Sludge dewatering process and system employing combination of sludge wall-breaking and ultrahigh-pressure squeezer

A sludge dewatering and ultra-high pressure technology, which is used in water/sludge/sewage treatment, presses, sludge treatment, etc. problems, to achieve the effect of shortening the batch running time, reducing the dosage of chemicals, and shortening the mud feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

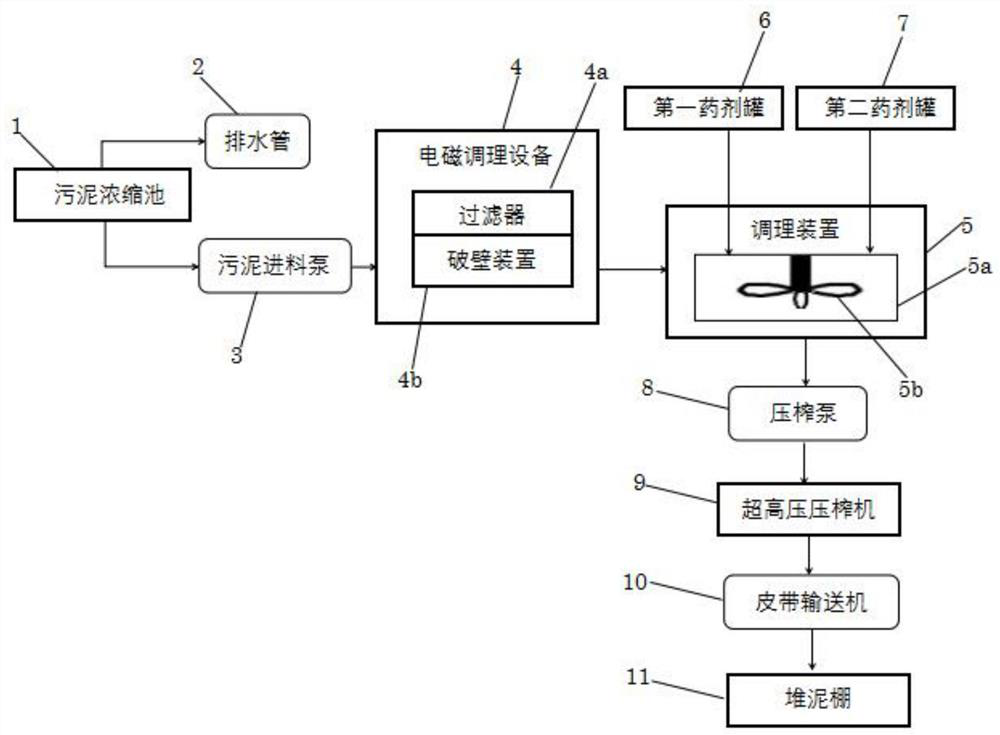

[0022] In order to achieve the technical means of the present invention, the creation of features, to achieve the purpose and effect readily apparent understood, the following examples in conjunction with the accompanying drawings of the sludge and sludge dewatering process of the present invention and the broken EHV press for binding specifically addressed.

[0023] like figure 1 , The present embodiment provides a sludge deep dehydration treatment system, comprising: a sludge thickening tank, the sludge feed pump 3, the solenoid conditioning device 4, the conditioning means 5, 6 can first agent, second agent tank 7, 8 press the pump, high pressure press 9, the conveyor belts 10 and 11 shed mud stack.

[0024] Sludge thickening tank 1 for storing the sludge was allowed to stand. Sludge thickening tank 1 cell reinforced concrete structure. An upper end portion of the sludge thickening tank 1 is provided with a drain pipe 2. High moisture content sludge remain in the original sludg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com