Carbon-doped nano-titanium dioxide adsorbing material for reducing harmful components of cigarettes

A nano-titanium dioxide, adsorption material technology, applied in the direction of tobacco, application, smoke oil filter, etc., to achieve the effect of high coke reduction and harm reduction, good adsorption and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The carbon-doped nano-titanium dioxide adsorption material designed in the present invention for cigarette harm reduction is characterized in that: the carbon-doped nano-titanium dioxide adsorption material is prepared by the following method, and the steps include:

[0027] (1) Preparation of nano-carbon sol by electrochemical method: the solid carbon material is used as the positive electrode, and the material whose electrode potential is inert greater than or equal to carbon is used as the negative electrode, and an AC pulse current is passed into the electrode containing the electrolyte for reaction. After several times of stirring, the nano carbon sol can be obtained.

[0028] (2) Dilute tetrabutyl titanate with ethanol, add iminodiacetic acid dropwise, adjust and control the pH value of the solution, and stir the resulting mixture;

[0029] (3) Add the carbon sol solution diluted with ethanol dropwise to the mixture in the step (2), stir, and rinse the resulting n...

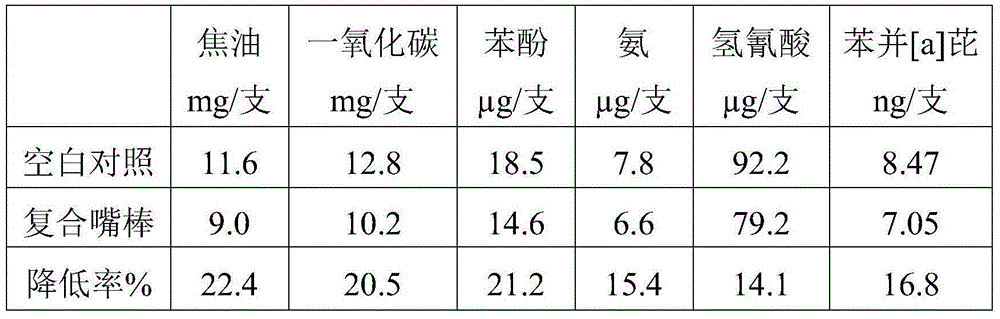

Embodiment 1

[0042]Preparation of nano-carbon sol by electrochemical method: use carbon rods as positive electrodes, use inert materials as negative electrodes, arrange the electrodes according to the positive and negative electrodes, and put them into an electrolytic solution prepared by sulfuric acid, hydrochloric acid, nitric acid, sodium chloride and water. In the liquid reaction tank, each group of electrodes is connected in parallel, and the positive and negative electrodes are separated by an insulating tape mesh. Then, a high-frequency AC pulse current is passed into the electrodes, and the temperature is controlled at 58 ° C. The frequency of the current is controlled at 20KHZ, the voltage is controlled at 5V, and the current density is controlled at 50mA / cm 2 Under the conditions of the reaction, stir once every 5 hours, finish the reaction after 5 days, and the solution in the tank is nano carbon sol;

[0043] The volume ratio of tetrabutyl titanate, ethanol and iminodiacetic ac...

Embodiment 2

[0051] Same as Example 1, the difference is;

[0052] The volume ratio of tetrabutyl titanate, ethanol and iminodiacetic acid is 15:52:3.

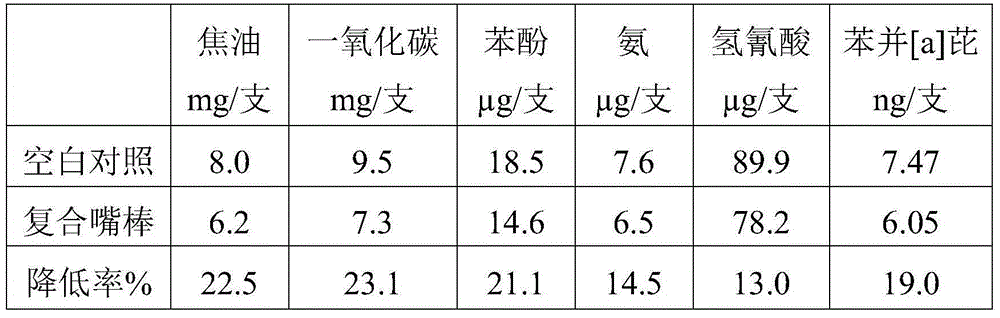

[0053] As shown in Table 2, compared with the effect of the composite mouthpiece on flue gas interception of the original acetate fiber control mouthpiece, tar, carbon monoxide, phenol, ammonia, hydrocyanic acid, and benzo[a]pyrene were all reduced to varying degrees, and tar, The reduction rates of carbon monoxide and phenol are above 20%.

[0054] Table 2: The trapping effect of composite mouthpieces and ortho acetate fiber control mouthpieces on smoke

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com