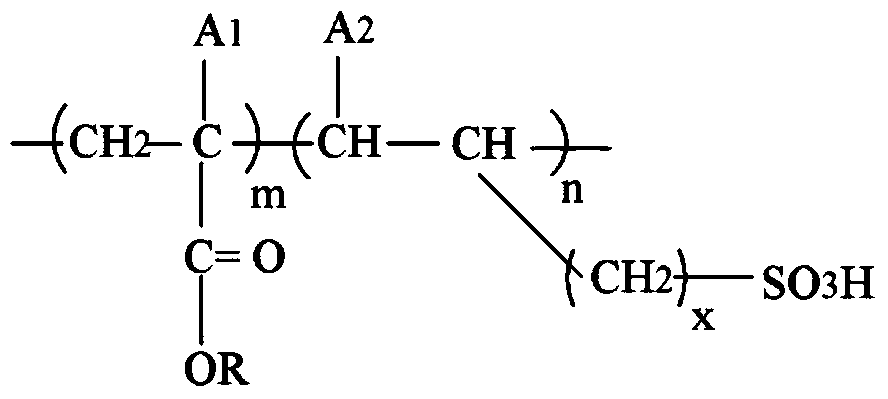

Demulsifier composition, lubricating oil composition, and method for improving demulsification performance of lubricating oil

A demulsifier and composition technology, applied in the field of demulsifier compositions, can solve the problems of adding a lot, not easy to ensure the quality of lubricating oil, and increasing the production cost of lubricating oil, and achieve the effects of good stability and excellent oil-water separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

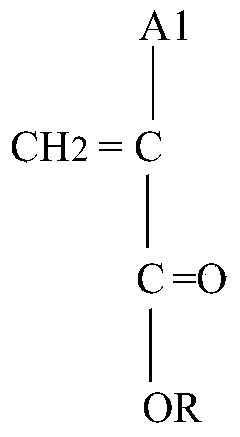

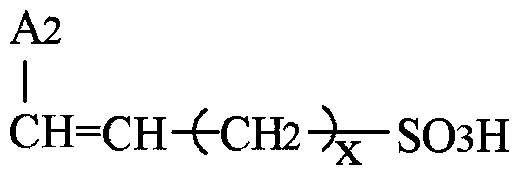

Method used

Image

Examples

Embodiment 1

[0064] The preparation of embodiment 1 propylene sulfonic acid mixture

[0065] Add 80 grams of petroleum ether at 30°C to 60°C in a 500mL autoclave with stirring, heating, and cooling bath, then close the reaction kettle, turn on the stirring, and pass it into a cooling bath for temperature control, and then use a high-pressure pump to inject 40 grams (0.952mol) of propylene, and feed high-purity nitrogen, control the pressure of the reactor between 0.8 ~ 1MPa, control the temperature of the reactor at 0 ~ 10 ° C, heat the cylinder with sulfur trioxide, and place it in an electronic Measure on the scale, then control the heating temperature so that the pressure of the sulfur trioxide cylinder is greater than the pressure of the autoclave, and open the outlet valve of the sulfur trioxide cylinder, and pass the gas into the vent pipe of the autoclave, and then into the liquid phase of the autoclave for Sulfonation reaction, the amount of sulfur trioxide feed is 77.7 grams (0.97...

Embodiment 2

[0066] The preparation of embodiment 2 butylene sulfonic acid mixture

[0067] Add 70 grams of normal hexane in a 500mL autoclave with stirring, heating and cooling bath, then close the reactor, open the stirring, and pass into the cooling bath for temperature control, then use a high-pressure pump to pour 38 grams of butene ( 0.679mol), and feed high-purity nitrogen, control the pressure of the reactor between 0.8~1MPa, control the temperature of the reactor at 0~10°C, heat the steel cylinder storing sulfur trioxide, and place it on an electronic scale for measurement. Then control the heating temperature so that the pressure of the sulfur trioxide cylinder is greater than the pressure of the autoclave, and open the outlet valve of the sulfur trioxide cylinder, and the gas is passed into the vent pipe of the autoclave, and then passed into the liquid phase of the autoclave to carry out the sulfonation reaction. Sulfur trioxide feed rate is 54.88 grams (0.686mol), at this mome...

Embodiment 3

[0068] The synthesis of embodiment 3 four (4-hydroxyphenyl) porphyrins

[0069] Add 10 grams of p-hydroxybenzaldehyde (M=122.12, 0.0819 mol), 160 ml of propionic acid and 10 ml of dimethyl sulfoxide mixed solvent into a three-necked flask with reflux, stirring, and temperature control devices, and heat up to 125-130 ° C for reflux , then drop 5.5 grams of pyrrole (M=67.09, 0.0819mol), the reflux reaction time is 140 minutes, then import the material into a beaker, put it into a refrigerator and cool it to 2-4°C, and filter it after standing for 10 hours to obtain blue crystals, Then the crystals were washed with propionic acid, recrystallized with absolute ethanol, and separated through a 100-mesh silica gel column to obtain a blue-purple segment. The solvent was evaporated and crystallized with absolute ethanol to obtain tetrakis (4-hydroxyphenyl) porphyrin 4.5 gram.

[0070] Structural characterization of the product: It can be seen from its ultraviolet spectrum that there ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com