Coalescence fiber material for oil-water separation

A technology for coalescing fiber materials and oil-water separation, applied in the field of coalescing fiber materials, to achieve good engineering application prospects, low cost, and the effect of improving water-catching and gathering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

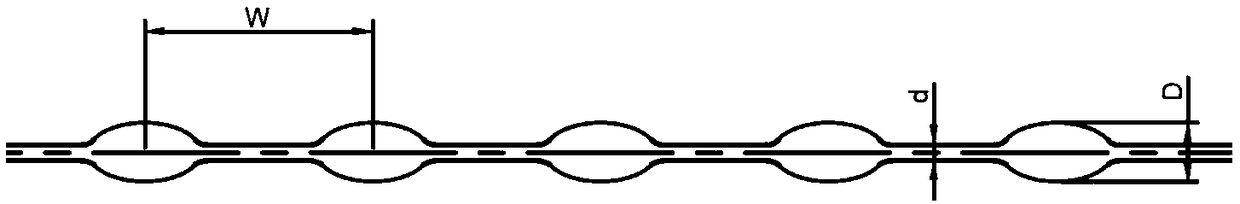

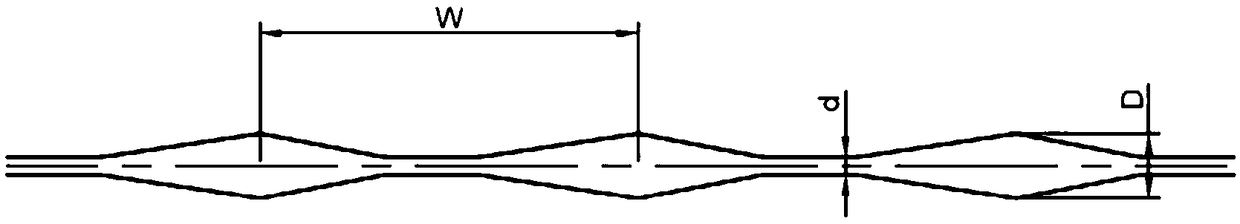

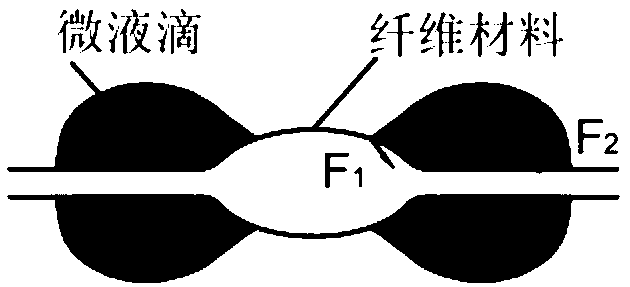

[0030] The diameter of the fine segment of glass fiber prepared by the melt-blown method is 7 μm; the maximum diameter D in the middle of the variable-diameter structure is about 20 μm; the period length of the variable-diameter structure is about 100 μm, because the coalescing fiber material forms a filter material with a thickness of about 1 mm. The hydrorefining produced by the steam stripping process in the process of collecting petroleum refining is used as the research object. The original diesel oil has a water content of about 500ppm and is turbid in appearance. After passing through the coalescence filter material woven by the coalescence fiber material with variable diameter structure, the appearance is clear and transparent, and the water content is less than 100ppm.

[0031] The filter material woven by the coalescing fiber material used for oil-water separation provided by the present invention can capture tiny water droplets in the oil-water mixture and realize ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com