Preparation method of compound flocculating agent for adsorbing metal ions

A technology of metal ions and flocculants, applied in chemical instruments and methods, flocculation/precipitation water/sewage treatment, separation of microorganisms, etc., can solve the problems of low activity, poor adsorption, and low utilization rate of flocculants, and achieve high-efficiency flocculation, The effect of improving utilization and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

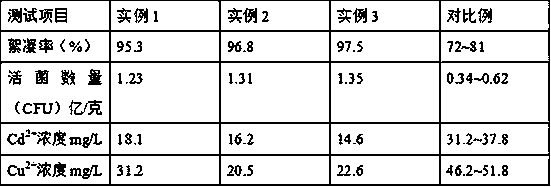

Examples

preparation example Construction

[0029] A preparation method of a composite type adsorption metal ion flocculant, comprising the steps of:

[0030] (1) Take the sludge and add it to a beaker with deionized water at a mass ratio of 1:5, place it on a magnetic stirrer and stir for 10 minutes, let it stand for 1~2 hours, centrifuge, collect the supernatant, and take the mass of the supernatant Four equal parts were inoculated into No. 1 bacterial liquid medium, No. 2 mold liquid medium, No. 3 actinomycete liquid medium, and No. 4 fungal liquid medium respectively according to the mass ratio of 2:9, and cultivated at 25~33°C for 3 For ~5 days, according to the same inoculum size and the same culture conditions, repeat the enrichment culture twice to obtain No. 1, No. 2, No. 3 and No. 4 enrichment culture solutions, and use 0.9% normal saline to No., No. 2, No. 3, and No. 4 enriched culture medium were diluted to 10 -6 Dilution, after dilution, No. 1, No. 2, No. 3, and No. 4 enriched culture fluids were obtained,...

example 1

[0035] Raw material for flocculant extraction: take the sludge in the river water and store it at 4°C.

[0036] No. 1 Bacterial Solid Medium: In terms of parts by mass, take 3 parts of beef extract, 6 parts of peptone, 15 parts of agar, 2 parts of NaCl, 1000 parts of water, pH 7, sterilized at 121°C for 20 minutes.

[0037] No. 2 mold solid medium: in parts by mass, take 20 parts of sucrose, NaNO 3 1 copy, K 2 HPO 4 0.5 parts, MgSO 4 0.2 parts, FeSO 4 0.01 parts, 13 parts of agar, 1000 parts of water, pH 7, sterilized at 115°C for 20 minutes.

[0038] No. 3 actinomycetes solid medium: by mass parts, take 18 parts of soluble starch, KNO 3 0.6 parts, K 2 HPO 4 0.3 parts, MgSO 4 ·7H 2 O0.2 parts, FeSO 4 ·7H 2 0.02 parts of O, 0.4 parts of NaCl, 15 parts of agar, 1000 parts of water, pH 7, sterilized at 121°C for 20 minutes.

[0039] No. 4 fungal solid medium: in parts by mass, 180 parts of potatoes, 20 parts of sucrose, 18 parts of agar, 1000 parts of water, natural p...

example 2

[0049] Raw material for flocculant extraction: take the sludge in the river water and store it at 4°C.

[0050] No. 1 Bacterial Solid Medium: In terms of parts by mass, take 5 parts of beef extract, 10 parts of peptone, 20 parts of agar, 3 parts of NaCl, 1000 parts of water, pH 7.4, and sterilize at 121°C for 20 minutes.

[0051] No. 2 mold solid medium: by mass parts, take 25 parts of sucrose, NaNO 3 2 copies, K 2 HPO 4 0.8 parts, MgSO 4 0.3 parts, FeSO 4 0.03 parts, 15 parts of agar, 1000 parts of water, pH7.2, sterilized at 115°C for 20min.

[0052] No. 3 actinomycetes solid medium: in parts by mass, take 20 parts of soluble starch, KNO 3 1 copy, K 2 HPO 4 0.6 parts, MgSO 4 ·7H 2 O0.5 parts, FeSO 4 ·7H 2 0.03 parts of O, 0.7 parts of NaCl, 20 parts of agar, 1000 parts of water, pH 7.4, sterilized at 121°C for 20 minutes.

[0053] No. 4 fungal solid medium: in parts by mass, 200 parts of potatoes, 22 parts of sucrose, 20 parts of agar, 1000 parts of water, natural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com