Preparation method of polyacrylonitrile/reduced graphene oxide composite oil absorption material

A graphene composite and polyacrylonitrile technology, which is applied in chemical instruments and methods, separation methods, general water supply saving, etc., can solve the problems of complex preparation process, low reproducibility, and low oil absorption ratio, and achieve simple preparation process, The effect of low cost and fast oil absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In the first step, the length of the polyacrylonitrile fiber is chopped to 5 mm, and then put into a pulverizer for further shearing to make the fiber evenly dispersed, and 0.1 g of the polyacrylonitrile fiber is weighed for future use.

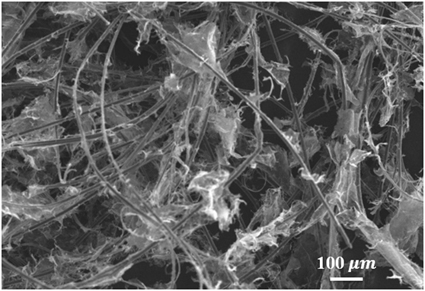

[0028] The second step is to prepare an aqueous solution of reduced graphene oxide: mix 30 mg of graphene oxide, 30 mg of ascorbic acid and 30 g of distilled water, and stir for 30 min in a magnetic stirrer with a rotation speed of 500 rpm. Mix 0.1 g of polyacrylonitrile fibers weighed in the first step with the reduced graphene oxide aqueous solution, and after the polyacrylonitrile fibers are completely soaked, ultrasonically disperse for 20 minutes to obtain a pasty polyacrylonitrile / reduced graphene oxide dispersion.

[0029] In the third step, after sealing the polyacrylonitrile / reduced graphene oxide dispersion liquid obtained in the second step, put it into an oven with a temperature of 80° C. for hydrothermal treatment for 3 hou...

Embodiment 2

[0033] In the second step, the quality of graphene oxide was 15 mg, the quality of ascorbic acid was 15 mg, and the quality of polyacrylonitrile fiber was 0.3 g. All the other steps were the same as in Example 1.

Embodiment 3

[0035] The quality of graphene oxide in the second step is 180 mg, the quality of ascorbic acid is 180 mg, and the quality of polyacrylonitrile fiber is 0.1 g, and the rest of the steps are the same as in Example 1.

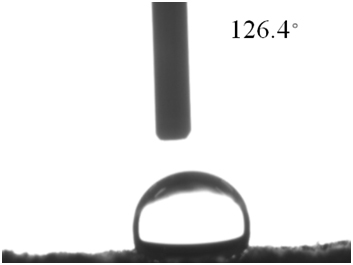

[0036] The contact angle photos of water droplets on the longitudinal surface of the adsorption material are as follows: Figure 4 shown. It can be seen from the figure that the addition of silane coupling agent can increase the water contact angle of the composite material to a certain extent, making the hydrophobic property of the material better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com