Preparation method for high-molecular surfactant

A surfactant and polymer technology, applied in the field of surfactant preparation, can solve the problems of unfavorable long-term storage and production application, the increase of ASA emulsion particles, unfavorable ASA sizing, etc., and achieve the reduction of interfacial tension and good emulsification effect , easy adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: a kind of preparation method of macromolecule surfactant, comprises the following steps:

[0041] Step 1. Mix sodium phosphate, 50% polyacrylamide aqueous solution, dimethylaminoethyl methacrylate (DMAM) and water evenly,

[0042] Step 2, heating the mixture obtained in step 1 to 35~45°C;

[0043] Step 3, add cyclohexanone peroxide dropwise to the mixture obtained in step 2, and add dropwise for 15 minutes;

[0044] Step 4. Gradually heat up the mixture obtained in Step 3 to 60-70°C, and keep the temperature at 60-70°C for 4 hours;

[0045] Step five, add epichlorohydrin to step four, and keep warm at 60~70°C for 130 minutes,

[0046] Step 6. Cool down to 20~25°C, and discharge to obtain polymer surfactant;

[0047] The polymeric surfactant obtained was prepared into an alkenyl succinic anhydride (ASA) emulsion to illustrate the use effect of the polymeric surfactant.

[0048] Preparation of alkenyl succinic anhydride (ASA) emulsion:

[0049] Add a cert...

Embodiment 2

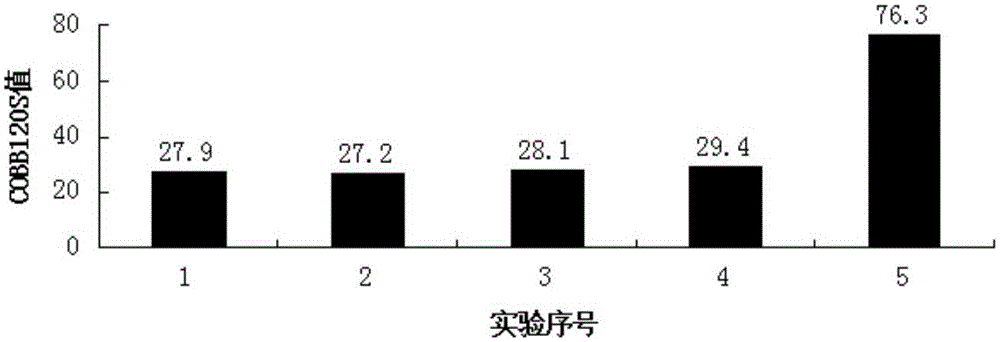

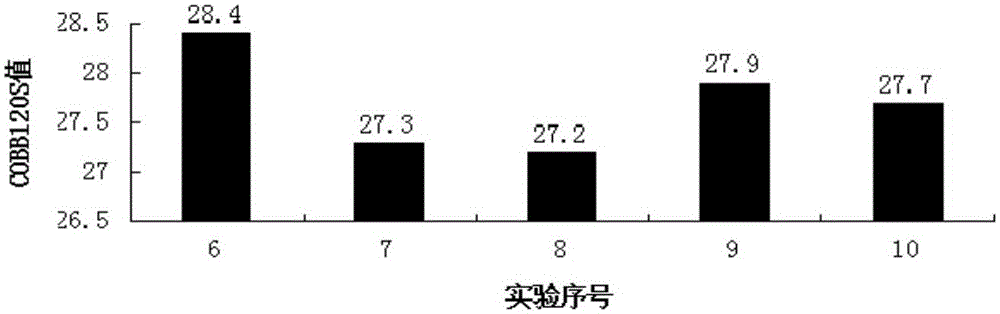

[0056] Embodiment 2: other conditions are with example 2 in embodiment 1, and difference is to change the consumption of dimethyl diallyl ammonium chloride, and concrete data see table 2;

[0057] Prepare alkenyl succinic anhydride (ASA) emulsion, method is with embodiment 1, and concrete data sees table 2.

[0058] Table 2: Effect of the amount of dimethyl diallyl ammonium chloride on product quality

[0059]

[0060] The data in Table 2 shows that when the ratio of polyacrylamide aqueous solution and dimethylaminoethyl methacrylate is 5:1, the yield of emulsifier obtained is the highest, the value of COBB120S is the smallest, and the water resistance effect is the best.

Embodiment 3

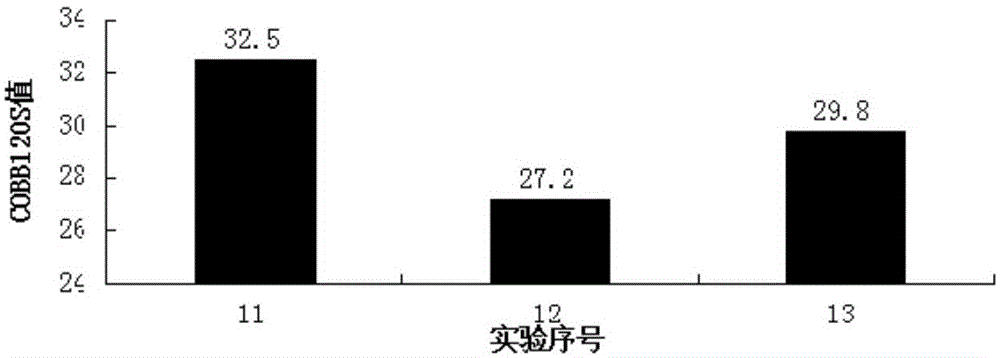

[0061] Embodiment 3: other conditions are with example 2 in embodiment 1, difference is to change reaction temperature, investigate the impact of temperature change on product quality, concrete data see table 3;

[0062] Prepare alkenyl succinic anhydride (ASA) emulsion, method is with embodiment 1, and concrete data sees table 3.

[0063] Table 3: Effect of Temperature on Product Quality

[0064] serial number temperature / ℃ Product mass / g Yield / % Viscosity / COBB120S 11 50-60℃ 438 94.8% 10 32.5 12 60-70℃ 453 98.1% 15 27.2 13 70-80℃ 450 97.4% 24 29.8

[0065] The data in Table 3 shows that when the holding temperature is 60-70°C, the yield of the obtained emulsifier is the highest, the COBB120S value is the smallest, and the water resistance effect is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com