Combined electroplating equipment with flocculation function and electroplating method thereof

An electroplating equipment and combined technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, electrolysis process, etc., can solve the problems of wasting available resources, cumbersome electroplating steps, and low degree of mechanization, and achieve convenient flocculation treatment, facilitate electroplating work, and improve the effect of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

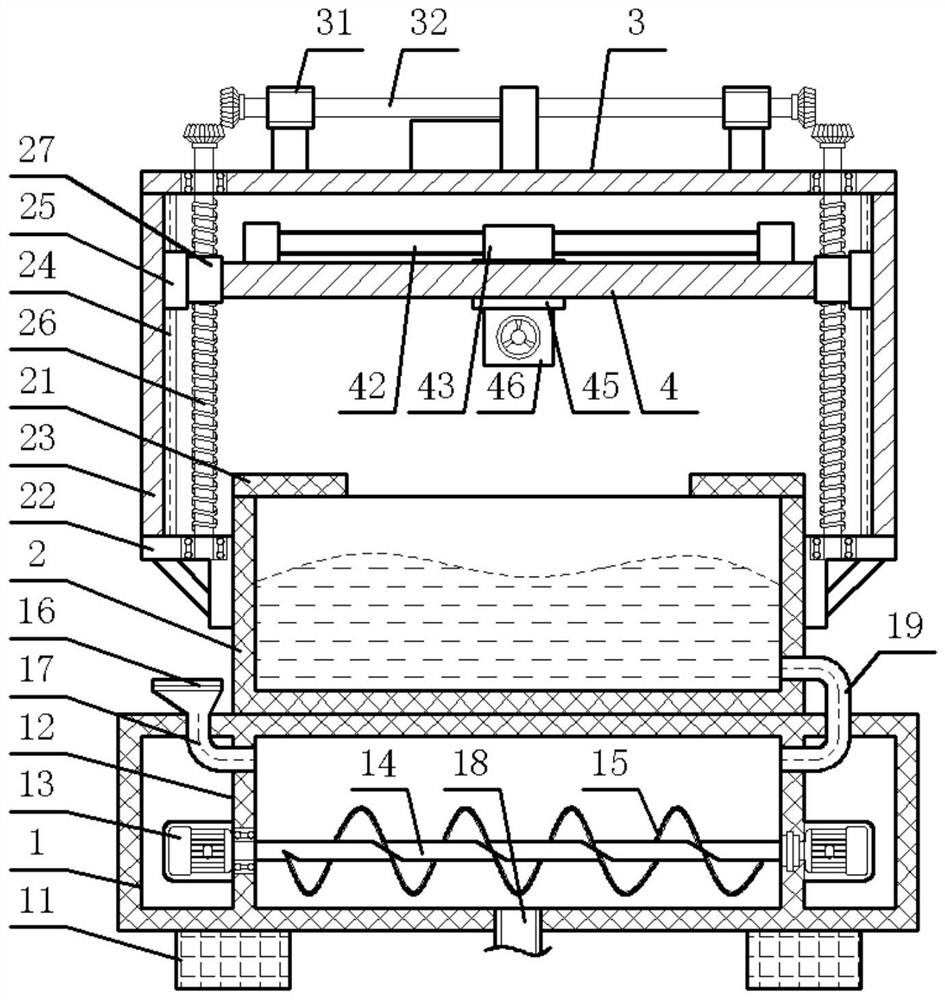

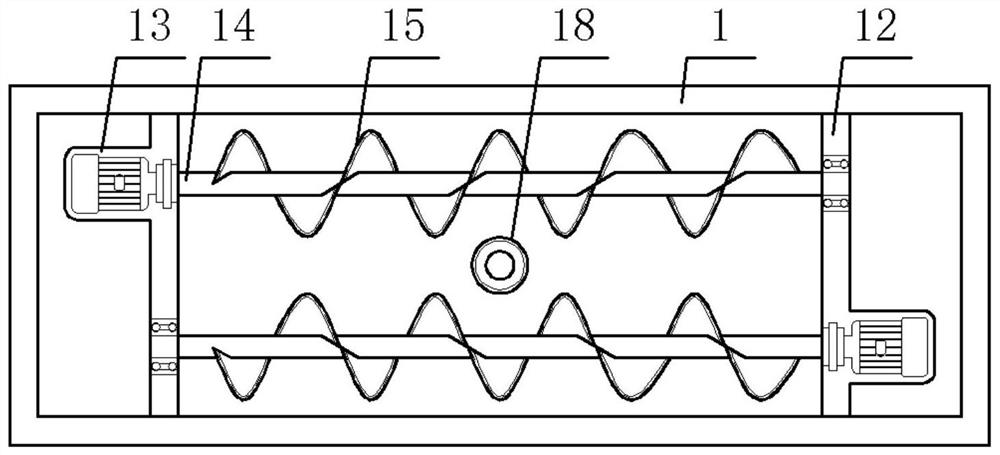

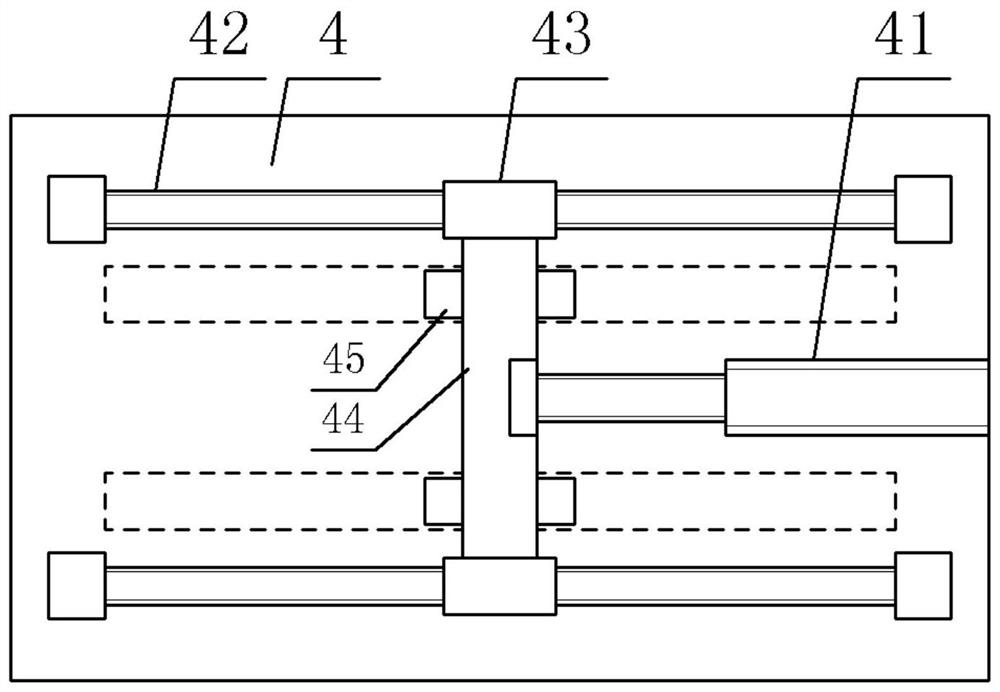

[0039] Example 1: In order to simplify the tedious operation steps of electroplating, improve the mechanization of electroplating operation, and further improve the efficiency of sewage treatment, a combined electroplating equipment with flocculation function is proposed in this example, see Figure 1-5 , including a flocculation box 1, an electroplating box 2, a stirring component, a lifting component, a driving mechanism, a sliding mechanism, and a clamping component. The flocculation box 1 is a rectangular box placed horizontally and horizontally, and the electroplating box 2 is open on the top surface. The bottom surface of the electroplating box 2 and the top surface of the flocculation box 1 are fixedly welded; the two sides of the flocculation box 1 are provided with a pair of sealing partitions 12, which are located between the pair of sealing partitions 12 and the flocculation box 1 A flocculation chamber is formed inside, and stirring components are staggeredly instal...

Embodiment 2

[0045] Embodiment 2: In order to realize manual clamping of the workpiece, in the present invention, the clamping assembly includes a manual wheel 53, a clamping threaded rod 52, and a clamping backing plate 5. The middle of the clamping plate 46 located in the front is provided with a A clamping threaded barrel 51 that penetrates through is provided with a clamping threaded rod 52 that spirally penetrates through the clamping threaded barrel 51, and a manual wheel 53 is provided at the outer end of the clamping threaded rod 52; located between the two clamping plates 46 A pair of clamping pads 5 are arranged between them, and the clamping plate 46 located at the rear is fixedly connected with the clamping pad 5 at the rear. The inner end of 52 is snap-fitted and inserted into the turning groove; the upper and lower ends of the threaded barrel 51 are recessed on the front clamping plate 46 with a pair of limit holes, and limit rods 54 for sliding connection are inserted into th...

Embodiment 3

[0046] Embodiment 3: In order to further realize the actual use operation to this application, refer to Image 6 , in this embodiment, the electroplating method of the combined electroplating equipment with flocculation function is proposed, comprising the following steps:

[0047] Step 1, the stirring motor 13 is electrically connected to the external power supply through the first power cord, the drive motor 33 is electrically connected to the external power supply through the second power cord, and the telescopic cylinder 41 is electrically connected to the external power supply through the third power cord; 2, pour an appropriate amount of electroplating solution, and place the workpiece to be electroplated on the middle of the top surface of the support plate 21;

[0048] In step 2, the lifting assembly is driven by the driving mechanism, and then the lifting plate 4 is driven down to an appropriate clamping height; the motor shaft of the driving motor 33 is controlled to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com