Preparation method of bacterial cellulose membrane for oil-water separation and with pore diameter adjusted by potato starch

A bacterial cellulose membrane and bacterial cellulose technology, applied in the field of oil-water separation, can solve problems such as low separation efficiency and secondary environmental pollution, and achieve the effects of strong biodegradability, high oil-water separation efficiency, and simple and economical way to obtain raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

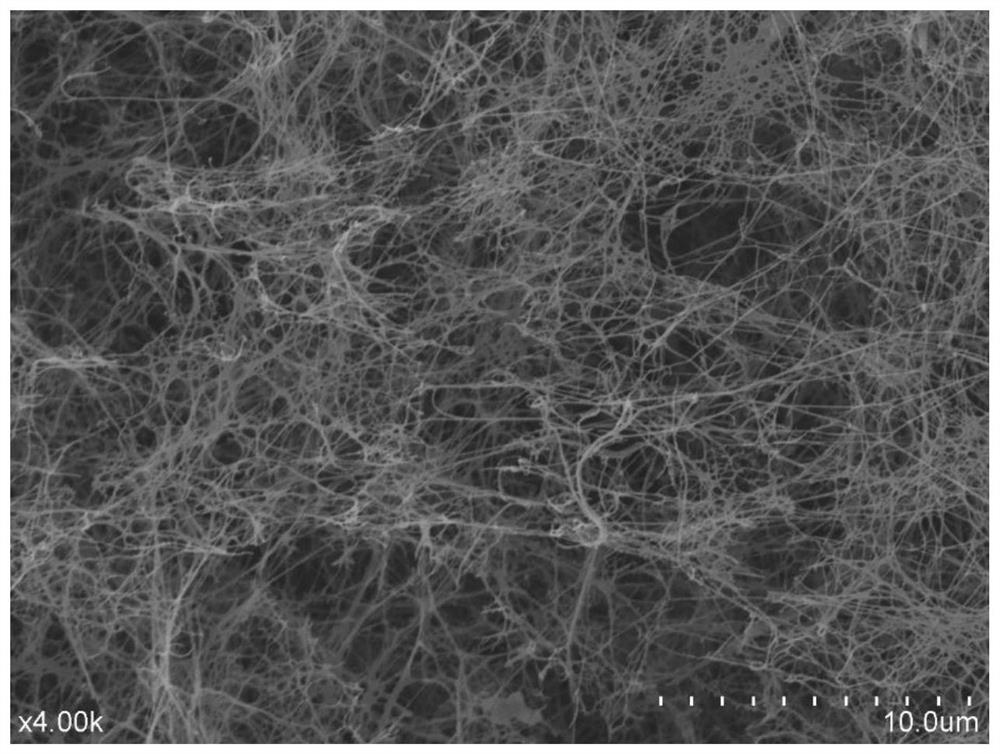

[0026] A preparation method utilizing potato starch to regulate the pore size of bacterial cellulose membrane for oil-water separation, comprising the following steps:

[0027] 1. Prepare bacterial cellulose / starch film medium:

[0028] Weigh 25g of glucose, 7.5g of yeast extract, 10g of tryptone, and 10g of disodium hydrogen phosphate in 950mL of water, stir to dissolve, adjust the pH to 6.0 with glacial acetic acid, and dilute to 1L. Then, take by weighing 0g, 0.5g, 1g, 1.5g, 2g, 2.5g potato starch respectively in the Erlenmeyer flask of 250mL, subpackage in the above-mentioned Erlenmeyer flask that starch of different quality has been housed in substratum, each Erlenmeyer flask Add 100mL medium, pregelatinize at 80°C for 20 minutes, and sterilize at 115°C for 30 minutes to obtain medium with starch content of 0%, 0.5%, 1%, 1.5%, 2%, and 2.5%. .

[0029] 2. Preparation of 0.9% normal saline:

[0030] Sodium chloride 9g, add a certain amount of MilliQ water, stir until dis...

Embodiment 1

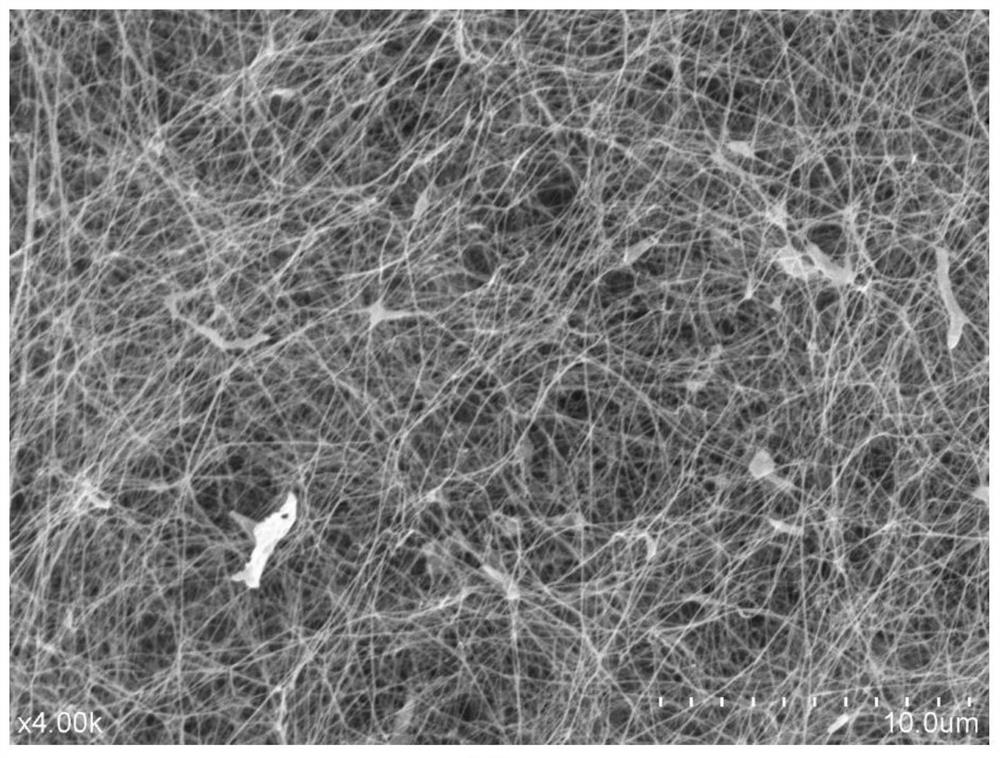

[0043] The pretreated bacterial cellulose / starch film with a starch content of 0% was placed in a 10% tetraethyl orthosilicate / ethanol solution, stirred for 4 hours, the sample was taken out, washed repeatedly with 75% (v / v) alcohol, and then placed in NH 3 ·H 2After stirring in O / ethanol solution for 1 h, it was washed several times with 75% (v / v) ethanol, and soaked in deionized water to exchange the solvent. The bacterial cellulose / silica membrane obtained in the above steps was freeze-dried for 24 hours.

[0044] Use hexadecyltrimethoxysilane / ethanol solution (3wt%) to soak for 2 hours at 50° C. to endow it with hydrophobicity.

Embodiment 2

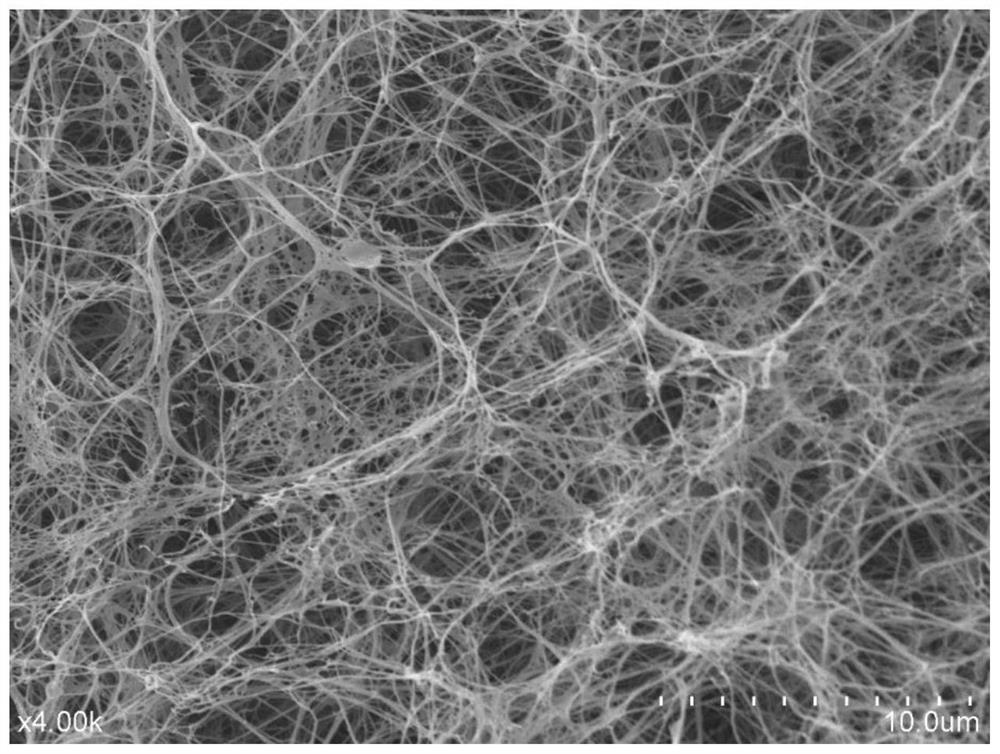

[0046] The pretreated bacterial cellulose / starch film with a starch content of 0.5% was placed in 10% tetraethyl orthosilicate / ethanol solution, stirred for 4 hours, the sample was taken out, washed repeatedly with 75% (v / v) alcohol, and then placed in NH 3 ·H 2 After stirring in O / ethanol solution for 1 h, it was washed several times with 75% (v / v) ethanol, and soaked in deionized water to exchange the solvent. The bacterial cellulose / silica membrane obtained in the above steps was freeze-dried for 24 hours.

[0047] Use hexadecyltrimethoxysilane / ethanol solution (3wt%) to soak for 2 hours at 50° C. to endow it with hydrophobicity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com