Micro-nanofiber material with linear groove characteristics and orderly forming method thereof

A technology of micro-nano fiber and forming method, which is applied in the direction of filament/thread forming, fiber treatment, textile and paper making, etc. It can solve the problems of swelling and irregular interface not conforming to the expected design, etc., so as to increase the specific surface area and improve the liquid The effect of fast transmission characteristics and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

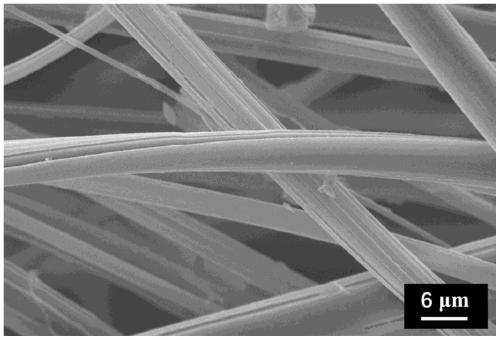

Embodiment 1

[0046] Polypropylene (melting point 167 ℃, isotactic index 97.6%, ash 0.012%) and polyester (melting point 110±8 ℃, intrinsic viscosity 0.568 dL / g, carboxyl-terminal content 19 mol / t;) as raw materials. Firstly, the polyester chips are dried, the preferred drying temperature in this example is 60°C, and the drying time is 8 hours; secondly, the polypropylene and polyester chips are blended according to the mass fraction of 50% / 50% to obtain its Blended polymer chips; after that, the blended polymer chips are fed into the screw extruder to soften and melt into polypropylene / polyester blended melt.

[0047] The diameter of the screw extruder used in this example is 20mm, and the length-to-diameter ratio is 1:28; the heating in the 5 zones is respectively set as: the temperature in the first zone is 170°C, the temperature in the second zone is 190°C, the temperature in the third zone is 210°C, and the temperature in the fourth zone 220°C and zone 5 temperature 220°C.

[0048] Th...

Embodiment 2

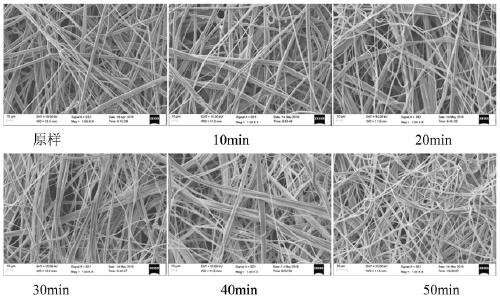

[0052] The difference between embodiment 2 and embodiment 1 is that the etching time is 0 ~ 50min, and the fiber surface morphology of the obtained sample is as follows: figure 2 shown.

Embodiment 3

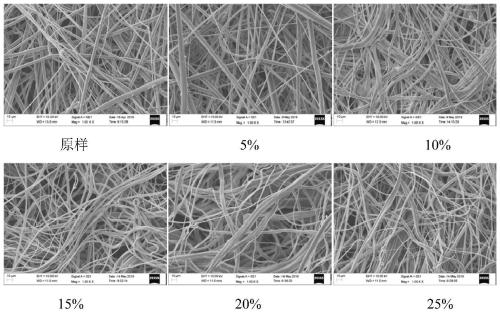

[0054] The difference between embodiment 3 and embodiment 1 is that the concentration of the etching solution selected is 5-25%, and the fiber surface morphology of the obtained sample is as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Scale | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com