Coral micropowder-based waterproof grouting material suitable for offshore island water-enriched stratum

A technology for water-rich formations and grouting materials, applied in the field of grouting materials, can solve the problems of poor water resistance and dispersion, low grouting filling rate, difficult coagulation and coagulation, etc. Filling rate, fast setting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

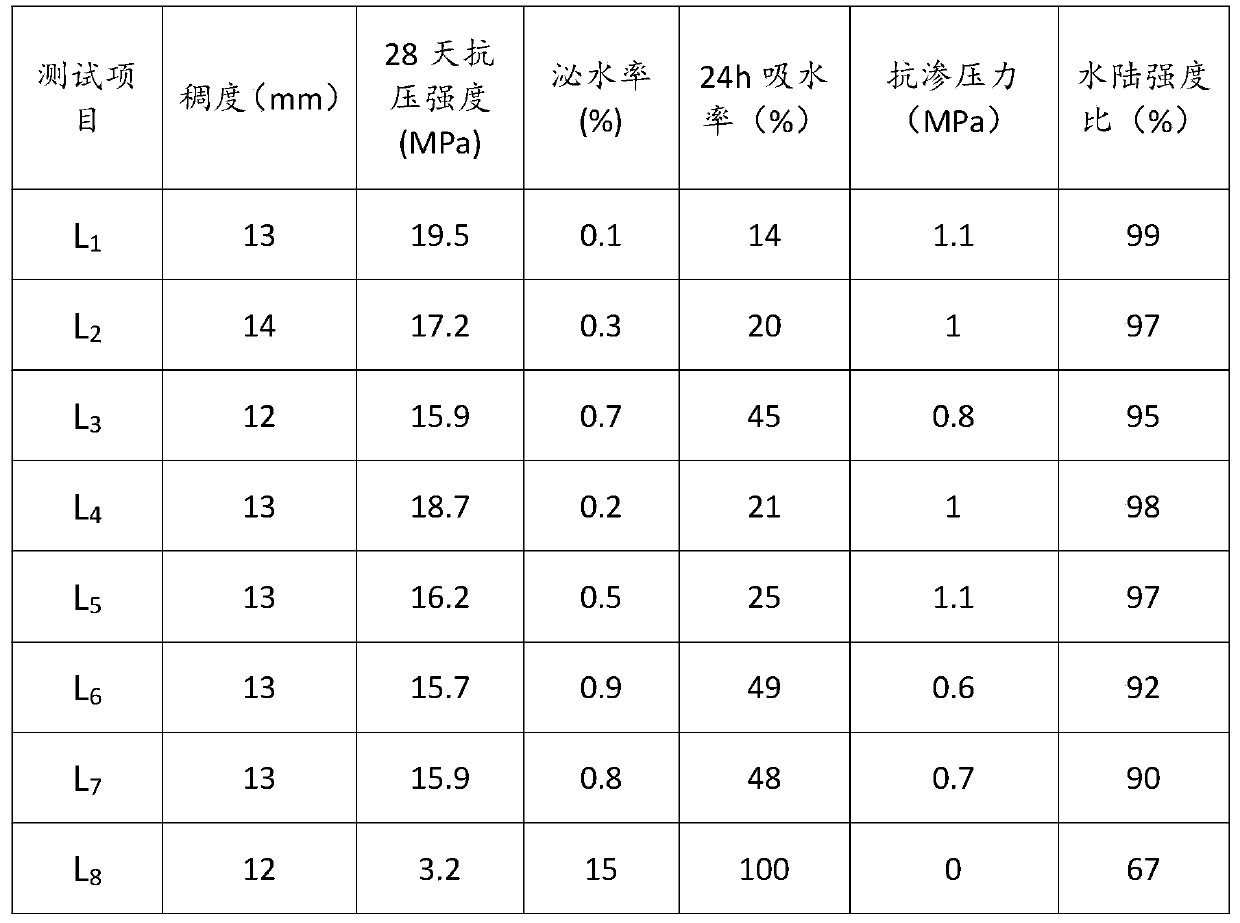

Examples

Embodiment 1

[0015] Coral micropowder-based water-resistant grouting material 2117g suitable for the water-rich strata of offshore islands in this embodiment is made of the following quality raw materials: coral micropowder 941g, 52.5 grade ordinary Portland cement 400g, first grade fly ash 541g, silicon 118g of fine powder, 73g of methylolacrylamide water-resistant dispersant, 2g of silane impregnating agent, 35g of composite anti-corrosion and rust inhibitor, 7g of high-performance water reducing agent;

[0016] The fineness modulus of the coral micropowder is ≤1.0, and the mud content is ≤0.5; it comes from islands in the South China Sea;

[0017] The passing rate of the 325 mesh fineness of the first-class fly ash is 88%, which is collected from the flue gas after coal combustion in thermal power plants;

[0018] The silicon micropowder is SiO 2 Silica fume with a content ≥ 92%, the model is CABR-SF101, purchased from China Academy of Building Research;

[0019] The model of the meth...

Embodiment 2

[0025] Coral micropowder-based water-resistant grouting material 2117g suitable for offshore island water-rich formations of this embodiment is made of the following quality raw materials: coral micropowder 941g, 42.5 grade ordinary Portland cement 471g, first grade fly ash 447g, silicon Micropowder 82g, polyurethane water-resistant dispersant 88g, silane impregnating agent 1g, borate inorganic corrosion inhibitor 71g, high-performance water reducing agent 16g;

[0026] The fineness modulus of the coral micropowder is ≤1.0, and the mud content is ≤0.5; it comes from islands in the South China Sea;

[0027] The passing rate of the 325 mesh fineness of the first-class fly ash is 88%, which is collected from the flue gas after coal combustion in thermal power plants;

[0028] The silicon micropowder is SiO 2 Silica fume with a content ≥ 92%, the model is CABR-SF101, purchased from China Academy of Building Research;

[0029] The model of the polyurethane water-resistant dispers...

Embodiment 3

[0035] Coral micropowder-based water-resistant grouting material 2200g suitable for the water-rich strata of offshore islands in this embodiment is made of the following quality raw materials: coral micropowder 1200g, 42.5 grade ordinary Portland cement 500g, first grade fly ash 330g, silicon Micropowder 60g, polyurethane water-resistant dispersant 63g, silane impregnating agent 1g, borate inorganic corrosion inhibitor 40g, high-performance water reducing agent 6g;

[0036] The fineness modulus of the coral micropowder is ≤1.0, and the mud content is ≤0.5; it comes from islands in the South China Sea;

[0037] The passing rate of the 325 mesh fineness of the first-class fly ash is 88%, which is collected from the flue gas after coal combustion in thermal power plants;

[0038] The silicon micropowder is SiO 2 Silica fume with a content ≥ 92%, the model is CABR-SF101, purchased from China Academy of Building Research;

[0039] The model of the polyurethane water-resistant dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com