Patents

Literature

82results about How to "Good adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for adsorbing phosphorus pollutants in water by using waste residues in iron and steel industry

InactiveCN101973599AReduce concentrationGood adsorptionOther chemical processesWater/sewage treatment by sorptionRoom temperatureDistilled water

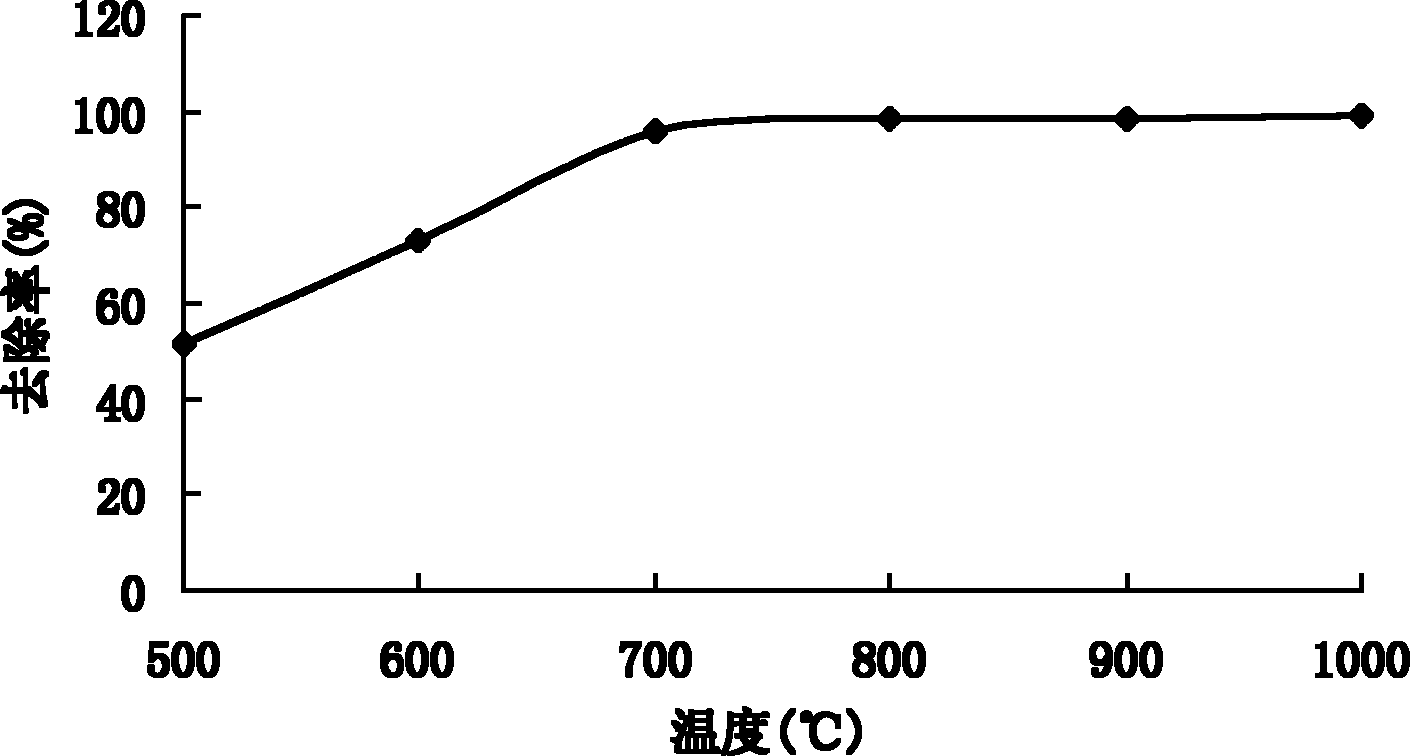

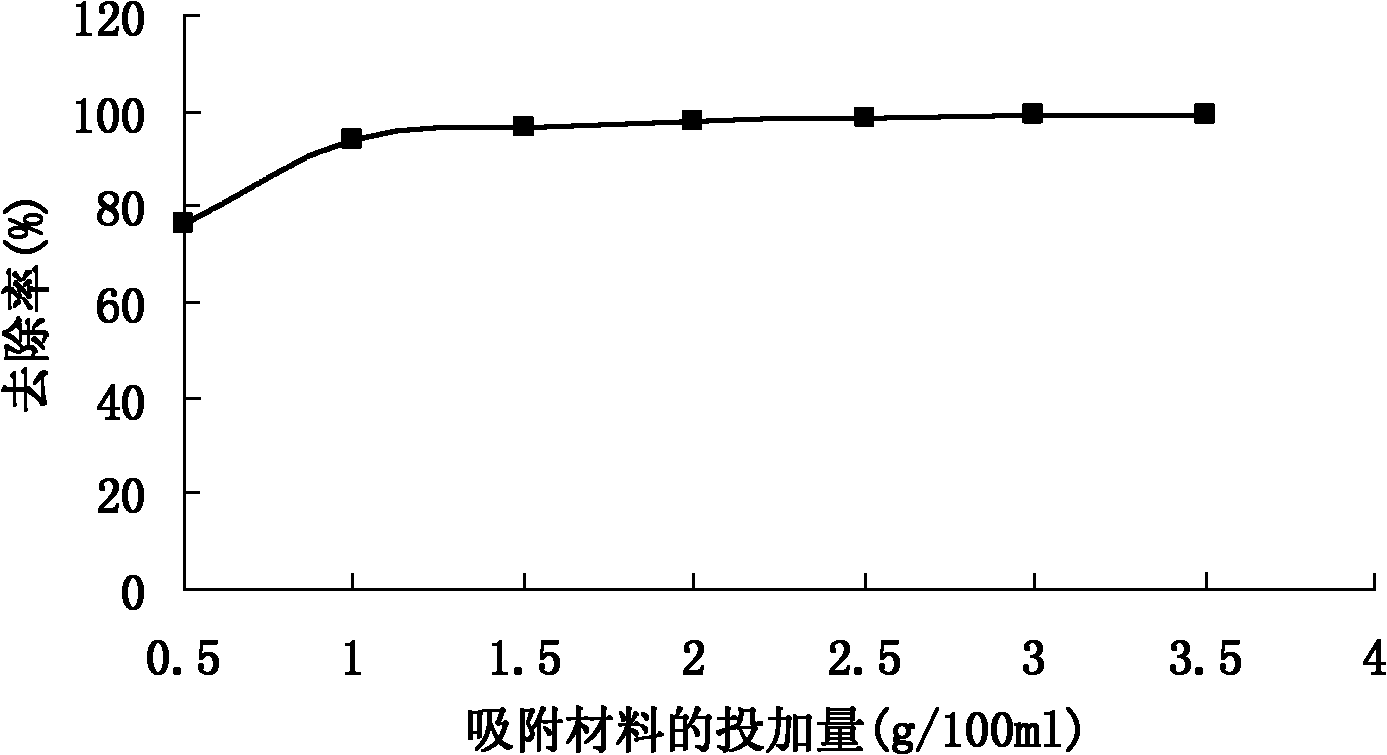

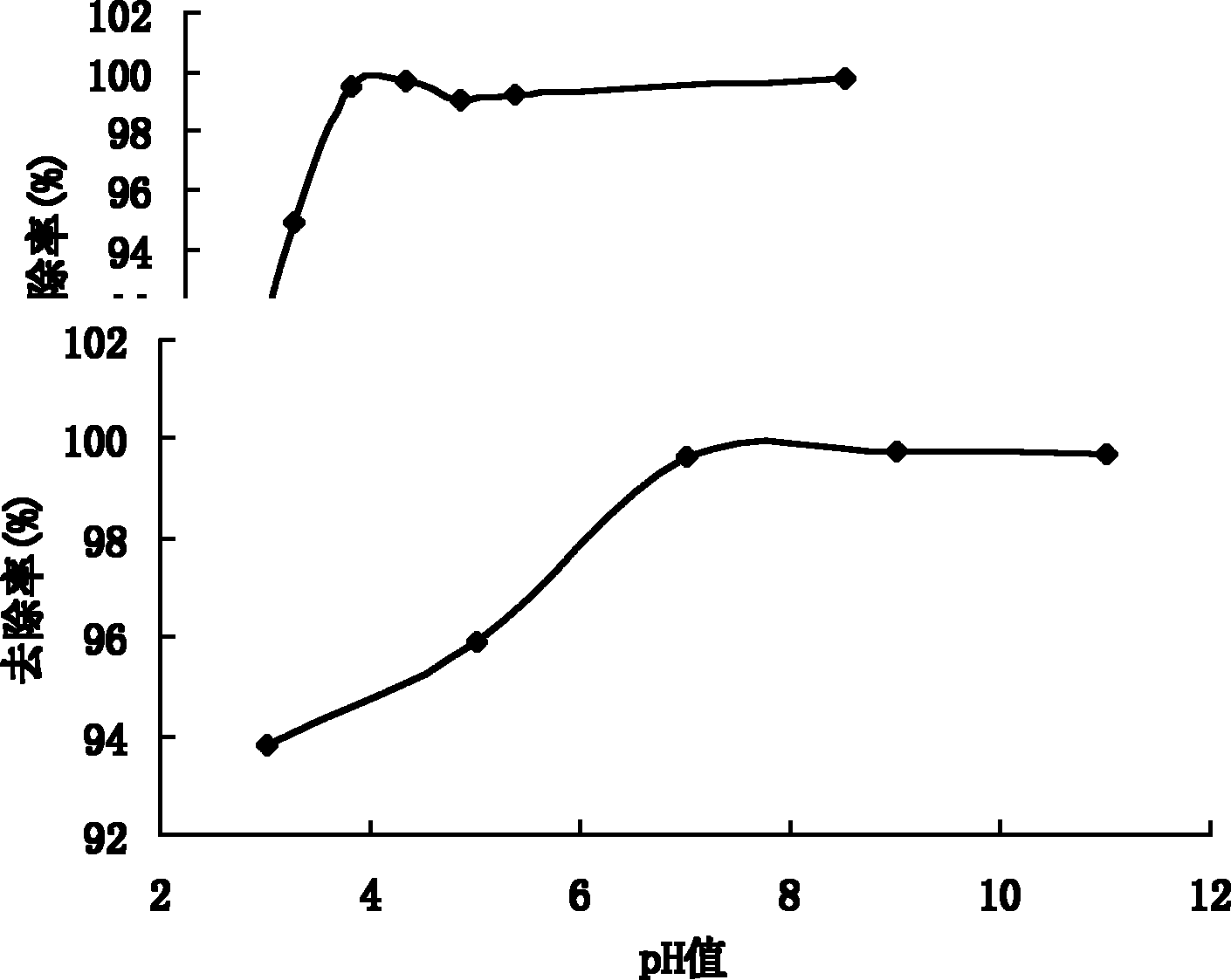

The invention relates to a method for adsorbing phosphorus pollutants in water, in particular a method for adsorbing phosphorus pollutants in water by using waste residues in the iron and steel industry. The method is characterized by comprising the following steps of: 1) crushing slag to 5 to 10 meshes, washing by using distilled water and drying for later use; grinding iron tailings to 200 meshes for later use; and mixing the following raw materials in percentage by mass: 45 to 55 percent of slag, 35 to 45 percent of iron tailings and 5 to 15 percent of binder so as to prepare a composite material for later use; 2) laying the composite material in a container, calcining in a high-temperature resistance furnace, raising the temperature to 100 DEG C at a speed of 4-8DEG C per minute, keeping the temperature for 60 minutes, raising the temperature to between 700 and 800 DEG C at a speed of 10-12DEG C per minute, keeping the temperature for 1 to 1.5 hours, and naturally cooling to room temperature so as to prepare an adsorbing material; and 3) adding the adsorbing material into wastewater with the phosphorus content of less than 30mg / L according to a ratio of 1-1.5g / 100mL, regulating the pH value of the wastewater to 7 to 9, and reacting with full mixing to remove over 98 percent of phosphorus from the wastewater. In the method, the waste residues in the iron and steel industry are better utilized to realize treatment of wastes with wastes, and the phosphorus-removing rate is high.

Owner:WUHAN UNIV OF TECH

Nitrous oxides gas adsorbing substance and preparation method thereof

InactiveCN101480603AHigh adsorption capacityGood adsorptionOther chemical processesDispersed particle separationAmount of substanceActive carbon

The invention relates to a gas adsorbent of nitrogen oxides and a preparing method thereof in the technical field of air pollution. The gas adsorbent of the nitrogen oxides comprises active carbon, alkaline substances and metallic oxides. The preparing method comprises surface active modification, solution impregnation and metal load which are combined for preparing the gas adsorbent of the nitrogen oxides. The obtained adsorbent has high adsorption rate, large adsorption capacity and long penetration time to the nitrogen oxides, the preparation cost is lower than that of the prior art, and the preparation process is simple.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

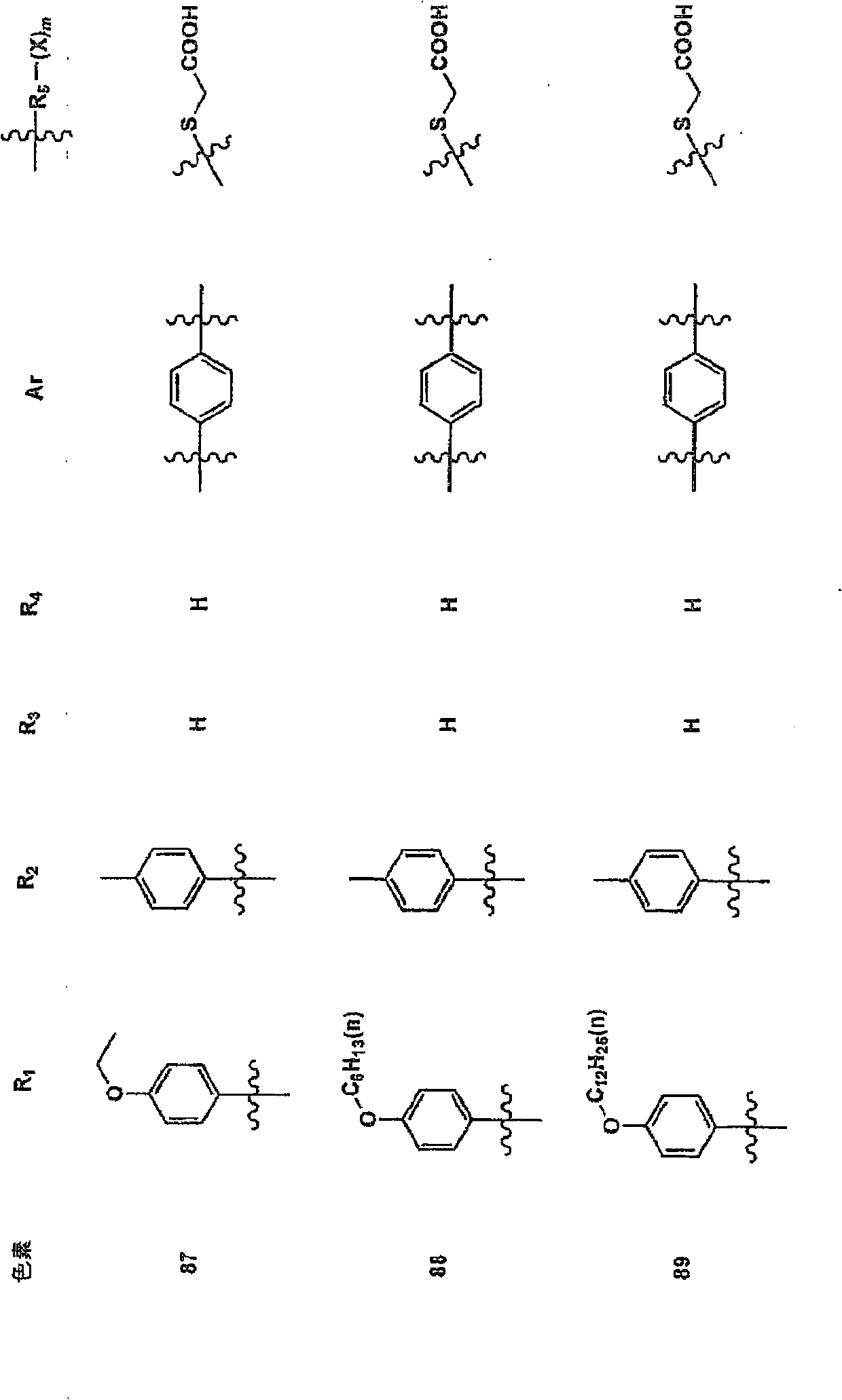

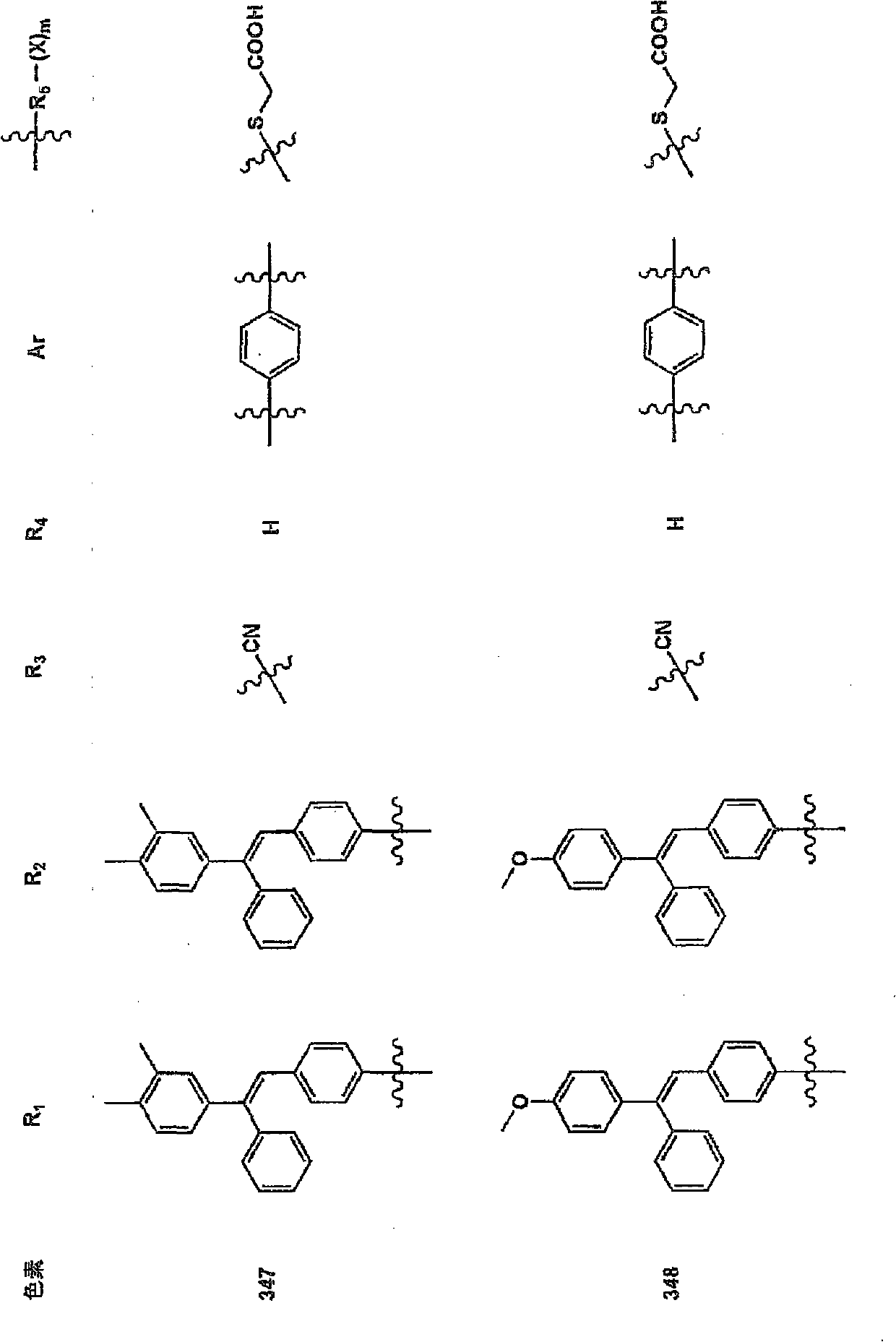

Photoelectric conversion element and solar cell

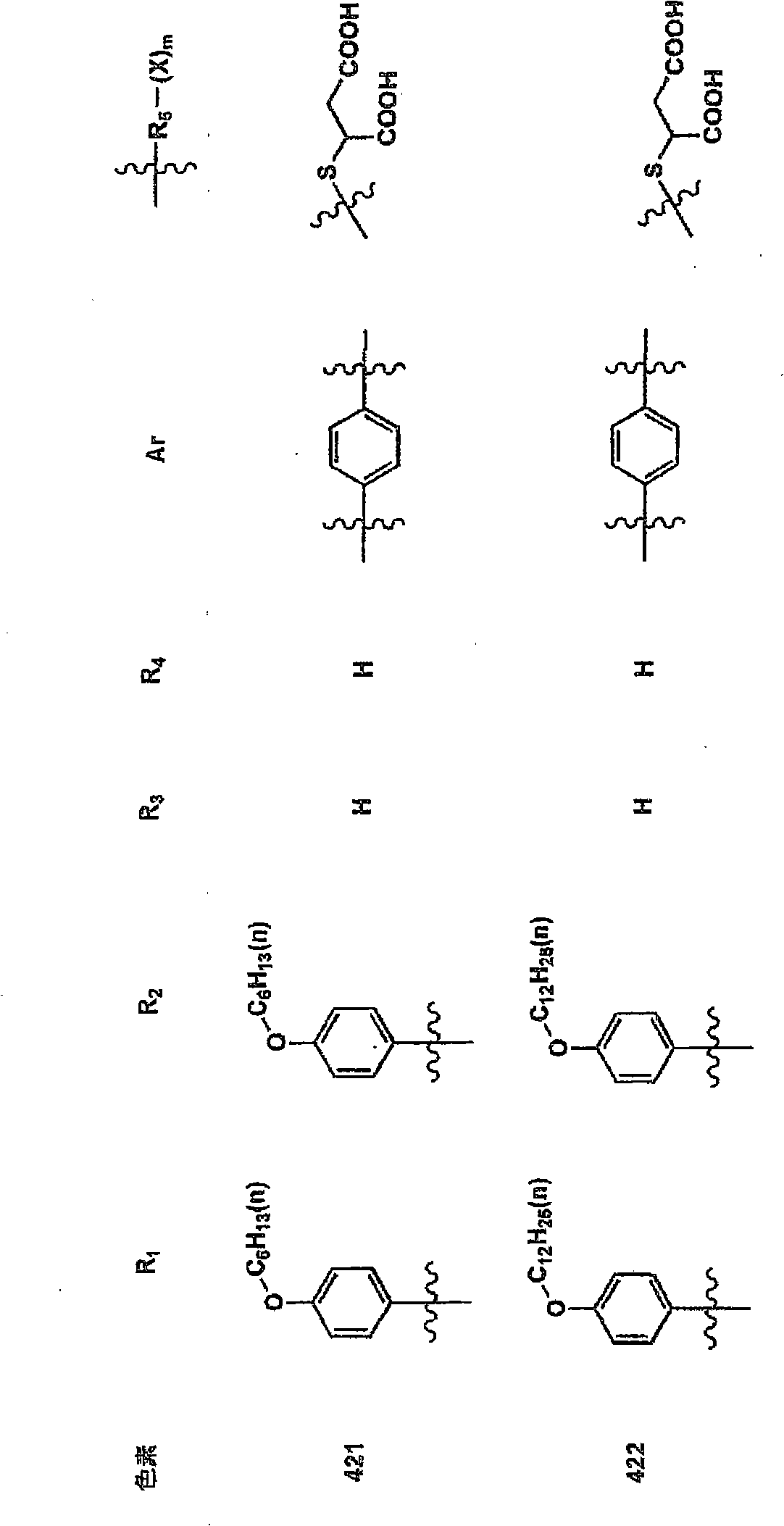

InactiveCN101867018AGood adsorptionImprove photoelectric conversion efficiencyStyryl dyesElectrolytic capacitorsOxide semiconductorEngineering

Owner:KONICA MINOLTA BUSINESS TECH INC

Attapulgite/polyacrylic acid nano compound gel containing sodium alginate and preparation method thereof

InactiveCN106633106AImprove stabilityGood adsorptionAerosol deliveryInorganic non-active ingredientsNitrogen gasPolyacrylic acid

The invention discloses attapulgite / polyacrylic acid nano compound gel containing sodium alginate and a preparation method thereof. The attapulgite / polyacrylic acid nano compound gel is characterized by being prepared from, by weight, 1-3 parts of sodium alginate, 5-10 parts of attapulgite, 1-2 parts of calcium carbonate, 15-20 parts of hydrochloric acid solution, 30-40 parts of zinc sulfate solution, a proper amount of absolute ethyl alcohol, 2-5 parts of silane coupling agent KH-570, 1-2 parts of bamboo fiber, 2-5 parts of silane coupling agent KH-550, 2-3 parts of chitosan, 0.4-1 part of cerium nitrate, 5-10 parts of acrylic acid, a proper amount of nitrogen and a proper amount of distilled water. The compound gel can be matched with added chitosan, is rich in amino, can provide amino to be grafted to the attapulgite, participate in crosslinking and enhance the stability of a network structure, and meanwhile the chitosan has very good absorbability and can increase the carrying-attaching amount of a carrier. By being matched with the added sodium alginate and the like, pore channels of the attapulgite are enriched, and the adsorption capacity is also enhanced.

Owner:ANHUI BOSHUO TECH

Method for recovering terramycin from terramycin production wastewater.

InactiveCN101781035AGood adsorption speedGood adsorptionOrganic chemistryWater contaminantsLiquid wasteHigh concentration

The invention relates to a method for recovering terramycin from terramycin c wastewater, in particular to a method for treating terramycin wastewater. The method comprises the following steps: first adjusting the PH value of the terramycin production wastewater and clarifying the wastewater by filtration; loading the absorption column with a hydrophilic zeolite molecular sieve (one of the 3A, 4A, 5A, 10 X, 13 X or Y types of molecular sieves); running the clarified terramycin wastewater through the absorption column, with the velocity of the flow between 1 to 12 BV / h under the temperature of 5-100 DEG C, the terramycin is absorbed by the absorption column; then desorbing the solution by alkali solution (Ammonia, sodium hydroxide solution or sodium carbonate solution) of 0.1 to 2.0 M under the temperature of 10 to 100 DEG C with the velocity of the flow between 1 to 4 BV / h to get high-concentration terramycin alkali solution; after the crystallization treatment, the crystal oxytetracycline dihyclorate obtained can directly be used as drug product. The recycle rate of the terramycin is 40-90 percent. The method of the invention is easy to operate and the zeolite molecular sieve can be repeatedly used. The treatment cost of the invention is lower than the treatment cost of methods of the same type. The method of the invention can be widely applied to recover terramycin from terramycin production wastewater.

Owner:TONGJI UNIV

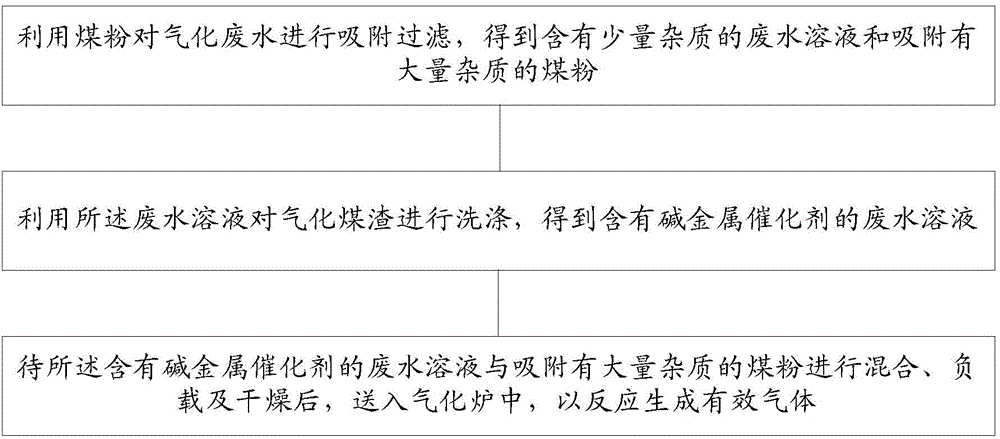

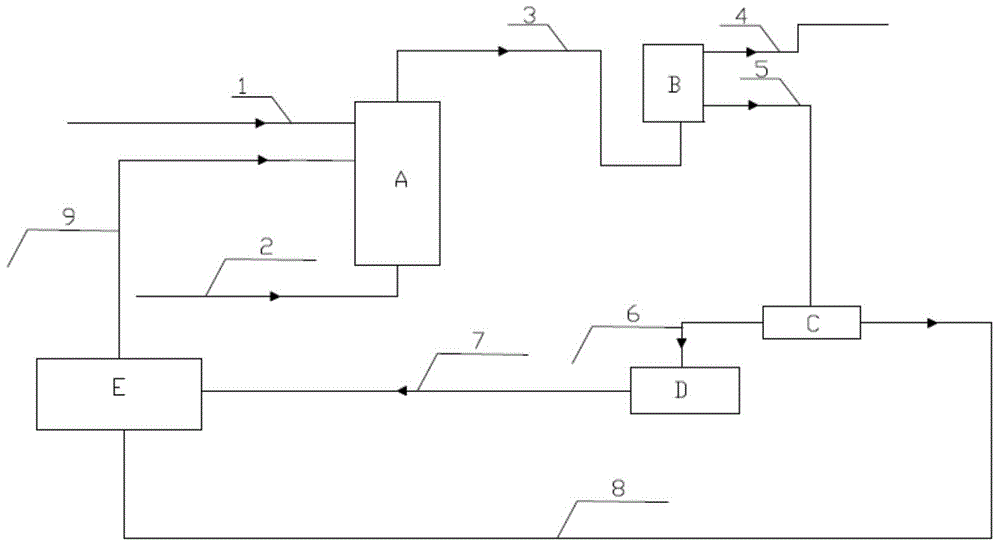

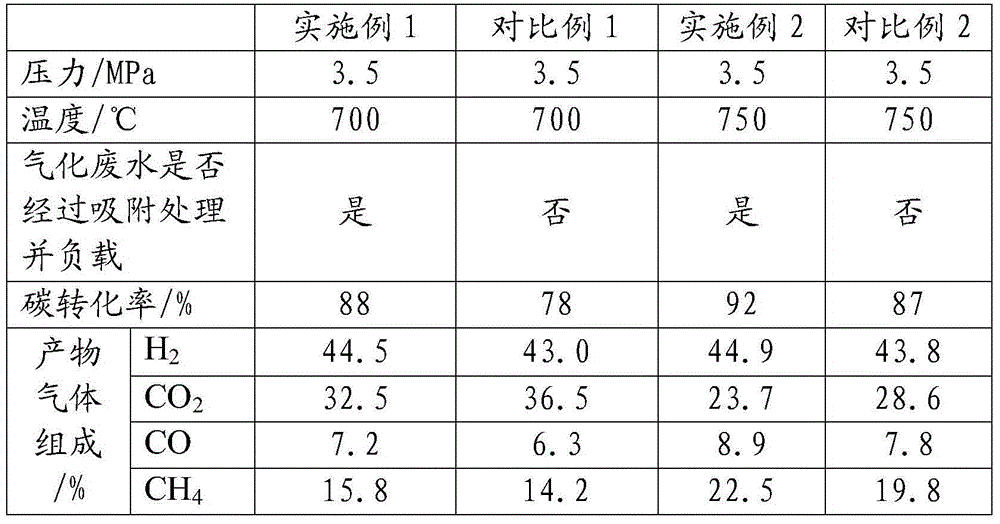

Coal gasification wastewater treatment method

ActiveCN104449859AGood adsorptionEliminate waste water treatment processGasification processes detailsMultistage water/sewage treatmentCoal wasteCinder

The embodiment of the invention provides a coal gasification wastewater treatment method, and belongs to the field of the treatment of coal gasification wastewater, so as to improve the overall efficiency of the coal gasification treatment. The coal gasification wastewater treatment method comprises the following steps: adsorbing and filtering the gasification wastewater by virtue of pulverized coal to obtain a wastewater solution containing few impurities and pulverized coal adsorbed with many impurities; washing gasification coal cinders by virtue of the wastewater solution to obtain a wastewater solution containing an alkali metal catalyst; mixing, loading and drying the wastewater solution containing the alkali metal catalyst and the pulverized coal containing many impurities, and feeding a mixture into a gasification furnace to generate effective gas through reaction. The treatment method disclosed by the invention is applicable to the treatment of the coal gasification wastewater.

Owner:ENN SCI & TECH DEV

Environment-friendly water purifying agent for aquaculture and preparation method thereof

InactiveCN108217782ALarger than the areaGood adsorptionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionChemistryAluminium salts

The invention discloses an environment-friendly water purifying agent for aquaculture. The environment-friendly water purifying agent is prepared from the following raw materials in parts by weight: 34-36 parts of aluminum potassium sulfate dodecahydrate, 20-22 parts of polydimethyl diallyl ammonium chloride, 18-22 parts of polyacrylamide, 14-16 parts of attapulgite, 12-16 parts of fly ash, 10-12parts of activated charcoal, 9-11 parts of nano-silica, 9-11 parts of nano-silicon oxide, 7-9 parts of nano-titania, 6-8 parts of chitosan, 5-7 parts of disodium edetate, 3-5 parts of graphene oxide,2-4 parts of aluminum sulfate and 1-3 parts of polymerized ferric sulfate. According to the environment-friendly water purifying agent for the aquaculture, provided by the invention, the water purifying agent is environmentally friendly and efficient, meanwhile, is good in water purifying effect, cannot cause secondary pollution and has a relatively high use value and a good application prospect.

Owner:HFEI PUBANG AGRI TECH CO LTD

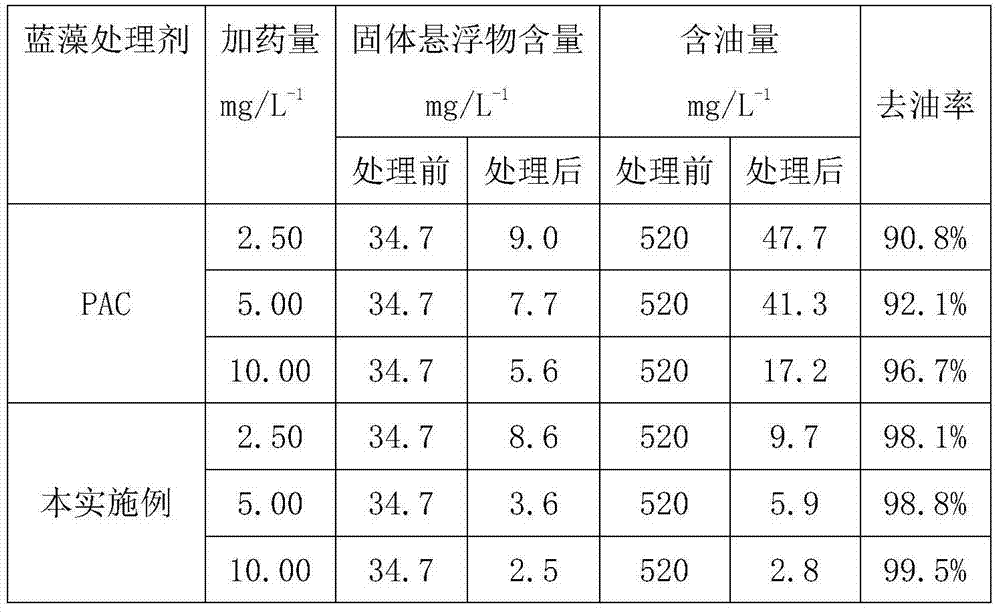

Sodium bentonite processing agent for blue-green algae and preparation method thereof

A sodium bentonite processing agent for blue-green algae is prepared from the following raw materials in parts by weight: 10-20 parts of serpentine, 40-45 parts of sodium-base bentonite, 2-3 parts of magnesium chloride, 8-13 parts of calcium chloride, 15-20 parts of potassium ferrate(VI), 12-16 parts of equisetum hyemale, 13-16 parts of pericarpium granati, 3-5 parts of polymaleic acid, 3-4 parts of sodium pyrophosphate, 2-3 parts of urea, 3-5 parts of anhydrous sodium sulfate, 3-5 parts of boric acid, 4-6 parts of polyvinyl alcohol, proper amount of water, and 3-4 parts of an adsorption auxiliary agent. By adding potassium ferrate(VI), the processing agent for blue-green algae has synergic effects of oxidation, adsorption, flocculating, precipitation, sterilization, disinfection, decoloring and deodoring, also does not generate any toxic and harmful substances, is capable of increasing water dissolved-oxygen content, has good removal effects on ammonia nitrogen, nitrites and algae in water, and is used to remove fulvic acid and suspensions in water and eutrophication phenomenon in fresh water. The processing agent for blue-green algae is good in dispersing suspending property and good in adsorption property, and can help to rapidly aggregate and salvage blue-green algae.

Owner:WUHU XIANGRONG FOOD

Flue gas adsorption desulfurizer and preparation method thereof

InactiveCN103736453ALarge specific surface areaGood adsorptionOther chemical processesDispersed particle separationPerliteChemistry

A flue gas adsorption desulfurizer is prepared from the following raw materials by weight: 100-120 parts of charcoal, 10-12 parts of zinc chloride, 30-35 parts of magnesium chloride, 20-24 parts of calcium oxide, 50-55 parts of attapulgite, 20-24 parts of straw, 3-4 parts of expandable graphite, 30-35 parts of expanded perlite, 30-35 parts of eclipta alba, 15-18 parts of raw radix astragali, 12-14 parts of peanut shells, 2-3 parts of glycerin, 2-3 parts of stearic acid polyoxyethylene ester, 4-5 parts of auxiliary agents, and a proper amount of water. By using plant raw materials such as straw and the like, through high temperature charring and processing with chemicals such as zinc chloride and the like, the desulfurizer of the invention is provided with a form with a developed pore structure and a large specific surface area, has high-efficient adsorption effect, also generates alkaline substances, and realizes high-efficient desulfurization; by using expandable graphite, expanded perlite and attapulgite, the desulfurizer of the invention has developed pores, and increased desulfurization capacity; the desulfurizer of the invention can also reduce the discharge of harmful gas such as flue dust, carbon monoxide, and the like, and reduce flue gas blackness.

Owner:WUHU ZHONGLU IND

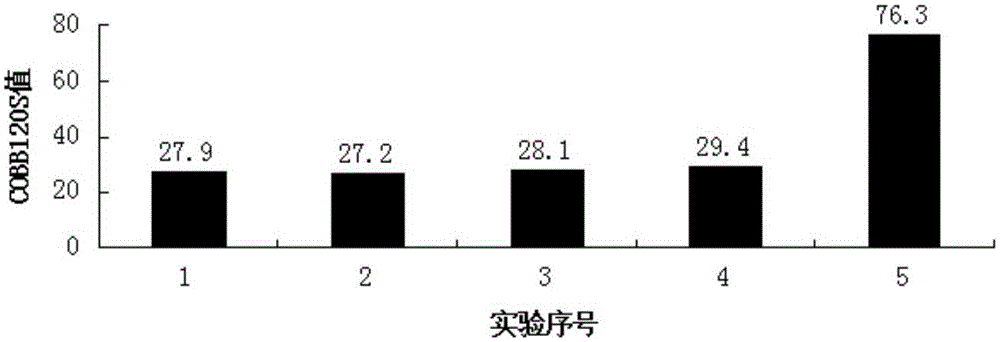

Preparation method for high-molecular surfactant

InactiveCN105085896AGood adsorptionReduce interfacial tensionWater-repelling agents additionEmulsionPolyacrylamide

The invention relates to a preparation method for a high-molecular surfactant. The method comprises the following steps: uniformly mixing sodium phosphate, polyacrylamide aqueous solution, diallyldimethylammonium chloride and water to form a mixture, wherein the mass ratio of the polyacrylamide aqueous solution to the cationic monomer is 20-5:1; heating the mixture obtained in the step 1 to 30-50 DEG C; dropwise adding cyclohexanone peroxide into the mixture obtained in the step 2; gradually heating the mixture obtained in the step 3 to 55-95 DEG C, and keeping warm at 55-95 DEG C for 4 h; and step 4, adding a cyclic ether compound into the system obtained in the step 4, keeping warm at 50-80 DEG C for 120-150 min, cooling to 20-25 DEG C, and discharging so as to obtain the high-molecular surfactant. The obtained high-molecular surfactant possesses extremely high activity, relatively high solid content and relatively good stability, and is applicable to preparation of alkyl ketene dimmers (AKD), alkenyl succinic anhydride (ASA) and other papermaking chemical emulsions.

Owner:TIANHE CHEM SUZHOU CO LTD

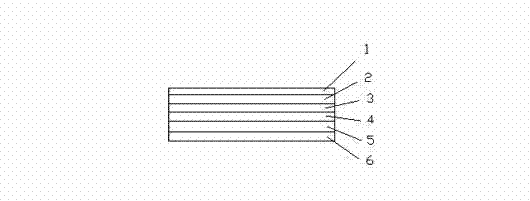

Novel antibacterial mask fabric

InactiveCN103203910AGood adsorptionGood sterilizationProtective garmentMetal layered productsRespiratorEngineering

The invention discloses a novel antibacterial mask fabric comprising an outer fabric layer. A first filtering adsorbent fiber layer is arranged on the inner surface of the outer fabric layer; a first antibacterial fabric layer is arranged on the inner surface of the first filtering adsorbent fiber layer; a second filtering adsorbent fiber layer is arranged on the inner surface of the first antibacterial fabric layer; a second antibacterial fabric layer is arranged on the inner surface of the second filtering adsorbent fiber layer; and an inner fabric layer is arranged on the inner surface of the second antibacterial fabric layer. According to the scheme, the novel antibacterial mask fabric has excellent filtering adsorbent property and brilliant antibacterial and bactericidal performances, and can meet requirements of masks used for various places.

Owner:范绍明

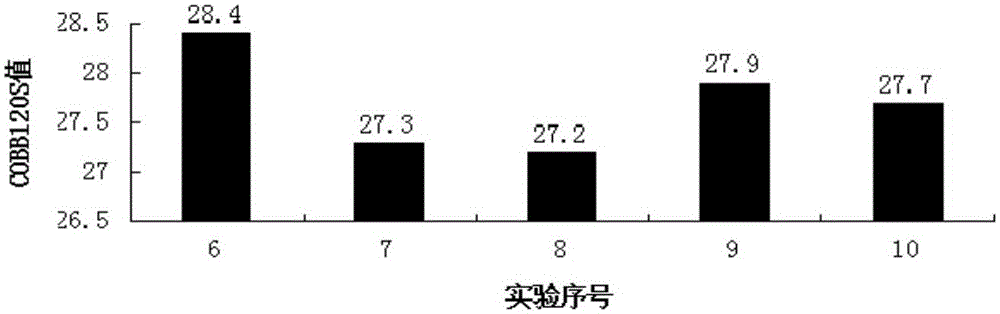

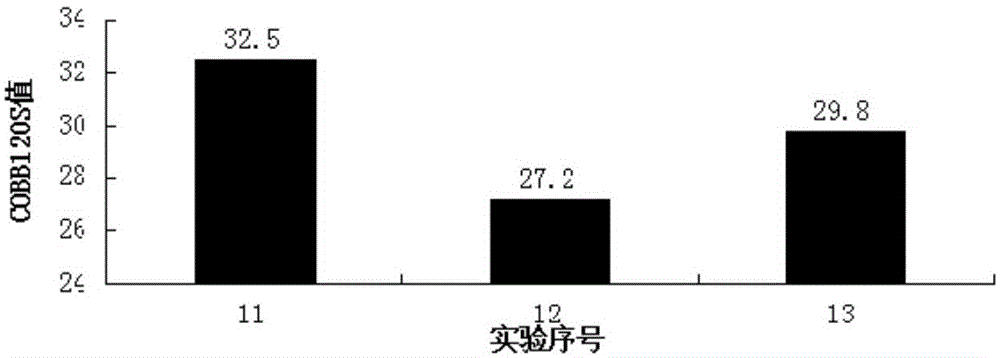

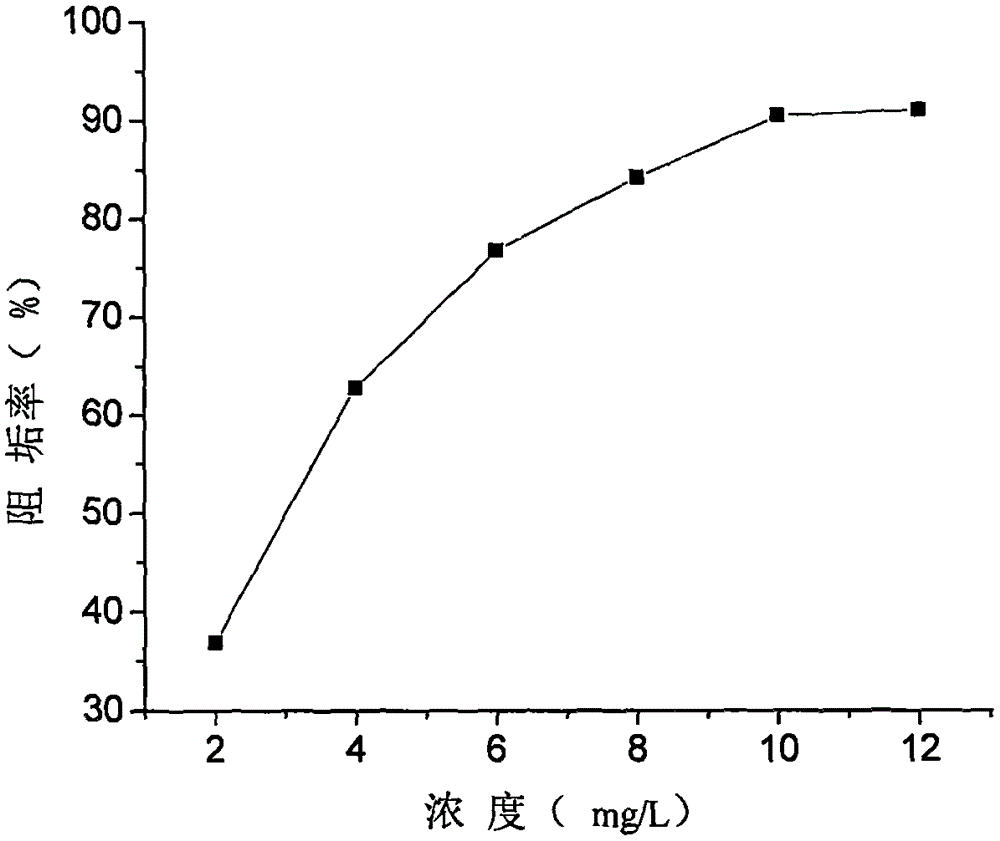

Preparation method for hyperbranched polycarboxylic acid polymer scale inhibitor

InactiveCN105820291ALarge specific surface areaGood adsorptionSpecific water treatment objectivesScale removal and water softeningIonIndustrial water treatment

The invention is a preparation method for a hyperbranched polycarboxylic acid polymer scale inhibitor. The scale inhibitor has good scale inhibition property for calcium carbonate, calcium phosphate, calcium sulfate, barium sulfate, strontium sulfate and so on, and has high tolerability for calcium ion. Moreover, the scale inhibitor has no affection on water quality, has characteristics of simple synthetic technology, small amount and the like, and can be used for processing industrial water with complex scale and high scale-forming ion concentration.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

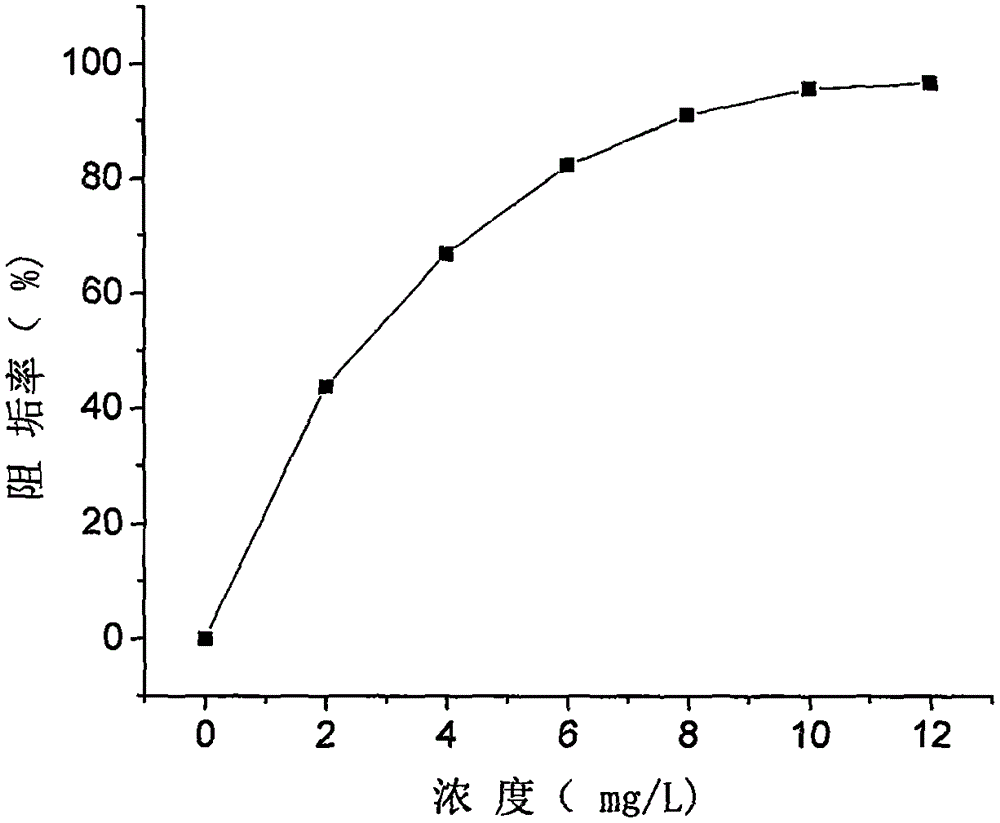

Preparation method and application of fly ash defluorination agent

InactiveCN108311095AGood adsorptionImprove adsorption efficiencyOther chemical processesWater contaminantsIndustrial wasteIon adsorption

The invention relates to the field of preparation of defluorination agents, and concretely relates to a preparation method and an application of a fly ash defluorination agent. The preparation methodof the fly ash defluorination agent comprises the following steps: fully mixing fly ash with clay; adding water, granulating the obtained mixture to prepare ceramsite, and drying the ceramsite; placing the dried ceramsite in a kiln, heating the kiln to 200-300 DEG C, keeping the temperature for 5-30 min, continuously heating the kiln to 950-1150 DEG C, keeping the temperature for 5-30 min, naturally cooling the obtained ceramsite, and taking out the ceramsite; and immersing the sintered ceramsite in an acid, alkali or salt solution, filtering the immersed ceramsite, and drying the filtered ceramsite to obtain the fly ash defluorination agent. The preparation method has the advantages of recycling of the industrial waste solid fly ash, low raw material cost and great social benefits. The fly ash defluorination agent has the advantages of good adsorptivity, high fluorine ion adsorption efficiency and large adsorption capacity. The fly ash defluorination agent can be used as an adsorbentfor a simple water treater, and can adsorb fluorine ions after being directly added to high-fluorine water and stirred.

Owner:XILINGOL VOCATIONAL COLLEGE

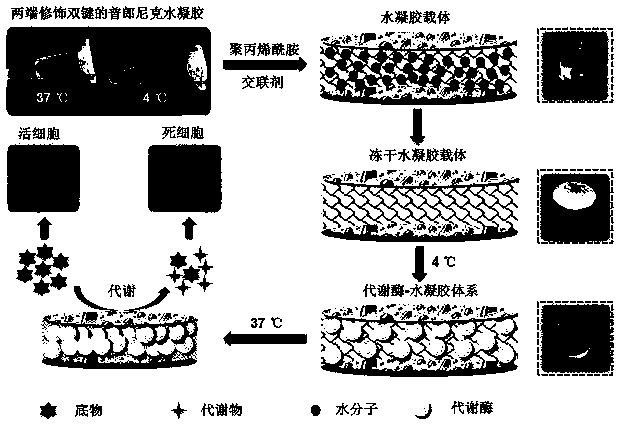

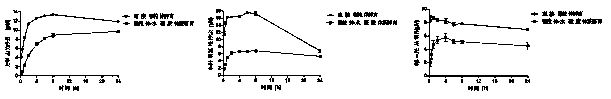

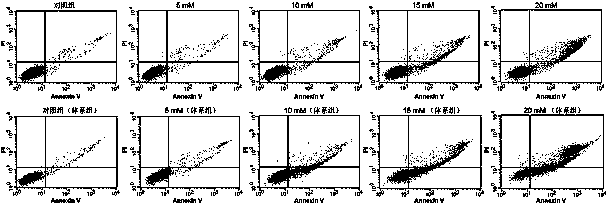

Metabolic enzyme-hydrogel system for drug metabolism, drug effect and toxicity evaluation

ActiveCN104342427AGood adsorptionSuitable mechanical strengthMicrobiological testing/measurementOn/in organic carrierProtein proteinDiamine

The invention belongs to the technical field of medicine, and relates to a metabolic enzyme-hydrogel system for drug metabolism, drug effect, and toxicity evaluation. The system is composed of drug metabolic enzymes and hydrogel carriers, wherein the drug metabolic enzymes are composed of protein macromolecules having metabolism functions such as microsomes, recombinant enzymes, and the like; and the hydrogel carriers are prepared by carrying out reactions among pluronics, amine acrylate, and diamine acrylate in the presence of a catalyst namely N,N,N',N'-tetramethyldiethylamine. The metabolic enzyme-hydrogel system is prepared by the following steps: subjecting the interlinked hydrogel carriers to pretreatments of cleaning and freeze-drying, and absorbing drug metabolism enzymes with controllable concentration by the hydrogel carriers so as to form the metabolism-hydrogel system. The metabolism enzyme-hydrogel system has the advantages of proper mechanical strength, non-toxicity, good repeatability, convenient operation, and thermal sensitivity, is capable of comprehensively predicting the effects of drugs and metabolic substances thereof on cells, and thus precisely evaluates the drug effect and toxicity of the drugs.

Owner:FUDAN UNIV

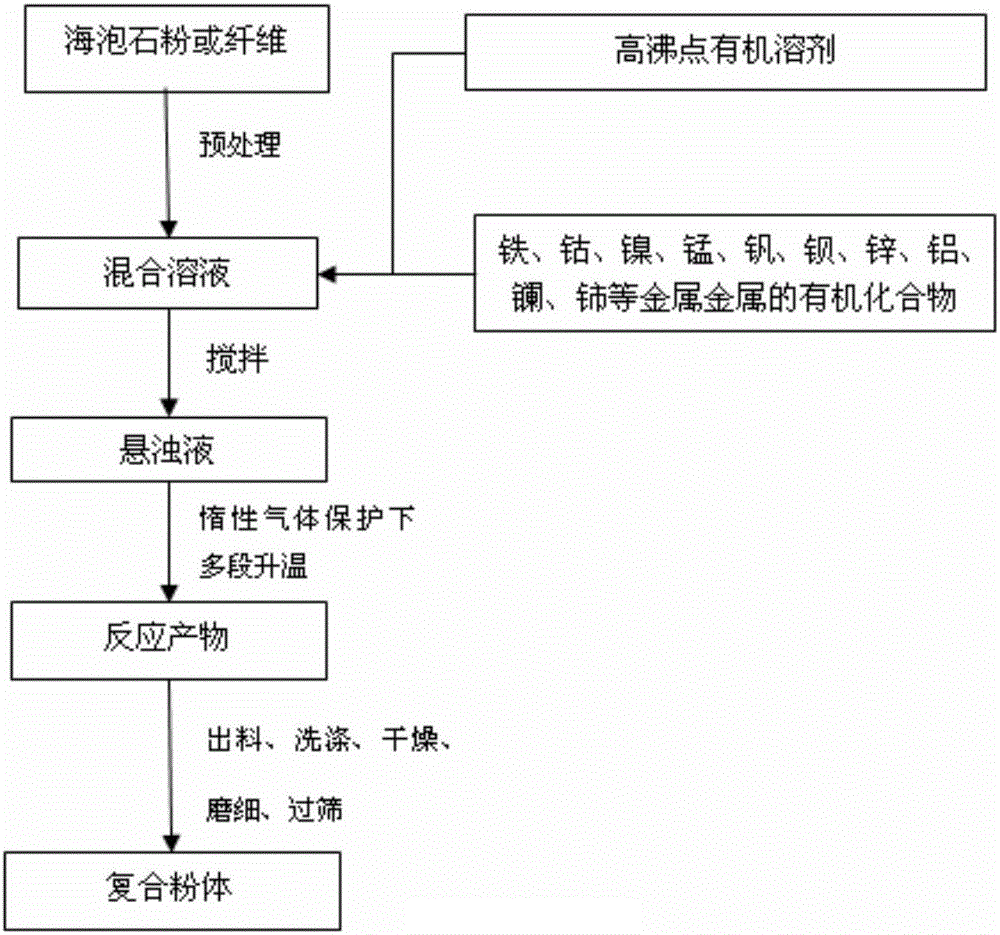

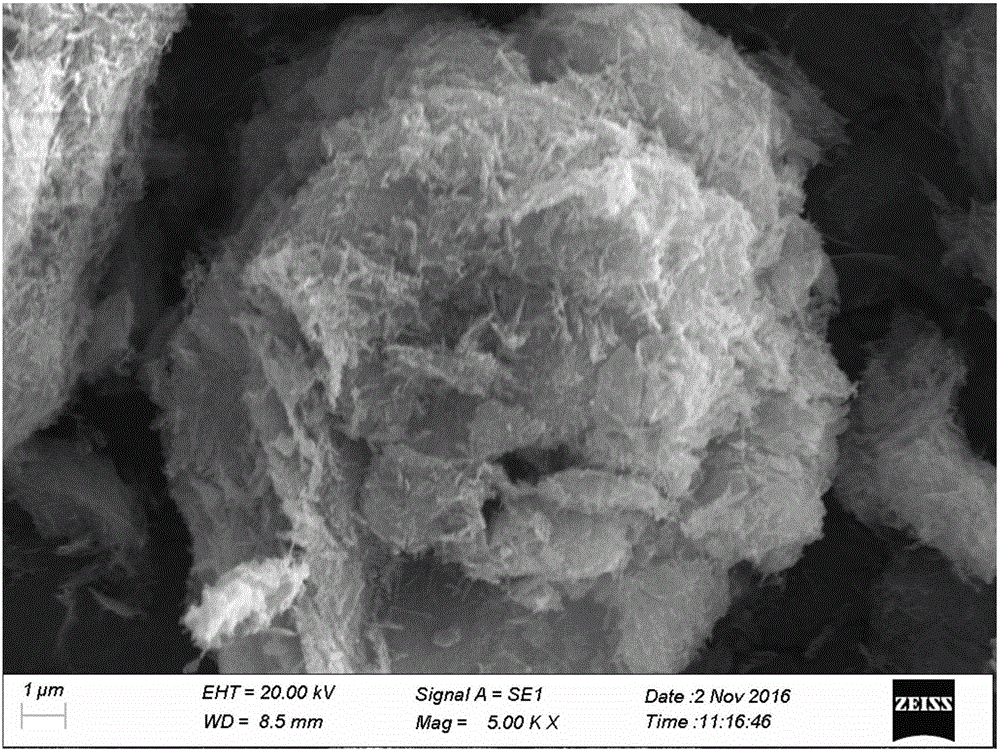

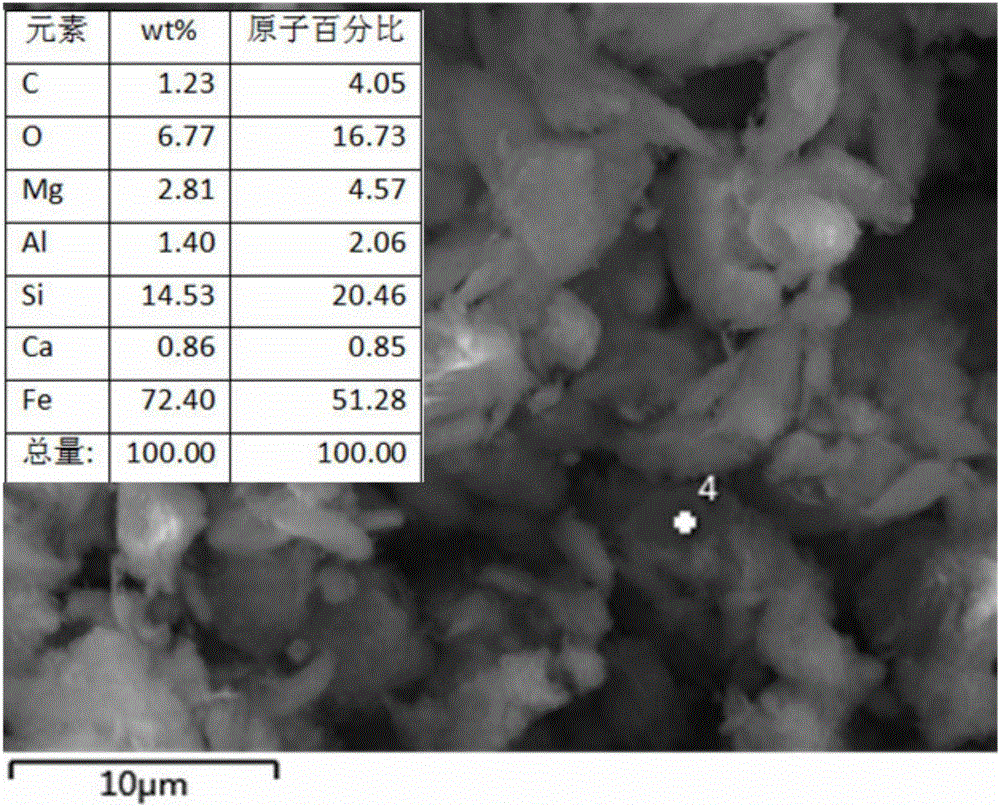

Preparing method for load magnetic metal sepiolite composite powder or fiber

ActiveCN106583752AGood adsorptionIncrease loadTransportation and packagingMetal-working apparatusSilane couplingSepiolite

The invention discloses a preparing method for load magnetic metal sepiolite composite powder or fiber. The method includes the steps that sepiolite powder or sepiolite fiber is fired or placed in a silane coupling agent to be soaked, and pretreated sepiolite powder or sepiolite fiber is obtained; and the pretreated sepiolite powder or sepiolite fiber is mixed with a magnetic metal organic matter solution, then the mixture is sealed in a reaction kettle to be subjected to a pyrolytic reaction, and the load magnetic metal sepiolite composite powder or fiber is obtained. Magnetic metal in the prepared composite material is evenly distributed in the surface or pores of sepiolite, the magnetic metal load is high, and the electromagnetic matching performance of the material can be adjusted according to the load and the metal ratio. The preparing method is simple in technology and low in cost, and large-scale production is facilitated.

Owner:CENT SOUTH UNIV

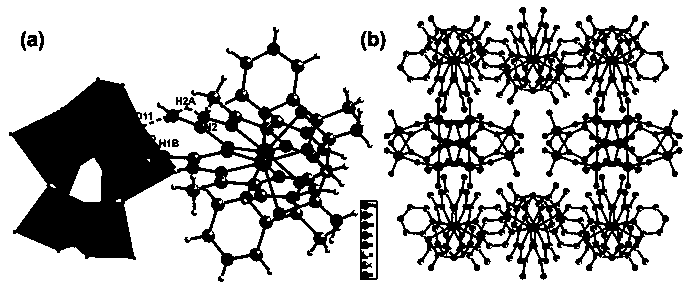

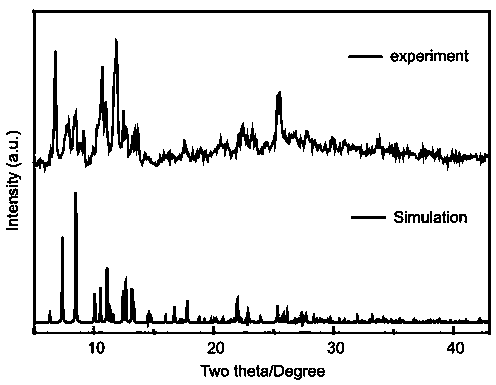

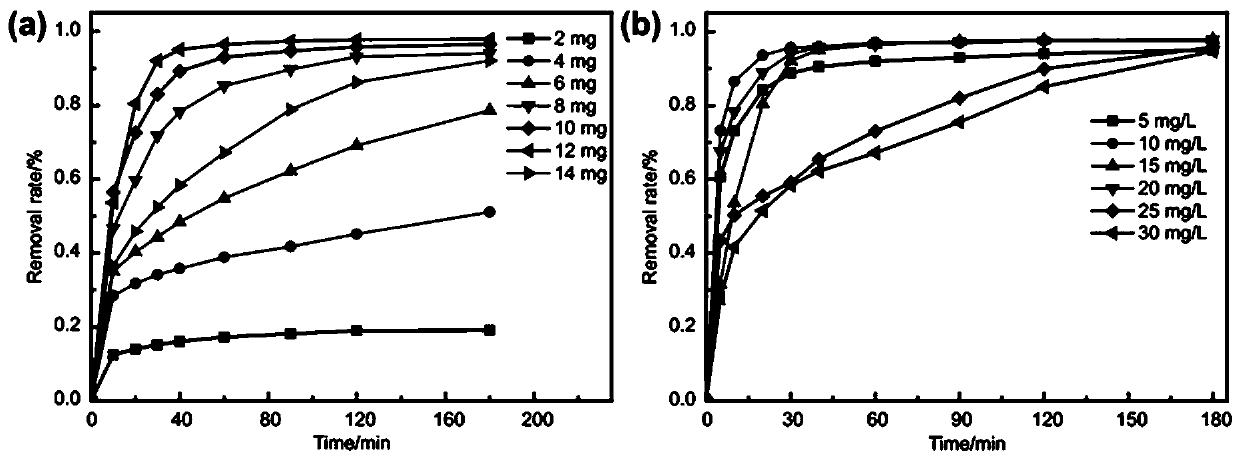

Polyacid complex, nanocomposite material containing same, and application of nanocomposite material in dye adsorption

InactiveCN110201640AAccurate understanding of structural featuresImprove adsorption capacityOther chemical processesWater contaminantsNanometreCell parameter

The invention relates to a polyacid complex. The chemical formula of the polyacid complex is [Ni(HL)2]2H2[P2Mo5O23].2H2O, wherein HL is 2-acetylpyrazine thiosemicarbazone. The polyacid complex belongsto the monoclinic crystal system, and has a C2 / c space group, and cell parameters are as follows: a = 3.0575(7) nm, b = 1.3276(3) nm, c = 1.7009(4) nm, alpha = 90 DEG, beta = 113.837 (5) DEG, and gamma = 90 DEG. The invention also provides a nanocomposite material containing the polyacid complex. The polyacid complex POMs with a good adsorption function is combined with magnetic Fe3O4 nanoparticles to form the magnetic nanocomposite material. The combination of the POMs and Fe3O4 nanoparticles makes the material have an increased adsorption efficiency and well achieve recycling under the action of an external magnetic field.

Owner:HENAN UNIVERSITY

First-tank flocculated-flow-preventing method used for aluminum-killed steel produced by using thin and medium slab continuous casting machine

The invention provides a first-tank flocculated-flow-preventing method used for aluminum-killed steel produced by using a thin and medium slab continuous casting machine. According to the invention, a first-tank desulphurization rate of an LF furnace is higher than 80%; weak argon stirring is adopted during a wire feeding process, a stirring time is controlled at 5-10min, and a calcium weight percentage in molten steel is no smaller than 0.0020%; a tundish baking temperature is no lower than 1100 DEG C; a submerged entry nozzle baking temperature is no lower than 1100 DEG C; a time interval since the tundish baking device is raised until casting is started is shorter than 5min; argon blowing operation is carried out before an upper nozzle is installed; before the tundish is cast, argon is delivered in, and reductive atmosphere in the tundish is maintained. With the method, inclusions can be well absorbed by top slag, and can sufficiently float, such that the generation of flocculated flow can be controlled. With the method, a first-tank flocculated flow occurrence rate when aluminum-killed steel produced by using the thin and medium slab continuous casting machine is treated by using the LF furnace is reduced from 50% to 2%; a casting interruption accident caused by flocculated flow is avoided; and the stability of a steelmaking production process is ensured.

Owner:ANGANG STEEL CO LTD

Manufacturing method of papermaking sewage type cationic polyacrylamide

The invention provides a manufacturing method of papermaking sewage type cationic polyacrylamide, which is characterized in that triggering systems A and B are added in acrylamide and cationic monomer mixed liquor respectively to react in a vertical reaction kettle and generate gel and cationic polyacrylamide product whose ionic degree is 20-30 percent, molecular weight is 8000-12000 thousands, and apparent viscosity is more than 40 cP. The positive effects of the manufacturing method are as follows: on the basis of previous research, the method is creatively adopted to obtain the cationic polyacrylamide product whose ionic degree is 20-30 percent; molecular weight is 8000-12000 thousands; and apparent viscosity is more than 40 cP; and the cationic polyacrylamide has the characters of good adsorbability, high purity, good stability, and is safe and healthy.

Owner:QINGDAO NATHAN FLOCCULANT

Method for preparing mesoporous material by non-surface activator process

InactiveCN101062773AGood adsorption performanceGood adsorptionMolecular sieve catalystsOther chemical processesIonChemistry

The invention discloses a preparing method of medium hole material with non-surface activator method, which comprises the following steps: mixing metyl group with hydrogen polysiloxane and alcohol; adding into NaOH; vigorous stirring; dipping into deionized water with equivoluminal metyl group hydrogen polysiloxane; stirring; adding into silicic acid carbethoxyl; vigorous stirring; strewing and aging; drying; getting solid; grinding to powder; washing with deionized water; drying; getting the product. This invention possesses medium phase of 3D worm-hole like pore path with the specific surface area in the range of 450-700m2 / g and hole volume in the range of 0. 4-1. 8cm3g-1.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

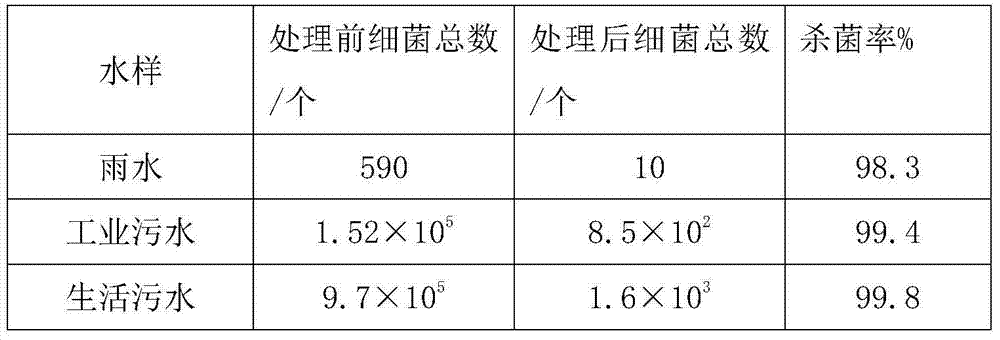

Alkaline detergent for fruit and vegetable and preparation method thereof

InactiveCN108102801AExcellent antibacterial and bactericidal propertiesGood adsorptionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPesticideAmmonium hydroxide

The invention discloses an alkaline detergent for fruit and vegetable and a preparation method thereof, and belongs to the technical field of daily chemical products. The alkaline detergent for fruitand vegetable comprises modified sepiolite, carbomer, sodium chloride, a surfactant, sodium bicarbonate, gellan gum and water, wherein the modified sepiolite is prepared by mixing and dispersing sepiolite powder and a magnesium nitrate solution to obtain a dispersing solution, reacting with ammonium hydroxide used as a precipitator, ageing, concentrating in a pressure reduction manner, cooling, filtering, drying and roasting; when preparing the detergent, carbomer, gellan gum and water are mixed; then sodium bicarbonate is added; pH is regulated; finally the modified sepiolite, sodium chlorideand the surfactant are added; and all materials are mixed and filled to obtain the alkaline detergent for fruit and vegetable. According to the technical scheme, the prepared alkaline detergent for fruit and vegetable has the characteristics of being outstanding in sterilizing and inhibiting bacteria, capable of removing pesticide, and obvious in cleaned fruit and vegetable storing stability by being compared with a traditional detergent for fruit and vegetable.

Owner:常州市瑞泰物资有限公司

Gas desulfurizer and preparation method thereof

InactiveCN103736370AGood adsorptionGood adhesionDispersed particle separationChemistryAluminium salts

A gas desulfurizer is prepared from the following raw materials by weight: 100-120 parts of bamboo charcoal, 30-34 parts of sodium phosphate, 3-4 parts of sodium dodecyl benzene sulfonate, 12-14 parts of sodium montmorillonite, 3-4 parts of aluminum sulfate, 8-10 parts of sodium metasilicate, 28-40 parts of edible mushroom culture materials, 20-24 parts of dandelions, 10-12 parts of chrysanthemum, 3-4 parts of sodium dodecyl sulfate, 4-5 parts of auxiliary agents, and a proper amount of water. By using edible mushroom culture materials, dandelions and chrysanthemum to process active carbon, the desulfurizer of the invention not only can adsorb sulfur, carbon, black smoke and the like, but also is environment-friendly, energy-saving, and antibacterial; by using sodium montmorillonite, the desulfurizer of the invention is good in adsorptivity, good in caking property, and good in catalysis, and saves active carbon; by using sodium phosphate and sodium metasilicate, the desulfurizer of the invention can realize rapid desulfurization; The desulfurizer of the invention is suitable for desulfurization and decarburization of natural gas, flue gas and the like.

Owner:WUHU ZHONGLU IND

Method for preparing composite fixed phase-change energy-accumulation material

The invention discloses a method for preparing a composite fixed phase-change energy-accumulation material. The method comprises the following steps: dissolving calcium nitrate and diammonium hydrogen phosphate respectively in deionized water, then performing mixing and stirring, adjusting the pH value by ammonia water, continuing to stir, and performing aging, suction filtration, drying and grinding so as to prepare hydroxyapatite powder as a support material; adding the hydroxyapatite powder and a phase-change material which has good compatibility with the hydroxyapatite powder into corresponding solvent deionized water or absolute ethyl alcohol respectively in a certain mass ratio, uniformly stirring, mixing the two solutions, uniformly stirring, drying, and grinding, thereby obtaining the composite fixed phase-change energy-accumulation material. The composite fixed phase-change energy-accumulation material is a novel phase-change energy-accumulation material, overcomes the defects that a conventional support material is high in cost, small in amount of accumulation phase-change material, low in heat conduction coefficient and serious in the influence on ambient environment, meets requirements of green chemicals, and has relatively wide prospects.

Owner:GUANGDONG YIHUA TIMBER IND +1

Use of polypyrrole composite fibers in viral adsorption

InactiveCN101804334AGood adsorptionSave materialOther chemical processesDeodrantsIn situ polymerizationAbsorption effect

The invention discloses polypyrrole composite fibers, relates to the use of the polypyrrole composite fibers in viral adsorption and belongs to the field of the use of functional fibers. Firstly, positive charges are introduced into fibers by an in-situ polymerization technique, so that the polypyrrole composite fibers have rich positive charges; and based on the principle that positive and negative charges attract mutually, viruses having negative charges are absorbed. The polypyrrole composite fibers have the advantages of no environmental and spatial limitation in use, cheap and readily available raw materials, simple production operation, light pollution, low cost, obvious virus absorption effect and good development and application prospects.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

Preparation method of curing agent applicable to sandy soil

InactiveCN105925271AImprove adsorption capacityHigh bonding strengthOther chemical processesOrganic fertilisersRoom temperatureFirming agent

The invention discloses a preparation method of a curing agent applicable to sandy soil, and belongs to the technical field of environmental protection engineering. The preparation method is characterized by comprising the following steps that 1, sodium carboxy methylcellulose and water are subjected to stirring and dissolving according to the mass ratio of 1:20, and a sodium carboxy methylcellulose solution is obtained; 2, anionic polyacrylamide and water are subjected to stirring and dissolving according to the mass ratio of 1:100, and an anionic polyacrylamide solution is obtained; 3, ferrous chloride and water are subjected to stirring and dissolving according to the mass ratio of 1:50, and a ferrous chloride solution is obtained; 4, under the room temperature condition, the sodium carboxy methylcellulose solution, the anionic polyacrylamide solution and the ferrous chloride solution are sequentially added into water for mixing and prepared into the curing agent. The curing agent has the advantage of being high in adsorption and cementation, inner pores of soil particles can be filled with the curing agent mixed with the sandy soil, the mixture serves as natural cement of the soil, the cured sand particles are not prone to disperse, and the sand fixation and anti-wind capability are high.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

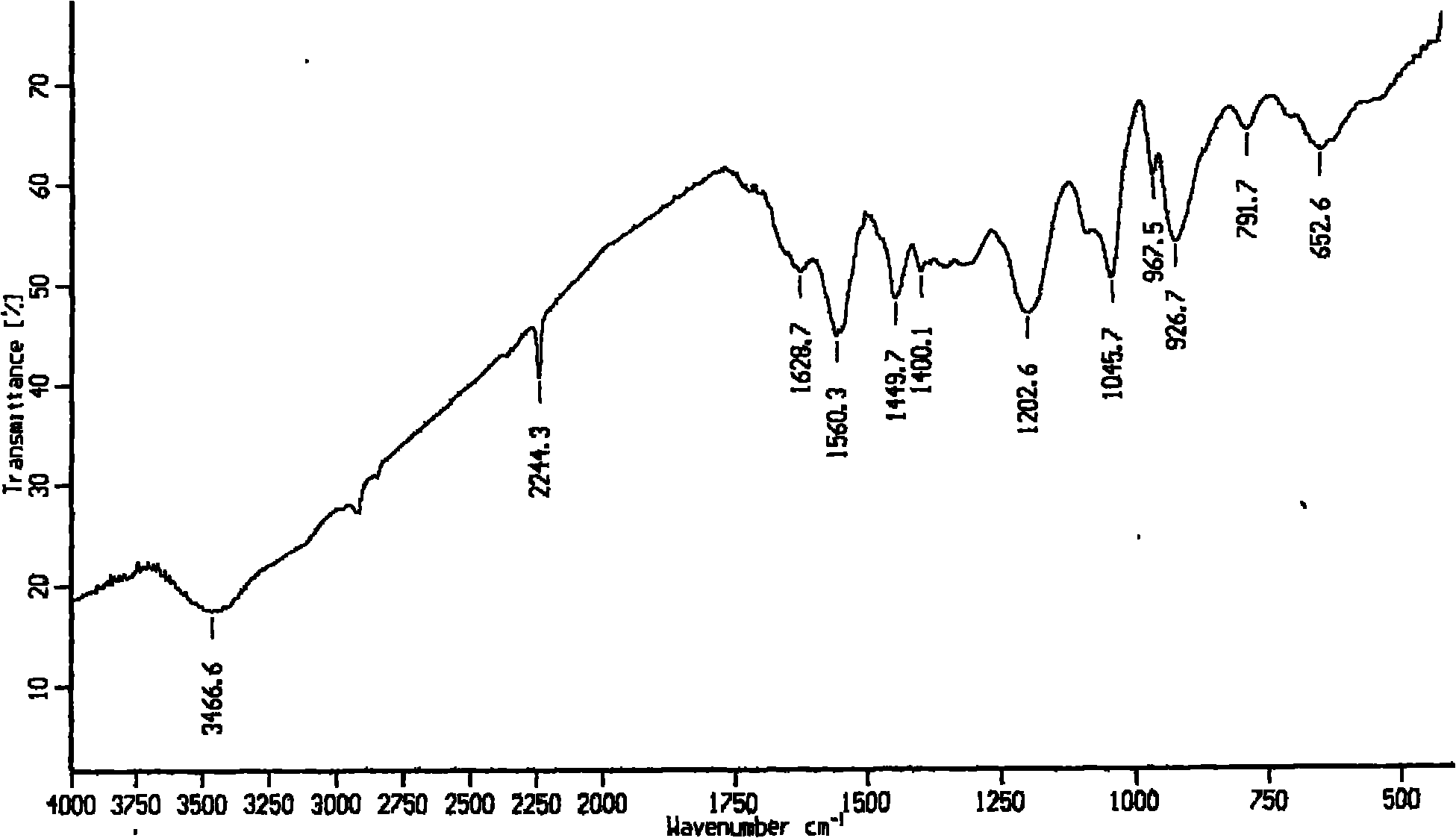

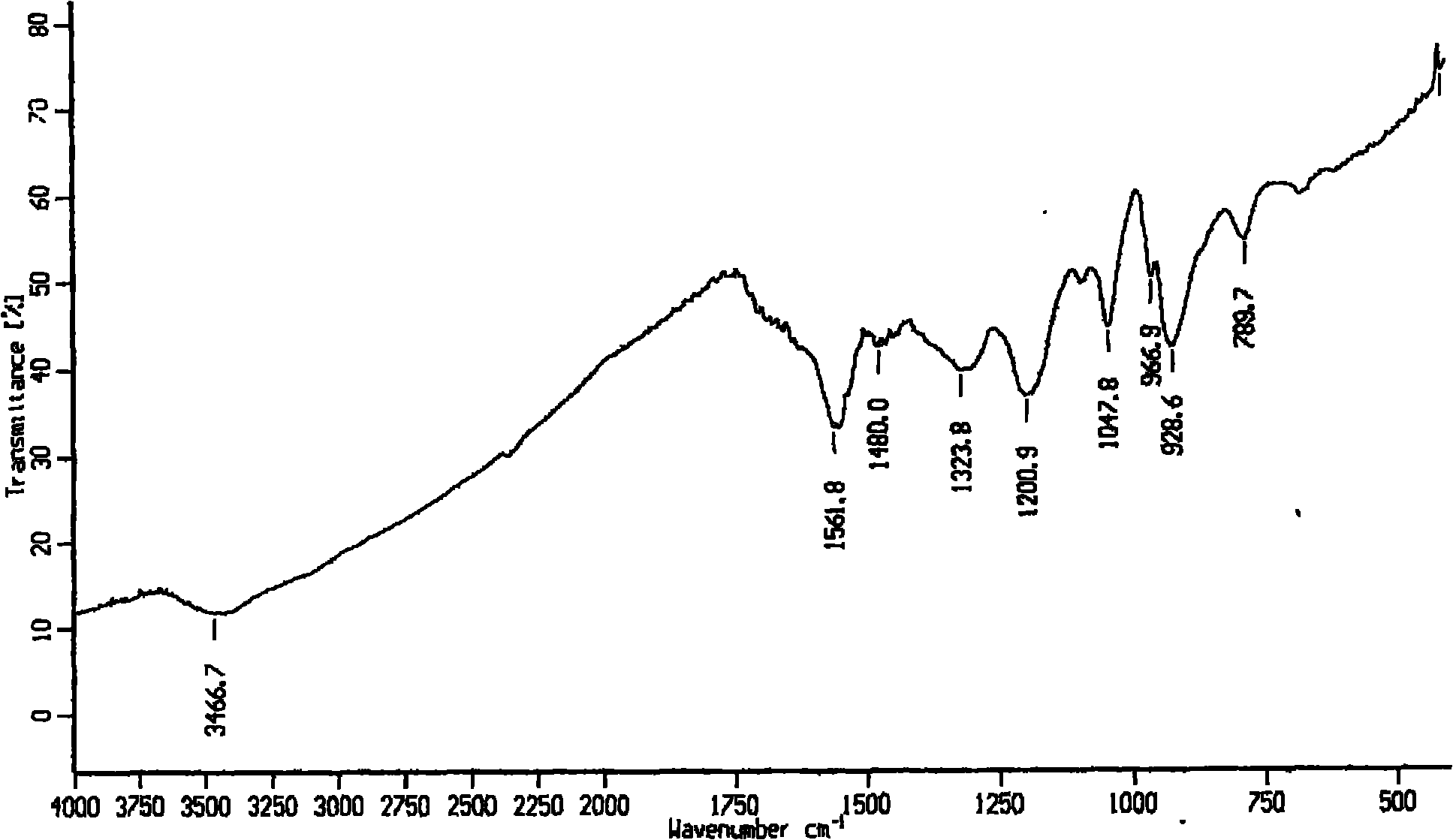

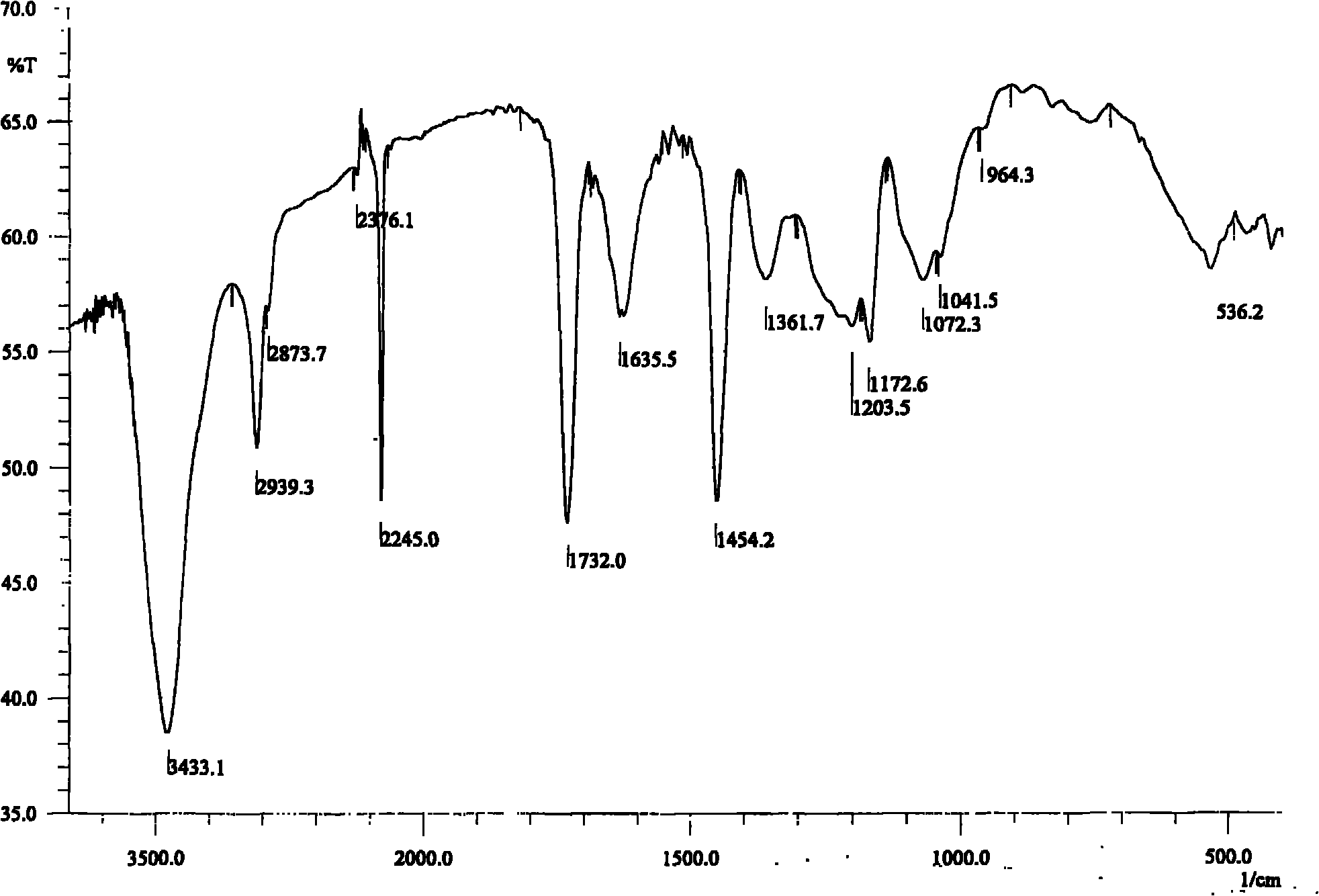

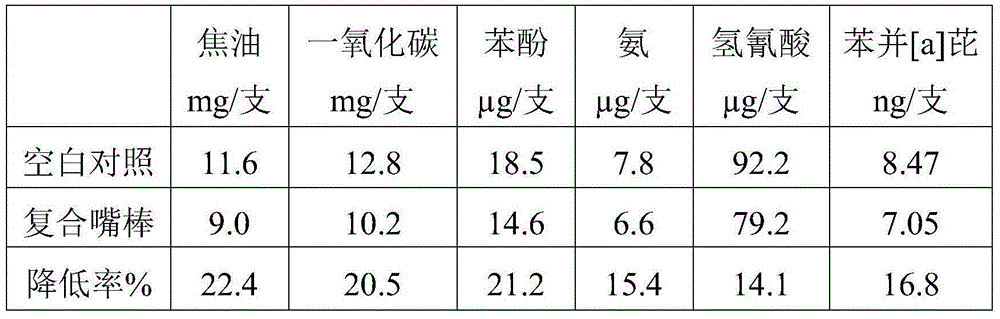

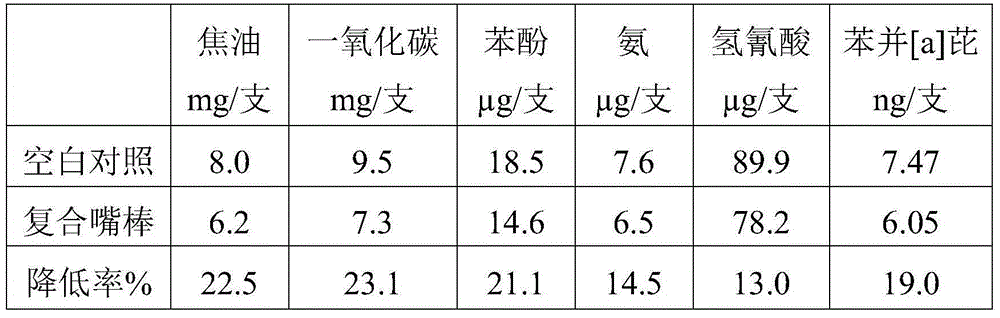

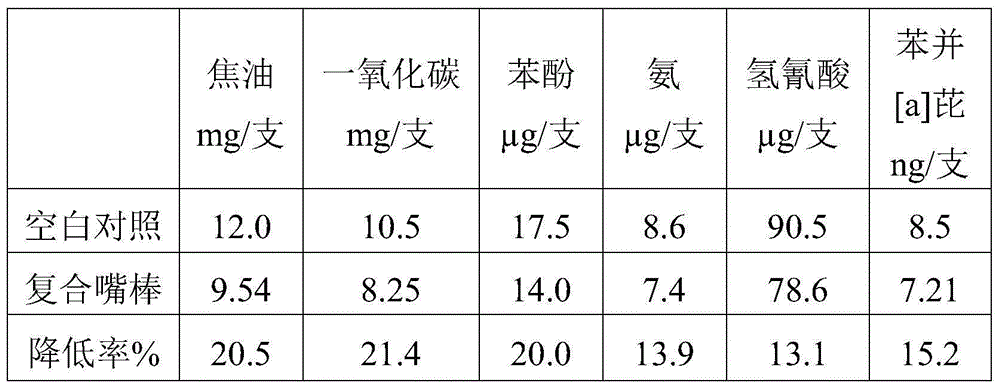

Carbon-doped nano-titanium dioxide adsorbing material for reducing harmful components of cigarettes

InactiveCN105032344AImprove securityGood adsorptionOther chemical processesTobacco smoke filtersCarbon dopedPhenols

A carbon-doped nano-titanium dioxide adsorbing material for reducing harmful components of cigarettes, designed by the invention, is prepared through the following steps: (1) preparing nano-carbon sol; (2) diluting tetrabutyl titanate with ethyl alcohol, dropwise adding iminodiacetic acid, adjusting and controlling the pH value of the solution, and stirring the obtained mixture; (3) dropwise adding the carbon sol solution diluted with ethyl alcohol into the mixture in the step (2), stirring, flushing the obtained new mixture with ethyl alcohol and water, and after removing the sediment, placing in a vacuum drying oven for drying, so as to obtain carbon-doped titanium dioxide gel; (4) heating the carbon-doped titanium dioxide gel for calcination to obtain the carbon-doped nano-titanium dioxide adsorbing material. The adsorbing material can be used for reducing harmful components of cigarette smoke, has a relatively high adsorption capacity, can effectively reduce harmful substances like carbon monoxide, ammonia and phenol in cigarette smoke, and is simple in the preparation process, less in material utilization amount and low in cost.

Owner:HUBEI CHINA TOBACCO IND

Stabilized lead-polluted soil restoration method

ActiveCN107282626AGood adsorptionImprove the stabilization effectContaminated soil reclamationTripolyphosphataseRisk Control

The invention discloses a stabilized lead-polluted soil restoration method and belongs to the field of heavy metal polluted soil restoration. Soluble tripolyphosphate and pyridinedicarboxylic acid modified sepiolite are mixed to prepare a compound stabilizer, the compound stabilizer is added in lead-polluted soil, even mixing is performed, a chlorine salt analysis agent solution is sprayed onto the polluted soil, then anaerobic curing is performed, and the polluted soil can meet the risk control requirement after stabilization. The lead contained in the soil can be firmly fixed in the soil through analysis, activation, precipitation, adsorption and other principles, and the migration capability and bioavailability of the lead are reduced.

Owner:爱土工程环境科技有限公司 +1

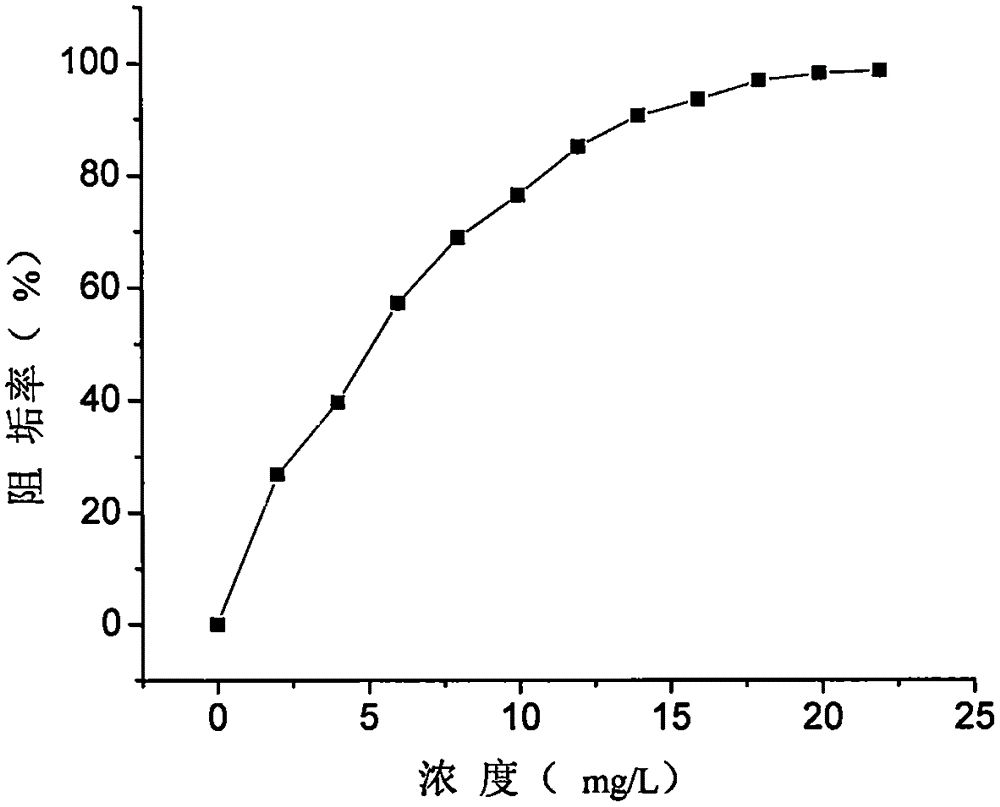

Waste water treating agent and application thereof

InactiveCN106379955AAbundant resourcesGood adsorptionWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationActivated carbonAluminium salts

The invention provides a waste water treating agent and an application thereof. The waste water treating agent mainly comprises the following ingredients in parts by weight: 20 to 30 parts by weight of chitosan, 10 to 15 parts by weight of ferric chloride, 5 to 10 parts by weight of activated carbon, 10 to 20 parts by weight of carbon nanofibers, 1 to 4 parts by weight of nano-silver, 5 to 8 parts by weight of silica gel and 1 to 5 parts by weight of aluminum sulfate. When the waste water treating agent is applied to waste water processing, when a dosage is 200mg / L, a waste water turbidity removal rate can reach to 98% or more, a total phosphorus removal rate can reach to 90% or more, a COD (Chemical Oxygen Demand) removal rate is 38% or more, and a BOD (Biological Oxygen Demand) removal rate is 80% or more. In addition, the waste water treating agent provided by the invention has the advantages of abundant raw material sources, low cost and good market application prospect.

Owner:过冬

Treatment method for dyeing wastewater of natural dye

ActiveCN106007061AGood flocculationGood adsorptionMultistage water/sewage treatmentDyeing processNatural fiberActivated carbon

The invention provides a treatment method for dyeing wastewater of natural dye. According to the method, the wastewater does not need to be decolored, all that is required is to add a little natural fiber fabric waste and a few of flocculating agents, and the wastewater can be treated through activated carbon. The treatment method can be repeatedly used for a printing and dyeing process, a large quantity of wastewater treating agents are saved, the treatment time is short in the whole process, and the cost is low.

Owner:湖州新嘉怡丝织印花有限公司

Attapulgite-polyacrylic acid nanocomposite gel with high adsorptivity and preparation method thereof

InactiveCN106582564AImprove stabilityGood adsorptionOther chemical processesAlkali metal oxides/hydroxidesChemistryNitrogen gas

The invention discloses attapulgite-polyacrylic acid nanocomposite gel with the high adsorptivity and a preparation method thereof. The attapulgite-polyacrylic acid nanocomposite gel is characterized by being prepared from, by weight, 2-4 parts of nano-zeolite powder, 5-10 parts of attapulgite, 1-2 parts of silicon dioxide, 15-20 parts of a hydrochloric acid solution, 30-40 parts of a zinc sulfate solution, an appropriate amount of absolute ethyl alcohol, 1-3 parts of nylon fibers, 2-5 parts of a silane coupling agent KH-570, 2-5 parts of a silane coupling agent KH-550, 2-3 parts of chitosan, 0.4-1 part of cerous nitrate, 5-10 parts of acrylic acid, an appropriate amount of nitrogen and an appropriate amount of distilled water. According to the attapulgite-polyacrylic acid nanocomposite gel with the high adsorptivity and the preparation method thereof, chitosan added in a cooperative mode is rich in amino groups, and therefore not only can the amino groups be provided to be grafted on attapulgite to participate in crosslinking to enhance the stability of the network structure of the gel, but also the carrier adsorption amount of carriers can be increased due to the fact that chitosan has the very good adsorptivity; by adding the nano-zeolite powder and the like in a cooperative mode, the advantages of being good in adsorption performance and high in strength are given to the material.

Owner:ANHUI BOSHUO TECH

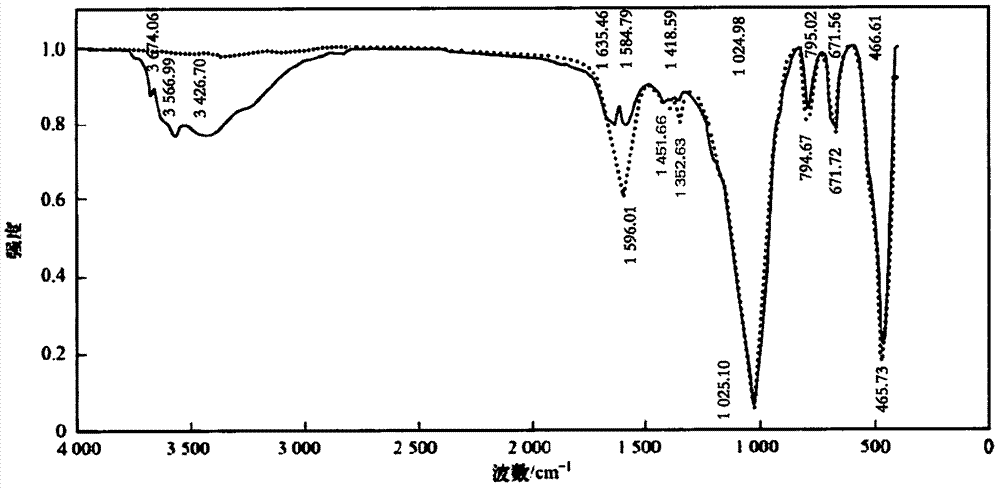

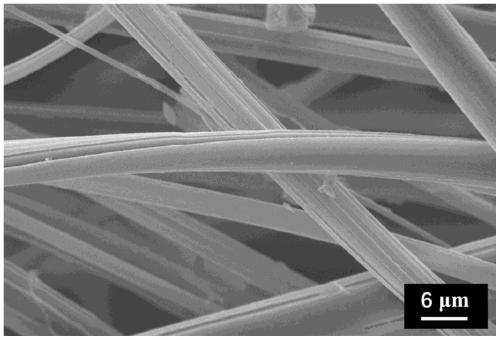

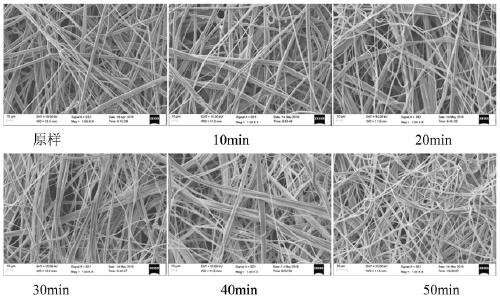

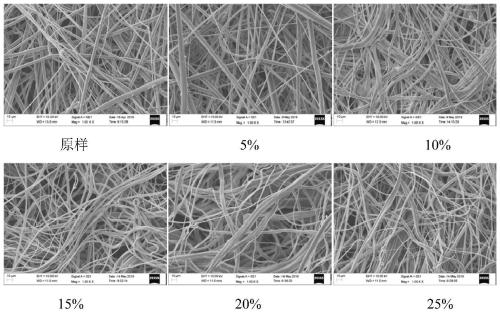

Micro-nanofiber material with linear groove characteristics and orderly forming method thereof

ActiveCN111088539ALarge specific surface areaGood adsorptionFilament/thread formingMicro nanoPolymer chemistry

The invention provides a micro-nanofiber material with linear groove characteristics and an orderly forming method thereof. The micro-nanofiber material is characterized by being composed of two non-compatible thermoplastic high-molecular polymers, wherein the fiber diameter is distributed between 0.1 and 30 [mu]m, and the surface of the fiber is provided with an ordered linear groove feature shape with the dimension of 1-200 nm and the arithmetic average roughness of the fiber surface between 0.1 and 0.98; the orderly forming method comprises the steps of two-component melt blending, high-speed hot gas flow drafting and net forming, ordered etching and the like, and has the advantages of short process flow and high structural characteristic (fiber diameter distribution and linear grooves)controllability; and the micro-nanofiber material with the linear groove characteristics not only has a large specific surface area fiber diameter distribution, but also has a linear groove-shaped special-shaped fiber surface rough morphology, and has great application potential in the fields of liquid rapid transmission, efficient low-resistance gas-solid separation, oil-water separation and thelike.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com