Patents

Literature

34results about How to "Good flocculation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combination type efficient sludge dewatering conditioning method

ActiveCN104891779AFully dehydratedHas strong oxidizing propertiesSludge treatment by de-watering/drying/thickeningSulfatePotassium ferrate

The invention relates to a combination type efficient sludge dewatering conditioning method and belongs to the field of sludge dewatering preprocessing. According to the technical scheme, the method includes performing acidification treatment on sludge to be dewatered through concentrated sulfuric, adjusting the pH of a sludge system to range from 3.5 to 5, and stirring for 15 to 30min through a stirring blade; adding strong oxidizing agent, namely potassium ferrate, with the content of 0.2% to 4% of the total solid sludge into acidified sludge after water dissolving, stirring for 2min in the speed of 200 to 300 r / min rapidly, and stirring for 20 to 40min in the speed of 80 to 150 r / min slowly; adjusting the pH to range from 3.5 to 5 through concentrated sulfuric, adding ferrous sulfate with the content of 4% to 8% of the total solid sludge after preparing the ferrous sulfate as solution with the concentration of 20% to 50%, after stirring and scattering, adding H2O2, with the concentration of 30%, with the content of 4% to 8% of the total solid sludge, and reacting for 30 to 50min completely during slow stirring; finally, adding quicklime with the content of 3% to 8% of the total solid sludge into the sludge conditioning system, adjusting the system pH to range from 6 to 8, scattering the quicklime evenly, and dewatering.

Owner:BEIJING UNIV OF TECH

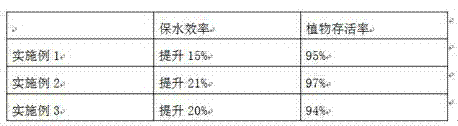

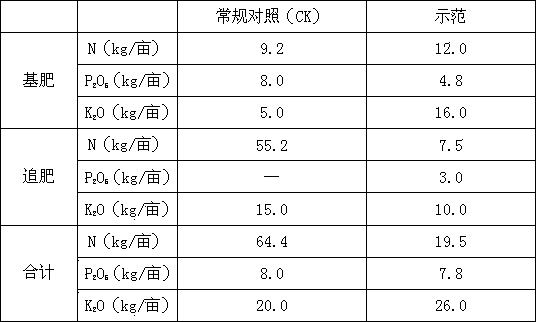

Under-root-mulching water-retention transplantation method used in arid region

InactiveCN104488659AGood flocculationSmall frictional resistanceForestryHorticulture methodsFungicideFertilizer

The invention provides an uder-root-mulching water-retention transplantation method used in an arid region. The method comprises the following steps: (1) preparation for transplanting; (2) root cutting and shrinking to a root ball; (3) application of water retention measures; (4) lifting and transporting; and (5) transplanting, wherein water-soluble high-molecular polymer polyacrylamide selected and used as an antitranspirant in the step (1) is insoluble in most organic solvents, has good flocculability, can reduce friction resistance among liquids, is poisonless and tasteless, poses no pollution to plants and can retain moisture very well; a soil fungicide and and a rooting agent which is capable of promoting germination of new roots are applied on the cuts of pruned roots so as to facilitate rapid recovery of a root system damaged in the processes of transplanting and maintaining of a plant; an added water-retaining agent can improve the permeability of soil, has a certain effect on moisture conservation, improves stress resistance of a plant and can save 30% of fertilizer; in addition, a water-retention film is used, so considerable evaporation of moisture is prevented and a good moisture retention effect is obtained.

Owner:于瑞德

Combined conditioning method for sludge high-efficient dehydration

InactiveCN104973750AImprove sludge dewatering performanceGood flocculationSludge treatment by de-watering/drying/thickeningPre treatmentEnvironmental chemistry

The invention relates to a combined conditioning method for sludge high-efficient dehydration, and belongs to the field of sludge dehydration pretreatment. The method comprises the following steps: acidifying sludge to be dehydrated by concentrated sulfuric acid, adjusting the pH value of the sludge system to a range of 3.5-5, continuously stirring the sludge system by a stirring pad for 15 to 30 minutes; adding a strong oxidant (potassium ferrate) accounting for 0.2 to 4% of the total dried sludge weight into the acidified sludge, wherein the potassium ferrate is dissolved by water before addition; rapidly stirring the sludge for 2 minutes at a stirring speed of 200 to 300 r / min, then slowly stirring the sludge for 20 to 40 minutes at a stirring speed of 80 to 150 r / min; then adding polymeric ferric sulfate accounting for 6 to 12% of the total dried sludge weight into the sludge conditioning system, wherein the polymeric ferric sulfate is dissolved by water to prepare a solution with a mass concentration of 20-50% before addition; keeping on stirring at a slow stirring speed for 15 to 30 minutes; then adding quicklime accounting for 3 to 8% of the total dried sludge weight into the sludge conditioning system, adjusting the pH value to a range of 6-8, evenly dispersing the quicklime, and immediately dehydrating the sludge.

Owner:BEIJING UNIV OF TECH

Garlic straw-nanocopper composite blue alga treatment agent and preparation method thereof

InactiveCN105858777AGood flocculationGood flocculation effectBiocideOther chemical processesWater qualityAllium sativum

The invention discloses a garlic straw-nanocopper composite blue alga treatment agent. The blue alga treatment agent is prepared from, by weight, 40-60 parts of diatomite, 5-10 parts of plant ash, 5-10 parts of garlic straws, 3-5 parts of nanocopper, 0.2-0.4 parts of acrylamide, 3-5 parts of sodium gluconate, 0.3-0.5 parts of polyethyleneimine, 0.03-0.05 parts of ammonium persulfate, 1-2 parts of alum, 0.5-1 part of hydroxyethylurea, and 10-15 parts of a composite assistant. The blue alga treatment agent has the advantages of good adsorption activity and flocculation performance, very good flocculation effect on blue algae, fast blue alga removal rate, low cost, no secondary pollution, high cyanotoxin adsorption and removal efficiency, good removal effect on various organic and inorganic pollution substances in water, bacterium killing and alga inhibiting efficacy, effective improvement of the quality of water, lasting effectiveness, and suitableness for treatment of complex water environment.

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

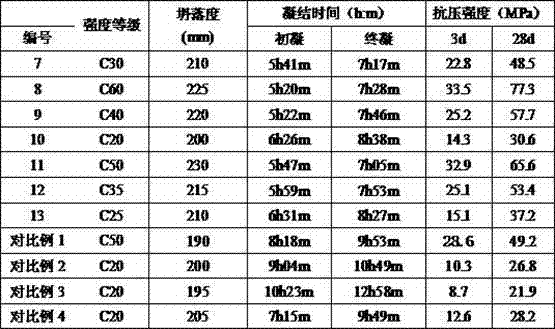

Modified phosphorous slag powder, concrete prepared from modified phosphorous slag powder and preparation method of concrete

ActiveCN103755186AReduce dosageReduce the effect of hydration reaction rateSolid waste managementMetallurgyStarch

The invention provides a modified phosphorous slag powder, a concrete prepared from the modified phosphorous slag powder and a preparation method of the concrete, and belongs to the technical field of concrete preparation. The modified phosphorous slag powder comprises a phosphorous slag powder, an organic salt and cationic starch. The organic salt and the cationic starch are used for modifying the phosphorous slag powder in stead of common chemical excitation carried out on the phosphorous slag by using an inorganic alkali activator in the prior art; when the modified phosphorous slag powder is used for preparing the concrete, the dosage of the modified phosphorous slag powder accounts for 38-70wt% of the total amount of the cementing material; the 3d compressive strength of the concrete ranges from 14.5 to 33.5MPa, and the 28d compressive strength of the concrete ranges from 30.6 to 77.3MPa, and the stability of the concrete is good; the utilization rate of the phosphorous slag powder is greatly reduced while the cost of the concrete is reduced, and therefore, the environmental pollution problem caused by the phosphorous slag can be reduced.

Owner:北京东方建宇混凝土科学技术研究院有限公司

Printing and dyeing wastewater treatment process

ActiveCN105481205AGood flocculationGood oxidationWater treatment parameter controlWater treatment compoundsAnaerobic treatmentTreatment costs

The invention discloses a printing and dyeing wastewater treatment process, and aims at solving the problems that for a traditional printing and dyeing wastewater treatment process, the effluent quality is poor, and the treatment cost is high. According to the technical scheme, the printing and dyeing wastewater treatment process comprises the following steps that wastewater is filtered by a grid and pumped into an adjusting tank, and the pH of the wastewater is adjusted; the wastewater treated in the first step is pumped into a primary reaction tank, activated sludge is put into the primary reaction tank, standing is conducted for 0.5 h, Mg2SO4 is added according to the wastewater quantity of 2-4 g / m<3>, FeSO4 is added according to the wastewater quantity of 1-3 g / m<3>, a direct current of 120-150 V is energized, and the wastewater stays for 2-4 h; the wastewater is pumped into a closed facultative tank, and the wastewater stays in the facultative tank for 4-7 h; the wastewater is pumped into an efficient anaerobic bioreactor, and sundries in the wastewater are removed through anaerobic treatment; effluent in the efficient anaerobic bioreactor is pumped into an efficient air flotation tank, and air flotation is conducted. The printing and dyeing wastewater treatment process is good in effluent quality and low in treatment cost.

Owner:景成环境科技(杭州)有限公司

Seafood flavoring bean curd and preparation method thereof

InactiveCN105432802AHigh content of sulfhydryl groupsGood flocculationCheese manufactureFood scienceFlavorPiper methysticum

The invention discloses seafood flavoring bean curd. The seafood flavoring bean curd is made from, by weight parts, 400-410 parts of soybean, 30-32 parts of sugarcane juice, 30-32 parts of scallop muscle, 5-6 parts of ground pepper, 2-3 parts of mulberry leaf, 4-5 parts of fruit of Chinese wolfberry, 1-2 parts of hawthorn, 3-4 parts of lotus leaf, 1.6-1.8 parts of chitosan, 1.6-1.8 parts of calcium chloride and 200-210 parts of 0.1% acetic acid solution. According to the method, superhigh pressure treatment is adopted for soybean milk, a hydrophobic region of soyabean protein can be exposed to increase the sulfhydryl content of the soybean protein, the soybean protein reacts with a coagulating agent again to form gel, the shortcomings of the fission of food color, fragrance and taste and the nutrient loss caused by traditional hot processing are overcome, vitamin C can restrain lipid substances in soybeans from being oxidized to generate peroxide to produce beany flavor, a chitosan mixed coagulating agent has good bacteriostasis on colibacillus, staphylococcus aureus and mould, the expiration date of the bean curd can be effectively prolonged, and the seafood flavoring bean curd can reduce lipid.

Owner:王传法

Modified zeolite-nanocarbon cyanobacteria treatment agent and preparing method thereof

InactiveCN105776403AGood adsorption activity and flocculation performanceGood flocculationSpecific water treatment objectivesWater/sewage treatment by flocculation/precipitationMaleic anhydrideAmmonium sulfate

The invention discloses a modified zeolite-nanocarbon cyanobacteria treatment agent. The modified zeolite-nanocarbon cyanobacteria treatment agent is prepared from, by weight, 30-40 parts of zeolite, 10-20 parts of kieselguhr, 3-5 parts of nanocarbon, 0.1-0.2 part of maleic anhydride, 1-2 parts of ethyl orthosilicate, 3-5 parts of kapok fibers, 0.2-0.4 part of acrylamide, 0.3-0.5 part of hydroxyethyl cellulose, 0.03-0.05 part of ammonium persulfate and 10-15 parts of a composite assistant. The cyanobacteria treatment agent has good adsorption activity and flocculating performance, has very good flocculation on cyanobacteria, is high in cyanobacteria removing speed, low in cost and free of secondary pollution, also has a good adsorption and removing effect on cyanobacteria toxins and various organic and inorganic pollutants in water, especially has the decomposition and conversion effects on organic pollutants and toxins, and is capable of effectively improving the water quality and suitable for treatment in complex water environments.

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

Blue alga treatment agent adopting licorice root residues as raw material, and preparation method thereof

InactiveCN105858831AGood flocculationHigh activityBiocideOther chemical processesWater qualityLicorice roots

The invention discloses a blue alga treatment agent adopting licorice root residues as a raw material. The blue alga treatment agent is prepared from, by weight, 5-10 parts of the licorice root residues, 3-5 parts of pine needle powder, 0.2-0.4 parts of sodium dodecyl sulfonate, 30-40 parts of diatomite, 20-30 parts of meerschaum, 3-5 parts of glutinous rice flour, 0.2-0.4 parts of acrylamide, 0.03-0.05 parts of ammonium persulfate, 0.5-1 part of an EVA emulsion and 10-15 parts of a composite assistant. The blue alga treatment agent has the advantages of good adsorption activity and flocculation performance, very good flocculation effect on blue algae, fast blue alga removal rate, low cost, no secondary pollution, high cyanotoxin adsorption and removal efficiency, good removal effect on various organic and inorganic pollution substances in water, bacterium killing and alga inhibiting efficacy, effective improvement of the quality of water, and suitableness for treatment of complex water environment.

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

Cordierite-polylactic acid fiber composite blue-green alga treating agent and preparing method thereof

InactiveCN105776402AGood flocculationHigh activityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionSodium BentoniteSodium potassium tartrate tetrahydrate

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

Loss-control fertilizer additive and preparation method thereof

InactiveCN103964976AGood flocculationStrong environmental protectionFertilizer mixturesNutrientFertilizer

The invention relates to a loss-control fertilizer additive and a preparation method thereof, belonging to the technical field of agricultural fertilizers. The additive is prepared from the following raw materials in parts by weight: 30.00-49.50 parts of bentonite, 30.00-49.50 parts of smectite, 1.00-37.00 parts of polyacrylamide, 0-0.50 part of chitosan, 0-1.00 part of compound sodium nitrophenolate, 0-0.50 part of DMPP (dimethyl-phenyl-piperazinium) and 0-1.00 part of DA-6. The loss-control fertilizer additive has the advantages of high environment friendliness and favorable flocculability, can effectively prevent the nutrients in the fertilizer from loss, and does not influence the fertilizer absorption of crops, thereby achieving the goal of long lasting. Meanwhile, the loss-control fertilizer additive has the effect of improving the soil; after being applied into soil, the loss-control fertilizer additive can loosen the soil structure and improve the physical behaviors of the soil; and thus, the loss-control fertilizer additive has multiple functions and is very effective.

Owner:YUNNAN YUNYE FERTILIZER

Modified active carbon waste water flocculant and preparation method thereof

InactiveCN103508534AGood flocculationHigh strengthWater/sewage treatment by flocculation/precipitationChemistryActivated carbon

A modified active carbon waste water flocculant is composed of following raw materials in parts by weight: 100 to 120 parts of active carbon, 10 to 12 parts of acrylic acid, 3 to 4 parts of acrylamide, 10 to 12 parts of methacryloxyethyltrimethyl ammonium chloride, 10 to 12 parts of calcined gypsum, 5 to 6 parts of dried alum, 8 to 10 parts of modified attapulgite, 1 to 2 parts of silane coupling agent KH-550, and a right amount of water. The preparation method uses acrylic acid, acrylamide, and methacryloxyethyltrimethyl ammonium chloride to modify the active carbon, so the modified active carbon has a better flocculation effect on pollutants in water; adds calcined gypsum and dried alum into the flocculant to enable the flocculant to have an antibiotic effect, the preparation method adds the silane coupling agent KH-550 into the flocculant to strengthen the intensity of the flocculant to make the flocculant difficult to disintegrate.

Owner:BENGBU DEMO FILTRATION TECH

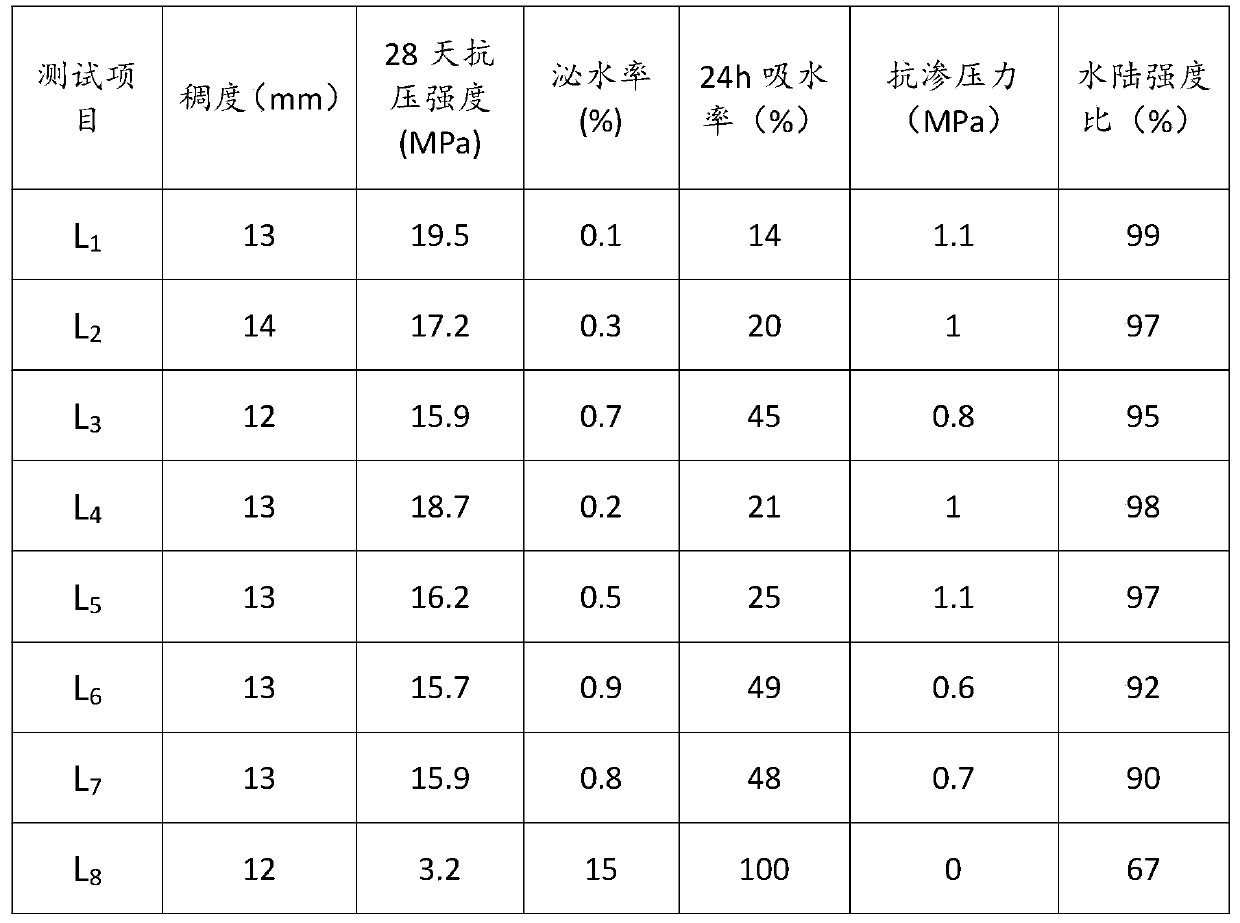

Coral micropowder-based waterproof grouting material suitable for offshore island water-enriched stratum

InactiveCN109970415AReduce the amount of groutImprove water retentionPulverized fuel ashAbsorption rate

The invention discloses a coral micropowder-based waterproof grouting material suitable for an offshore island water-enriched stratum. The coral micropowder-based waterproof grouting material suitablefor the water-enriched stratum is prepared from, by mass, 30-60% of coral micropowder, 15-25% of common Portland cement, 13-30% of pulverized fuel ash, 2-6% of silicon micropowder, 2-5% of a water-resistance dispersing agent, 0.05-0.1% of a silane impregnant, 1-4% of a corrosion-prevention rust-resistance agent and the balance high-performance water-reducing agents. The coral micropowder-based waterproof grouting material has the advantages of being good in fluidity and water resistance and dispersibility, low in water absorption rate and bleeding rate and good in seepage resistance; the coral micropowder-based waterproof grouting material can resist corrosion and dispersion on the water-enriched stratum when used for grouting construction of the offshore island water-enriched stratum, and can be quickly coagulated, and construction operation is facilitated.

Owner:CHINA ACAD OF BUILDING RES +3

Chemical reagent for wastewater treatment

InactiveCN106477650AGood flocculationFast purificationSpecific water treatment objectivesWater/sewage treatment by flocculation/precipitationChemistryEnvironmental chemistry

The invention discloses and provides a chemical reagent for wastewater treatment; wastewater is treated by means of flocculating, coagulation enhancement, conditioning, defoaming, and sterilizing, inorganic and organic components cooperate to act as a coagulant, and therefore the chemical reagent has excellent flocculating effect. The chemical reagent has the advantages of high purifying speed, good effect, good environmental friendliness, low toxicity and the like, is low in production cost and is suitable for wide popularization.

Owner:ANHUI RUIZHIXIN INFORMATION TECH CO LTD

Natural high polymer flocculant and preparation method thereof

ActiveCN103880139AGood flocculationMild reaction conditionsWater/sewage treatment by flocculation/precipitationPotassium persulfatePolymer science

The invention relates to a natural high polymer flocculant and a preparation method thereof. An initiator potassium persulfate or ammonium persulfate is added into lignins and humic acids used as raw materials to initiate copolymerization of the lignins and humic acids, thereby preparing the lignin / humic acid copolymer natural high polymer flocculant. The preparation method has the characteristics of mild reaction conditions and simple technique. The prepared lignin / humic acid copolymer natural high polymer flocculant has favorable flocculation action on heavy metal wastewater, dye wastewater, montmorillonite suspensions and the like. By adopting the cheap and accessible natural high polymers as the raw materials, the preparation method has great advantage in production cost, and can easily implement industrialization and generate favorable economic benefit.

Owner:长春一汽综合瑞曼迪斯环保科技有限公司

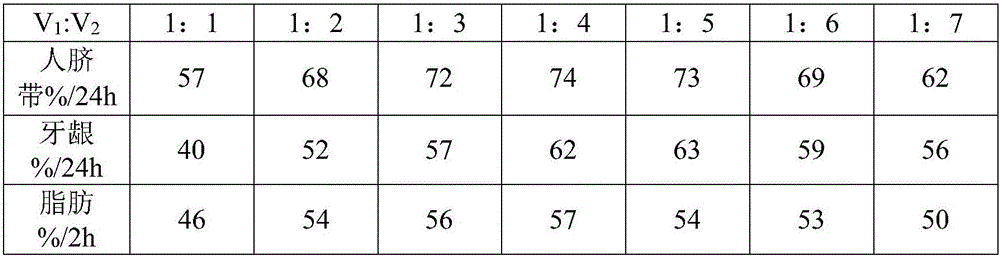

Gleditsia delavayi total saponins extracting and purifying method

InactiveCN106309540AGood flocculationSatisfied with the purityCosmetic preparationsToilet preparationsFiltrationSolvent

The invention provides a gleditsia delavayi total saponins extracting and purifying method. The method takes gleditsia delavayi shells as a raw material, and the method comprises the following steps: 1) the dried gleditsia delavayi shells are crushed to 10-20 meshes, then the powder is put in a pressurization solvent extraction apparatus, 1-10 times of distilled water is added, the pressurization solvent extractor is sealed, the material is pressurized and extracted for 40 min at the temperature of 80-110 DEG C and the pressure of 2.5-4.0 Kg / cm<2> for 3 times, solid-liquid separating is carried out, and the extracts are merged; 2) the above extracts are cooled to room temperature, 1-7% of Rhodococcus erythropolis is added and cultured for 2-10 days at the temperature of 20-35 DEG C, and a liquid supernatant is taken; 3) the membranes with the molecular weight cut-off of 15000, 5000, and 2000Da are respectively used for separating, wherein the membrane filtration work pressure is 0.1-0.2 MPa; 4) the extract through the 2000Da membrane is concentrated; and 5) a concentrate is subjected to spray drying to obtain the gleditsia delavayi total saponins powder.

Owner:四川小叶本草生物科技有限公司

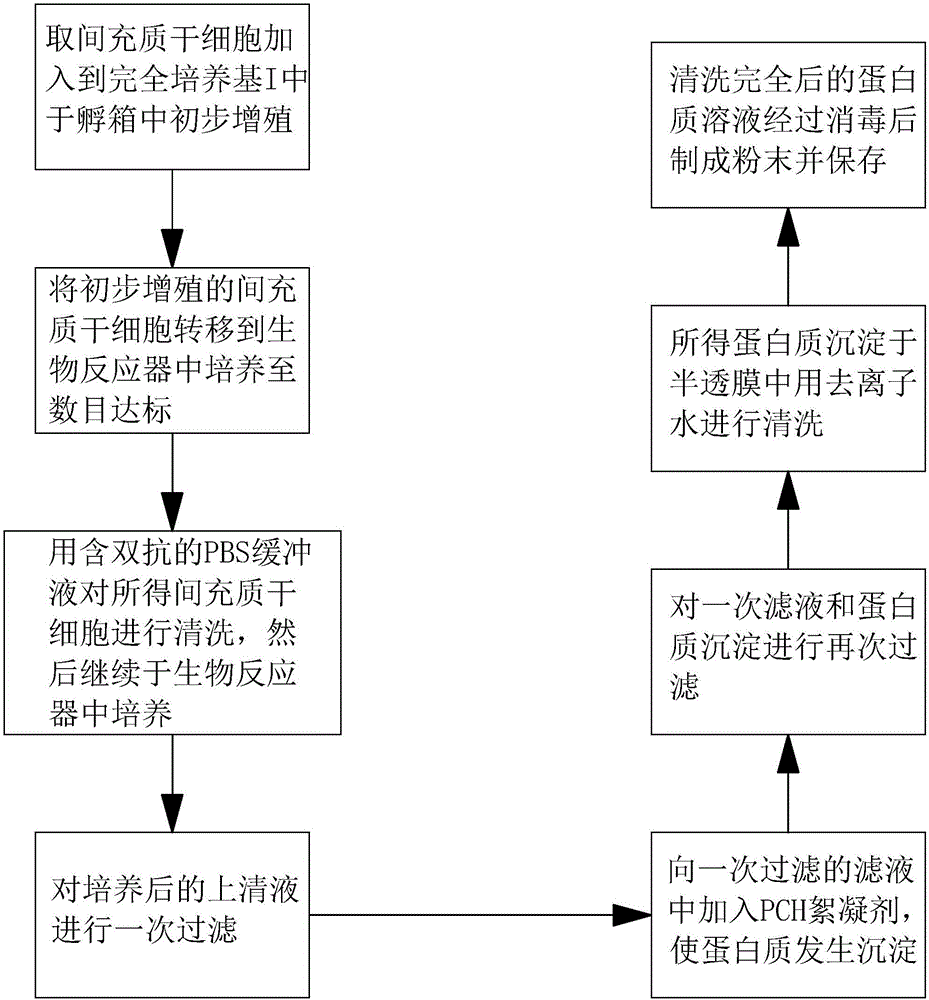

Cultivation method of mesenchymal stem cell secretin

InactiveCN106636261AHigh purityNot transgenderCulture processMicroorganism based processesLoss rateMesenchymal stem cell

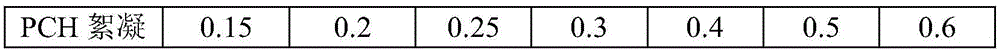

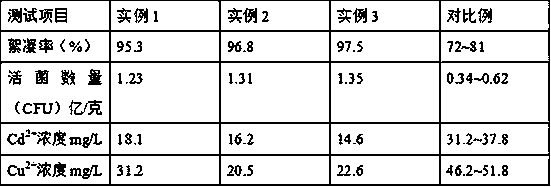

A cultivation method of mesenchymal stem cell secretin comprises the following steps: S1, taking a mesenchymal stem cell and adding into a bioreactor for cultivation, obtaining a target amount, and washing mesenchymal stem cells in the bioreactor with a double-antibody-containing PBS buffer solution;S2, adding a complete medium I and the double-antibody-containing PBS buffer solution into the bioreactor to continue cultivation; S3, collecting supernate in the bioreactor, adding a PCH flocculating agent into the supernate, and precipitating protein in the supernate; S4,putting a protein precipitate obtained in S3 into a semi-permeable membrane, and using deionized water to repeatedly wash the protein precipitate in the semi-permeable membrane; S5, utilizing the deionized water to load a mesenchymal container with protein, and obtaining a protein liquid as the mesenchymal stem cell secretin. The cultivation method not only can effectively improve the space utilization rate and reduce the usage amount of a nutrient medium, but also improves the protein purity and reduces the loss rate.

Owner:浙江译美生物科技有限公司

Treatment method for dyeing wastewater of natural dye

ActiveCN106007061AGood flocculationGood adsorptionMultistage water/sewage treatmentDyeing processNatural fiberActivated carbon

The invention provides a treatment method for dyeing wastewater of natural dye. According to the method, the wastewater does not need to be decolored, all that is required is to add a little natural fiber fabric waste and a few of flocculating agents, and the wastewater can be treated through activated carbon. The treatment method can be repeatedly used for a printing and dyeing process, a large quantity of wastewater treating agents are saved, the treatment time is short in the whole process, and the cost is low.

Owner:湖州新嘉怡丝织印花有限公司

Ternary polymerization polymeric flocculant and preparation method thereof

ActiveCN103937004AMany active groupsGood flocculationWater/sewage treatment by flocculation/precipitationViscous liquidDyeing wastewater

The invention relates to ternary polymerization polymeric flocculant and a preparation method thereof. The preparation method is characterized in that lignin, ethylene glycol and humic acid are used as raw materials and are initiated to polymerize by using an initiating agent under certain reaction conditions, so that the lignin-ethylene glycol-humic acid ternary polymerization polymeric flocculant is prepared. The prepared lignin-ethylene glycol-humic acid ternary polymerization polymeric flocculant is brownish black viscous liquid, non-toxic and environmental friendly, contains numerous active groups and has a good flocculation effect on various electroplating wastewater, dye wastewater, municipal sewage, coking wastewater, montmorillonoid suspension liquid and the like.

Owner:泽惠环境科技(广州)有限公司

Preparation method of compound flocculating agent for adsorbing metal ions

The invention discloses a preparation method of a composite flocculant for adsorbing metal ions, and belongs to the technical field of flocculants. The present invention separates and screens four microbial flocculant-producing bacteria with the highest flocculation activity from river sludge, mixes and ferments to obtain microbial flocculants, and produces high molecular compounds such as glycoproteins, mucopolysaccharides, proteins, cellulose, and nucleic acids. After soaking in water, the fine particles and natural colloidal particles in the water can be condensed into large flocs, which can be removed from the water. They have high-efficiency flocculation and improve the utilization rate and activity of the flocculant. Using α-ketoglutaric acid to modify chitosan, synthesize chitosan derivatives with higher adsorption capacity, introduce -NH2 to react with carbonyl groups, and introduce carboxyl groups to form stable five-membered ring chelation with metal ions It can effectively absorb heavy metal ions in wastewater. The invention solves the problems of low utilization rate, poor adsorption and low activity of the current flocculant for sewage treatment.

Owner:张芸

Sewage treatment method

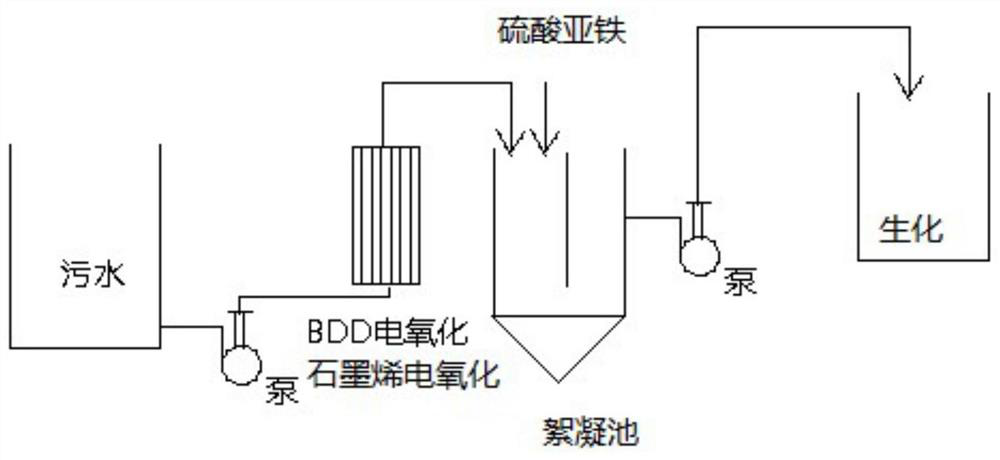

PendingCN112047539AImprove biodegradabilityIncreased mineralizationWater contaminantsMultistage water/sewage treatmentEnvironmental chemistryGraphene electrode

The invention discloses a sewage treatment method. The method comprises the following steps: step 1, pretreating sewage by adopting an electrode; step 2, performing flocculation treatment in a flocculation tank by adopting ferrous sulfate as a flocculating agent; and step 3, treating by adopting a biochemical process. The method has the beneficial effects that the BDD electrode or the graphene electrode is used for pretreatment so that COD in the sewage is reduced, organic matters which are difficult to biodegrade are decomposed into small molecular organic matters, organic nitrogen is converted into inorganic nitrogen, and organic phosphorus is converted into inorganic phosphorus, the biodegradability of the sewage is greatly improved, the mineralization degree of pollutants in the sewageis improved, and subsequent flocculation treatment is facilitated; part of pollutants can be removed through flocculation treatment, the pollutants can react with residual active oxygen of electrooxidation, and the influence on the subsequent biochemical process is reduced. The sewage treatment method is easy to operate and can be used for effectively treating sewage.

Owner:KUNSHAN MAYMUSE ENVIRONMENTAL TECH

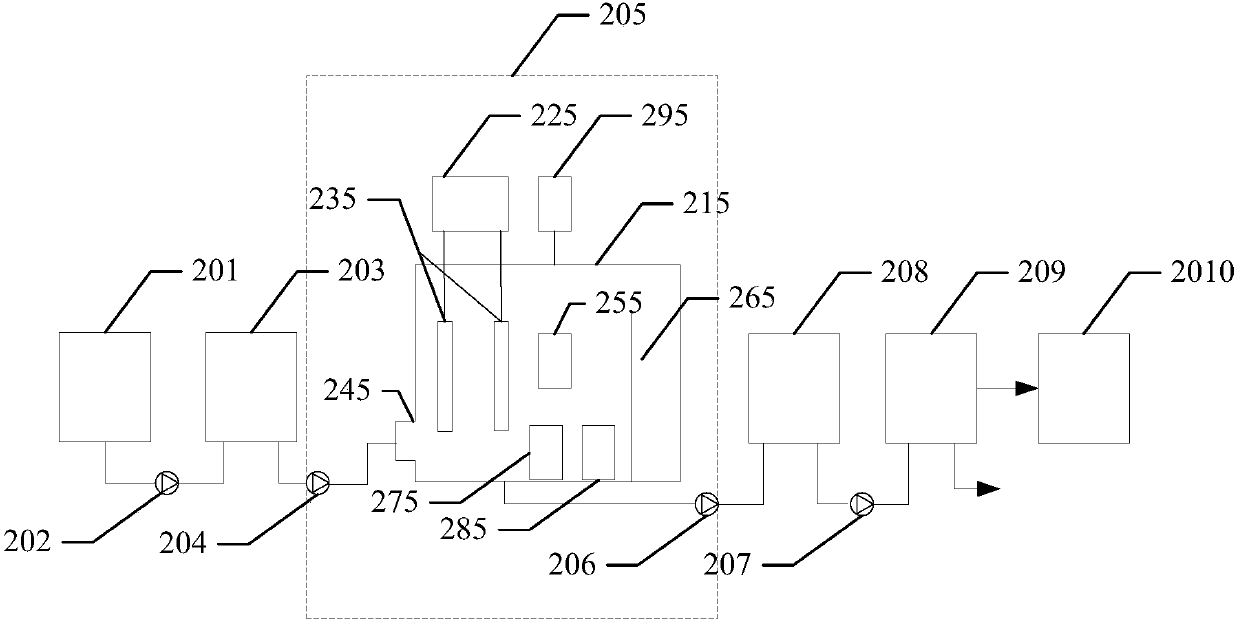

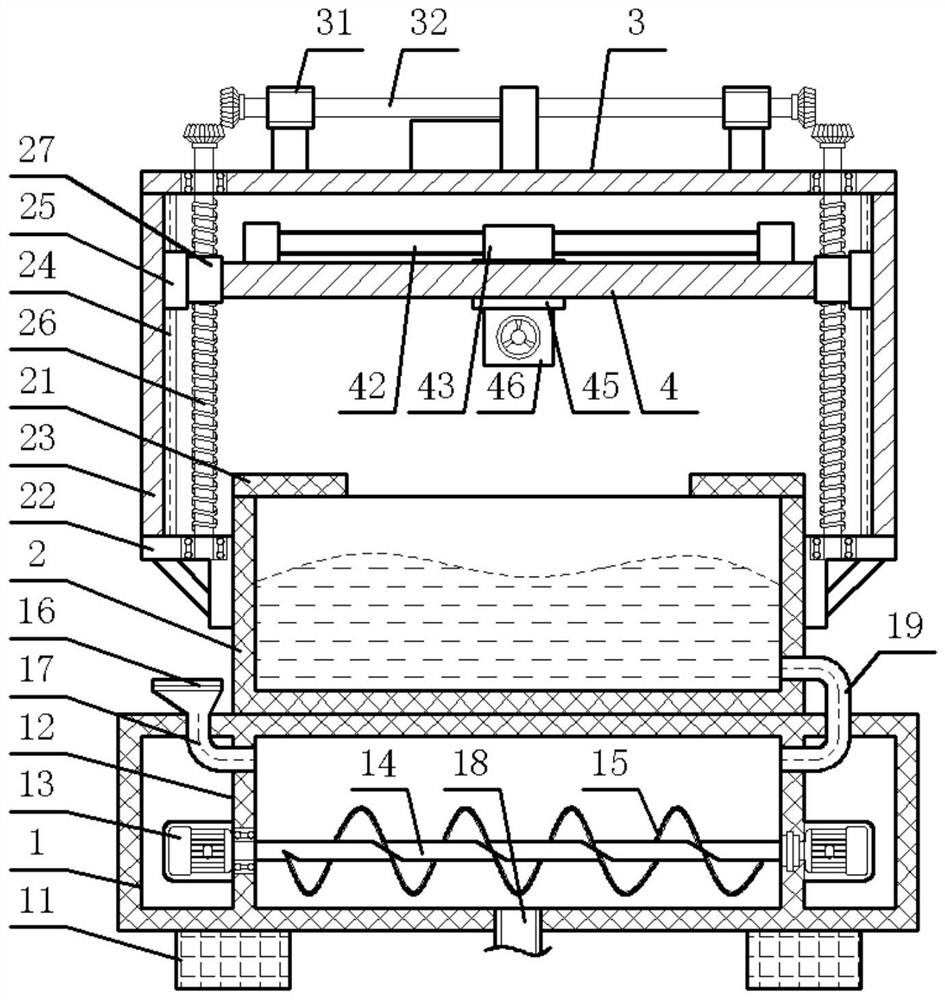

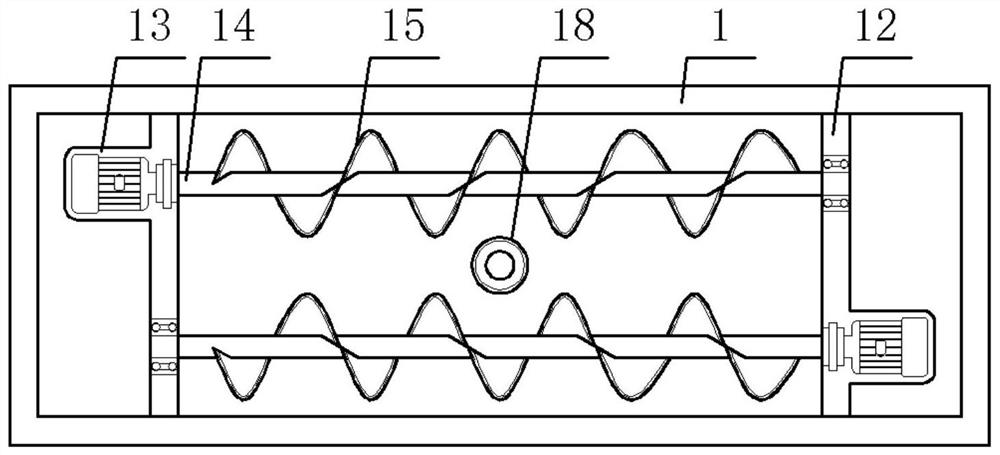

Sludge treating system

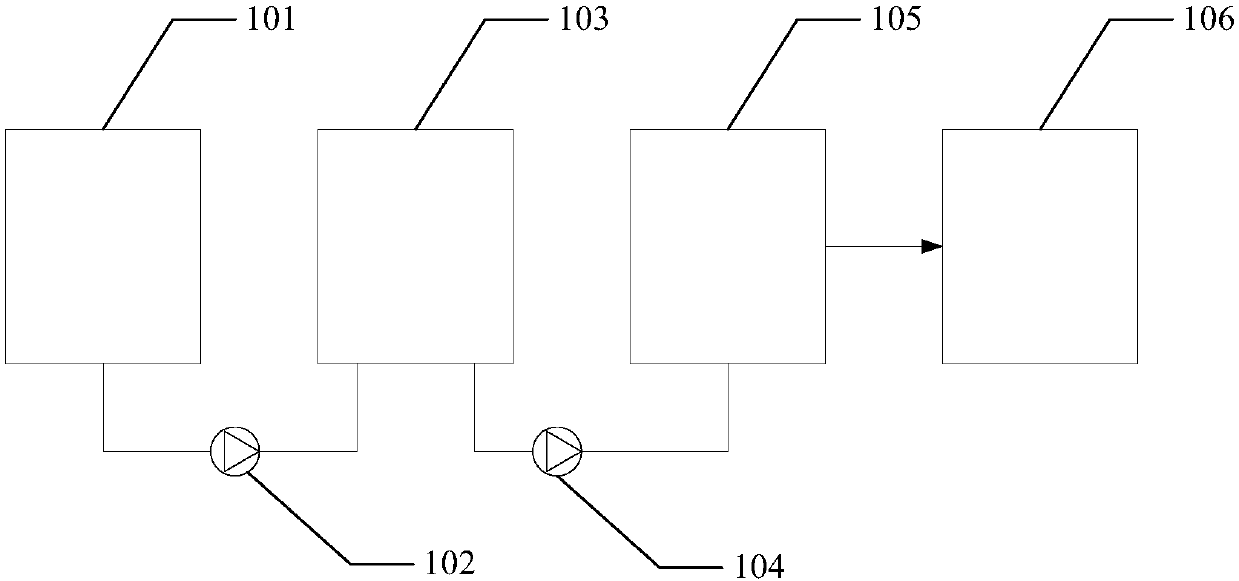

PendingCN107601796AGood flocculationSolve pollutionSludge treatment by de-watering/drying/thickeningElectricityFlocculation

The invention provides a pollutant treating system relating to the technical field of pollutant treatment. The pollutant treating system comprises a sludge tank, a first pump, an electrolysis adjusting barrel, a second pump, an electric flocculation device and a pressure filter, wherein the sludge tank is connected with the adjusting barrel by the first pump and is used for storing sludge to be treated and conveying the sludge to be treated into the electrolysis adjusting barrel; the electrolysis adjusting barrel is connected with the electric flocculation device by the second pump and is usedfor adding chloride ion electrolyte into the sludge to be treated and pumping the sludge to be treated in the electrolytic adjusting barrel into the electric flocculation device by the second pump; the electric flocculation device is used for electrolyzing the sludge to be treated under the condition that the current density is 50-400A by utilizing internal iron or aluminum positive and negativeelectrodes, conveying the electrolyzed sludge into the pressure filter; and the pressure filter is used for filtering the electrolyzed sludge, and then solid sludge and filtrate are obtained. The pollutant treating system provided by the invention solves the problem that the sludge emission causes pollution to the environment.

Owner:李建光

Industrial wastewater purification treating agent

InactiveCN103739052AGood flocculationSmall frictional resistanceWater/sewage treatment by flocculation/precipitationIndustrial wastewater treatmentChemistry

The invention belongs to the field of wastewater treatment technology and in particular to an industrial wastewater purification treating agent for industrial wastewater treatment. The industrial wastewater purification treating agent is characterized by being prepared from the following components in parts by weight: 30-40 parts of polyacrylamide, 1-7 parts of alum (preferentially, 3-5 parts of alum), 20-30 parts of sodium chloride, and 15-25 parts of bentonite. The industrial wastewater purification treating agent has excellent flocculating effect, and is suitable for treating high-concentration industrial wastewater which contains suspended particles and is neutral or alkaline; the industrial wastewater purification treating agent has the advantages of high flocculating and purifying speed, good effect, low toxicity, less hazards and the like.

Owner:DALIAN ZHAOYANG SOFTWARE TECH

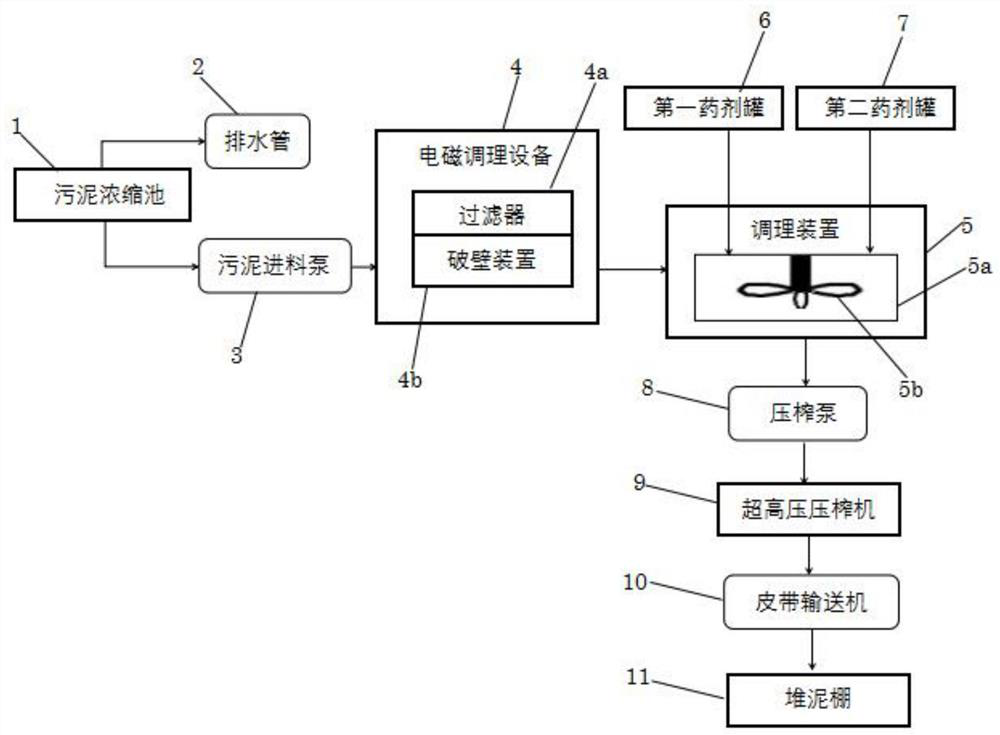

Sludge dewatering process and system employing combination of sludge wall-breaking and ultrahigh-pressure squeezer

PendingCN113716822AGood dehydration effectImprove filter press effectSludge treatment by de-watering/drying/thickeningPressesProcess engineeringUltra high pressure

The invention discloses a sludge dewatering process and system employing a combination of sludge wall-breaking and an ultrahigh-pressure squeezer. The sludge dewatering process comprises the following steps: 1) performing sludge wall-breaking treatment on raw sludge with a moisture content of 97%; 2) carrying out dosing flocculation conditioning on the sludge having been subjected to the sludge wall-breaking treatment; and 3) carrying out ultrahigh-pressure squeezing on the flocculated and conditioned sludge under a squeezing pressure of 2-10 Mpa until the water content of the squeezed sludge is lower than 50%, and then conveying the sludge for outward transportation treatment. The sludge dewatering process employing the combination of sludge wall-breaking and the ultrahigh-pressure squeezer has the advantages that chemical consumption is low; dehydration effect is good; and batch operation time is shortened, and operation efficiency is improved.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

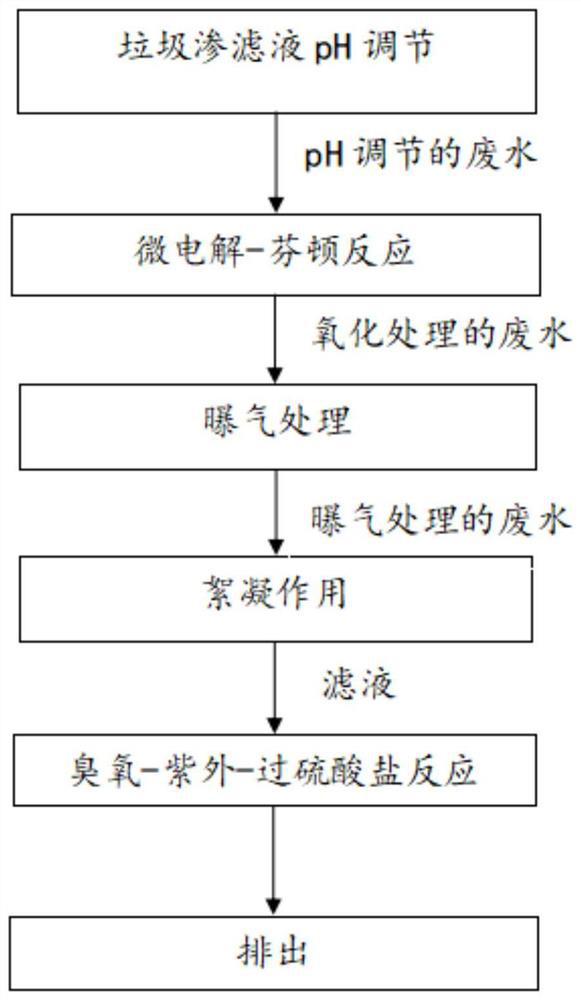

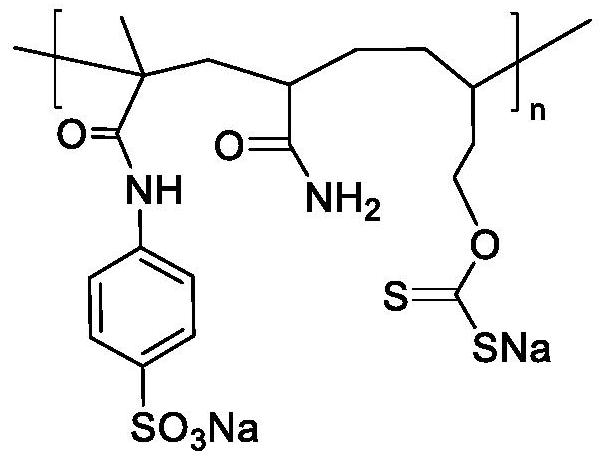

Treatment method of landfill leachate

ActiveCN114212921AHigh removal rateControls are responsiveWater/sewage treatment by irradiationWater treatment compoundsHydration reactionPersulfate

The invention relates to a landfill leachate treatment method, which belongs to the technical field of wastewater treatment, and comprises the following steps: 1, adjusting the pH value of landfill leachate to obtain pH-adjusted wastewater; step 2, adding an iron-carbon filler into the wastewater subjected to pH regulation, and then adding ferrous sulfate heptahydrate and hydrogen peroxide to obtain wastewater subjected to oxidation treatment; 3, aerating the wastewater subjected to oxidation treatment to obtain wastewater subjected to aeration treatment; step 4, adding a flocculating agent and a coagulant aid into the wastewater subjected to aeration treatment for flocculating settling, and filtering to obtain filtrate; and 5, adjusting the pH value of the filtrate, adding persulfate into the wastewater under the conditions of ultraviolet light irradiation activation and ozone aeration, carrying out an oxidation reaction, and discharging. According to the method, the removal rate of organic matters is increased through an iron-carbon micro-electrolysis-Fenton and ozone-ultraviolet-persulfate two-round composite oxidation process; and the modified anionic polyacrylamide coagulant aid is introduced, so that the flocculation effect is improved.

Owner:中新联科环境科技(安徽)有限公司

Vegetable bean curd and making method thereof

InactiveCN105265594AHigh content of sulfhydryl groupsGood flocculationCheese manufactureFood scienceAralia elataBiotechnology

The invention discloses vegetable bean curd. The vegetable bean curd is made from, by weight, 400-410 parts of soybeans, 10-11 parts of rice wine, 20-21 parts of aralia elata seem, 10-11 parts of sweet potato leaves, 5-6 parts of pepper powder, 2-3 parts of acanthopanax, 4-5 parts of cornu cervi, 2-3 parts of fructus psoraleae, 1-2 parts of morinda officinalis, 1.6-1.8 parts of chitosan, 1.6-1.8 parts of calcium chloride and 200-210 parts of 0.1% acetum. According to the method, hydrophobic areas of soybean protein can be exposed and the sulfydryl content of soybean protein can be increased by processing soybean milk under ultrahigh pressure, soybean milk and coagulator act to form gel, the disadvantages of food color, fragrance and taste deterioration, nutrient loss and the like caused by traditional thermal processing are avoided, the beany flavor caused by peroxide generated when lipid substances in soybeans are oxidized can be restrained through vitamin C, the chitosan mixed coagulator has good bacteriostasis effects on escherichia coli, staphylococcus aureus and moulds, the shelf life of the bean curd can be effectively prolonged, and the bean curd can tonify kidneys.

Owner:王传法

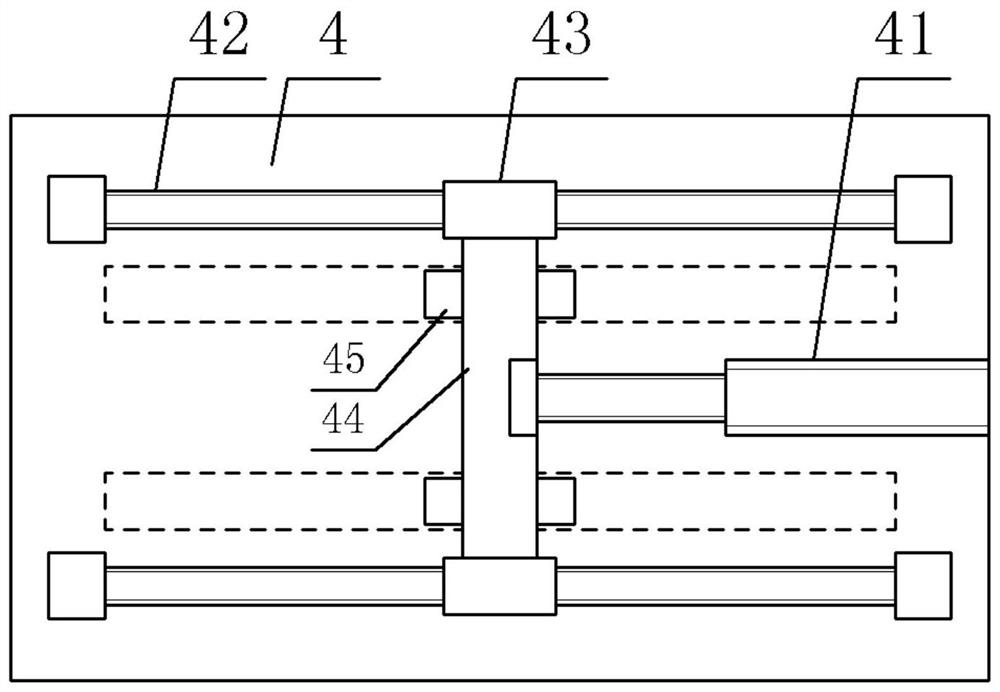

Combined electroplating equipment with flocculation function and electroplating method thereof

PendingCN112160009AConvenient plating workImprove efficiencyCellsWater contaminantsEngineeringSewage treatment

The invention discloses combined electroplating equipment with a flocculation function. The combined electroplating equipment comprises a flocculation box, an electroplating box, stirring assemblies,lifting assemblies, driving mechanisms, a sliding mechanism and a clamping assembly, wherein the stirring assemblies are arranged on each sealing partition plate in a staggered manner; the lifting assemblies are installed at the middle corners of the two side faces of the electroplating box; the driving mechanisms are installed on the top face of each transverse plate; a transversely-placed lifting plate is arranged over the top face of the flocculation box; the sliding mechanism is installed on the top face of the lifting plate; clamping plates are arranged on the bottom faces of two slidingplates in the sliding mechanism; and the clamping assembly is arranged between the two clamping plates. The invention further discloses an electroplating method of the combined electroplating equipment with the flocculation function. According to the combined electroplating equipment with the flocculation function provided by the invention, tedious operation steps of electroplating are simplified,the mechanization degree of the electroplating operation is improved, flocculation treatment of sewage after electroplating is facilitated through combined installation, and the sewage treatment efficiency is improved.

Owner:HEFEI UNIV OF TECH

A kind of antibacterial thin-wall stainless steel pipe and preparation method thereof

ActiveCN113201684BImprove antibacterial propertiesHigh surface hardnessLiquid surface applicatorsVacuum evaporation coatingAntimicrobial actionChemical composition

The invention belongs to the technical field of stainless steel processing, and in particular relates to an antibacterial thin-walled stainless steel pipe and a preparation method thereof. The surface of the stainless steel pipe of the present invention has an antibacterial strengthening layer, and the stainless steel pipe includes the following chemical components in weight percentage: Cr: 17.50-19.50%, Ni: 8.00-10.50%, Mo: 0.20-0.40%, Mn≤2.00%, Si≤0.75%, N≤0.10%, C≤0.07%, P≤0.04%, S≤0.03%, the balance is Fe and unavoidable impurities; the antibacterial strengthening layer is L‑CPA / Cu / C composite film. The antibacterial strengthening layer of the present invention not only endows the surface of the stainless steel pipe with good antibacterial performance, but also greatly improves the surface hardness, wear resistance and corrosion resistance, and avoids the adverse effect of adding copper directly to the stainless steel raw material on the thermal processing performance. At the same time, through a reasonable process, the unique network structure of L-CPA can fully exert the adsorption and purification function, and the Cu element can fully exert the antibacterial effect.

Owner:宁波市华涛不锈钢管材有限公司

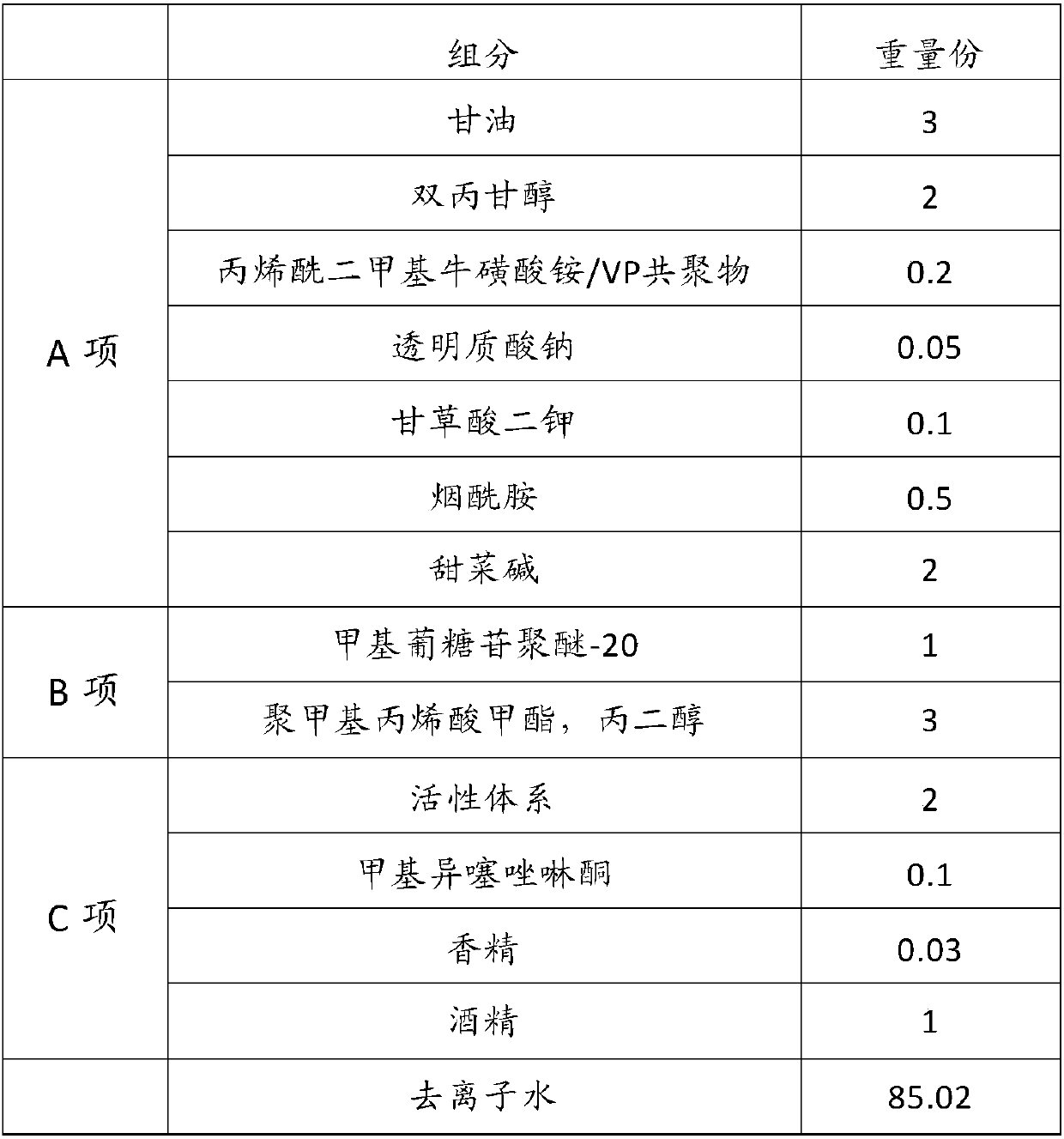

Active system and preparation method thereof

ActiveCN107669523AEffective combinationImprove antioxidant capacityCosmetic preparationsToilet preparationsActive systemsRaw material

The invention provides an active system and a preparation method thereof. The active system is prepared from the following raw materials in parts by weight: 3 to 6 parts of microalgae extracting solution, 1.32 to 6.26 parts of protective substance and 0.01 to 0.08 part of chitosan. According to the active system prepared through a formula and the method which are provided by the invention, on thebasis of increasing the original stability of the microalgae extracting solution, the favorable antioxidation function of the microalgae extracting solution is maintained.

Owner:ENN SCI & TECH DEV

Refreshing coffee bean curd and preparation method thereof

InactiveCN105341180AHigh content of sulfhydryl groupsExtended shelf lifeCheese manufactureFood scienceBiotechnologyEscherichia coli

The present invention discloses a refreshing coffee bean curd which is made of the following raw materials in parts by weight: 400-410 parts of soybeans, 20-22 parts of coffee beans, 3-4 parts of brown sugar, 5-6 parts of milk powder, 2-3 parts of rhizoma curcumae longae, 1-2 parts of mint leaves, 3-4 parts of lophatherum gracile, 2-3 parts of radix ophiopogonis, 1.6-1.8 parts of chitosan, 1.6-1.8 parts of calcium chloride and 200-210 parts of 0.1% acetic acid solution. The soybean milk is subjected to a ultra-high pressure processing milk, which can expose hydrophobic regions of soybean protein and increase the sulfydryl content of the soybean protein, and forms a gel with a coagulant, which avoids the shortcomings of food color, flavor and taste deterioration and nutrient losses caused by the traditional thermal processing. Vitamin C can inhibit the beany flavor produced by peroxides in the oxidization of lipids in the soybean. Besides, the chitosan is mixed with coagulant, which has a very good antimicrobial effect for escherichia coli, staphylococcus aureus and fungi and may effectively extend the shelf life of bean curd. The coffee bean curd can refresh oneself.

Owner:王传法

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com