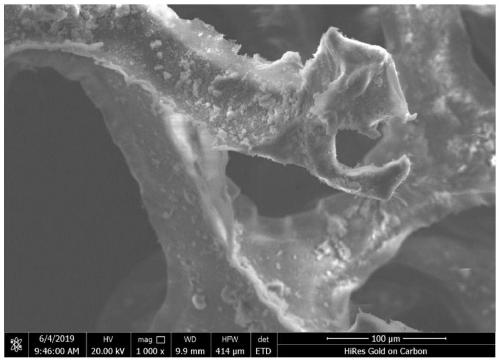

InactiveCN110387062AGood super-oleophilic and super-hydrophobic propertiesImprove hydrophobicityLiquid separationPolymer scienceOil water

The invention discloses a super-oleophylic and super-hydrophobic sponge for oil-water separation, and a preparation method and application of the super-oleophylic and super-hydrophobic sponge, and belongs to the technical field of oil-water separation materials. Nano-silica and an organic dispersion liquid of MQ silicone are painted on the surface of a sponge by adopting the dip-coating method, inthe process of drying, with the volatilization of a solvent, the MQ silicone and the nano-silica produce phase separation and deposit on the surface of the sponge, a micron-nanometer secondary composite structure is formed on the surface of the sponge, and a good structural basis is provided for the super-oleophylic and super-hydrophobic properties of the sponge. In addition, according to the MQsilicone and the nano-silica treated by a silane coupling agent which are deposited on the surface of the sponge, the surface of the sponge has a lot of silicon elements, since the silicon elements have very low surface energy and good affinity with non-polar oil, and good hydrophobic and oleophylic properties are achieved on the sponge. The sponge prepared by the preparation method has excellentoil-water separation performance, the process is simple, the raw materials are easy to obtain, the cost is low, and volume production can be achieved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

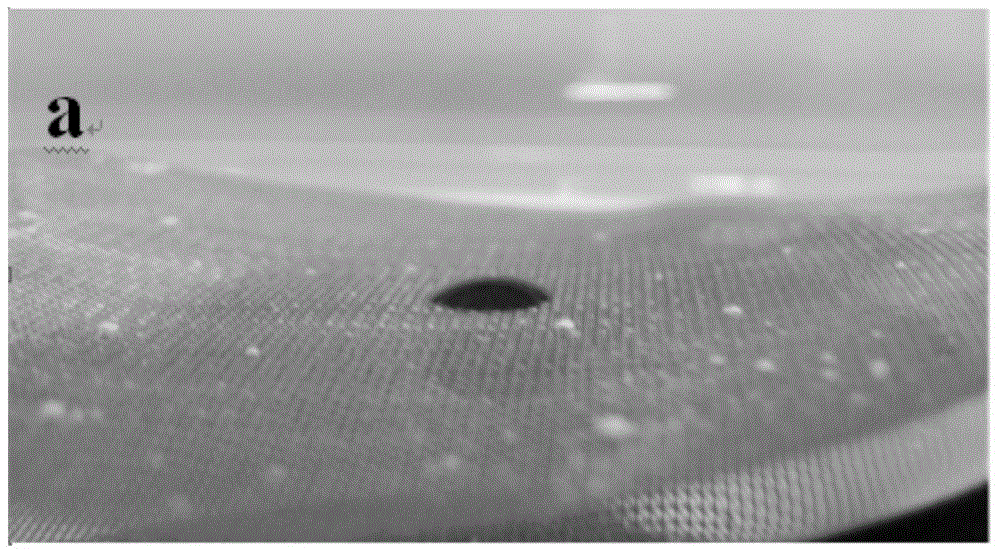

Oil-water separation net membrane with self-cleaning function and preparation method thereof

ActiveCN105498291AReduce cloggingImprove separation efficiencyNon-miscible liquid separationAlloyOil water

The invention discloses an oil-water separation net membrane with a self-cleaning function. The oil-water separation net membrane is prepared by taking a stainless steel net, an aluminum alloy net or a copper net as a base and chemically grafting (methyl) acrylic polymer containing amphoteric groups on the surfaces of the net and meshes, wherein the thickness of the net membrane is 0.50-2.50mm; the length and width of the net membrane are randomly set according to the requirements; the contact angle between the net membrane and water in air is less than 5 degrees; the contact angle between the net membrane and normal hexane under water is 160-165 degrees. A preparation method of the oil-water separation net membrane provided by the invention is simple; the stability is high; the permeability of pore space is high; the net membrane has the self-cleaning function; the oil-water separation efficiency is high; the oil-water separation net membrane can be applied to the fields of complex oil water mixture separation, oil-containing waste water treatment, and the like.

Owner:SHANDONG JIAOTONG UNIV

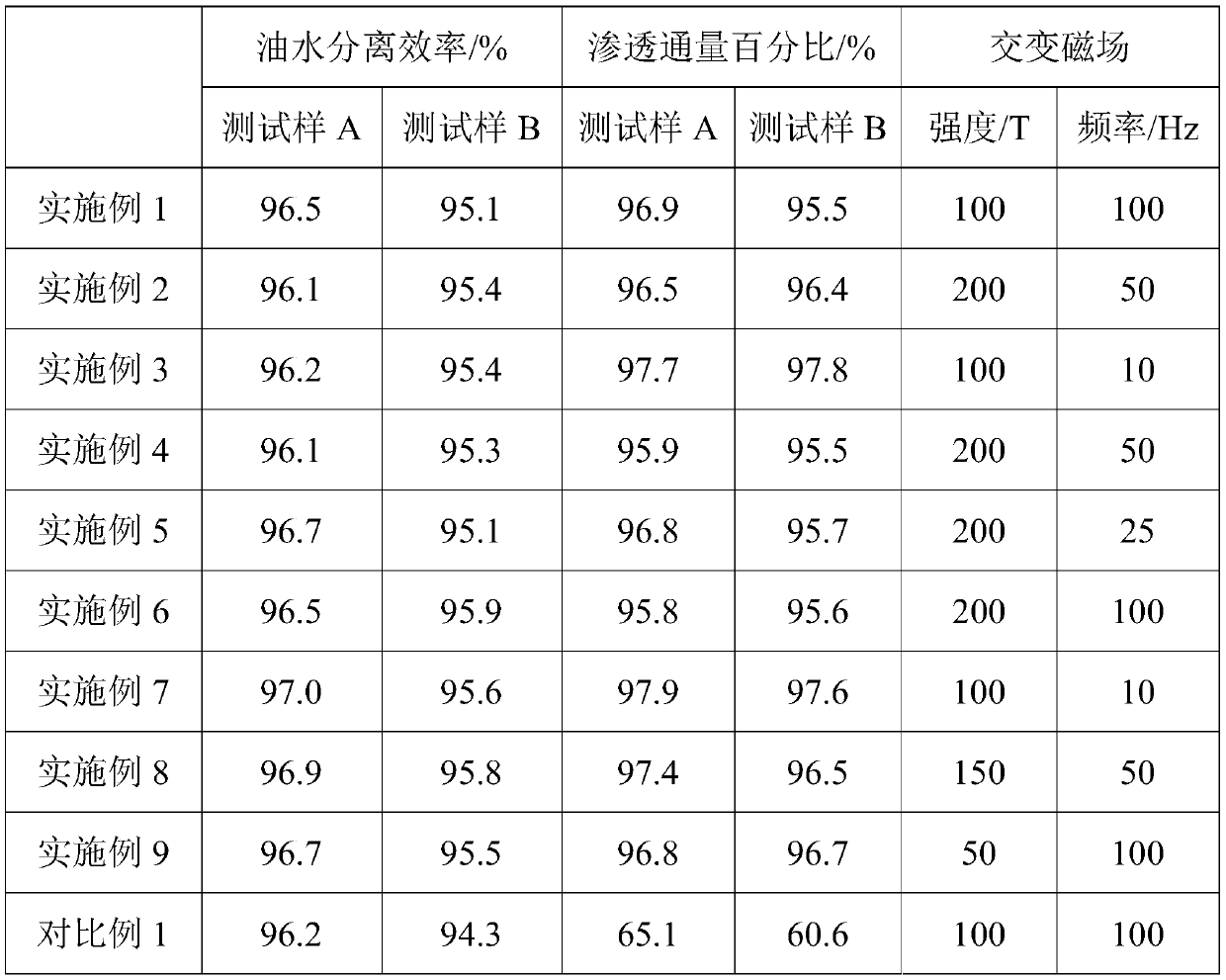

Magnetic response oil-water separation membrane, preparation method and self-cleaning method thereof

ActiveCN111330461AImprove pollutionRealize self-cleaningMembranesSemi-permeable membranesNanoparticlePhysical chemistry

The invention provides a magnetic response oil-water separation membrane, a preparation method and a self-cleaning method thereof. The magnetic response oil-water separation membrane comprises a basemembrane and magnetic composite nanoparticles chemically grafted on the surface of the base membrane. The oil-water separation membrane provided by the invention can realize self-cleaning of the membrane surface by utilizing periodic transformation of an external magnetic field; meanwhile, the oil-water separation membrane provided by the invention can well prevent oil macromolecules from being incontact with a membrane contact channel to pollute pore channels, so that the oil-water separation membrane can keep a certain membrane flux and stable separation efficiency, and has a good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

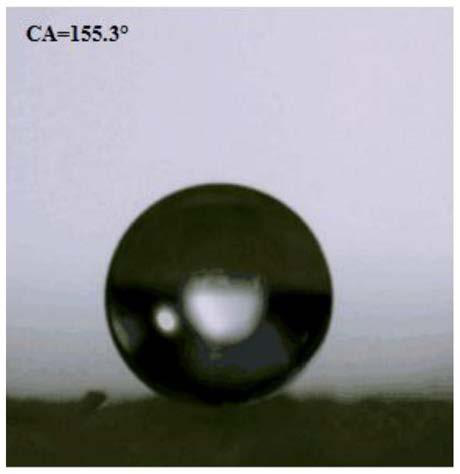

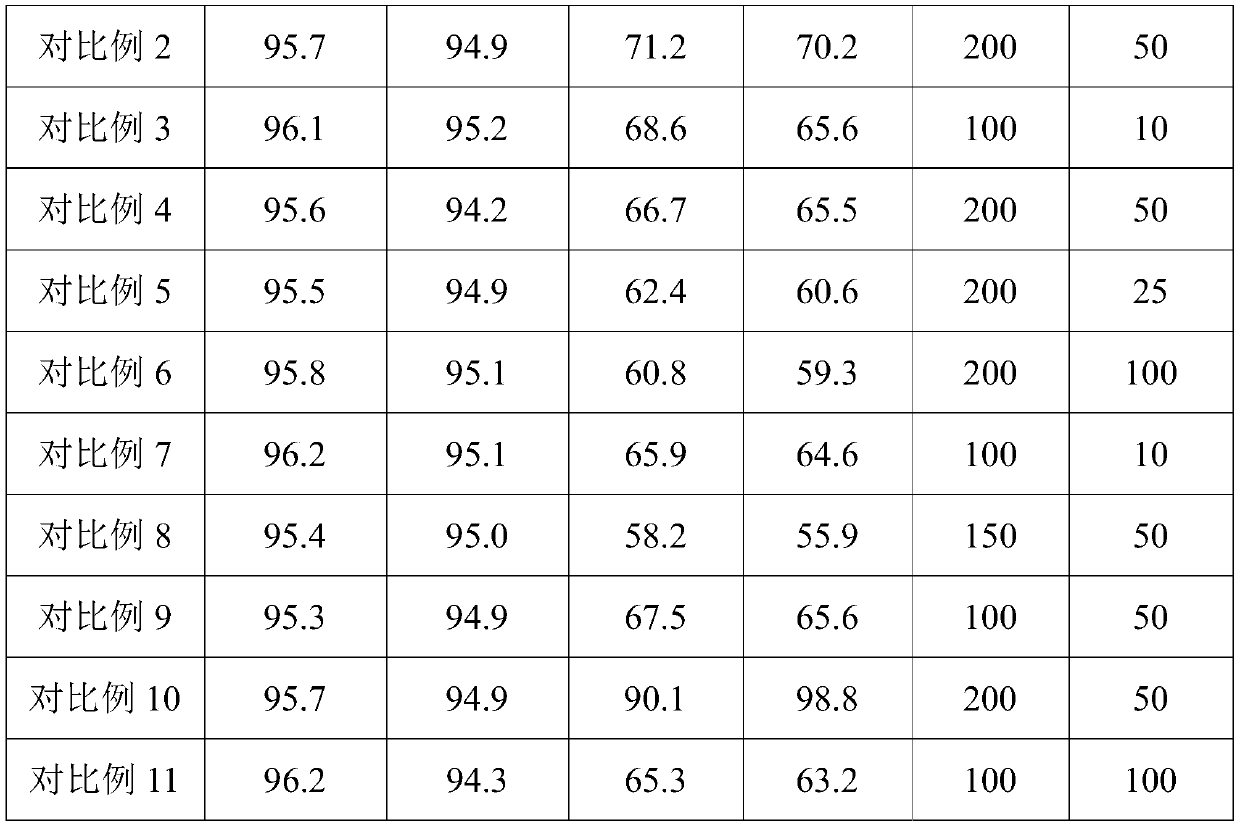

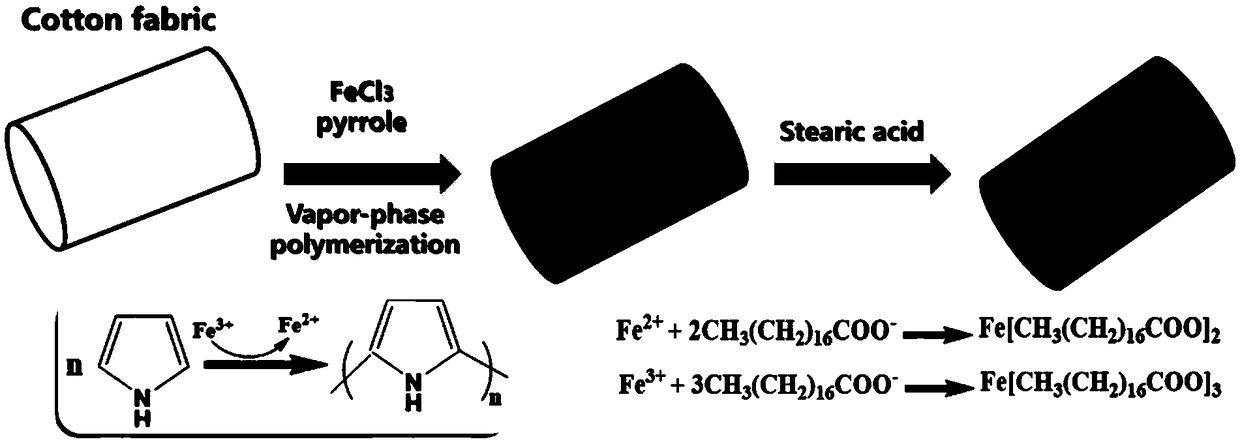

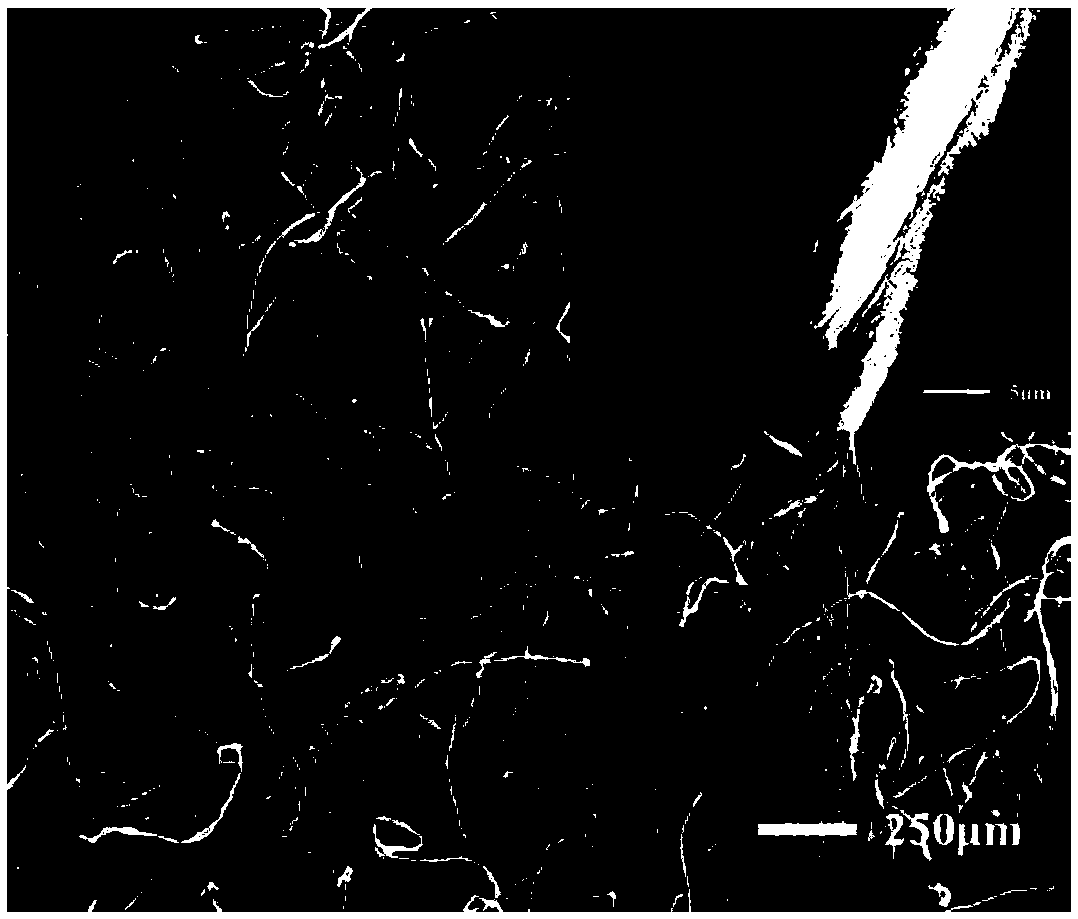

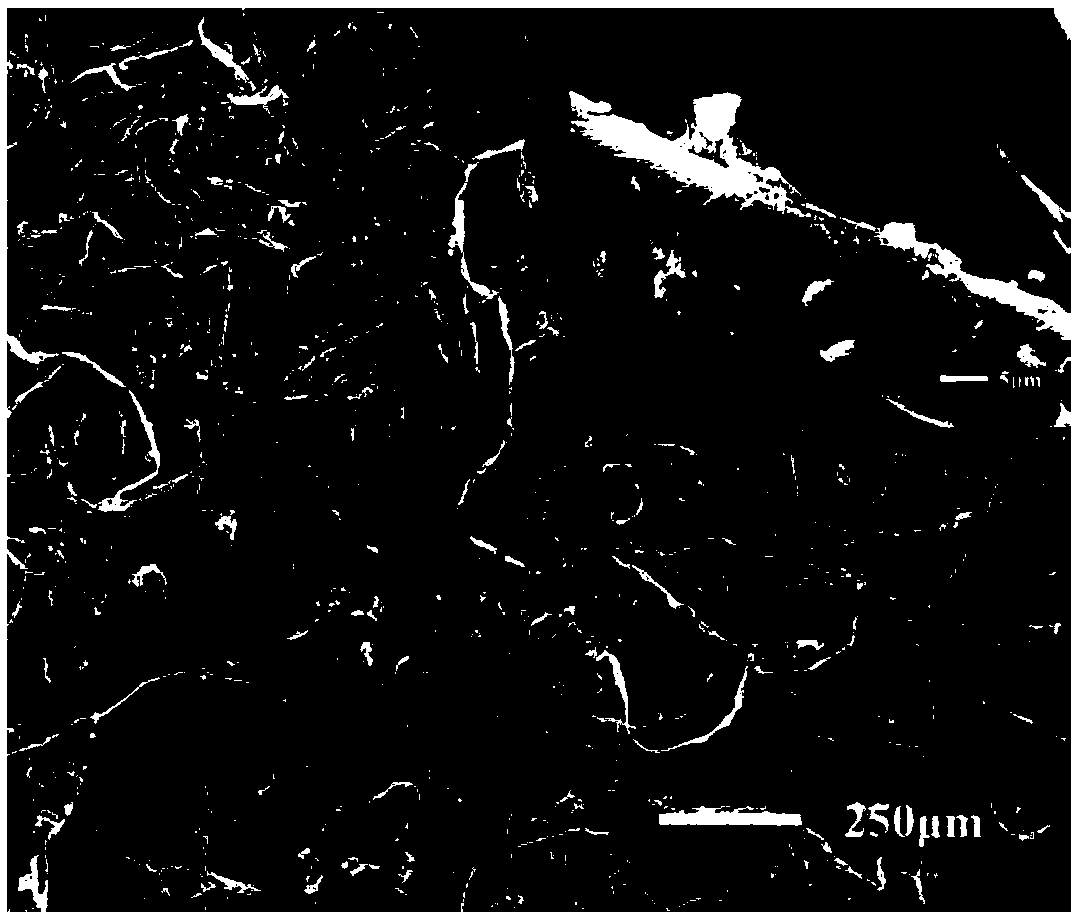

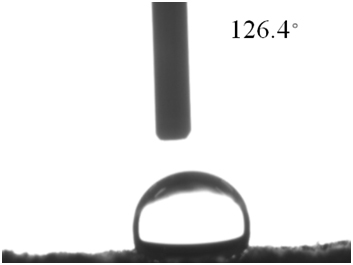

Super-hydrophobic/super-oleophilic cotton cloth as well as preparation method and application thereof

InactiveCN108660763AImprove permeabilityIncrease roughnessLiquid repellent fibresVegetal fibresRough surfacePolypyrrole

The invention discloses super-hydrophobic / super-oleophilic cotton cloth as well as a preparation method and application thereof. The super-hydrophobic / super-oleophilic cotton cloth is mainly preparedby carrying out polypyrrole coating on an infiltrated FeCl3 solution to form a rough surface of the cotton cloth and using residual FeCl3 on the cotton cloth to react with low surface energy stearic acid to generate hydrophobic ferric stearate precipitate on the surface of the cotton cloth. The water contact angle of the super-hydrophobic / super-oleophilic cotton cloth in air is greater than 150 degrees and the sliding angle is smaller than 10 degrees. In addition, oil is extremely easy to penetrate; the super-hydrophobic / super-oleophilic cotton cloth shows good super-hydrophobicity and super-oleophilic property; besides, the super-hydrophobic / super-oleophilic cotton cloth has the advantages of simple preparation process, lower material cost, greenness and environment friendliness and excellent self-cleaning ability.

Owner:SOUTHWEST UNIVERSITY

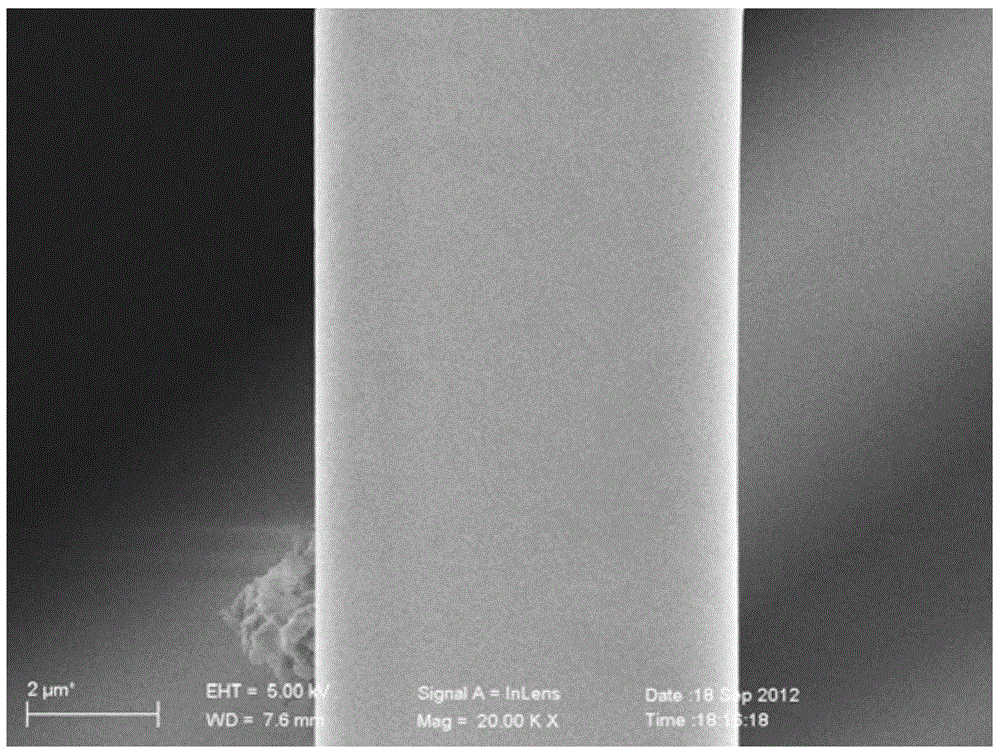

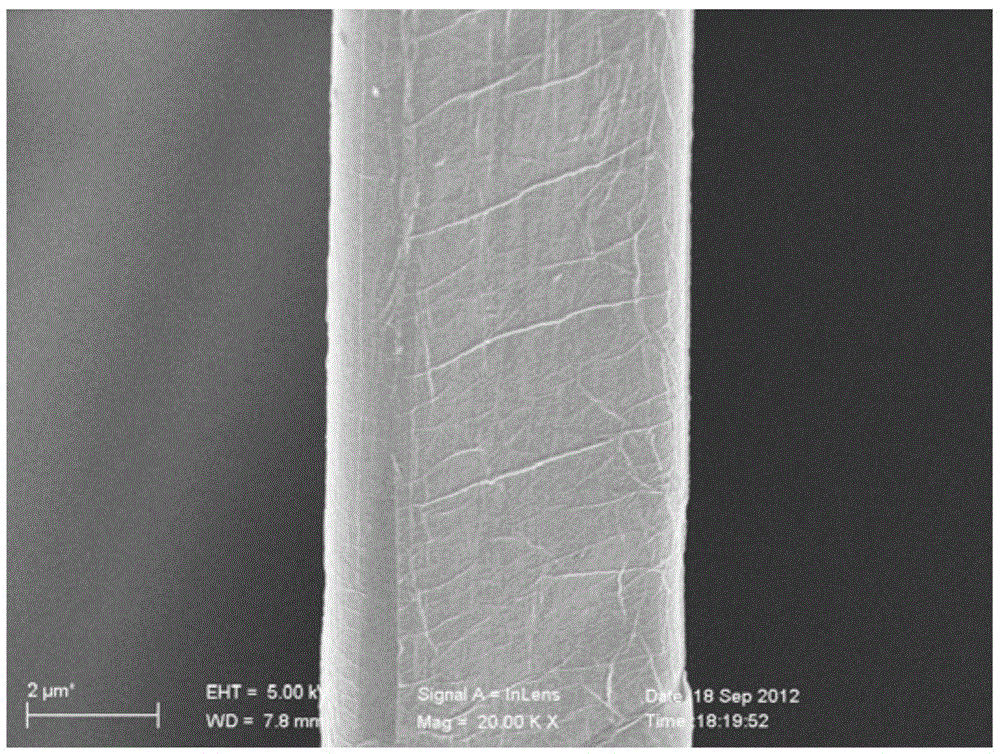

A kind of preparation method of oil-water separation material

ActiveCN103626171BImprove oil-water separation effectEasy to separateGrapheneLiquid separationCentrifugationMechanical stability

The invention provides a preparation method of an oil-water separation material, comprising the following steps: soaking a sponge material in a graphene oxide solution, taking out the obtained sponge material and centrifuging to obtain a graphene oxide-coated sponge material; The graphene-coated sponge material undergoes a reduction reaction under the action of a reducing agent to obtain an oil-water separation material. The oil-water separation material prepared by the present invention is the reduced graphene oxide coated sponge, the graphene layer is evenly coated, tightly coated, has good resilience and mechanical stability, and the reduced graphene oxide layer provides good hydrophobicity and lipophilicity , can be used in oil-water separation technology.

Owner:UNIV OF SCI & TECH OF CHINA

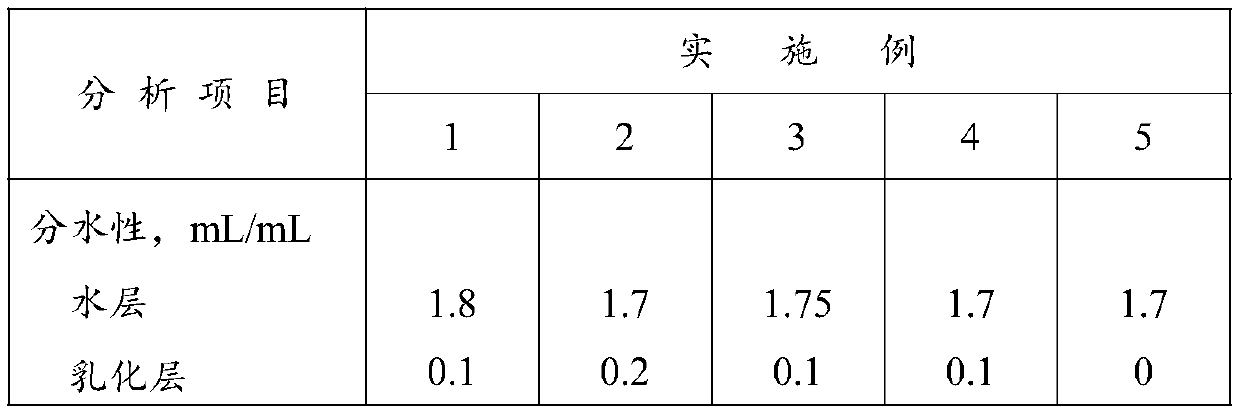

Marine diesel engine oil composition and preparation method and application thereof

InactiveCN111500349AImprove oil-water separation effectLubricant compositionDemulsifierFoaming agent

The invention discloses an oil composition for a marine diesel engine and a preparation method and application thereof, and mainly solves the technical problem that a demulsifier needs to be added into the oil composition for the marine diesel engine to improve the oil-water separation performance in the prior art. The oil composition for the marine diesel engine is prepared from the following components in parts by mass: 0.1-20 parts of a clearing agent; 0.1-20 parts of a dispersant, 0.6-15 parts of an antioxidant; 0.001-1 part of an anti-foaming agent; an 50-98 parts of base oil. The preparation method of the marine diesel engine oil composition comprises the following steps: adding the clearing agent, the dispersing agent, the antioxidant and the anti-foaming agent into the base oil atthe temperature of 50-60 DEG C, performing stirring for 0.5-3 hours, and performing complete dissolving to obtain the marine diesel engine oil composition. The present invention discloses the application of the marine diesel engine oil composition in marine diesel engines, thereby better solving the problems. The marine diesel engine oil composition and preparation method and application thereof are suitable for industrial application of lubrication of marine diesel engines.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing catechol-based hydrophilic modified organic tubular membrane

InactiveCN112844057AIncrease membrane fluxImprove throughputSemi-permeable membranesMembranesMembrane fluxTannic acid

The invention discloses a method for preparing a catechol-based hydrophilic modified organic tubular membrane, which comprises the following steps: soaking a membrane tube in pure water to obtain a completely infiltrated membrane tube; adding a catechol group-containing hydrophilic modifier and a silane coupling agent into a pH buffer solution to prepare a solution; and completely immersing the infiltrated membrane tube in the hydrophilic modifier solution, carrying out aeration treatment at the bottom of a hydrophilic modifier solution container to enable the hydrophilic modifier to be subjected to a full oxidation reaction, then conducting immersing in pure water to remove residues on the surface of the membrane tube, and conducting packaging to obtain a tubular membrane product. According to the method for hydrophilically modifying the organic tubular membrane through the catechol groups, the catechol group-containing hydrophilic modifier such as dopamine and tannic acid and the silane coupling agent are subjected to composite deposition on the surface of the membrane, so that the hydrophilicity of the membrane is improved, and the organic tubular membrane which is large in membrane flux, good in hydrophilicity and easy to clean is prepared. The method is simple to operate and easy for industrial production, improves the oil-water separation performance of partial material membranes, and expands the application range.

Owner:安徽普朗膜技术有限公司

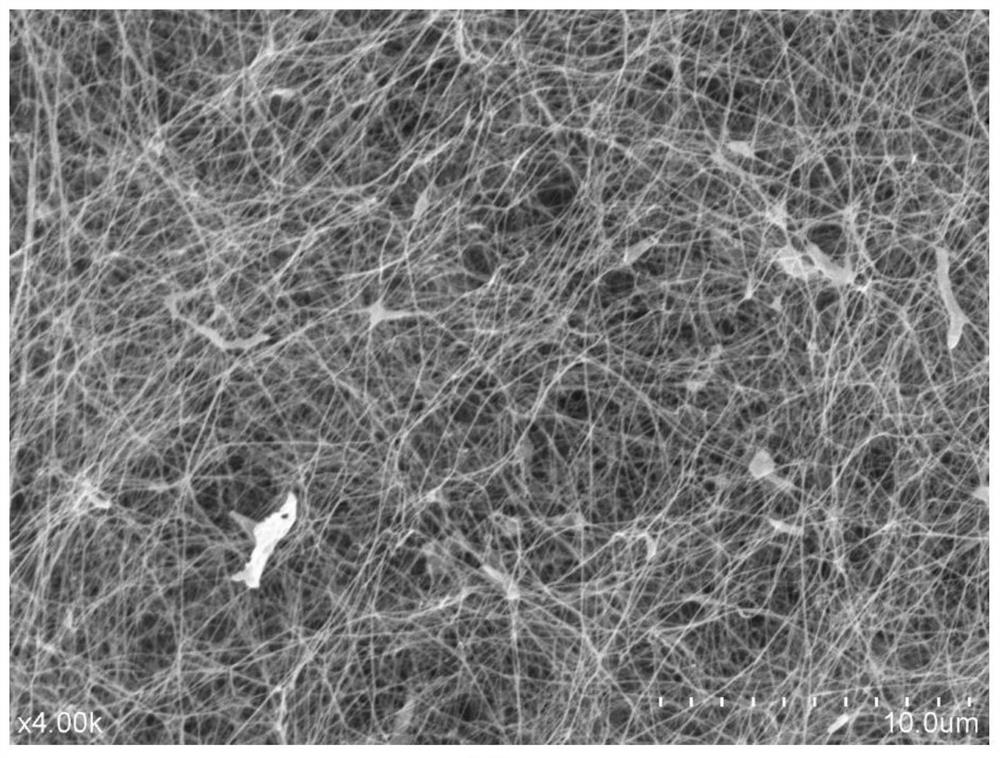

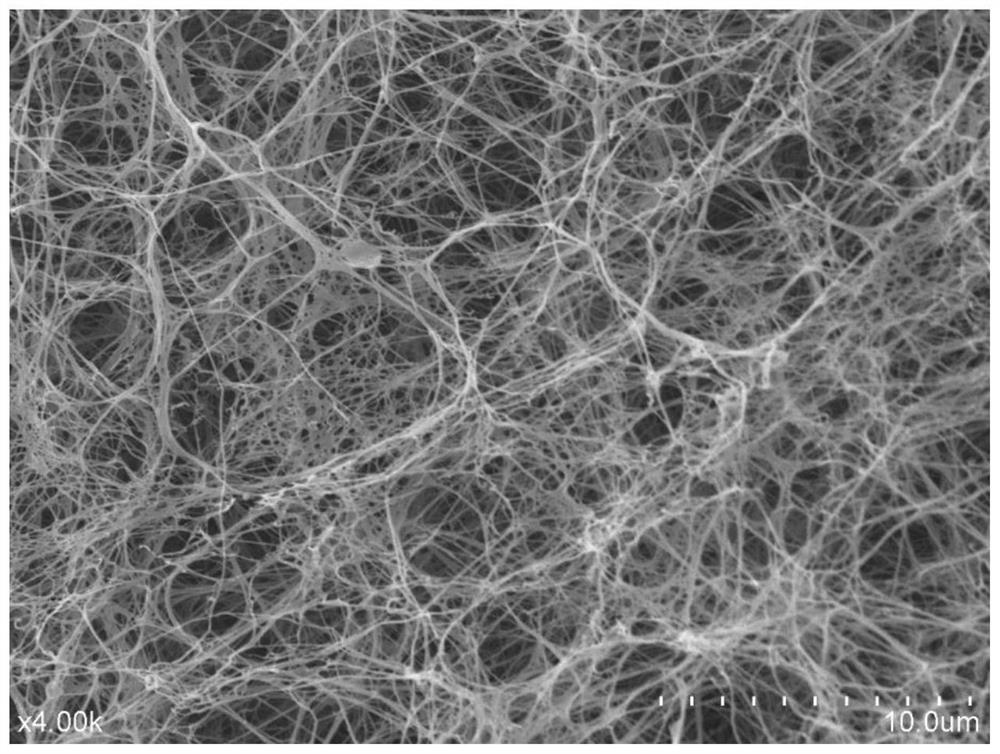

Preparation method of bacterial cellulose membrane for oil-water separation and with pore diameter adjusted by potato starch

ActiveCN112126109AGood oil-water separation effectImprove separation efficiencySemi-permeable membranesMicroorganism based processesBiotechnologyPotato starch

The invention discloses a preparation method of a bacterial cellulose membrane for oil-water separation and with the pore diameter adjusted by potato starch. The invention discloses a novel bacterialcellulose / silicon dioxide / hexadecyltrimethoxysilane oil-water separation composite membrane with good oil-water separation capability and high biodegradability, and a preparation method thereof, and belongs to the technical field of functional materials. The preparation method comprises the following steps: (1) culturing and purifying a bacterial cellulose / starch membrane; (2) preparing an ethyl orthosilicate / ethanol solution and a hexadecyl trimethoxy silane / ethanol solution; and (3) preparing the bacterial cellulose / silicon dioxide / hexadecyltrimethoxysilane oil-water separation composite membrane. The preparation method is simple, compared with a traditional oil-water separation mode, the prepared composite membrane not only has good oil-water separation capacity, but also has a series of advantages of high biodegradability, no toxicity or harm, shape plasticity and the like, and technical support is provided for saving water and oil resources and protecting the environment.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

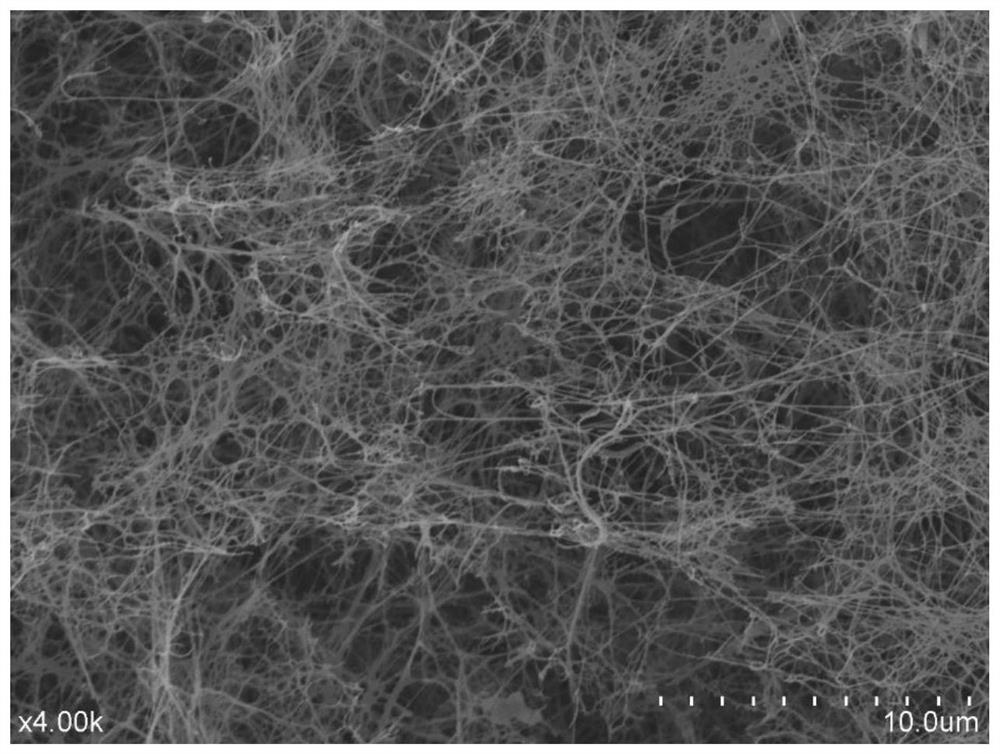

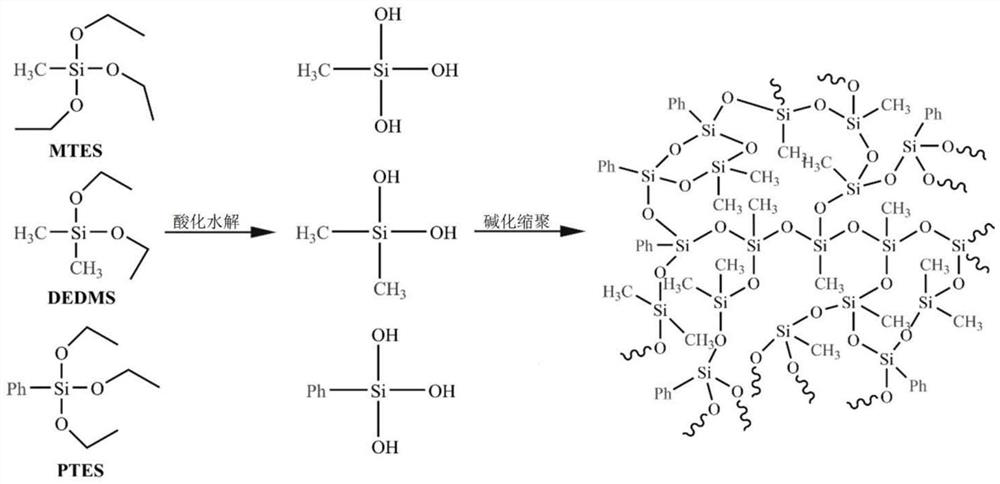

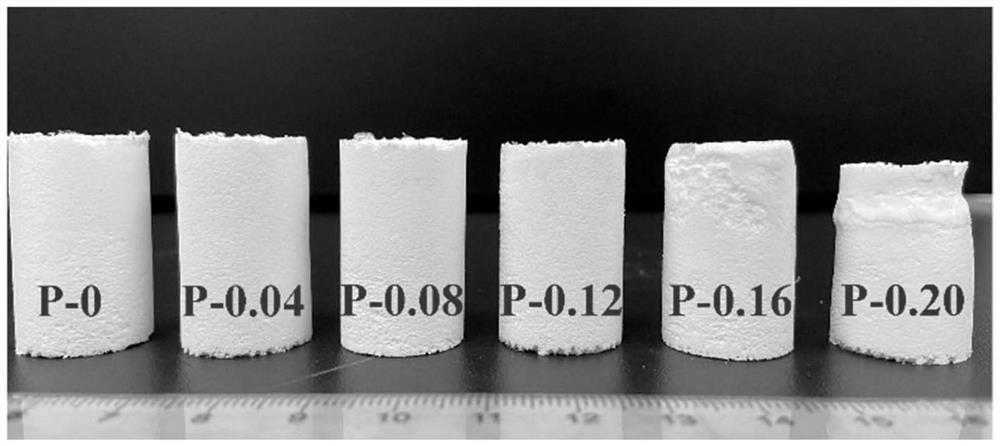

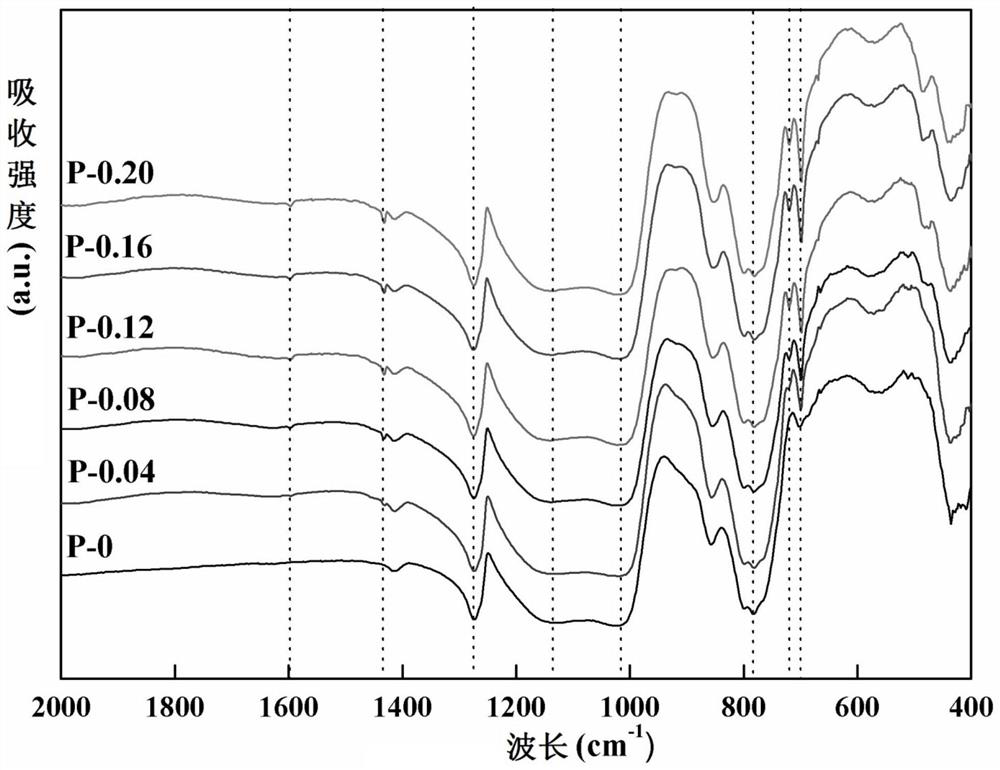

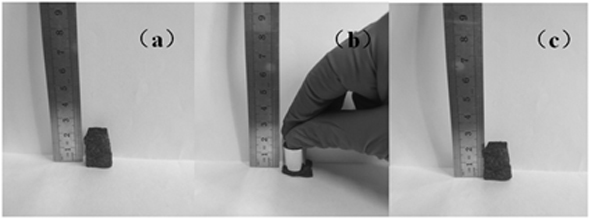

Phenyl-reinforced flexible silicon dioxide aerogel as well as preparation method and application thereof

PendingCN112897534AFirmly connectedClosely connectedSilicon compoundsNon-miscible liquid separationPhenyl groupMethyl group

The invention discloses phenyl reinforced flexible silicon dioxide aerogel as well as a preparation method and application thereof, wherein the phenyl reinforced flexible silicon dioxide aerogel is prepared by taking at least one first silicon source comprising a phenyl group and at least one second silicon source comprising a methyl group as precursors through a sol-gel method. The aerogel has the advantages of super-hydrophobicity, excellent mechanical property, good oil-water separation capacity, excellent thermal stability and excellent flame retardance. The preparation method comprises the following steps: step 1, preparing materials according to the phenyl reinforced flexible silicon dioxide aerogel; step 2, acidification hydrolysis: dissolving CTAB in an acid solution to obtain a mixed solution, adding a first silicon source and a second silicon source into the mixed solution, and continuously stirring to acidify and hydrolyze the first silicon source and the second silicon source; step 3, alkalization and polycondensation: alkali is added into the solution after acidification and hydrolysis, and gel is formed through alkalization and polycondensation; step 4, aging and drying the gel to obtain the phenyl reinforced flexible silicon dioxide aerogel.

Owner:SOUTHWEST UNIV

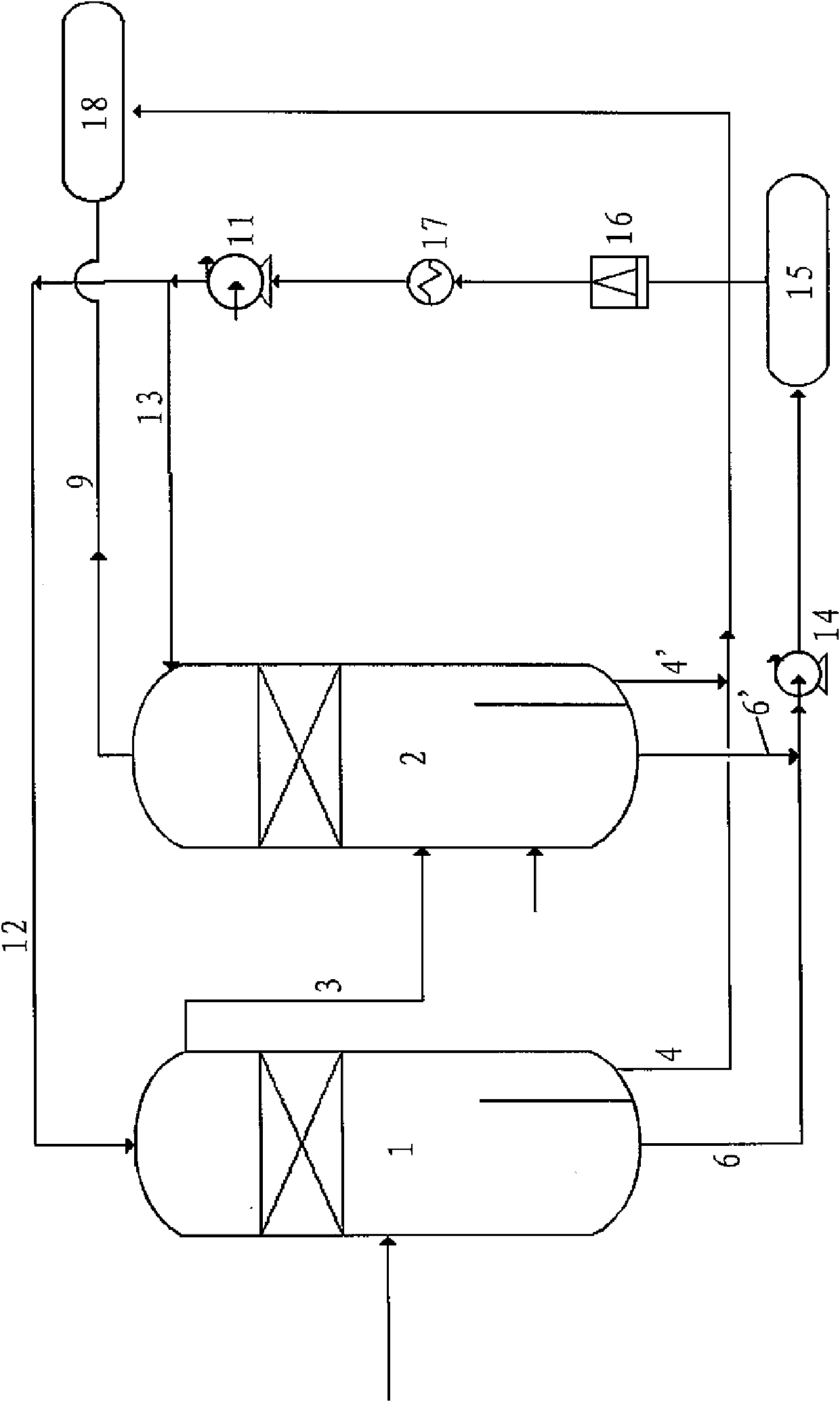

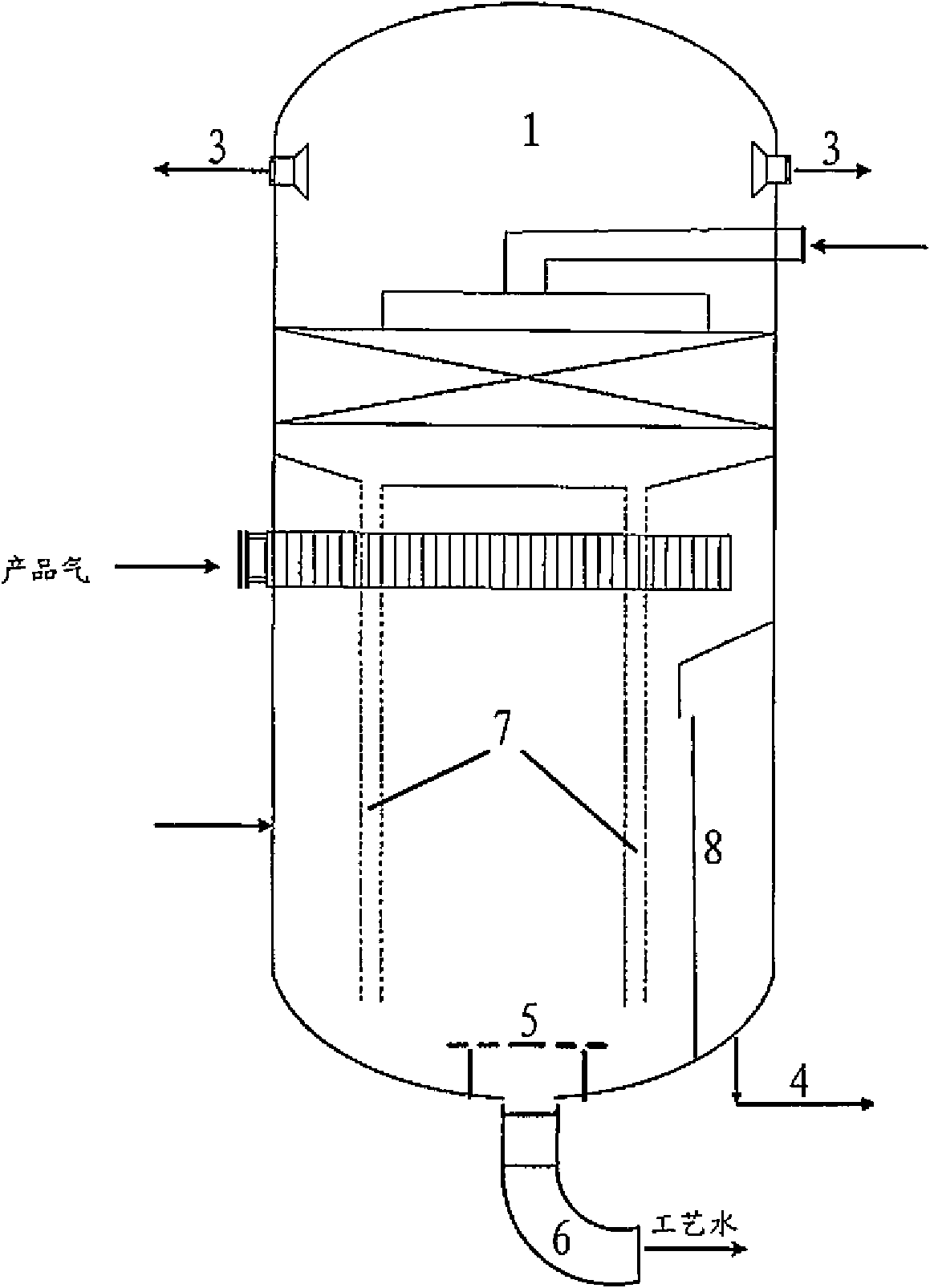

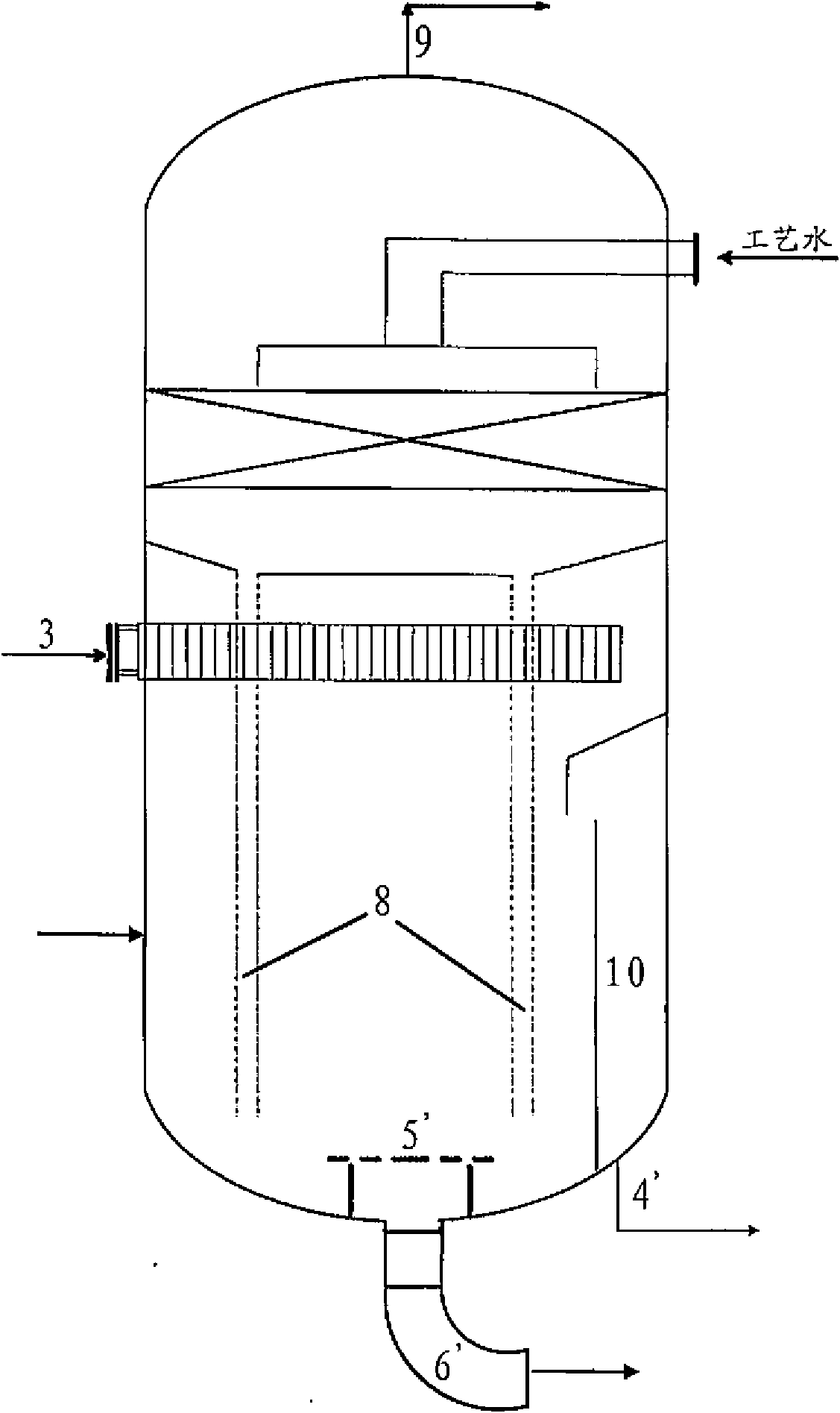

Method and device used for preventing cavitation of chilling water pump in process of preparing propylene from coal-based methanol

ActiveCN102345578BImprove oil-water separation effectAvoid cavitationPositive-displacement liquid enginesPulse equalisationCavitationChilled water

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

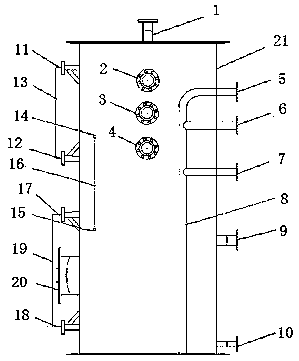

Device and method for separating oil and water on top of debenzolization tower with excellent separation effect

PendingCN110393950AImprove oil-water separation effectStable debenzene distillation operationDistillation regulation/controlHydrocarbon purification/separationDistillationEngineering

The present invention discloses a device and method for oil-water separation on the top of a debenzolization tower with excellent separation effect, and relates to the technical field of debenzolization of chemical production, and the device and method are used for improving the oil-water separation effect on the top of the debenzolization tower. The technical proposal is as follows: according tothe device and method, a plurality of liquid level gauges are adopted to display height of an oil-water separation interface of each part of a tank body, and the separation interface of an oil-water mixture in the tank body is controlled between a separation oil outlet and an oil-water mixture inlet through regulating control valves of different separated water outlets and different oil return ports, thus the oil-water separation effect is improved, it is ensured that separated oil does not carry water, and separated water does not carry oil, benzene oil is fully returned to the debenzolization tower, and the separated water is continuously discharged outside the debenzolization tower, debenzolization distillation operation is stabilized, the light benzene yield and quality are greatly improved, and significant economic benefits are achieved; and oil-water separation control operation is normalized and standardized, the operation efficiency is improved, the time for regulating oil-water separation to achieve optimal effect is effectively shortened, and safe and stable production of debenzolization distillation is ensured.

Owner:宣化钢铁集团有限责任公司

Preparation method of polyacrylonitrile/reduced graphene oxide composite oil absorption material

ActiveCN111888799AImprove thermal stabilityIncrease inertiaGeneral water supply conservationLiquid separationFreeze-dryingOxide composite

The invention discloses a preparation method of a polyacrylonitrile / reduced graphene oxide composite oil absorption material, belongs to the field of oil absorption materials, and aims to solve the problems that an existing polymer porous oil absorption material is low in oil absorption rate and complex in preparation process. The preparation method comprises the following steps of: chopping polyacrylonitrile fibers to 3-5mm; putting the chopped polyacrylonitrile fibers into a crusher; uniformly dispersing and infiltrating the chopped polyacrylonitrile fibers into a reduced graphene oxide aqueous solution; carrying out ultrasonic treatment for 10-30min; sealing an obtained product in a container; putting the container into a drying oven; carrying out hydrothermal reaction; cooling to roomtemperature; washing a reaction product with distilled water; freezing the reaction product in a refrigerator; and finally drying the reaction product in a freeze dryer to obtain the polyacrylonitrile / reduced graphene oxide composite oil absorption material. According to the preparation method, the polyacrylonitrile fibers are taken as a framework, and the reduced graphene oxide is taken as a reinforcing phase; the oil absorption material which is ultra-light, high in saturated oil absorption rate, high in oil absorption rate, stable in structure and capable of being recycled for multiple times is prepared through the hydrothermal method and freeze drying, and the oil absorption material is widely applied to the fields of oil stain leakage and the like.

Owner:TAIYUAN UNIV OF TECH

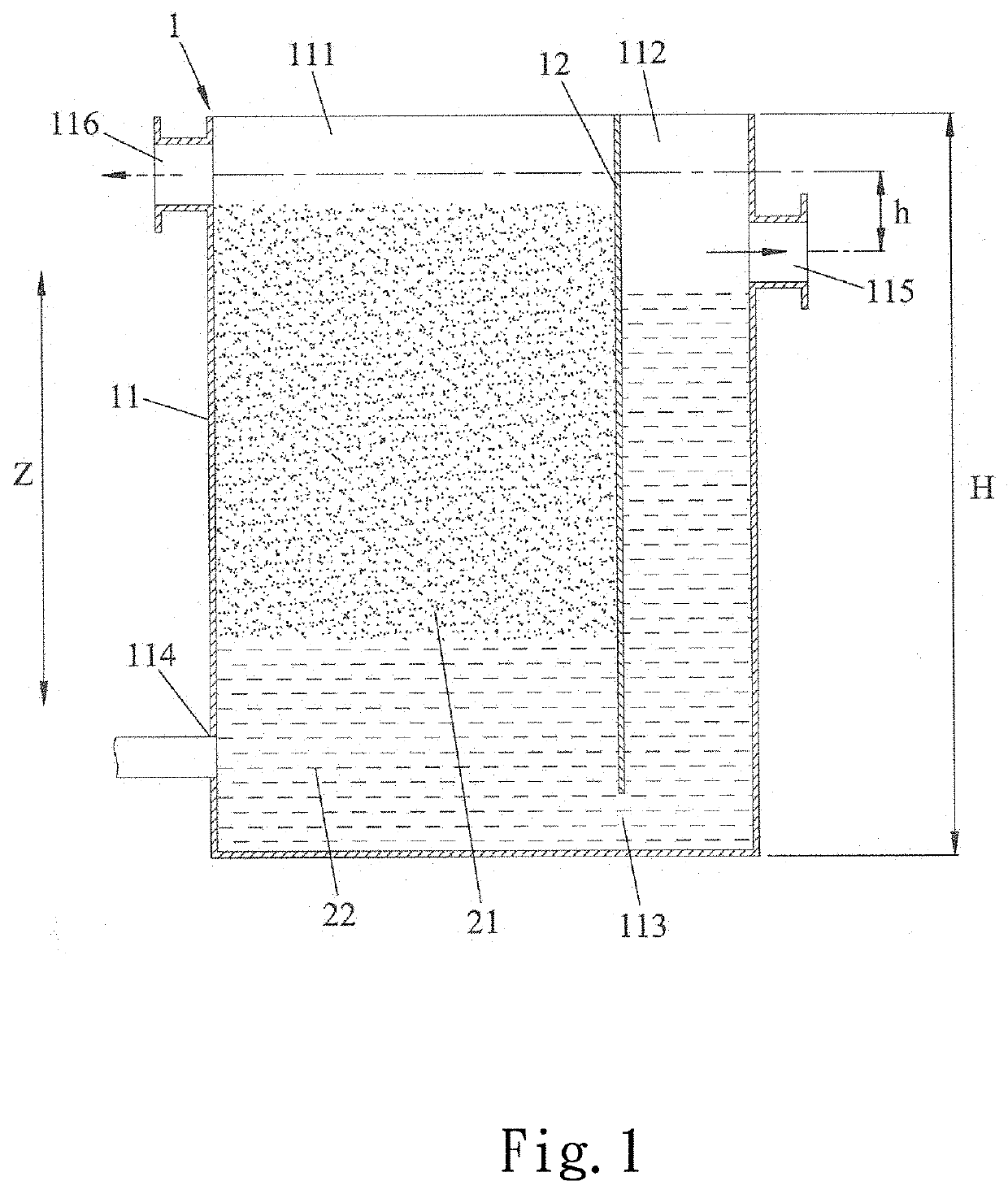

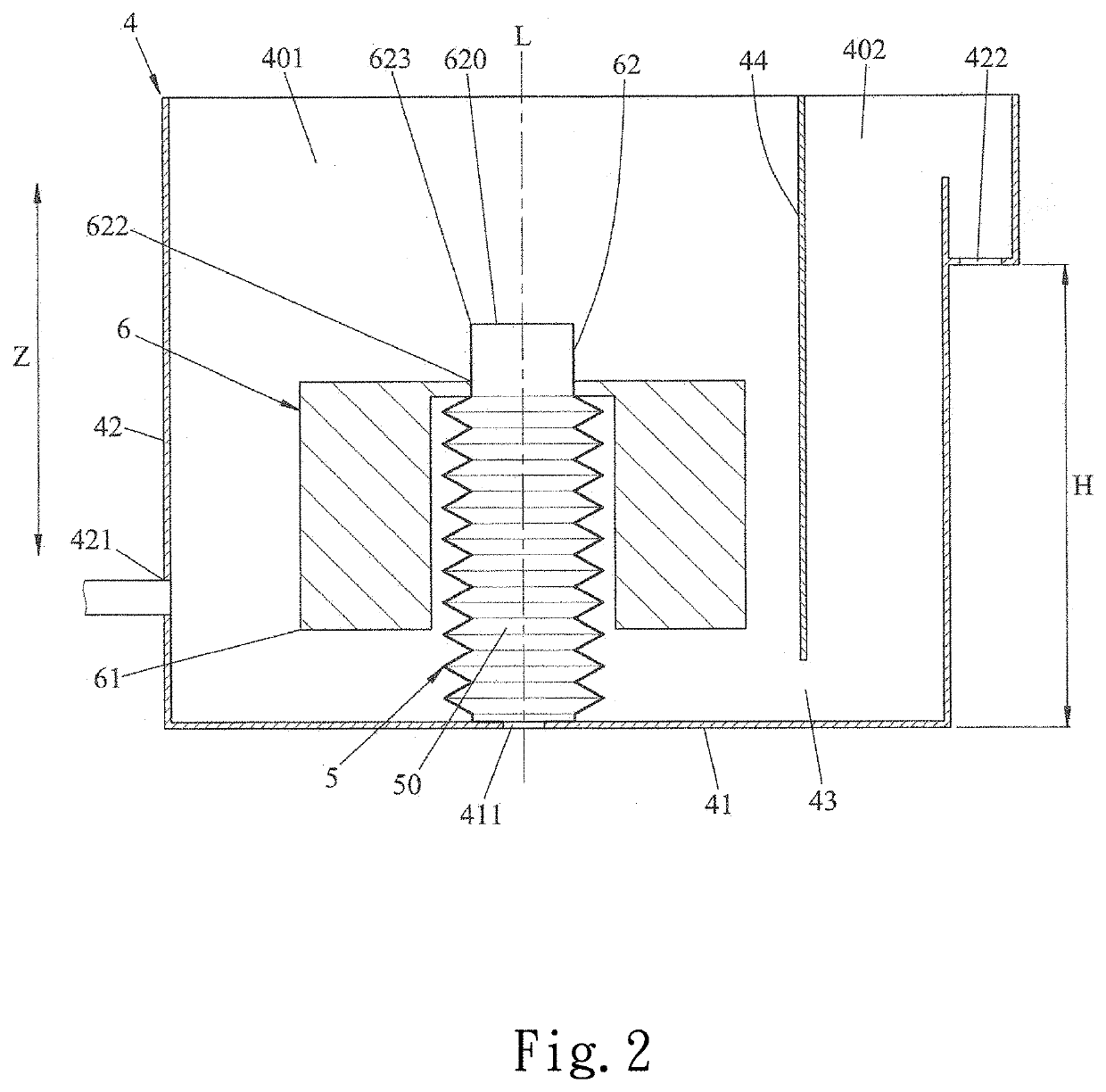

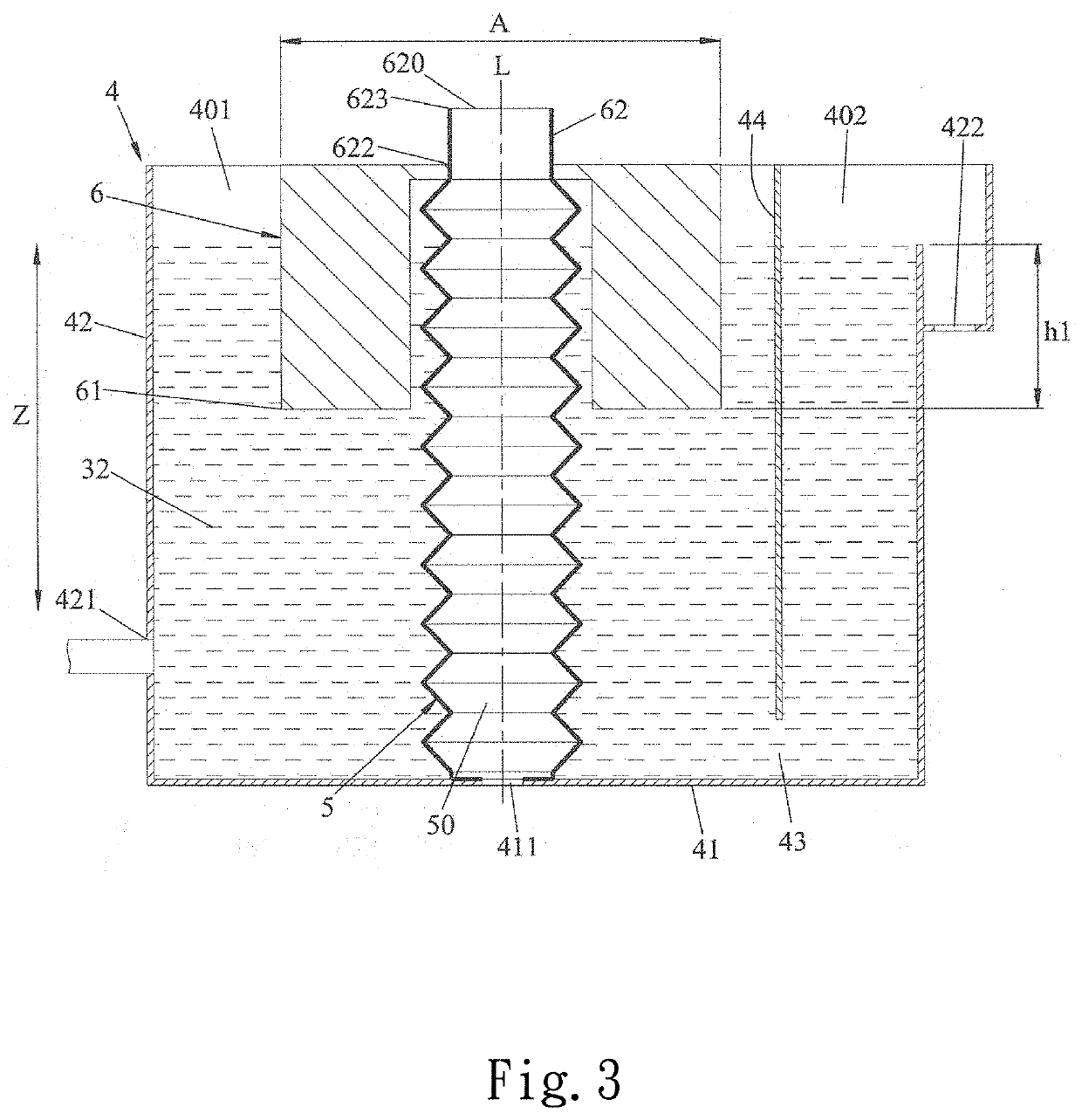

Oil-water separator with oil discharge outlet adjusting spontaneously

InactiveUS20200338474A1Reduce heightEasy to installLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesOil and greaseLiquid storage tank

An oil-water separator with an oil discharge outlet adjusting spontaneously includes a liquid storage tank with grease and wastewater, a telescopic pipe in the liquid storage tank, and a floater unit connected with the telescopic pipe. The liquid storage tank comprises an inlet for grease and wastewater input, and a water outlet for wastewater output. The floater unit comprises at least one floater floating between grease and wastewater, and an isolation member extending in the height direction between the floater and the telescopic pipe. The isolation member fluctuates along with height changes of wastewater and includes an oil discharge outlet for grease entering the telescopic pipe. Therefore, an oil outlet, adjusting height spontaneously, is configured by the at least one floater, such that the overall height is reduced, a sufficient difference of levels of grease and wastewater is generated by the isolation member, thereby improving the oil-water separation effect.

Owner:JENFU MACHINERY

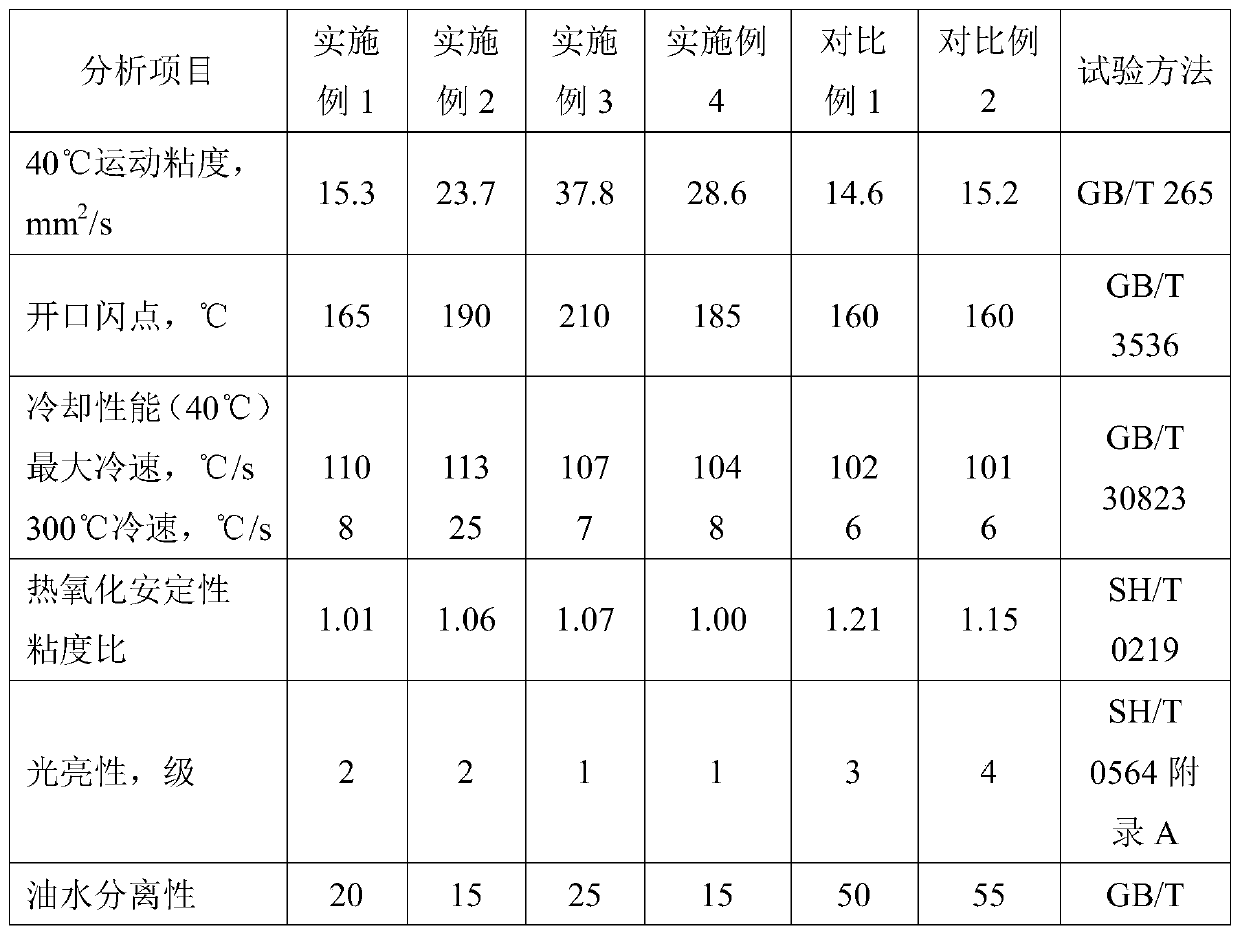

Fast bright quenching oil and preparation method thereof

The invention discloses fast bright quenching oil which is formed through mixing the following components in percentage by weight: 80-92% of base oil, 4-10% of a cooling accelerant, 1.5-5% of a surfactant, 0.5-3% of an auxiliary dispersing agent and 0.5-2% of an antioxidant. The invention further discloses a preparation method of the fast bright quenching oil. The fast bright quenching oil has excellent cooling performance, thermal oxidation stability and brightness and also has the oil-water separating performance; and according to the preparation method, base oil is added in a system twice to better disperse various additives in the formula, so that the stability of the additives in an oil product system is improved to prolong the using effect of an oil product.

Owner:NANJING KERUN LUBRICANTS +1

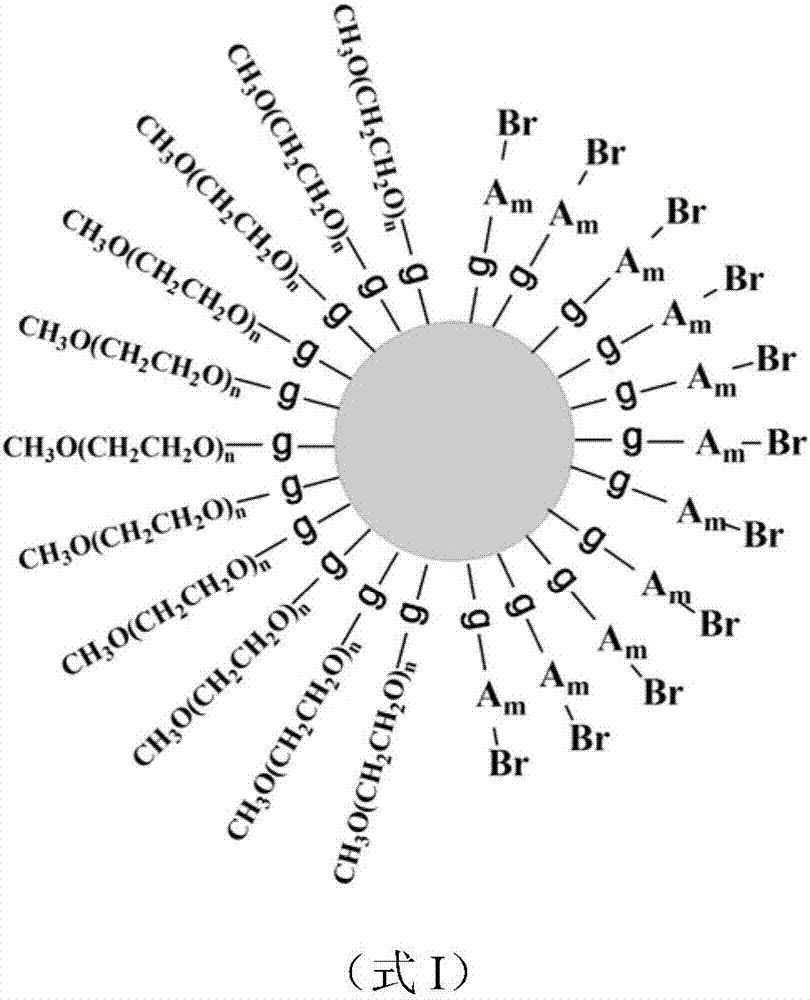

Demulsifier composition, lubricating oil composition, and method for improving demulsification performance of lubricating oil

ActiveCN105623783AImprove stabilityGood oil-water separation effectLubricant compositionDemulsifierEthylene oxide

The invention provides a demulsifier composition, a lubricating oil composition containing the demulsifier composition, and a method for improving the demulsification performance of lubricating oil. The demulsifier composition comprises an alkyl acrylate and alpha-alkenylsulfonic acid copolymer and a tetra(4-hydroxyphenyl)porphyrin-epoxypropane-ethylene oxide polymerization reaction product according to a mass ratio of 1-10:10-1. The demulsifier composition has the advantages of good stability, excellent oil-water separation effect and excellent demulsification effect, is especially suitable for separating a tiny amount of water from the lubricating oil, and is also especially suitable for industrial gear oil, steam turbine oil and marine crankcase oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Self-cleaning nano coating applicable to automobile windshield

InactiveCN107987634AGood mechanical protectionImprove oil-water separation effectAntifouling/underwater paintsPaints with biocidesSilanesAcrylic resin

The invention relates to the technical field of nano material development and discloses a self-cleaning nano coating applicable to an automobile windshield. A precipitation reaction method is utilizedfor preparing silicon dioxide with the particle size of 1-50nm, then a silane solution is utilized for modifying, the silicon dioxide is decomposed into an acrylic resin solution, and the windshieldis coated. The prepared super-hydrophobic oleophobic nano composite coating has excellent oil-water separating capability, and a layered microstructure composed of nano holes and microcells which arecommunicated each other appears on the surface of the coating, thereby having a self-cleaning effect on dust; and under the combined action of microtopography and chemical composition of a coating material, mechanical protection on glass is improved, and the self-cleaning nano coating disclosed by the invention also has ice covering resistance and corrosion resistance.

Owner:MAANSHAN LANKE REMFG TECH

Polyasparagine derivative modified stainless steel mesh membrane for oil-water separation and preparation method thereof

ActiveCN110670056BImprove oil-water separation effectImprove stabilityFatty/oily/floating substances removal devicesMetallic material coating processesImideEthanolamines

The invention discloses a polyasparagine derivative modified stainless steel net membrane for oil-water separation and a preparation method thereof. In the present invention, groups such as zwitterions, dopamine, long-chain alkyl groups and ethanolamine are grafted on the polysuccinimide polymer by ring-opening reaction, and the dopa / zwitterion function is obtained by modifying the surface of the stainless steel mesh Polyasparagine derivatives modified stainless steel mesh for oil-water separation. The polyasparagine derivative modified stainless steel mesh membrane for oil-water separation provided by the present invention has the characteristics of good oil-water separation effect and good stability; the polyasparagine derivative material used is biodegradable and environmentally friendly, After use, the waste will not cause secondary pollution to the environment. The preparation method of the polyasparagine derivative modified stainless steel omentum membrane for oil-water separation has simple and fast process, mild reaction, easy control and high safety.

Owner:QUANZHOU NORMAL UNIV

Nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery and preparation method thereof

ActiveCN103320110BGood viscosity reductionReduce dosageDrilling compositionDepressantSilicon dioxide

Disclosed is a high-temperature resistant nano composite mining additive for mining heavy oil and super heavy oil, which is prepared from 3-8 wt% of a modified nano-inorganic additive, 3-8 wt% of petroleum sulfonate, 10-40 wt% of a viscosity depressant, 5-15 wt% of an emulsifier, 2-10 wt% of a surface wetting agent, 2-10 wt% of a penetrant, 5-10 wt% of a polymer modifier,and 1-8 wt% of a catalyst, with a balance being water. Also disclosed is a preparation process for the above-mentioned high-temperature resistant nano composite mining additive for mining heavy oil and super heavy oil. The mining additive of the present invention has the advantages of a good high-temperature resistant performance, and an excellent emulsification performance and anti-salt performance, thereby significantly improving the efficiency of production and reducing the cost of mining.

Owner:GUNGHO CHARGE TIANJIN REFINED PETROLEUM TECH DEV

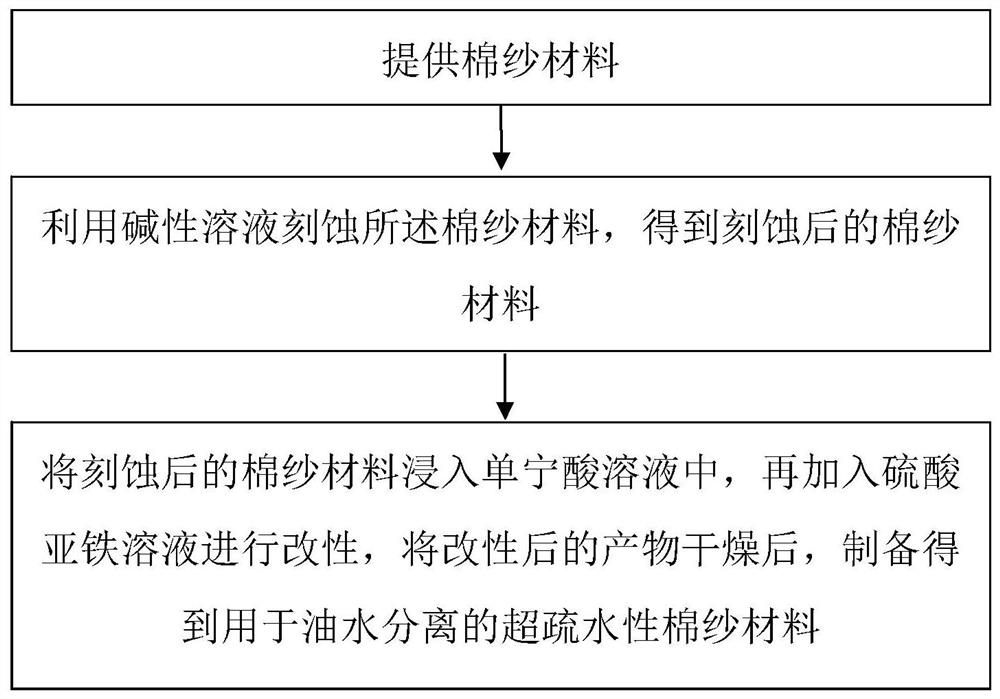

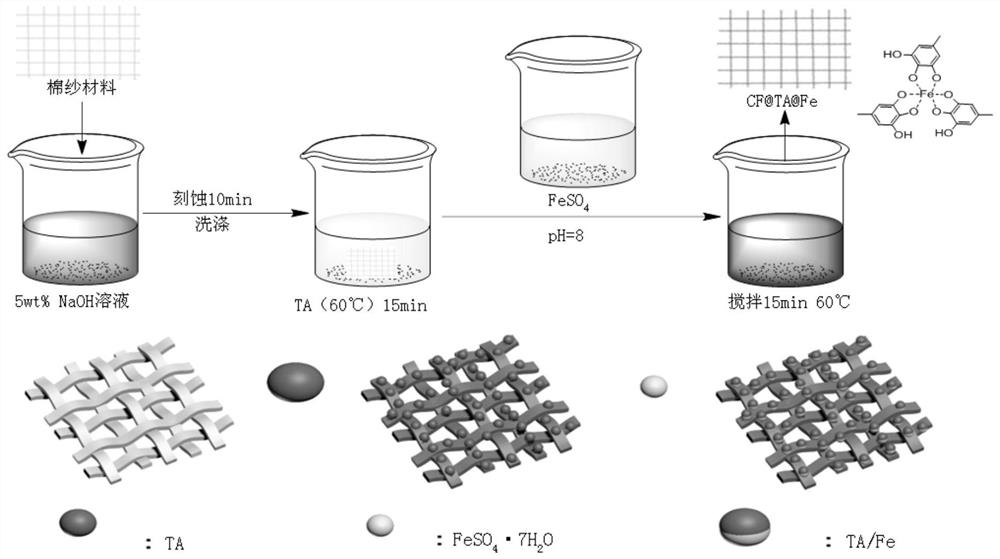

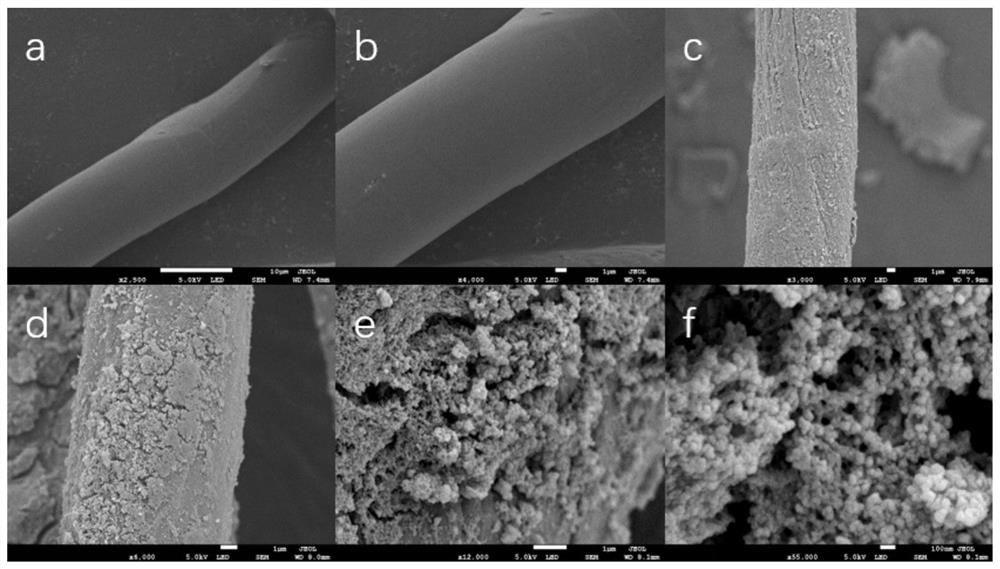

Super-hydrophobic cotton yarn material for oil-water separation as well as preparation method and application thereof

InactiveCN111871002AImprove adhesionImprove stain resistanceLiquid repellent fibresLiquid separationYarnPolymer science

The invention discloses a super-hydrophobic cotton yarn material for oil-water separation as well as a preparation method and application of the super-hydrophobic cotton yarn material. The preparationmethod of the super-hydrophobic cotton yarn material for oil-water separation comprises the following steps: providing a cotton yarn material; etching the cotton yarn material by using an alkaline solution to obtain an etched cotton yarn material; immersing the etched cotton yarn material into a tannic acid solution, then adding a ferrous sulfate solution for modification, circularly immersing the cotton yarn material into the mixed solution for multiple times, and drying the modified product to prepare the super-hydrophobic cotton yarn material for oil-water separation. The super-hydrophobiccotton yarn material for oil-water separation has good oil-water separation performance.

Owner:SHENZHEN UNIV

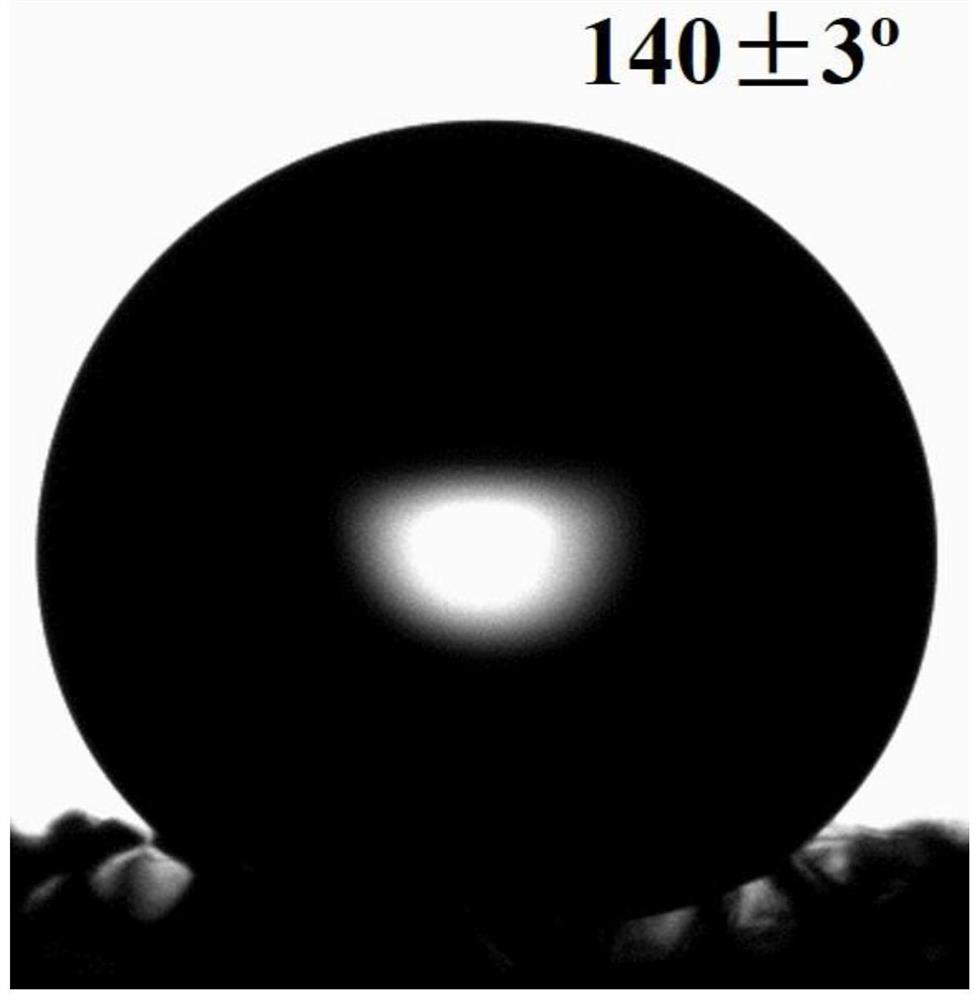

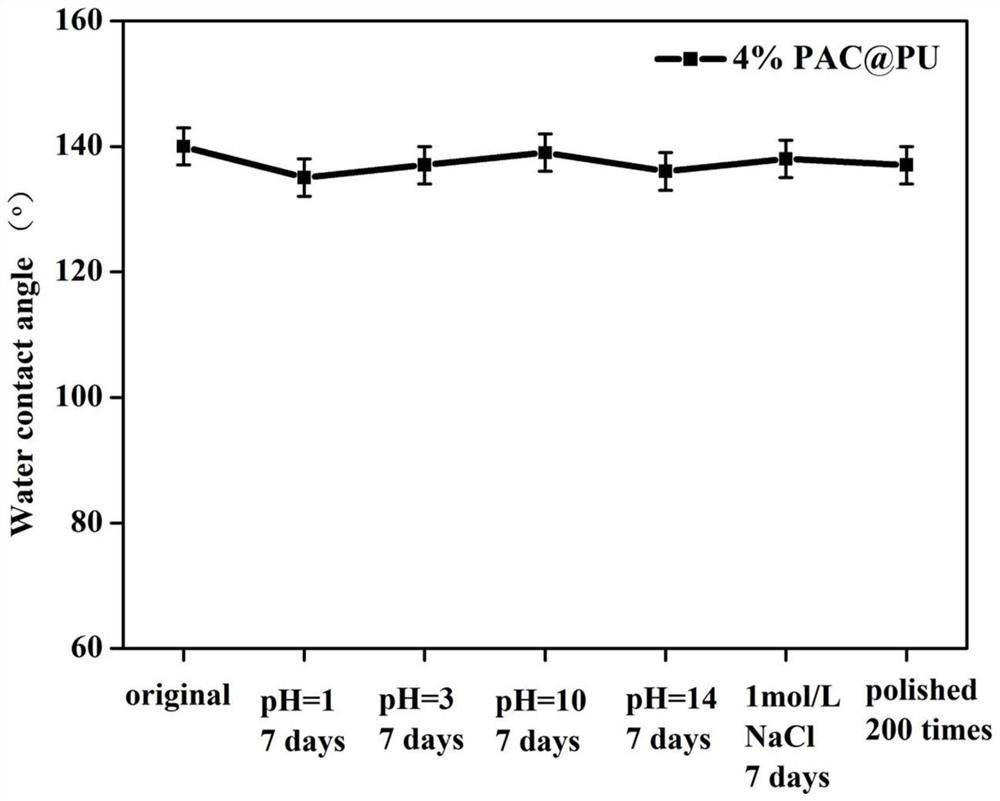

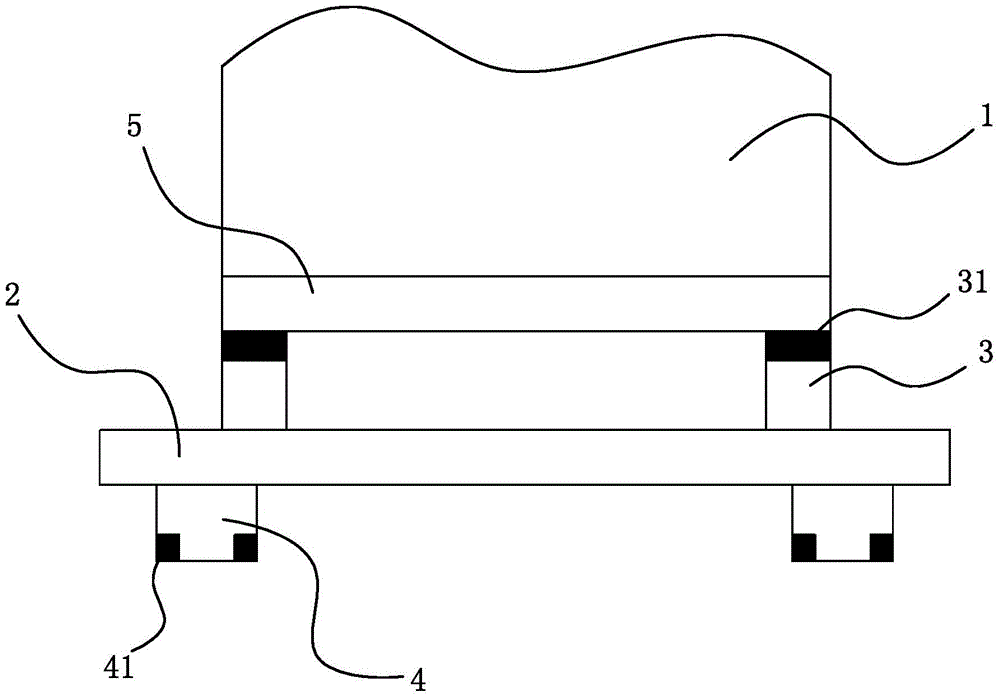

Composite polyurethane foam emulsion separation material, and preparation method and application thereof

ActiveCN113072677AOvercome the problem of easy sheddingEfficient separationLiquid separationAluminium chloridePolymer science

The invention discloses a composite polyurethane foam emulsion separation material. The separation material is polyaluminum chloride in-situ composite polyurethane foam. The separation material is prepared from polyether polyol, a catalyst, a foaming agent, a foam stabilizer, isocyanate and polyaluminum chloride. The preparation method of the separation material adopts a quick foaming method, and comprises the following steps: adding commercial polyaluminum chloride into a polyurethane foam synthesis raw material, and uniformly dispersing the polyaluminum chloride into the foam synthesis raw material by stirring; and foaming and naturally curing to obtain the emulsion separation material. The preparation method is simple in process, short in period, mild in condition, green and environment-friendly, and easy for large-scale production and application. The emulsion separation material of the polyaluminum chloride in-situ composite polyurethane foam has excellent hydrophobicity and stable physical and chemical properties; and the efficient separation efficiency on oil-in-water type emulsification is realized, and the wide application prospect is realized in the field of oily sewage treatment.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of dissolving-resistant oil-water separation filter paper

InactiveCN109837803AImprove environmental performanceImprove oil-water separation performanceVegetable material additionReinforcing agents additionChemistrySaw dust

The invention provides a preparation method of dissolving-resistant oil-water separation filter paper, and the preparation method comprises the following steps: obtaining raw materials; adding nano-diatomaceous earth, calcium carbonate, water-soluble phenolic resin, coconut fibers, saw dust, citric acid, zinc nitrate and microcrystalline cellulose into mixed slurry, and heating to 70-80 DEG C; after defibering by a defibering machine, grinding pulp, performing papermaking according to a conventional papermaking process, forming, squeezing and drying; compared with the prior art, the preparation method comprises the following beneficial effects: by selecting natural cotton fibers, gypsum fibers, and polyester fibers to serve as basic raw materials, the characteristics of oil-water resistance and high temperature resistance of the filter paper are provided, by addition of the saw dust, the environment-friendly performance is improved, and the oil-water separation performance of the filter paper material is effectively improved.

Owner:DONGGUAN LUAO FILTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com