Patents

Literature

61results about How to "Improve filter press effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

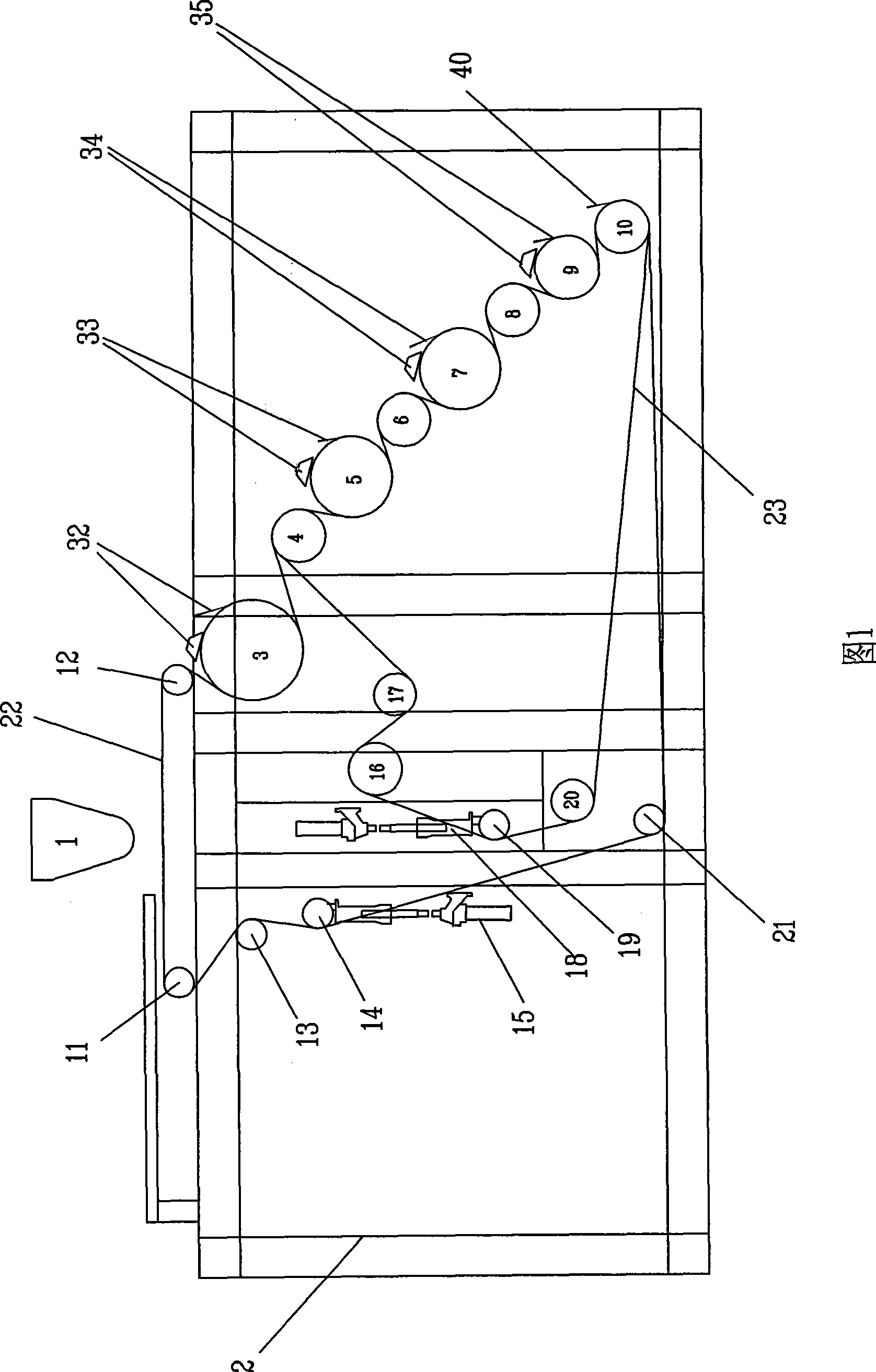

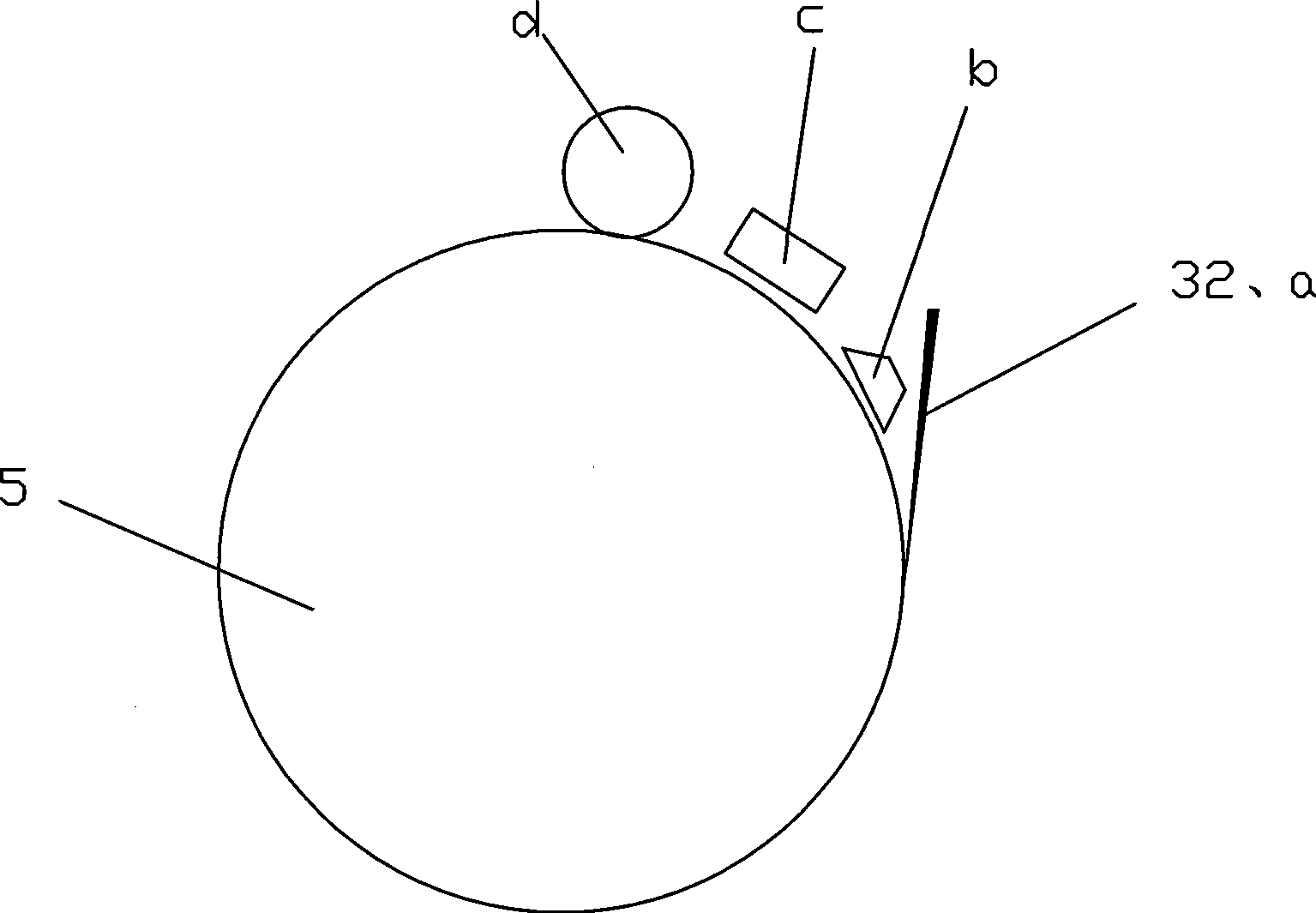

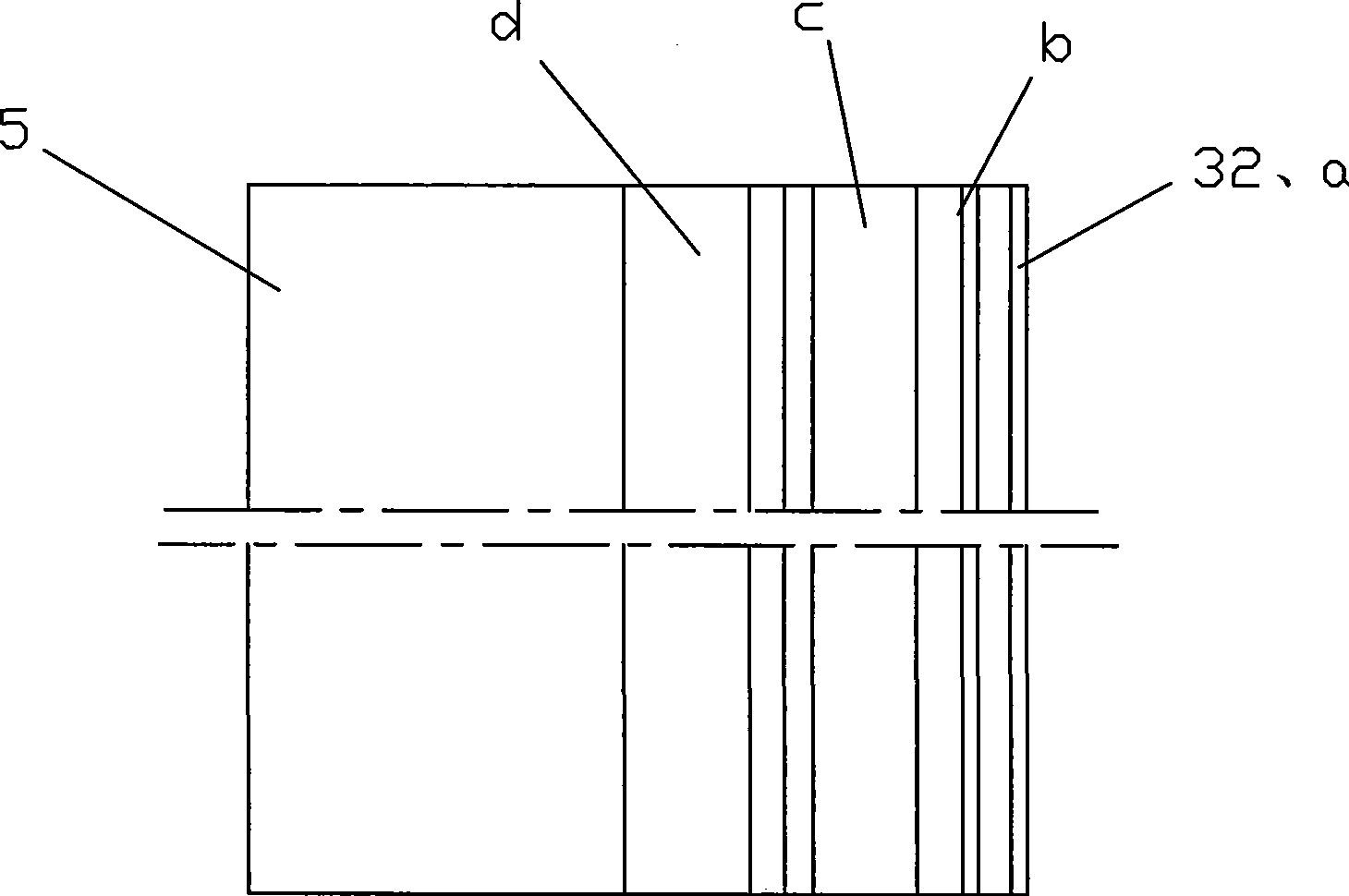

Lining band type filter press with press rolls for fixing mud

InactiveCN101376073ARestore elasticityImprove working conditionsPressesMoving filtering element filtersPulp and paper industryFilter press

The invention discloses a lining belt type pressure filter with a solid mud press roller. The press filter comprises a stander, a driving device, a feeding device, a press area and an auxiliary device, and has the structure that the press area comprises the solid mud press roll, a carrier roller, a guide roller, a filtering stripe and a compression lining belt; the solid mud press roller is a press roller with a solid mud layer covering the surface of the roller, and the solid mud layer adopts the material which has high elasticity, high recoverability, and high fraction coefficient, and is easy to separate from dehydrate material; the solid mud press roller is provided with a maintenance device, which is arranged behind the press position of the solid mud press roller, and the elasticity and the fraction coefficient of the solid mud layer can be recovered in time through the maintenance to the solid mud press roller by the maintenance device; the filtering stripe wraps the solid mud press roller, the carrier roller and the guide roller in sequence; the compression lining belt and the filtering stripe are stacked in parallel in the press segment of the press area; the driving device drives filtering stripe and the compression lining belt; and the feeding device and the auxiliary device are arranged in the corresponding positions of the filtering stripe. The pressure filter of the invention has solid mud structure, thereby effectively solving the problem of mud leaking and achieving better press filter effect.

Owner:ZHEJIANG HUAZHANG TECH

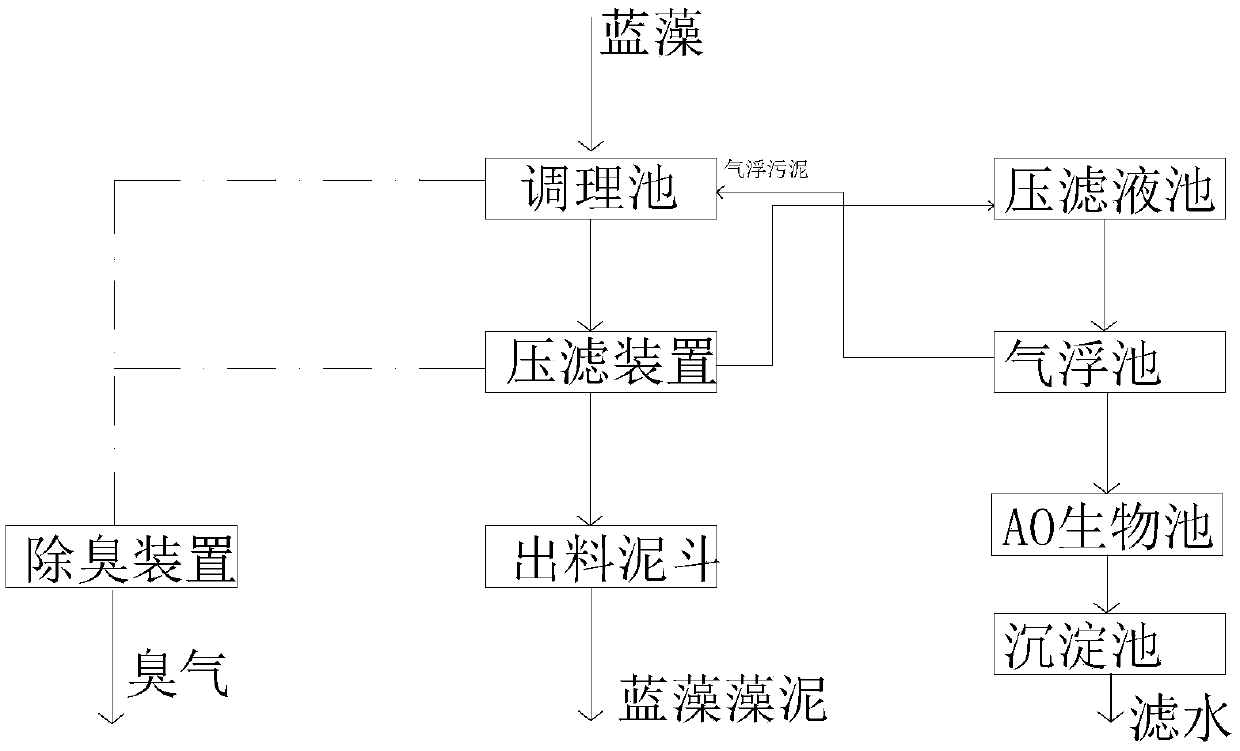

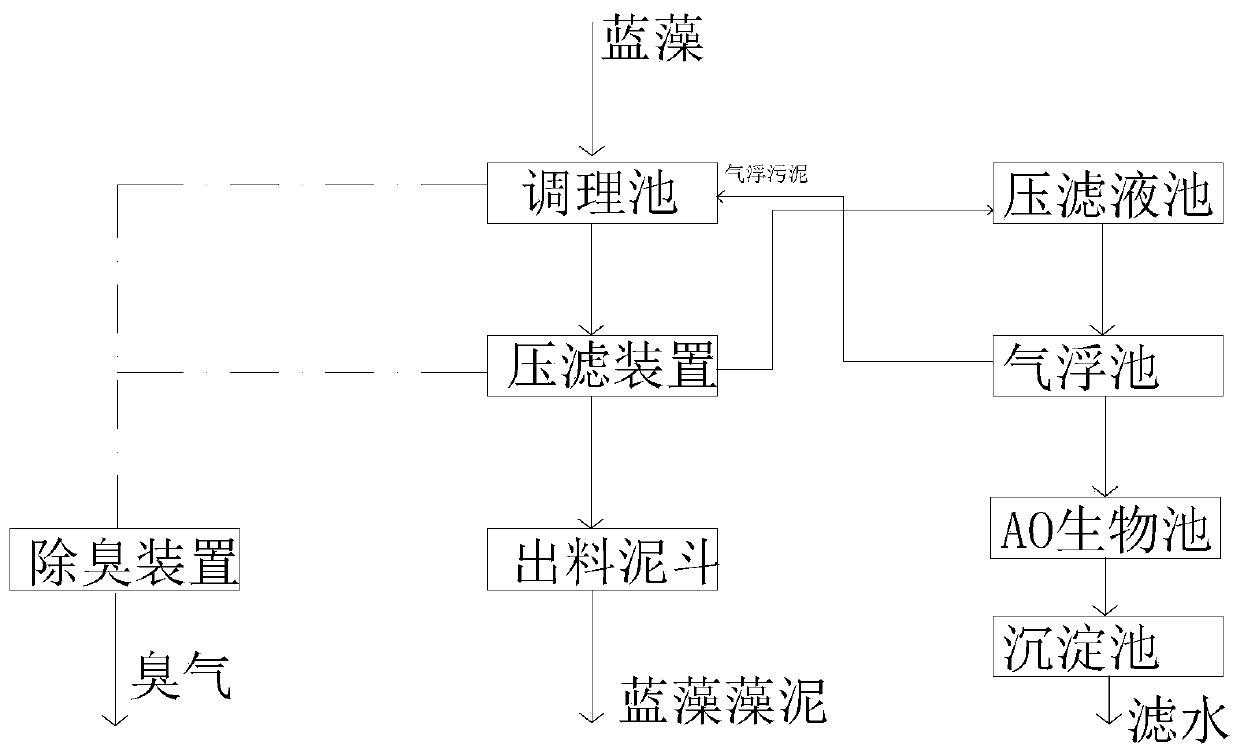

Method for deep dehydration of cyanobacteria

ActiveCN109553266AReduce the impactReduce processing loadSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAlkalinityFiltration

The invention belongs to the technical field of environmental engineering, and particularly relates to a method for deep dehydration of cyanobacteria. The method comprises the steps: conditioning cyanobacteria produced by an algae-water separation station, performing filter pressing so as to obtain cyanobacteria algae gel with a water content of 60% or below, and treating filtered water through analkali liquid, an air floating pool, an AO biological pool and a sedimentation tank so as to meet the urban sewage discharge standard, wherein the alkali liquid is used for adjusting the pH value ofthe filtered water to neutrality or weak alkalinity, in the air floating pool, a coagulant and coagulant aids are utilized to perform a coagulation reaction with the filtered water, and after floc isformed, solid-liquid separation is conducted through an air floatation effect. The problem of high water content of the cyanobacteria algae gel is solved, and the water content of the cyanobacteria algae gel can be reduced effectively after conditioning and pressure filtration are performed, so that reduction of the cyanobacteria is achieved after salvage is performed, and subsequent treatment isfacilitated.

Owner:无锡市水务集团有限公司

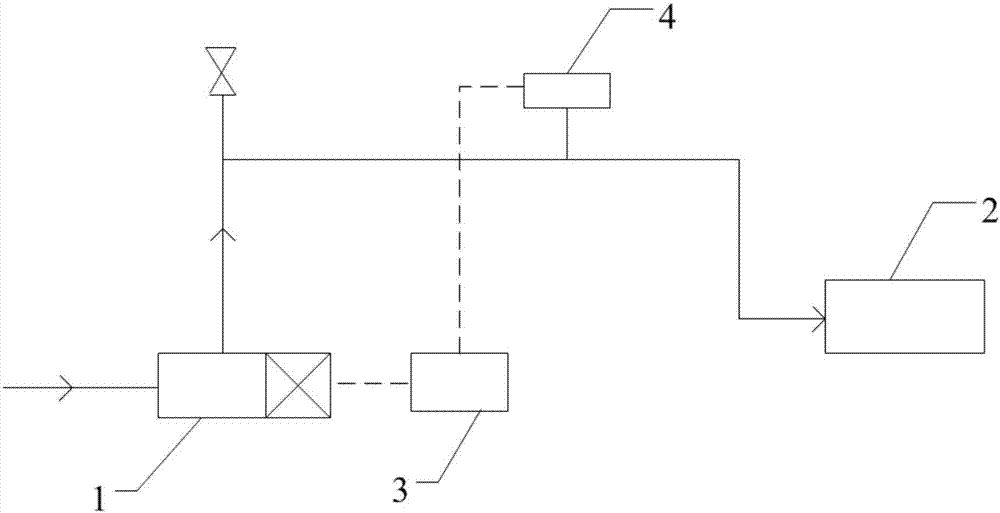

Sludge press filtration treatment system and method

ActiveCN107382011AImprove processing efficiencyEasy to operate manuallyWater treatment parameter controlSludge treatment by de-watering/drying/thickeningElectricitySignal on

The invention provides a sludge press filtration treatment system and method and relates to the technical field of sludge treatment. The sludge press filtration treatment system comprises a sludge pump, a press filter and a controller, wherein the sludge pump is connected with the press filter through a conveying pipeline, a pressure sensor is arranged on the conveying pipeline, and the controller is electrically connected with the sludge pump and the pressure sensor; the pressure sensor is used for detecting a pressure signal on the conveying pipeline and outputting the pressure signal to the controller, and the controller controls the operation state of the sludge pump according to the pressure signal. The technical problems that a current sludge dewatering treatment system is low in automation degree and low in treatment efficiency, the pressure is not stable in the sludge water conveying process, a sludge inlet system cannot be effectively controlled, and the service life and the press filtration effect of the press filter are affected are solved. Operation of a sludge pump is controlled according to pressure point location during sludge conveying of the press filter, the manual operation procedure is simplified, the intelligence degree is high, and the press filter operates stably.

Owner:杭州绿夏环境科技有限公司

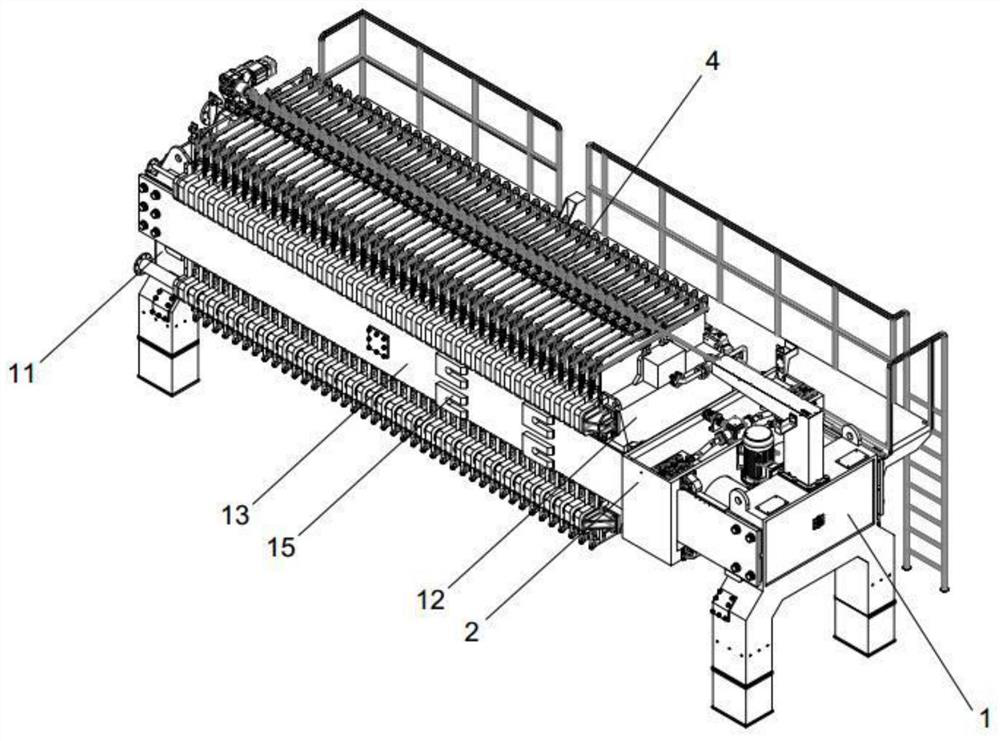

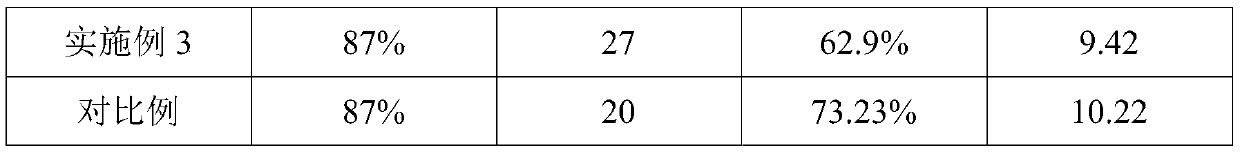

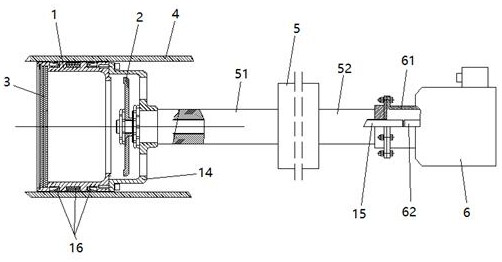

Cantilever type filter press

ActiveCN112121482AImprove work efficiencyRealize synchronous opening and closingFiltration separationMechanical equipmentFilter press

The invention provides a cantilever type filter press, which belongs to the field of mechanical equipment and comprises a rack, a fixed end plate is arranged at one end of the rack, and a movable endplate is arranged at the other end of the rack; the filtering device is arranged on the rack and comprises a plurality of filtering plate units provided with filtering cloth and a filtering cloth driving mechanism, and the filtering plate units are arranged between the movable end plate and the fixed end plate; the driving device is connected with the movable end plate and drives the movable end plate to move in the length direction of the rack; The tensioning oil cylinder is arranged on the rack; when the device is used, the driving device drives the movable end plate to push the filter plateunits in the filter device to be pressed, then materials are injected into the filter plate units, and the tensioning oil cylinder contracts to extrude and filter the materials; and after the filterpressing is finished, the driving device drives the filter plate units to separate, and then the filter cloth driving mechanism drives the corresponding filter cloth in the plurality of filter plate units to synchronously move so as to unload a filter cake.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

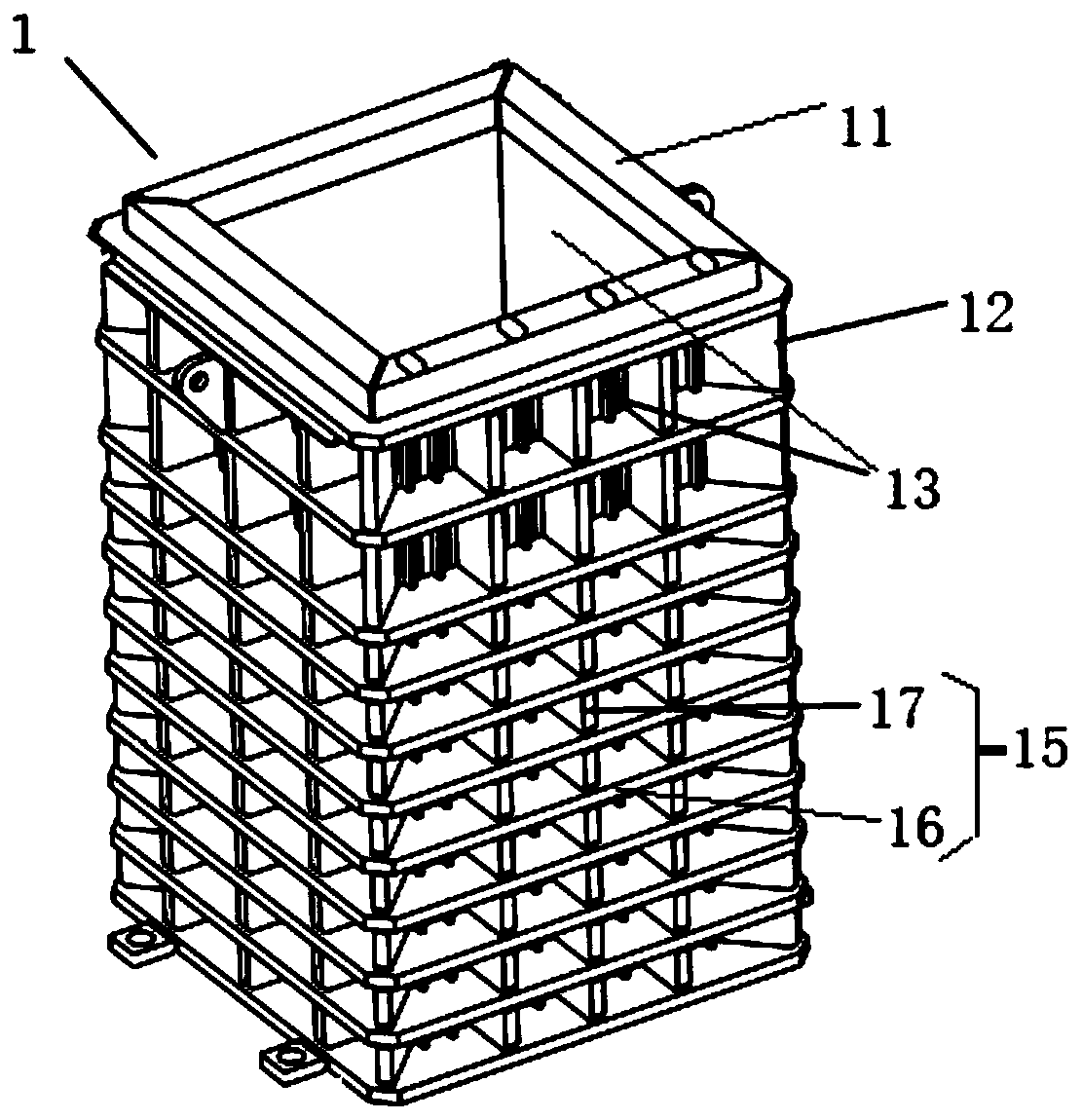

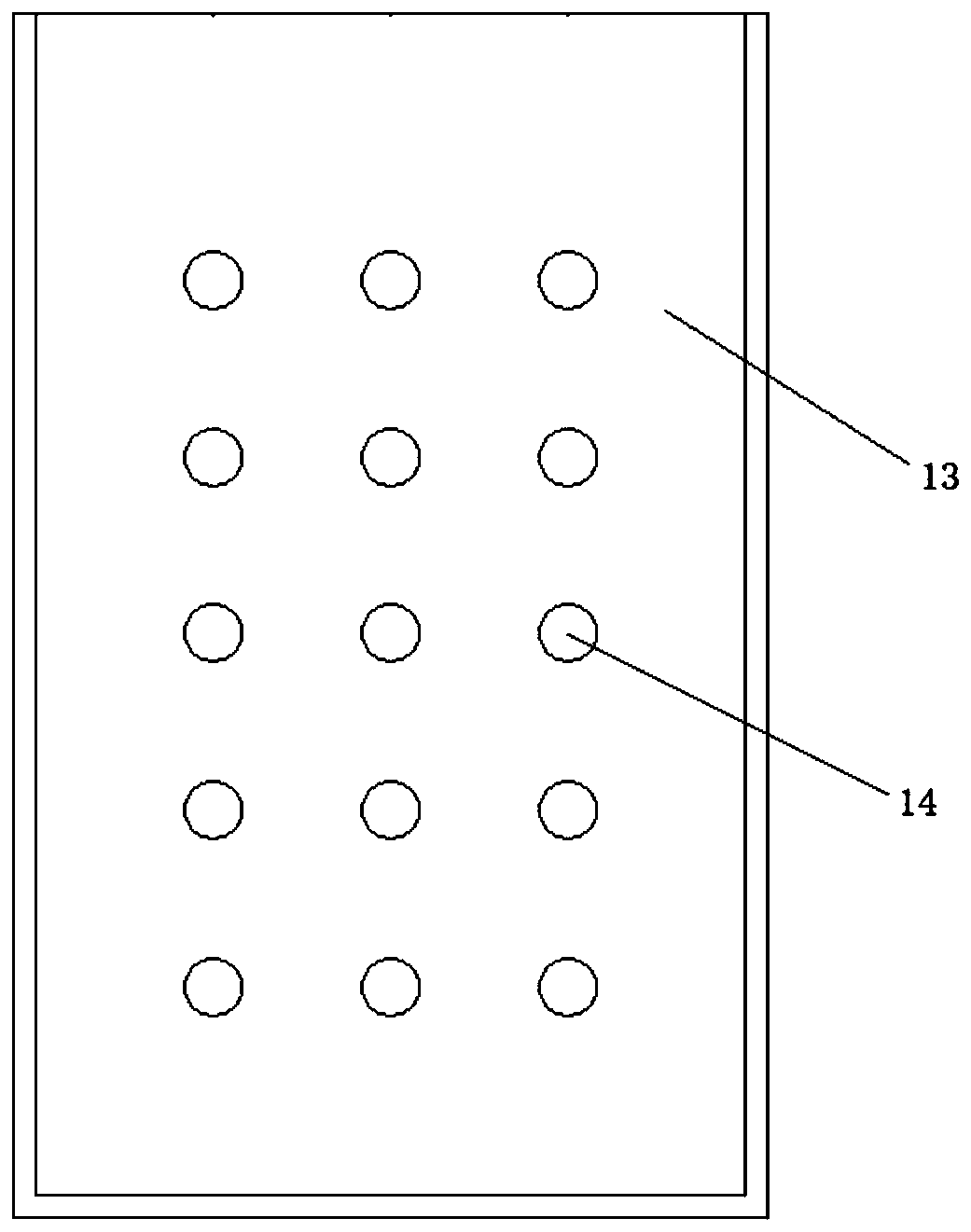

Partition-plate-free open-close type filter chamber for sludge dewatering

PendingCN111453962AAvoid the problems of fixing in the filter chamberReduce labor costsSludge treatmentFiltration separationFilter mediaStructural engineering

The utility model discloses a partition-plate-free open-close type filter chamber for sludge dewatering, and belongs to the technical field of sewage treatment. The filter chamber comprises two rectangular frames and four upright posts, and one upright post is arranged at each of four corners of each of the two rectangular frames to form a three-dimensional frame; a filter plate is arranged between every two adjacent stand columns on the inner side of the three-dimensional frame; a plurality of filter holes are formed in the filter plate; a filter chamber is defined by the filter plates; reinforcing rib plates for supporting the filter plate are arranged on the filter plate between every two adjacent stand columns on the outer side of the three-dimensional frame, wherein one side face of the filter chamber is of an open-close structure to form a filter chamber door; one side of the filter chamber door is rotationally connected with the stand columns connected with the filter chamber door, and the other side of the filter chamber door is matched with the adjacent stand columns to be closed. The filter chamber is opened / closed by arranging the filter chamber door, so that mud cakes obtained after filter pressing in the filter chamber are rapidly poured out, and the labor cost is reduced. The filter medium is directly mounted in the filter chamber, so that the time required for replacing the filter medium is shortened, and the working efficiency of the filter press is improved.

Owner:辽宁省环保集团有限责任公司 +2

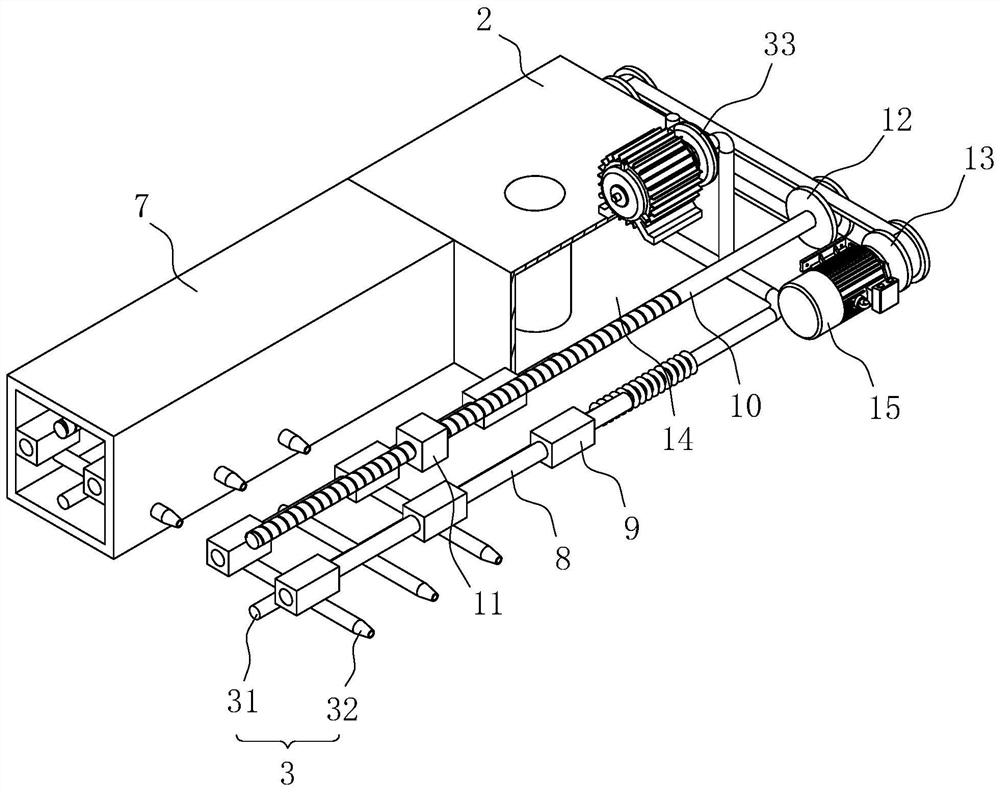

Mud filter pressing treatment device for ceramic production and processing, and using method thereof

InactiveCN111632423AEasy to useImprove filter press effectTransportation and packagingMixersEngineeringSlurry

The invention discloses a mud filter pressing treatment device for ceramic production and processing, and relates to the technical field of ceramic processing. The device comprises a box body, and a first push plate is in sliding fit with the interior of the box body; supporting rods are arranged on the two sides of the top of the box body; a fixed plate is fixed to the top ends of the supportingrods; first air cylinders are arranged on the two sides of the fixed plate; pressing plates are fixed to the ends of the two first air cylinders; a second cylinder is arranged at the top of the box body; the end of a piston rod of the second cylinder is fixedly connected with a second push plate; cavities are formed in the two ends of the bottom in the box body; an air blower is arranged in each cavity; the air outlet ends of the blowers communicate with an aerator pipe; and air guide pipes are arranged on the peripheral side surface of the aeration pipe in an array. Mud and a flocculating agent in the box body are mixed and reacted through aeration, flocculated coagulum and mud are filtered out under the action of the two first push plates to avoid the situation that the use amount of rawmaterials is increased due to escape of the slurry, and the mud obtained after filter pressing is automatically discharged, so the labor intensity of workers is reduced, and the working efficiency ofmud filter pressing is improved.

Owner:芜湖鑫霖森椽环保科技有限公司

Combined process for sludge treatment

InactiveCN111675466ASmall particle sizeReduce dry basis weight gainSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeWater treatment

The invention discloses a combined process for sludge treatment, and relates to the field of sludge treatment. The combined process comprises the following steps: 1) sludge conditioning: sequentiallyadding sulfuric acid, ferrous ions, a hydrogen peroxide solution and a metal oxide into to-be-treated sludge, stirring and carrying out an advanced oxidation reaction; 2) dehydration treatment: sending the sludge treated in the step 1) into a dehydration device for a dehydration treatment; 3) crushing and screening: feeding the sludge treated in the step 2) into a crusher, crushing, adding a biomass raw material, fully mixing, and feeding the crushed sludge into a screen for screening; and 4) granulation: feeding the sludge treated in the step 3) into a granulator for granulation. The sludge is conditioned by using an advanced oxidation method, so that the dry basis weight gain of the sludge is effectively reduced, no chloride ion is added in the treatment process, and the treatment difficulty and cost of filtrate are reduced. Dehydrated sludge is mixed with a biomass raw material for granulation, and can be used as a raw material for incineration of a biomass power plant.

Owner:AWS ENVIRONMENT TECH LTD

Resource utilization method of urban sludge

InactiveCN109467302AImprove qualityImprove dehydration effectSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSludge cakeInorganic salts

The invention discloses a resource utilization method of urban sludge. The resource utilization method sequentially comprises the following steps: adding sludge to a stirring barrel; adding a certainproportion of clean water to dilute the sludge, so that the water content of the sludge reaches 90% or more; then, adding an agent A to be fully mixed and stirred, wherein the agent A is compounded bya polymer flocculant and an inorganic salt; feeding the sludge into an integrated belt filter press; feeding the sludge added with the flocculant into a filter press for filter-pressing to obtain loose sludge cakes; piling up the loose sludge cakes at a ventilated place at room temperature for naturally drying until the water content is 60-65%; then, adding fermentation probiotics, an organic carbon source and a nitrogen source to be fully mixed and stirred; and performing three stages of fermentation until organic nutrient soil having the water content of 25-35% is obtained. The method has the advantage that the organic nutrient soil with better quality can be prepared.

Owner:JIANGSU XIANGYU ENVIRONMENTAL PROTECTION EQUIP +1

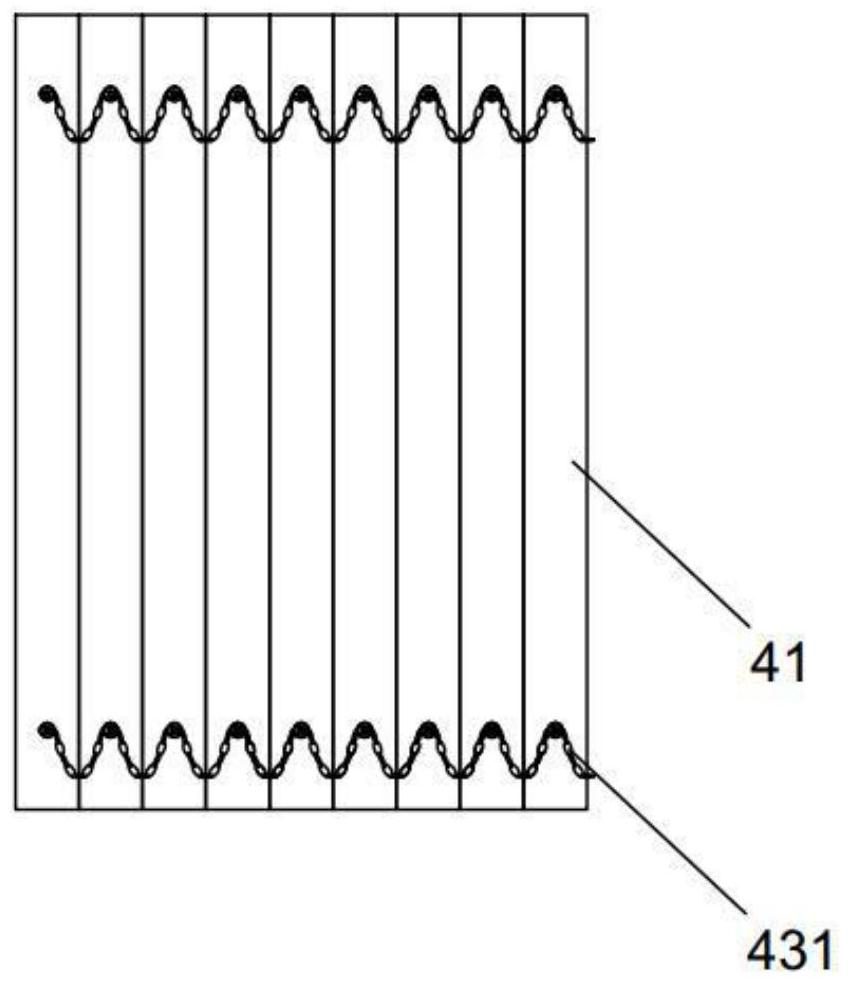

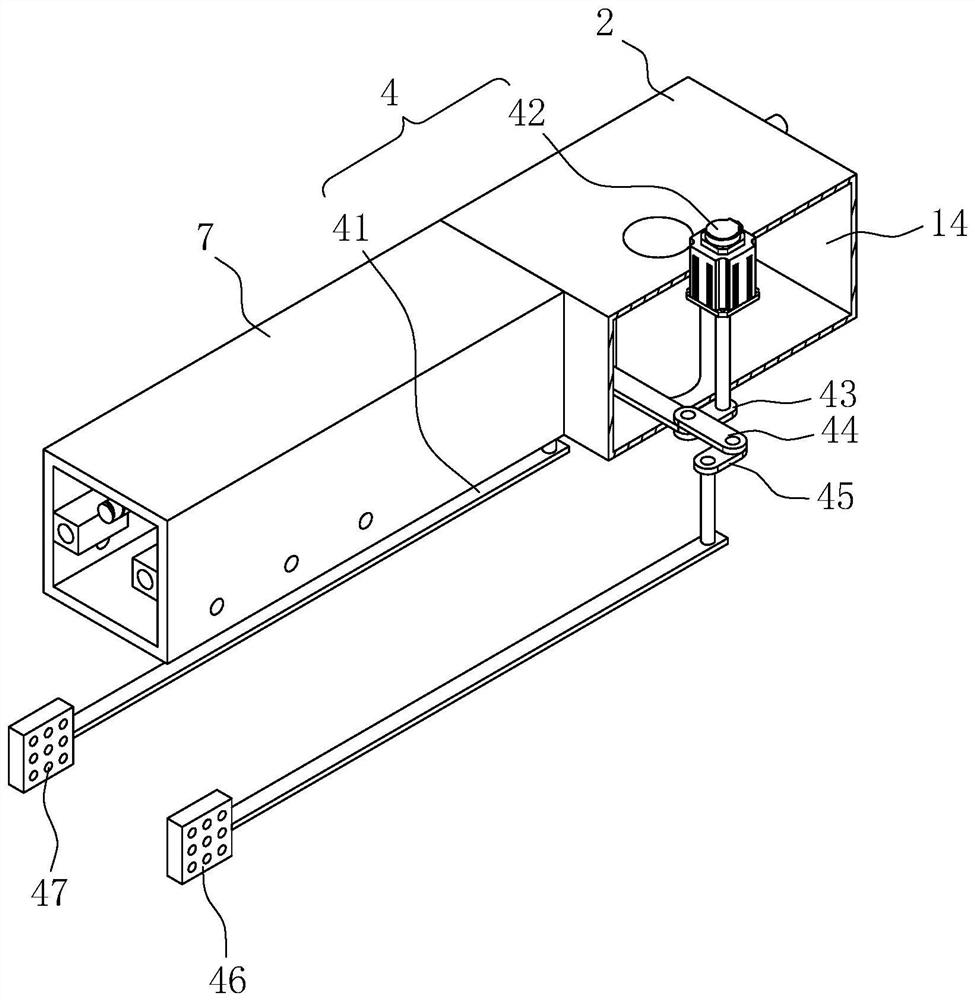

Improved filter press

The invention discloses an improved filter press, which is characterized in that a flexible linkage mechanism is creatively applied to the filter press, and flowing of feed liquid is used as power output at the same time, so that the flexible linkage mechanism can actively fluctuate to drive filter cloth to shake up and down all the time. Meanwhile, due to the fact that the flexible linkage mechanism can transmit locally excessive fluctuating force to the whole flexible linkage mechanism, the filter cloth can be evenly stressed on the whole. Meanwhile, the fluctuating filter cloth can ensure that filter holes are not blocked, water in filter residues can be discharged more sufficiently, and the filter pressing effect is improved.

Owner:福建省创绿机械股份有限公司

Recyclable filter cake filter pressing device based on sewage treatment

InactiveCN112604343AEnhance filter press firmnessEasy to take outStationary filtering element filtersTool bitElectric machinery

The invention discloses a recyclable filter cake filter pressing device based on sewage treatment. The device comprises an extrusion device and a filter pressing table, wherein a water receiving barrel is arranged on one side of the lower end of a top plate through cooperation of a first hanging rod and the annular wall of a protrusion, first bevel gears are oppositely arranged on the inner walls of the two sides of the water receiving barrel through cooperation of L-shaped plates and connecting rods, shifting plates are arranged on the outer walls of the connecting rods through rotating rings, a first rotating shaft with the upper end and the lower end provided with a second bevel gear and a third bevel gear respectively is suspended in the inner cavity of the water receiving barrel, double-blade tool bits are arranged on the outer wall of the first rotating shaft, the third bevel gear is connected with the first bevel gears in a meshed mode, the first rotating shaft is connected to a motor transmission shaft on the outer wall of a side plate through the second bevel gear meshed with a fourth bevel gear at the end of a second rotating shaft, after the motor is started, the second rotating shaft and the first rotating shaft are sequentially driven to rotate, the first rotating shaft drives the double-blade tool bits to smash sundries in the water receiving barrel while rotating, and the third bevel gear is matched with the first bevel gear and the connecting rod to drive the rotating ring to rotate, so that the sundries at the bottom of the water receiving barrel are turned over to be smashed, and the filter pressing effect of equipment is promoted.

Owner:葛新春

Side beam type filter press

ActiveCN112121487AImprove work efficiencyRealize synchronous opening and closingFiltration separationMechanical equipmentFilter press

The invention provides a side beam type filter press, which belongs to the field of mechanical equipment and comprises a rack, wherein a fixed end plate is arranged at one end of the rack, and a movable end plate is arranged at the other end of the rack; a filtering device which is arranged on the rack and comprises a plurality of filtering plate units provided with filtering cloth and a filteringcloth driving mechanism, wherein the filtering plate units are arranged between the movable end plate and the fixed end plate; a driving device which is connected with the movable end plate and drives the movable end plate to move in the length direction of the rack; when the filter press is used, the driving device drives the movable end plate to push the filter plate units in the filter deviceto be pressed, and then materials are injected into the filter plate units for filter pressing; and after the filter pressing is finished, the driving device drives the filter plate units to separate,and then the filter cloth driving mechanism drives the corresponding filter cloth in the plurality of filter plate units to synchronously move so as to unload a filter cake.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Filter press for achieving solid-liquid separation of wastewater

InactiveCN105879447AImprove the effectImprove efficiencyFiltration separationMechanical engineeringFilter press

The invention discloses a filter press for solid-liquid separation of waste water. The invention comprises a frame, four guide rollers are arranged on the frame, and a plurality of filter mechanisms are set on the guide rollers. The filter mechanism It includes a filter frame and a filter plate body, the filter frame and the filter plate body are sleeved on the guide roller, the surroundings of the filter plate body protrude outward to form a frame, and the four corners of the frame are provided with positioning holes. The upper end and the lower end of the frame are respectively provided with an upper chute and a lower chute, the upper chute and the lower chute are provided with a plate body, the upper chute is provided with a first elastic pressure block, and the lower chute is provided with a There is a second elastic pressing block, the length of the first elastic pressing block is greater than the length of the second elastic pressing block, the ends of the upper chute and the lower chute are equipped with locking blocks; the center of the plate body is provided with A feeding hole, a plurality of filter holes are evenly arranged around the feeding hole, and the filter holes are equipped with a filter cloth; the frame is also provided with a filter press mechanism.

Owner:SICHUAN KAIMING MACHINERY MFG

Dewatering method for stainless steel sludge

InactiveCN102897991AReduce hydrophilicityImprove dehydration effectSludge treatment by de-watering/drying/thickeningCalcium biphosphateMagnesium phosphate

The invention discloses a sludge processing method, which particularly relates to a dewatering method for stainless steel sludge. The dewatering method for the stainless steel sludge comprises the following steps of: adding polyacrylamide (PAM) into a concentration basin of stainless steel sludge of which the pH (potential of hydrogen) is 1.6-1.9 and the mass solid content is 8-10%, wherein the stainless steel sludge is generated by wet method smelting; enabling the concentration of the PAM in a stainless steel sludge basin to be 10-20ppm; then reacting for 15 minutes; then, adding calcium phosphate, magnesium phosphate or the mixture of the calcium phosphate and the magnesium phosphate, wherein the addition is 2-3.5% of the stainless steel sludge; carrying out stirring reaction for 15 minutes; and finally, carrying out mechanical filter pressing after reaction is finished. The dewatering method for the stainless steel sludge has the advantages of simple and convenient operation process and better dewatering effect, and is more favorable for further processing the sludge, and the environment is protected.

Owner:陈宇青

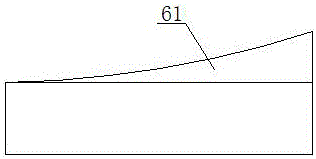

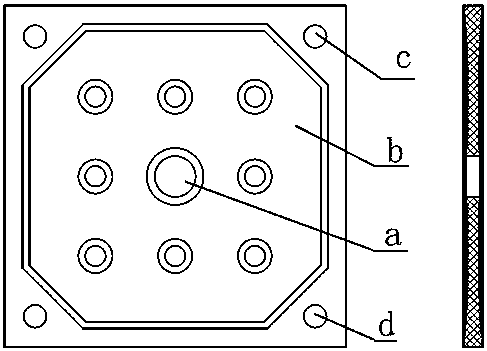

Filter plate for plate filter press

InactiveCN105903240AImprove removal efficiencyImprove filter press effectFiltration separationEngineeringFilter press

The invention discloses a filter plate for a plate filter press. The filter plate comprises a filter plate body of which four sides protrudes outwards to form a frame. Positioning holes are formed at four corners of the frame. An inclined plate body is arranged in the frame. The distance between the upper end of the plate body and a plane of the frame is shorter than the distance between the lower end of the plate body and the plane of the frame. The plate body and the frame are integrally molded to form the filter plate body. A feeding hole is formed at the center of the plate body. A plurality of filtering holes are uniformly formed around the feeding hole. Filtering holes are also formed in the lowest side of the plate body and provided with a filter cloth. An elastic frame matched with the plate body is arranged at one side of the filter plate body.

Owner:SICHUAN KAIMING MACHINERY MFG

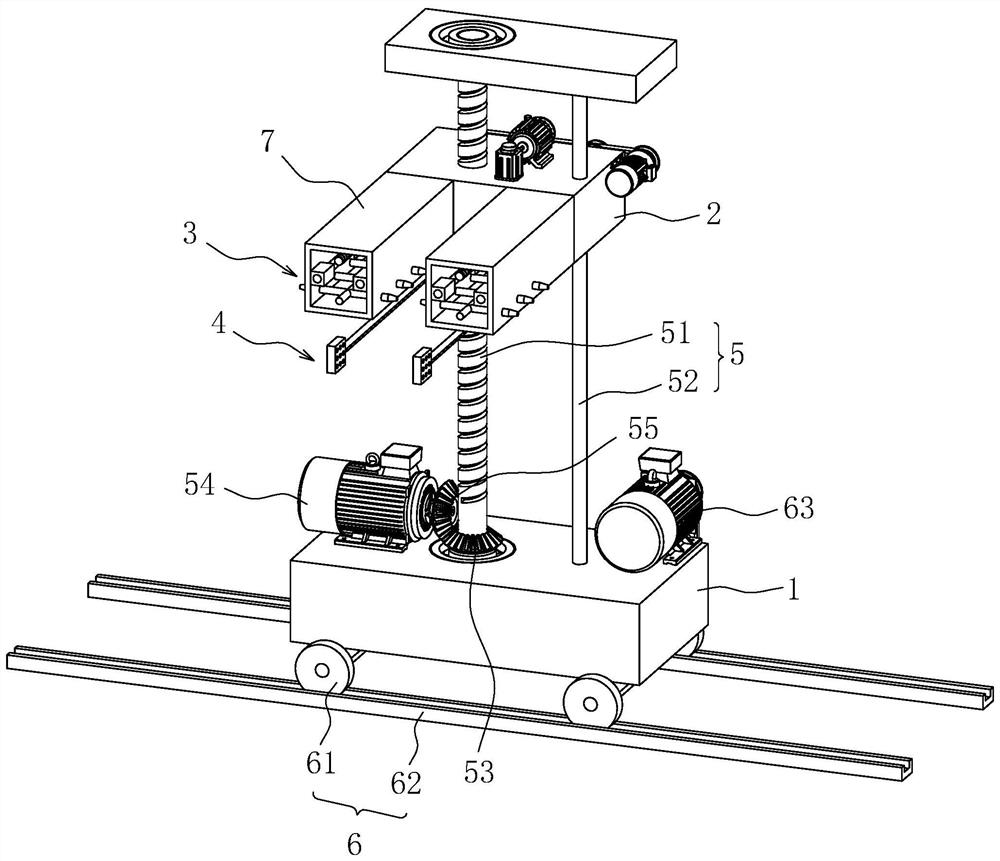

A filter press cleaning device

This application relates to the field of sewage discharge equipment, in particular to a filter press cleaning device, which includes a base and a mounting seat connected to the base, and a lifting assembly for lifting the mounting seat is provided between the base and the mounting seat. An installation chamber is provided, and a flushing assembly is provided in the installation chamber, a beating assembly for beating the filter plate is provided on the bottom surface of the installation seat, and a driving assembly for driving the base to move is provided on the base. The flushing assembly includes a delivery pipe arranged in the installation cavity, and a high-pressure nozzle connected to the delivery pipe. There are several high-pressure nozzles arranged at intervals along the length of the delivery pipe. A water pump is fixedly connected to the mounting base, and the delivery pipe communicates with the water pump. The present application has the effect of improving the cleaning effect of the filter plate, and further improving the filtering effect of the filter press.

Owner:昆山市天丰印刷包装有限公司

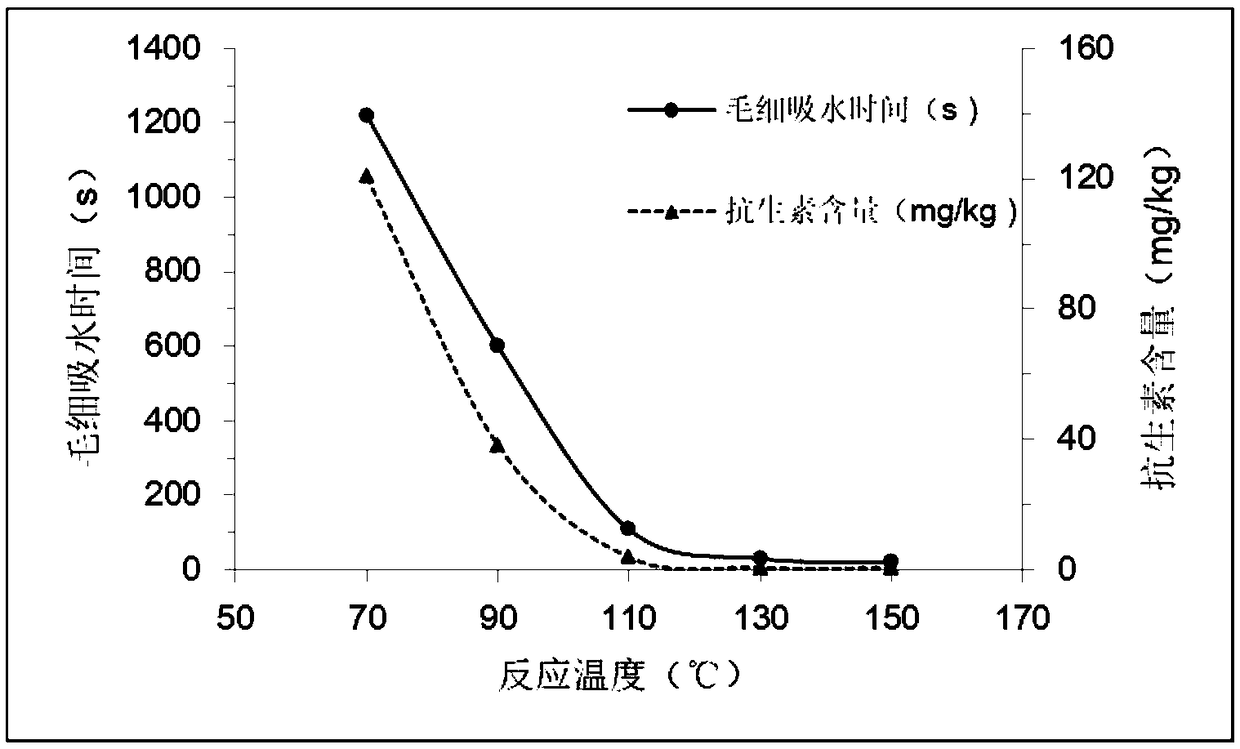

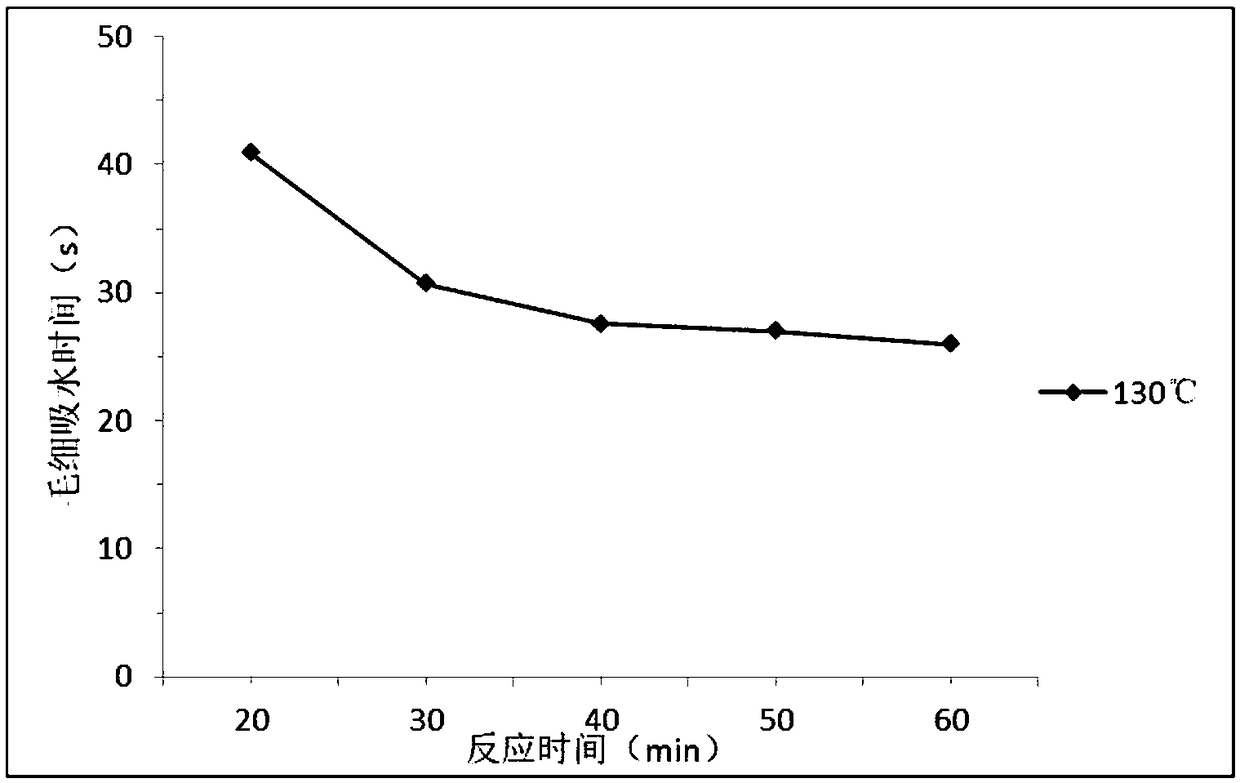

Poultry excrement hydrothermal treatment dewatering method

InactiveCN109320039AReduce capillary water absorption timeHigh degree of dehydrationSludge treatment by oxidationWater contaminantsFecesThermal treatment

The invention provides a poultry excrement hydrothermal treatment dewatering method which comprises the following steps: adding an oxidizing agent into fresh poultry excrement, mixing and performing hydrothermal reaction treatment; mixing the treated poultry excrement with a proper amount of water, then dewatering to finish the treatment on the poultry excrement. The poultry excrement hydrothermaltreatment dewatering method can perform dewatering treatment on the poultry excrement and has the advantages that equipment is simple and easy to operate, a treating speed is quick, a period is short, a dewatering degree is high, a solid recovery rate is high, energy consumption is low, cost is low, and a wide application prospect is achieved.

Owner:HUNAN AGRICULTURAL UNIV

Paper pulp dehydration device for decorative base paper production

PendingCN113152139AImprove functionalityImprove dehydration effectPulp de-wateringPulp bleachingPulp (paper)Paper production

The invention discloses a paper pulp dehydration device for decorative base paper production, which relates to the technical field of decorative base paper production. The paper pulp dehydration device comprises a base, the top of the base is fixedly provided with a washing dehydration cylinder through a mounting rack, and the top of the washing dehydration cylinder is fixedly connected with a raw pulp storage tank; a connecting channel is fixedly installed between the bottom of one end of the raw pulp storage tank and the washing dehydration cylinder, a vent hole is formed in the position, close to the top end of the washing dehydration cylinder, of the connecting channel, and a hollow rotating pipe is arranged in the center of the interior of the washing dehydration cylinder. The hollow rotating pipe is used for driving the eccentric rotating cylinder to eccentrically rotate, the rotating stirring rod is used for stirring to-be-processed paper pulp water, the inwards-concave area is in butt joint with the rectangular groove frame, the paper pulp water is preliminarily filtered, and in the process that the sleeve drives paper pulp to gradually approach the filter cover, the one-time filter pressing and dehydration function on the paper pulp is also completed, and the dehydration effect of the equipment on the paper pulp is enhanced.

Owner:马鞍山华旺新材料科技有限公司

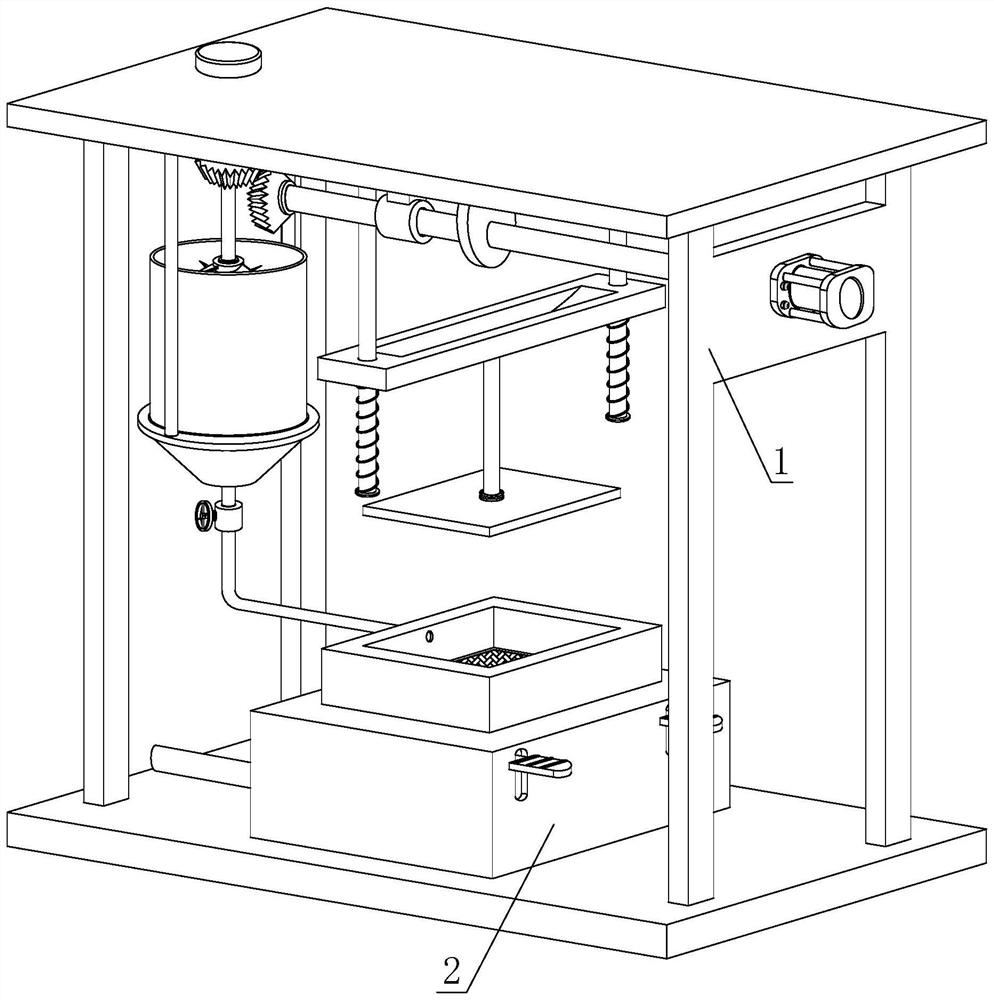

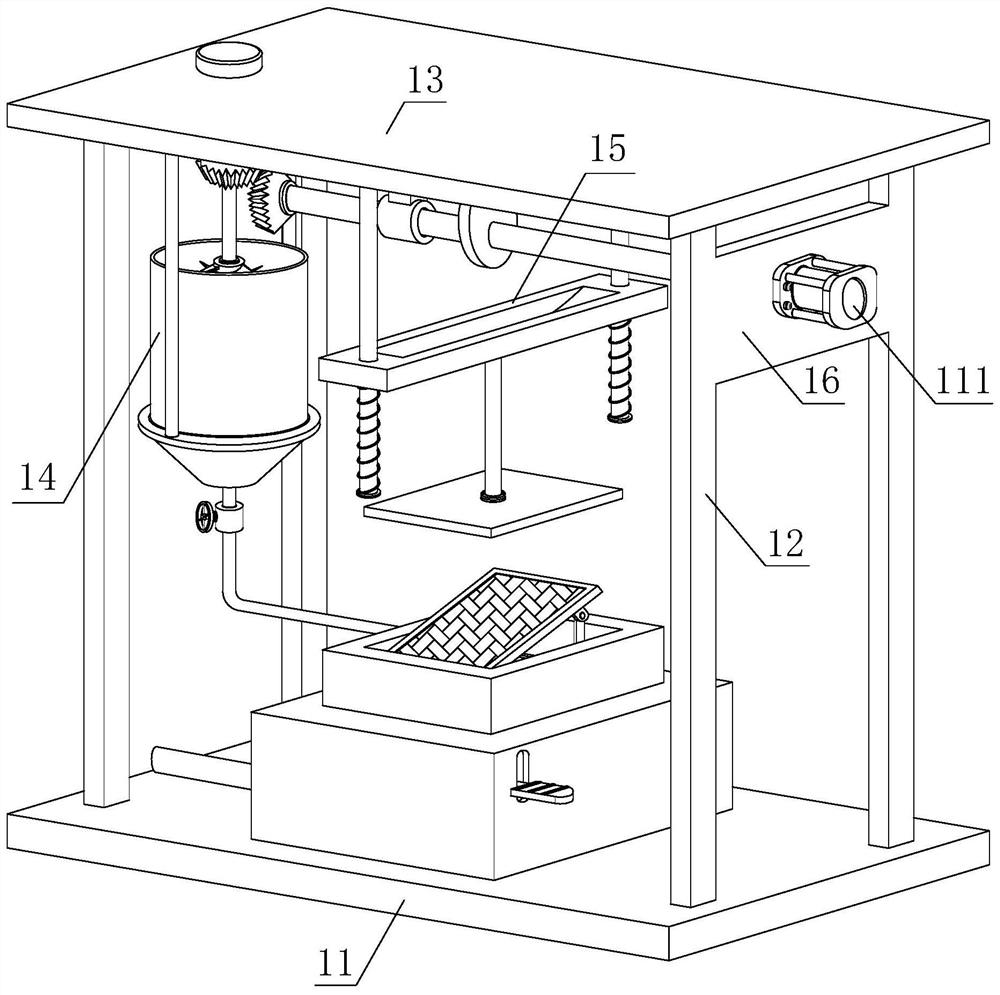

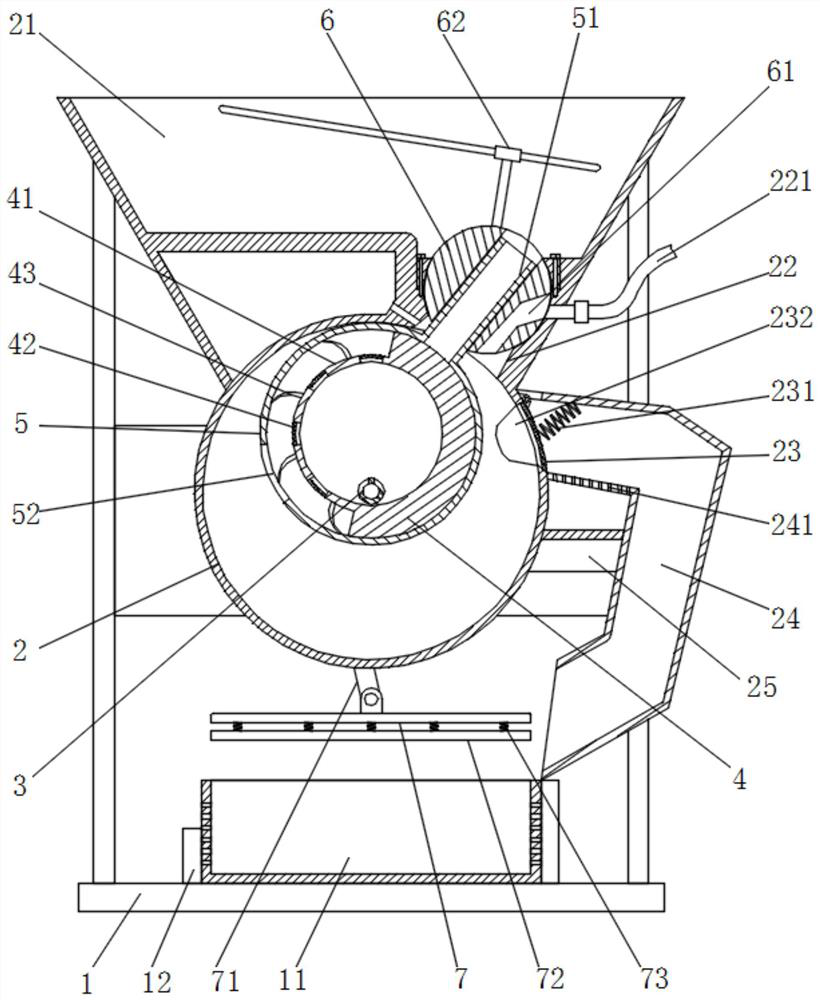

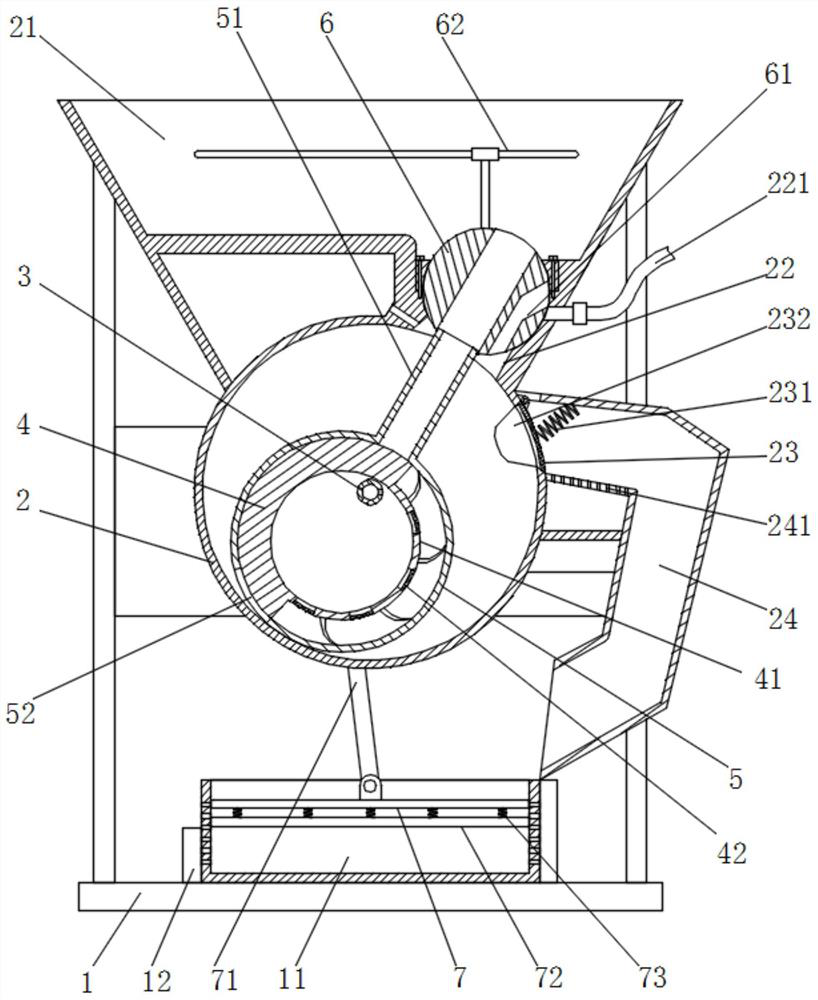

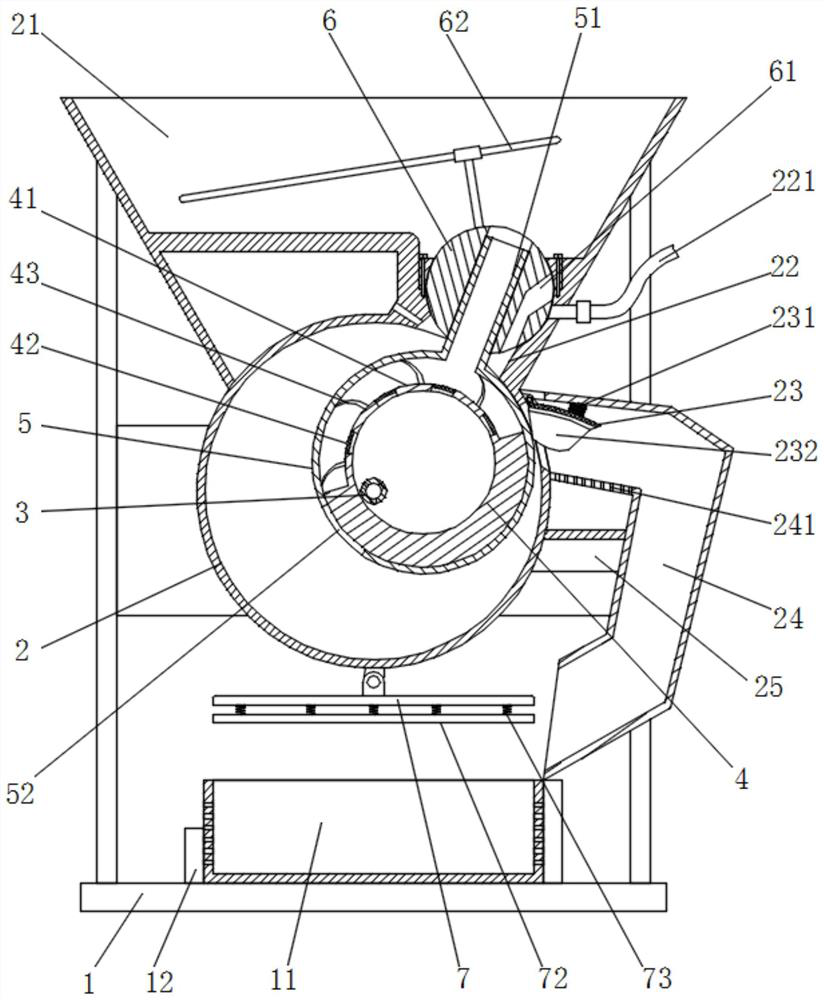

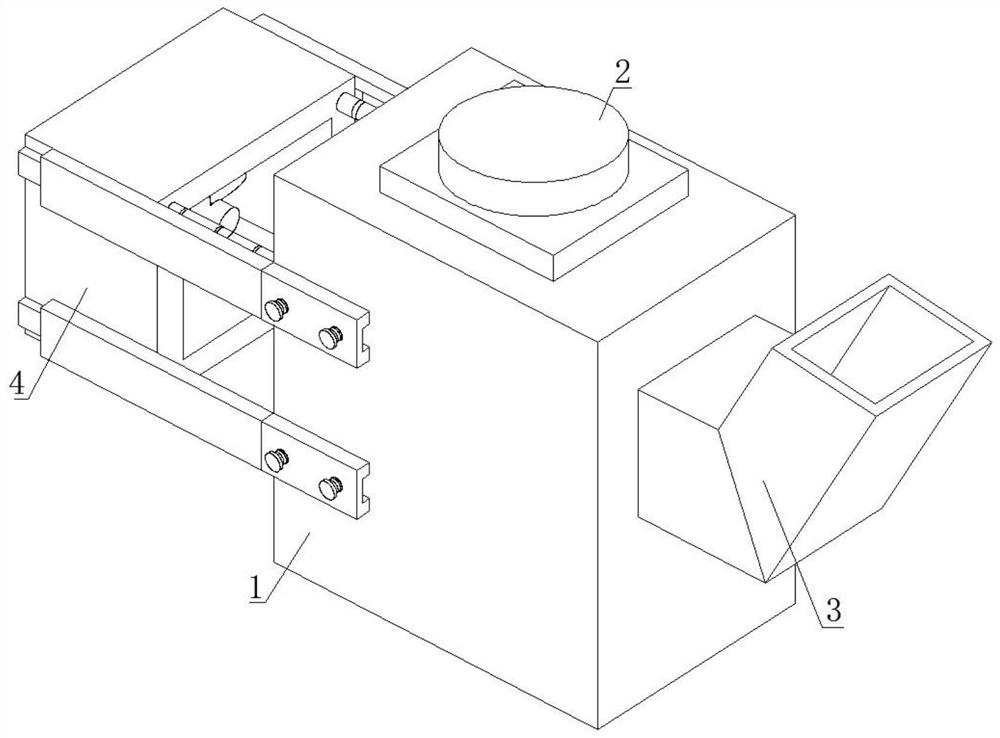

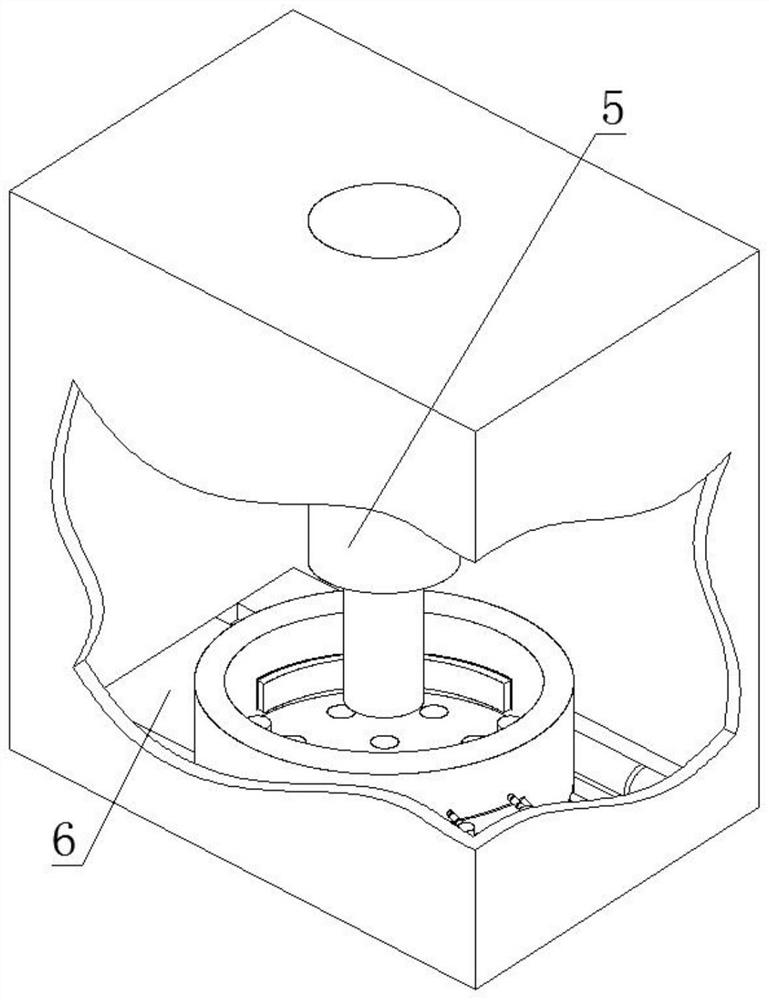

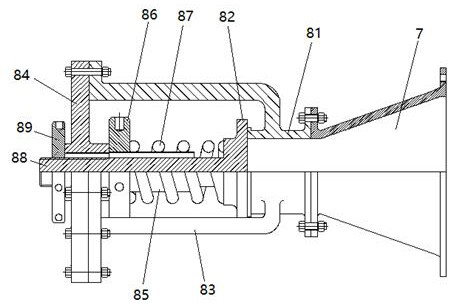

Concentration dewatering filter pressing device for solidifying sludge

The invention discloses a concentration dewatering filter pressing device for solidifying sludge. The device comprises a main box body and an external traction piece arranged at the upper end of the main box body, the main box body comprises a feeding mechanism arranged on one side of the main box body, an external connection mechanism arranged on the other side of the main box body, and a pressure guide mechanism arranged in the main box body, and one end of the pressure guiding mechanism is connected with the external traction piece. Clean water is added into an air bag, the air bag becomes larger slowly, an electromagnetic adsorption plate gets close to a brake magnetic block slowly, meanwhile, current is connected into the electromagnetic adsorption plate, the electromagnetic adsorption plate has magnetism opposite to that of the brake magnetic block, and therefore suction force is generated, the brake magnetic block is attracted, the brake magnetic block moves along a penetrating rod, a main pipe is loosened, a pressing cylinder falls into a placing cylinder, sludge filter pressing is completed, and the filter pressing effect is good.

Owner:SHENZHEN MUNICIPAL ENG

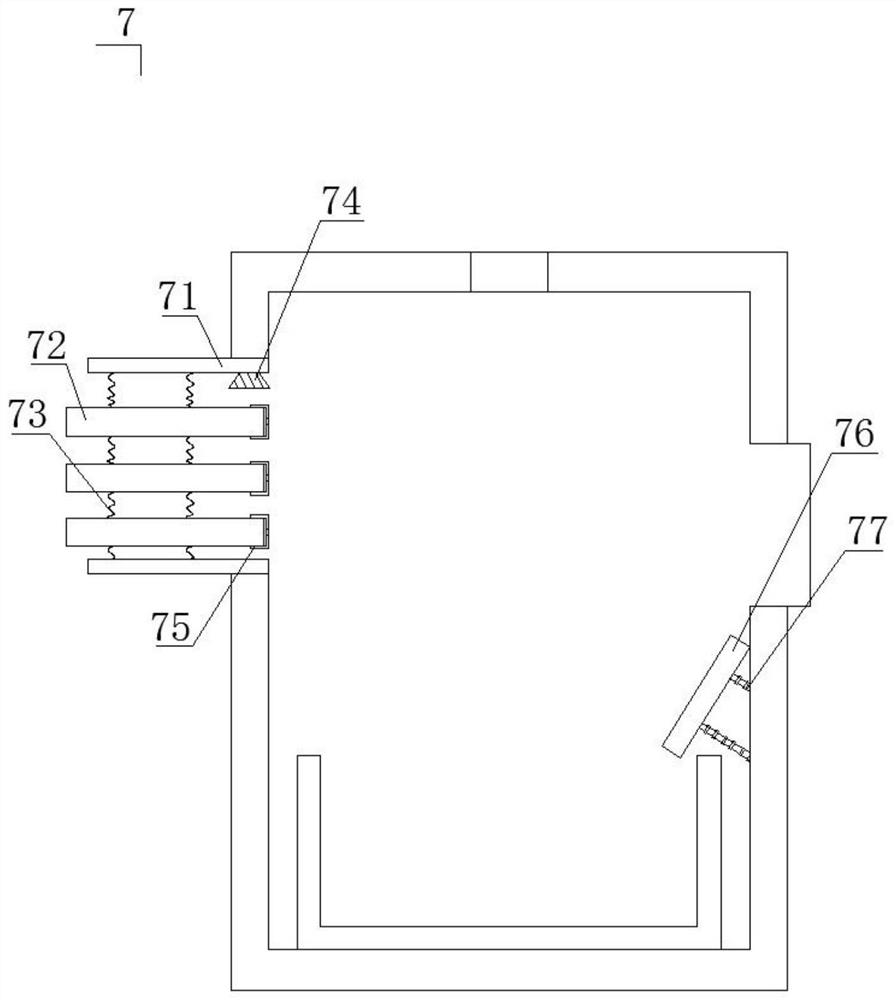

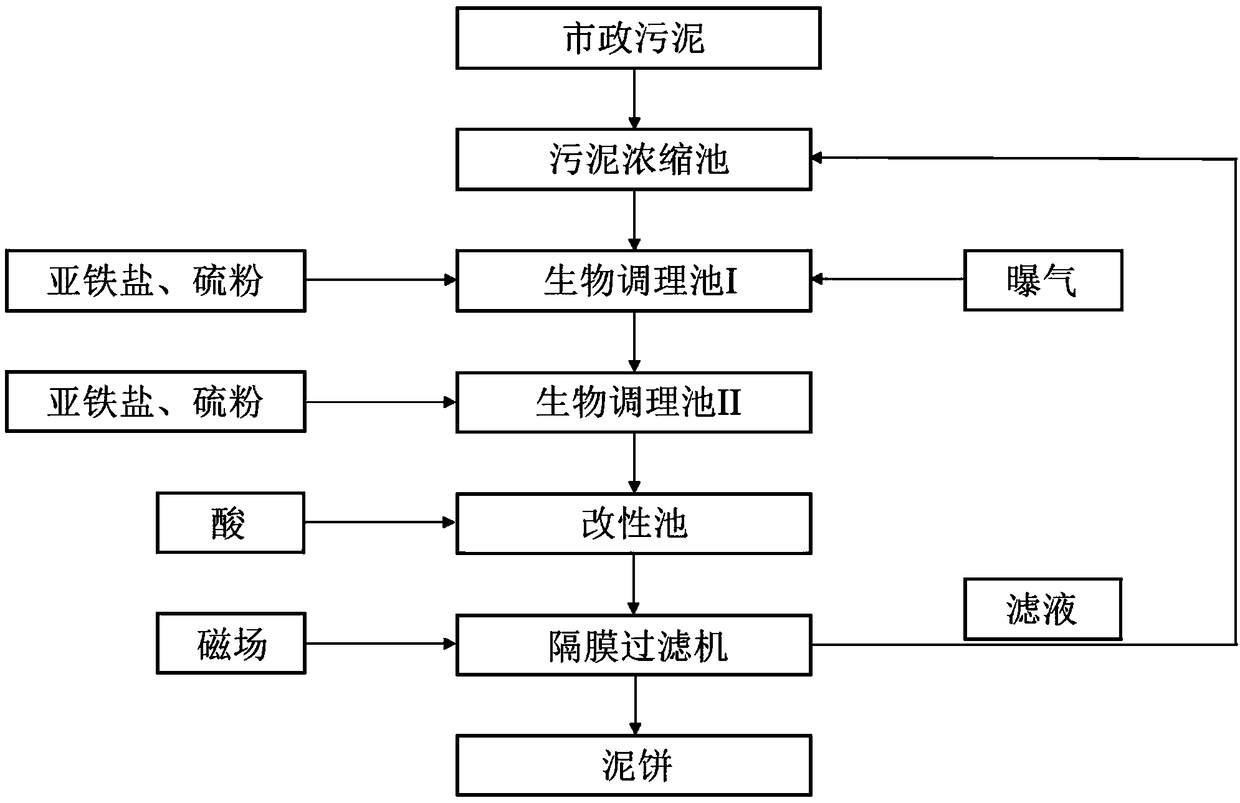

Municipal sludge reduction method

ActiveCN109020139ALess dosageGood reduction effectSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeSulfur

The invention discloses a municipal sludge reduction method. The method includes the steps of: 1) introducing municipal sludge into a sludge concentration tank for concentration, and letting the supernatant flow back to the front end of a sewage treatment plant; 2) introducing the concentrated municipal sludge into a biological conditioning tank I, adding ferrous salt and sulfur powder, conductingstirring and aeration, and performing first-stage conditioning; 3) introducing the municipal sludge subjected to the first-stage conditioning into a biological conditioning tank II, replenishing ferrous salt and sulfur powder, and conducting stirring and second-stage conditioning; 4) introducing the municipal sludge subjected to the second-stage conditioning into a modification tank, adding acid,and performing modification treatment; and 5) introducing the modified municipal sludge into a diaphragm filter, adding an external magnetic field, and performing filter pressing to obtain a filter cake and filtrate, subjecting the filter cake to concentrated treatment, and returning the filtrate to the sludge concentration tank. The municipal sludge reduction method provided by the invention hasthe advantages of small reagent dosage, low energy consumption, simple treatment process, good sludge reduction effect and the like, and can reduce the water content of sludge to 50% or below.

Owner:广州福之源环保科技有限公司

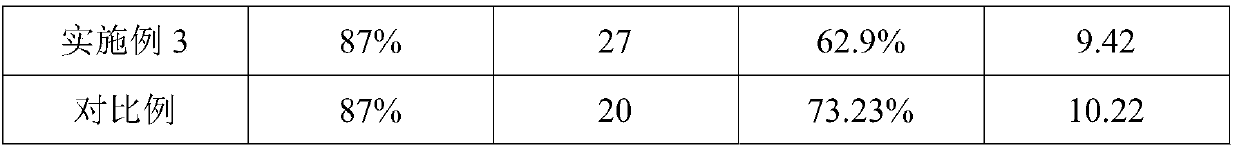

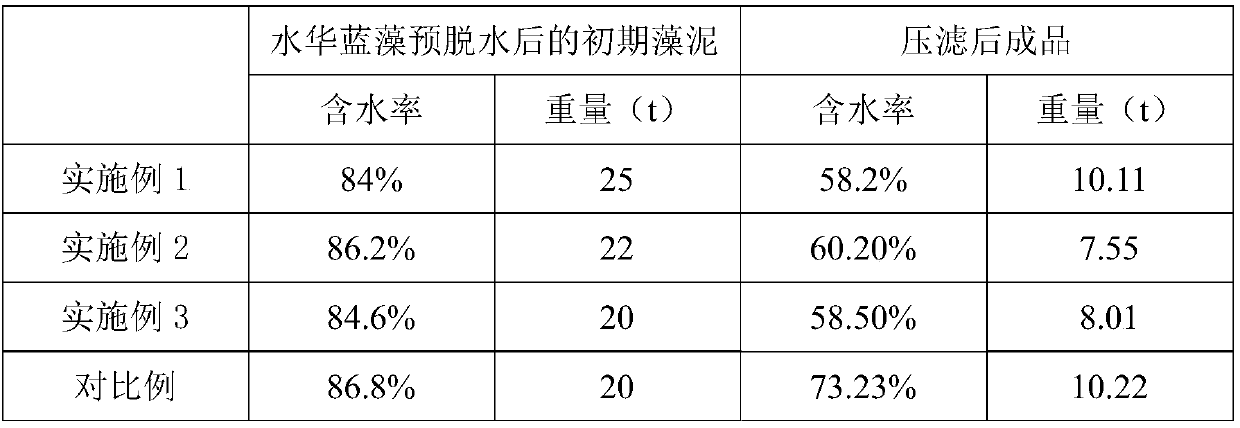

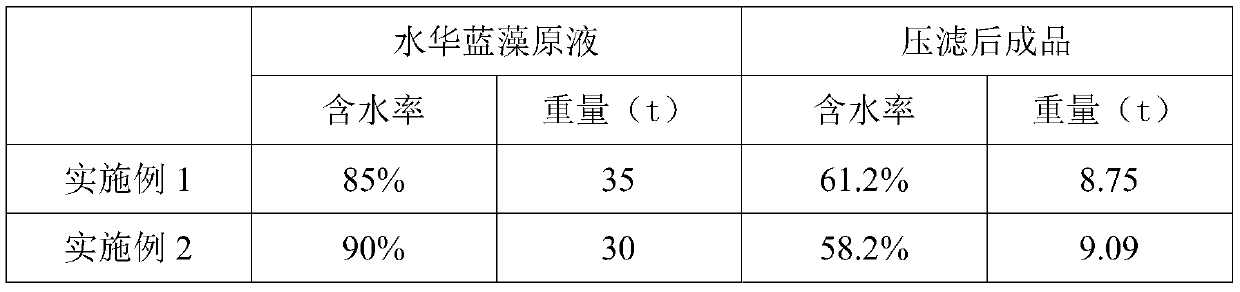

Pretreatment method for plate-frame pressure filtration of bloom-forming cyanobacteria

ActiveCN109650697AEasy to filterImprove filter press effectSludge treatment by de-watering/drying/thickeningAluminium chloridePretreatment method

The invention belongs to the technical field of environmental engineering, and relates to the technical field of treatment of bloom-forming cyanobacteria, in particular to a pretreatment method for plate-frame pressure filtration of bloom-forming cyanobacteria. The method comprises the following steps of 1, diluting and stirring initial-stage cyanobacteria mud which is obtained after bloom-formingcyanobacteria is pre-dehydrated into a cyanobacteria-water mixed liquid with the moisture content of 95%; 2, sequentially adding ferrous sulfate powder and hydrogen peroxide into the cyanobacteria-water mixed liquid, and conducting sufficient stirring to obtain a mixed solution A; 3, sequentially adding polyaluminum ferric chloride chemicals and quick lime into the mixed solution A, and uniformlystirring the materials to obtain the pre-adjusted bloom-forming cyanobacteria liquid. By means of the method, the problem in the prior art that bloom-forming cyanobacteria mud with the moisture content of 85-90% cannot be disposed is solved; through dilution and multiple reaction modes, bloom-forming cyanobacteria is pretreated, subsequent plate-frame pressure filtration is facilitated, and the pressure filtration effect can also be improved.

Owner:无锡市水务集团有限公司

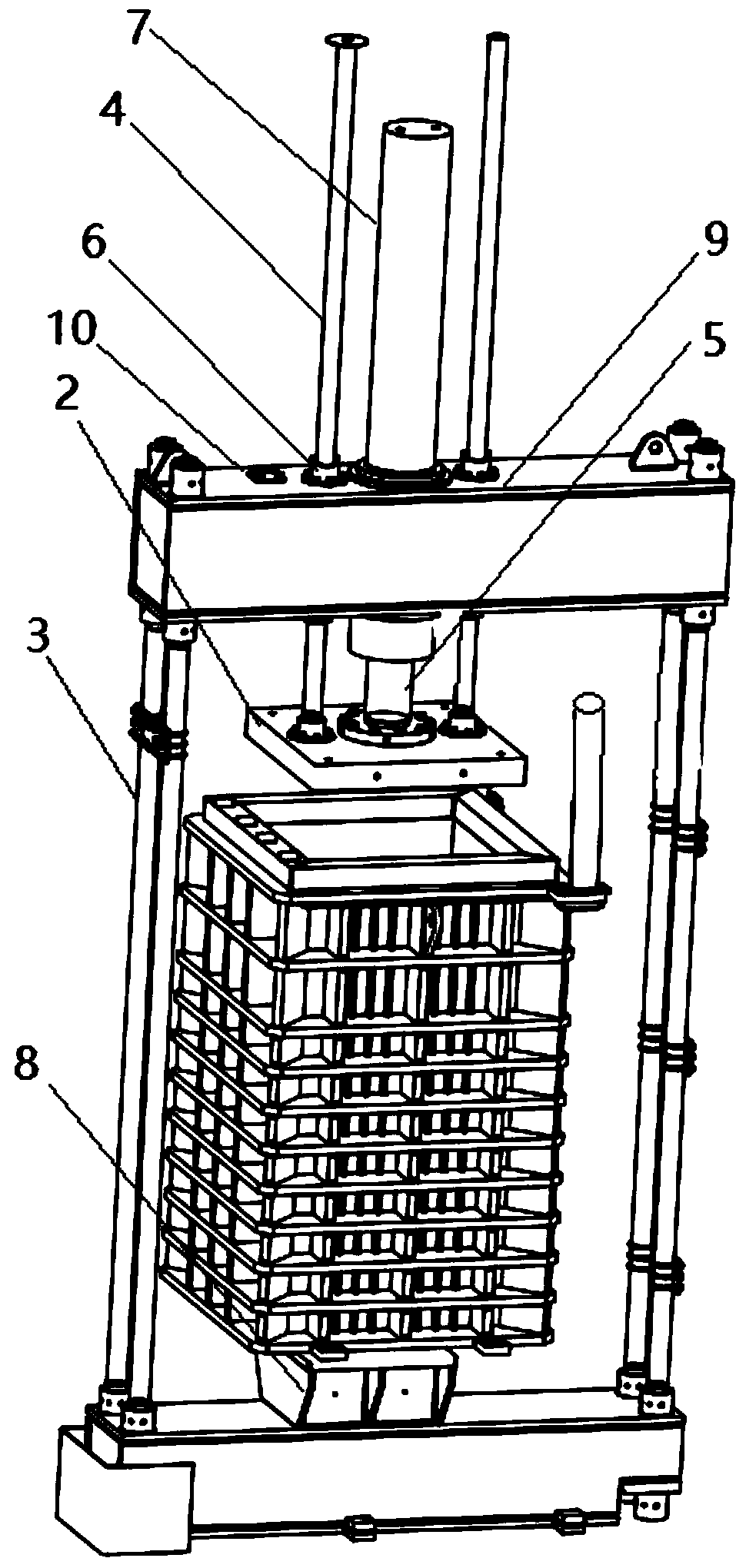

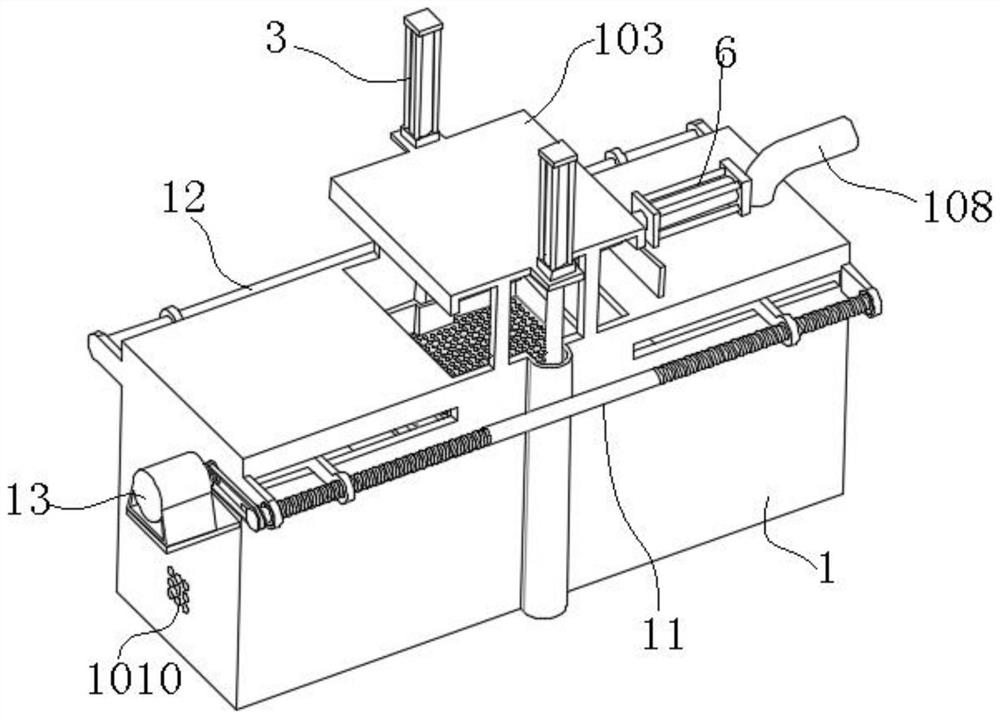

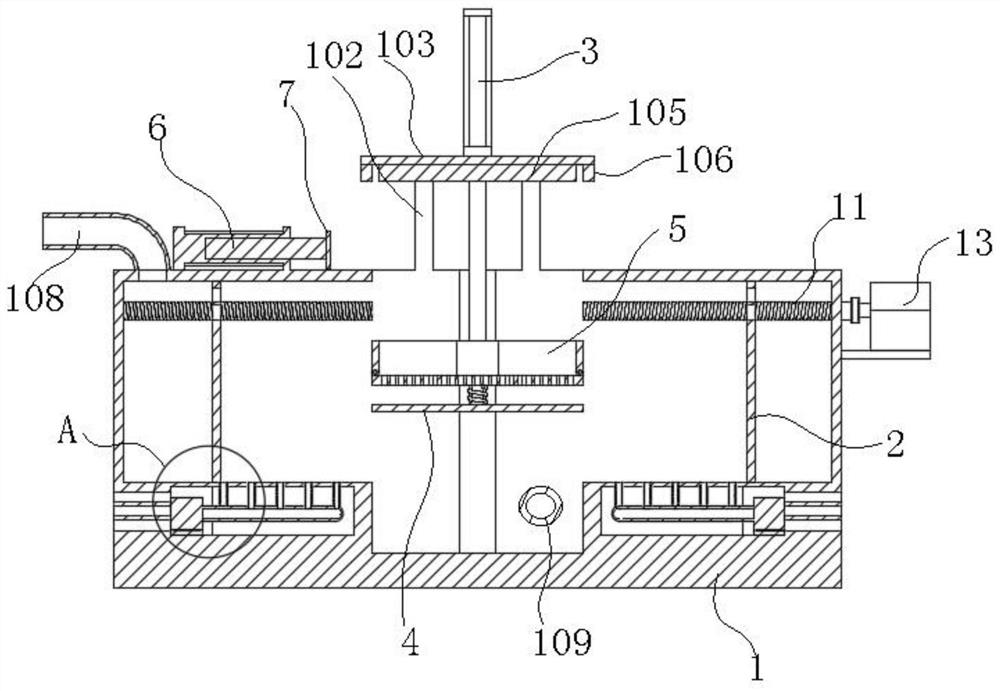

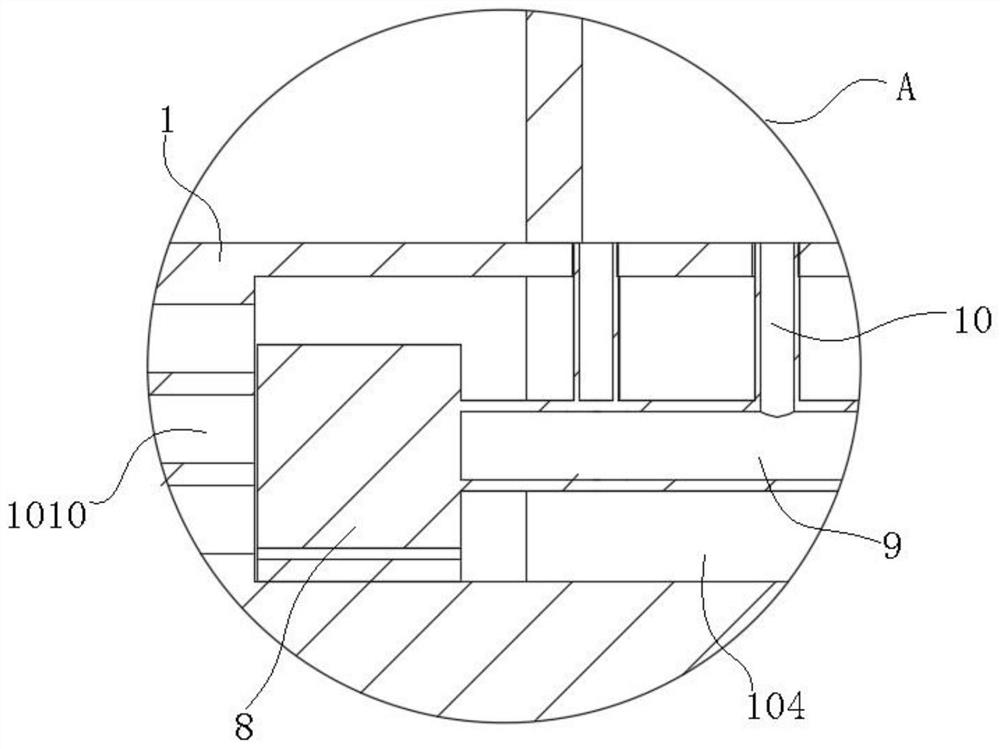

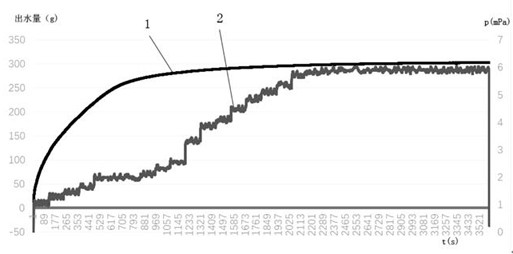

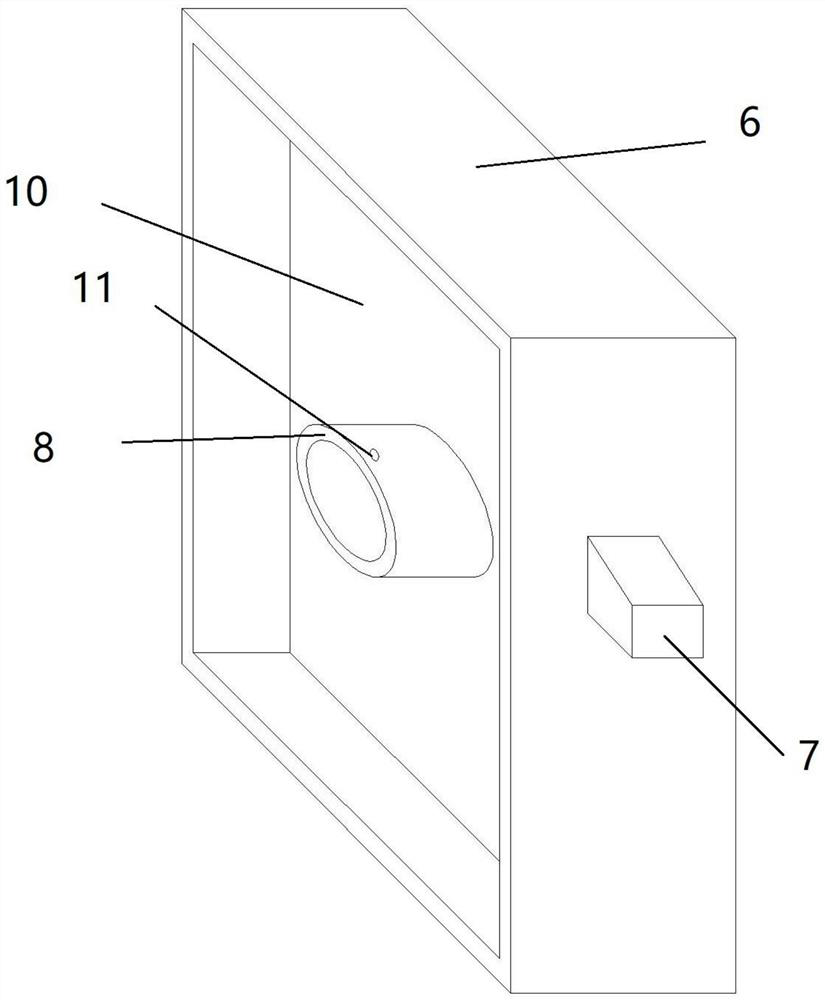

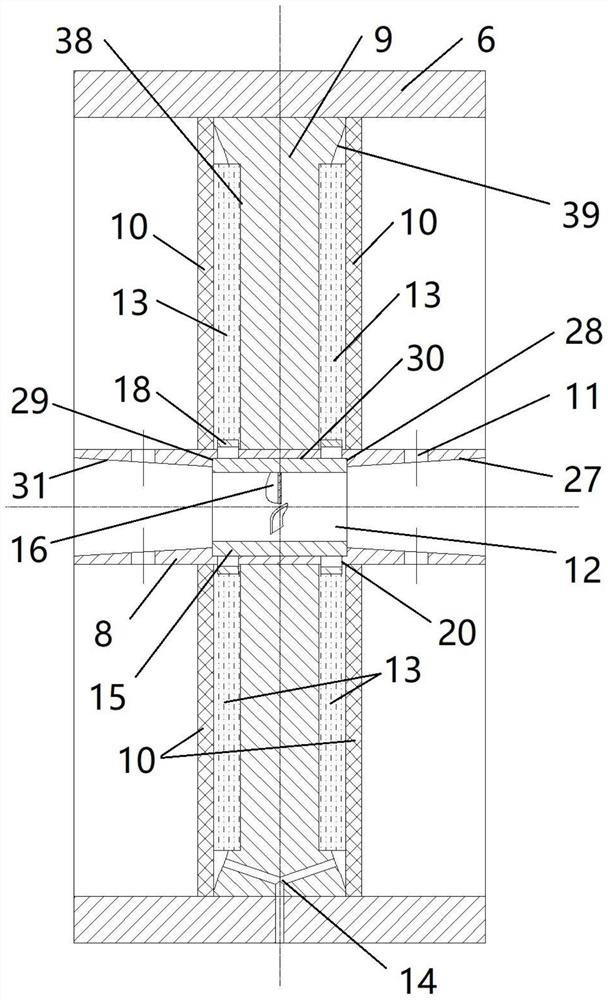

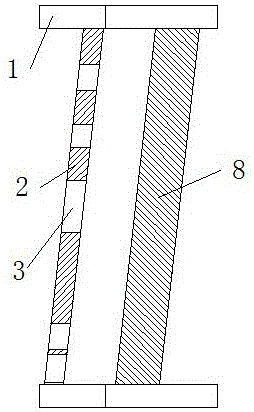

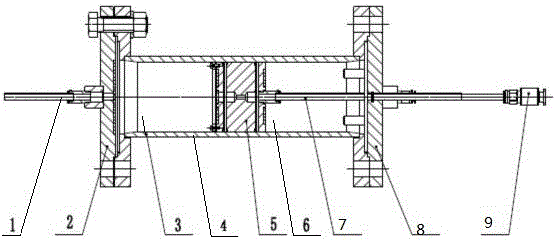

Three-chamber structure small-test filter-press analog device

InactiveCN106277696AImprove efficiencyEasy to operateSludge treatment by de-watering/drying/thickeningEngineeringHigh pressure

The invention relates to a three-chamber structure small-test filter-press analog device. The three-chamber structure small-test filter-press analog device comprises a sealed housing with two detachable ends, wherein the housing is divided into a working chamber, a middle chamber and a pressurizing chamber which are straightly arranged in sequence by a first piston and a second piston; filter cloth is arranged on the side walls of two ends of the working chamber respectively; the two ends of the working chamber are communicated with an outer drainage pipe and a drainage flow passage on the first piston respectively; the first piston and the second piston are connected through a first rigid inner drainage pipe; the first inner drainage pipe is communicated with drainage flow passages on the first piston and the second piston respectively; a second inner drainage pipe stretches into the pressurizing chamber in a sealing manner to be communicated with the drainage flow passage on the second piston; and high-pressure dielectric joints are arranged on the middle chamber and the pressurizing chamber respectively. The device adopts a three-chamber structure, the pistons after filter pressing is completed can be quickly reset, and the device is convenient in operation and high in efficiency.

Owner:SAFECLEEN TECH

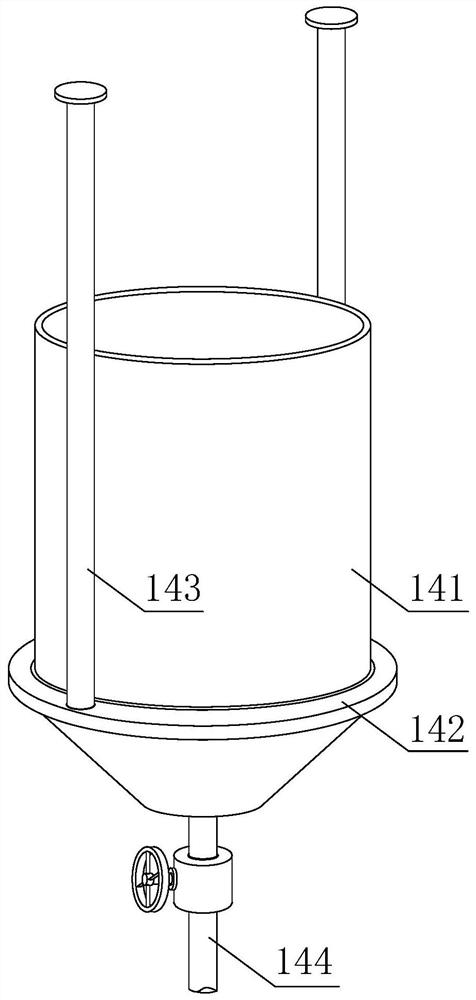

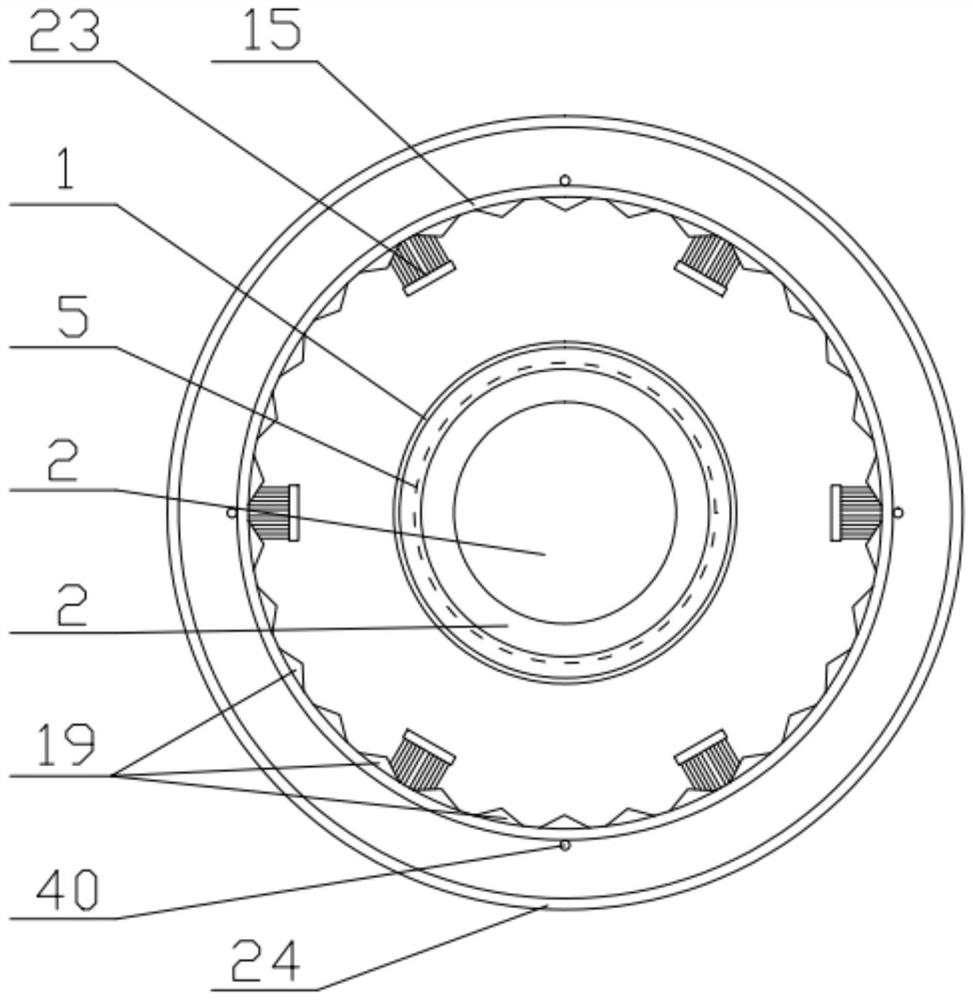

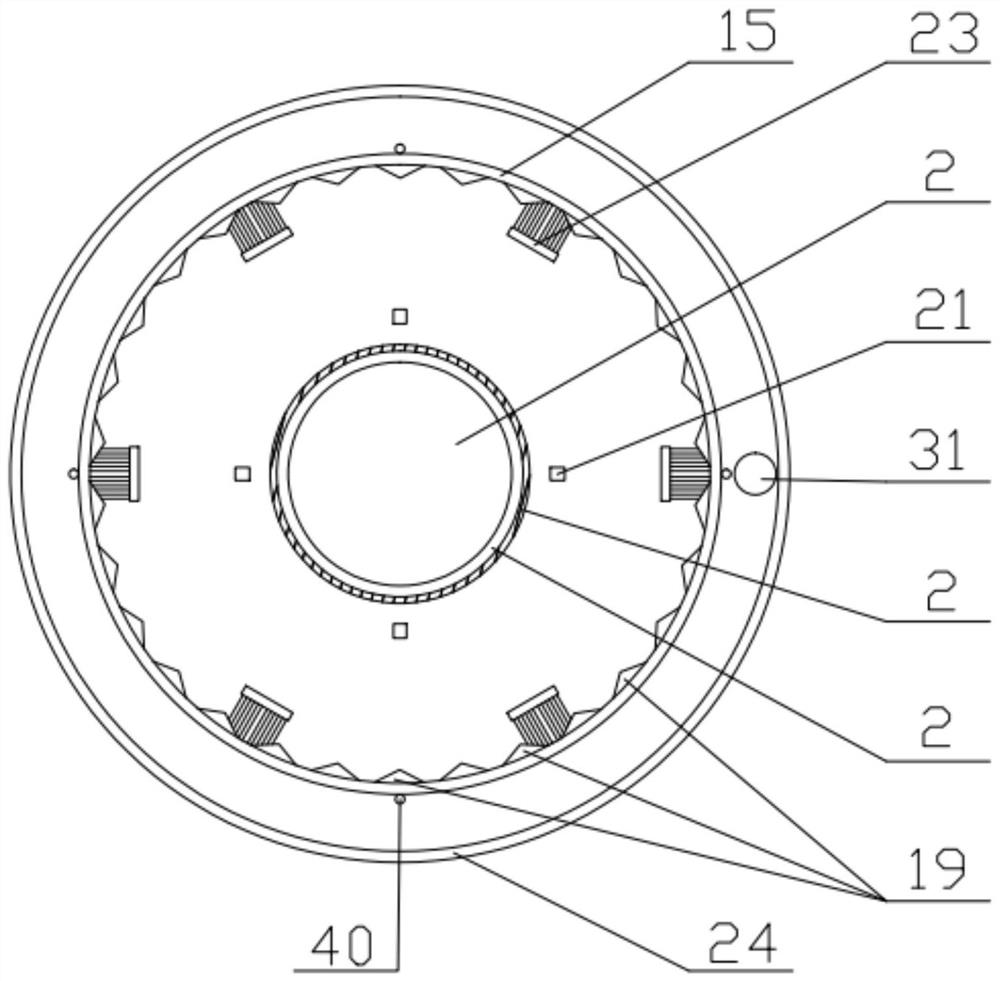

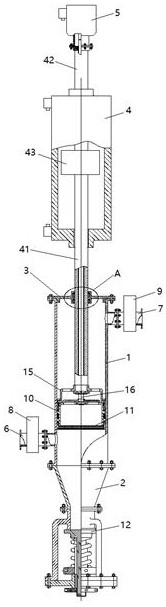

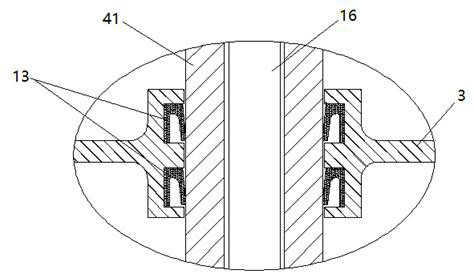

A kind of traditional Chinese medicine dregs medicine liquid separator

ActiveCN109200668BTo achieve the extrusion effectFully extractedPharmaceutical product form changeCentrifugesLiquid storage tankEngineering

The invention discloses a traditional Chinese medicinal residue-medicinal liquid separator, and belongs to the field of traditional Chinese medicine production equipment, wherein the separator includes a press filter cartridge, a centrifugal separation cartridge and a liquid collecting cartridge; a press hammer and a driving mechanism are arranged directly above the pressure filter cartridge; a rotating motor is connected at the bottom of the centrifugal separation cartridge; the bottom of the liquid collecting cartridge is connected with a liquid storage tank through an infusion tube, and a liquid taking port is arranged on the liquid storage tank. The press filter cartridge comprises a first circular side wall, and a support bottom plate and a covering top plate which are slidingly connected on the first circular side wall; a magnetic attraction effect exists between the press hammer and the covering top plate; the press hammer is connected with a movable rod of a telescopic sleeve rod structure; a buffer spring is fixed on a flange edge of the support bottom plate. The centrifugal separation cartridge includes a second circular side wall, a first top panel and a first bottom panel. The inner side wall of the second circular side wall is provided with a corrugated convex rib, and the centrifugal separation cartridge is internally provided with a cleaning brush fixed on the liquid collecting cartridge. A medicinal liquid can be completely and adequately extracted, the separation effect between the medicinal liquid and the medicinal residue is good, wasting of the medicinalliquid is avoided, the separation effect is good and the separation efficiency is high.

Owner:王华

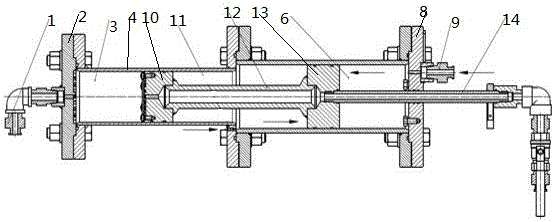

Filter press with movable check valve and use method of filter press

InactiveCN113457237AOmit configurationReduce investmentStationary filtering element filtersDamperCylinder block

The invention discloses a filter press with a movable check valve and a use method of the filter press. The equipment comprises a cylinder body, a compaction chamber, a reciprocating propelling device and a valve element driver, an on-off valve is mounted in the cylinder body in a sliding manner and comprises a valve body capable of moving back and forth along the inner wall of the cylinder body and a valve core for opening and closing an internal flow channel of the valve body; a detachable filter plate is mounted at the front end of the valve body; the reciprocating propelling device drives the valve body to move back and forth along the inner wall of the cylinder body, and the valve element driver drives the valve element to open or close an internal flow channel of the valve body; the front end of the compaction chamber is provided with an elastic damper capable of blocking the front port of the compaction chamber. According to the invention, the configuration of a high-power feeding pump is omitted, and the investment and operation and maintenance costs are effectively reduced. According to the equipment, the filter pressing efficiency and effect are greatly improved, the filter plate is reversely washed, blockage is automatically cleaned, and the service life of the filter plate is prolonged; therefore, the solid-to-liquid ratio of the filter cake is guaranteed, retreatment of the filter cake is avoided, and the transportation cost of the filter cake is reduced.

Owner:盛金平

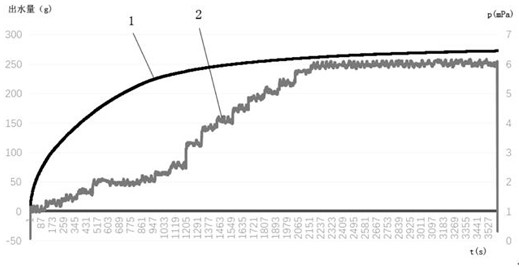

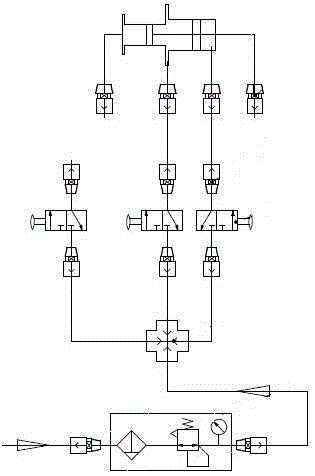

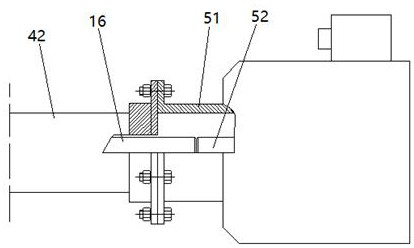

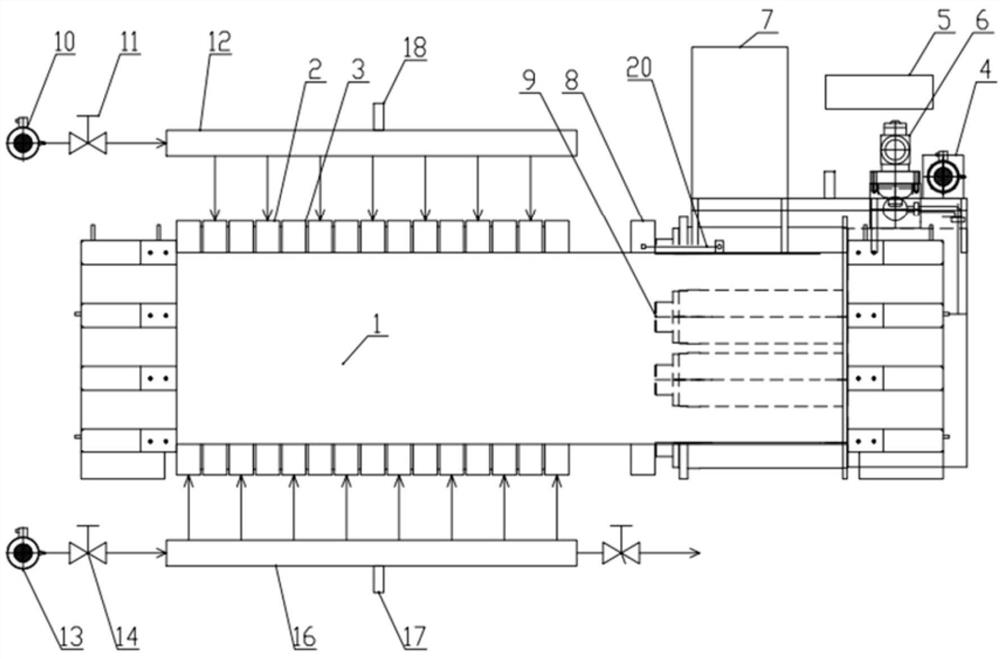

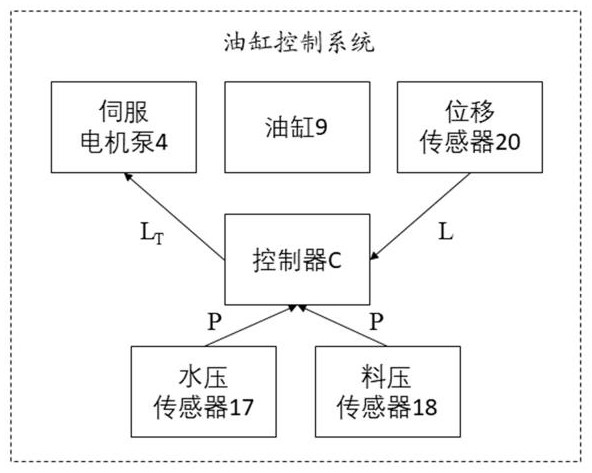

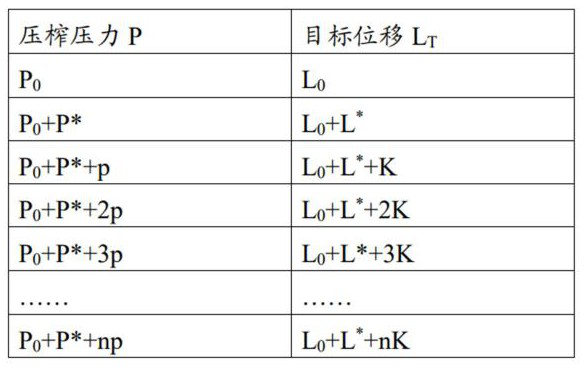

High-pressure filter press based on oil cylinder displacement control

ActiveCN113877258APrecise control of spacingEasy to controlServometer circuitsFluid-pressure convertersMechanicsDisplacement control

The invention provides a high-pressure filter press based on oil cylinder displacement control. A controller of the high-pressure filter press is configured to monitor the pressure value of a pressure fluid entering a closed chamber formed by a filter plate, and when the pressure value is increased by an initial pressure increment P* from an initial pressure P0, the controller sends out a control signal to control an oil cylinder to move by an initial displacement increment L*; and the pressure value continues to be monitored, and when the pressure value is increased by a constant pressure increment p, the controller sends out a control signal to control the oil cylinder to move by a constant displacement increment K. According to the above scheme, the control for maintaining the pressure is simple and accurate, cost is reduced, a failure rate is greatly reduced, and the high-pressure filter press can work under higher pressure, so filter pressing effect is improved.

Owner:山东菲特环保设备有限公司

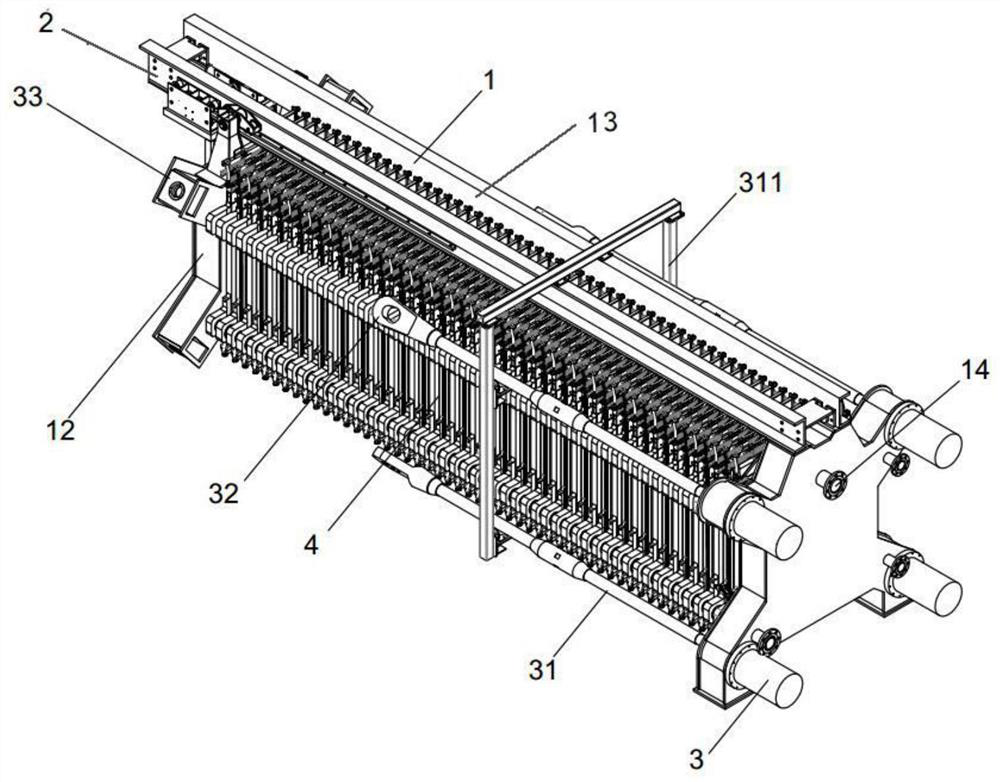

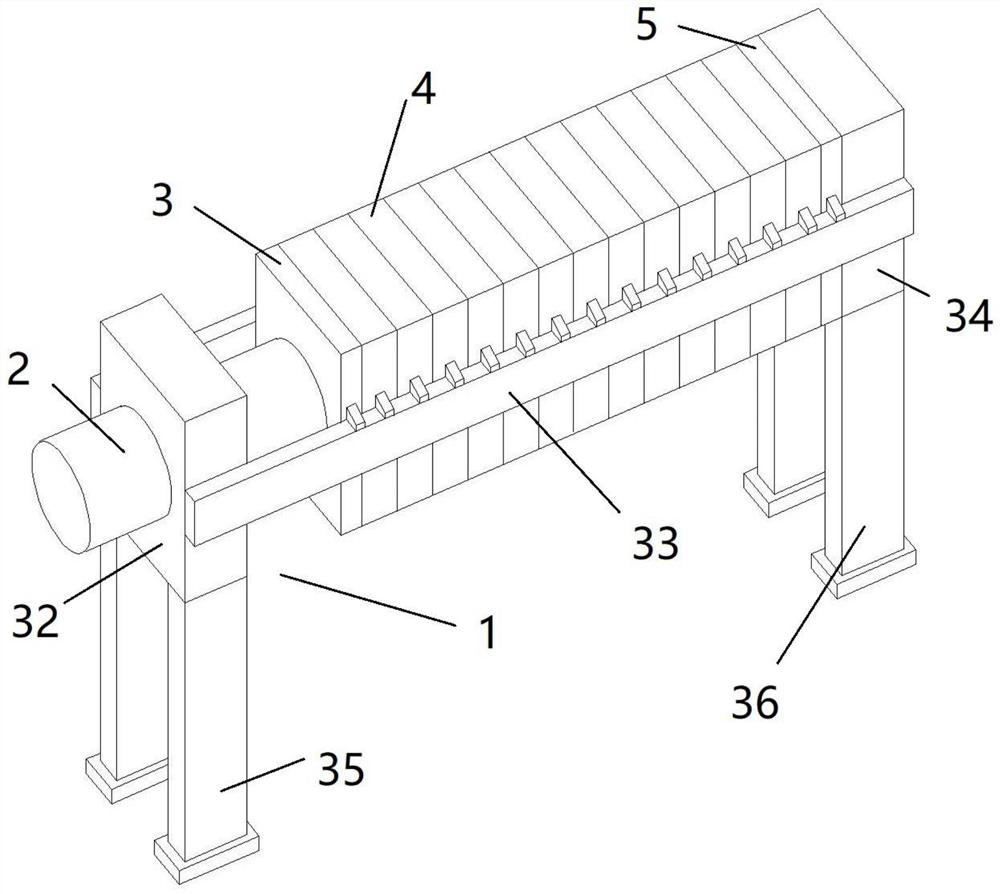

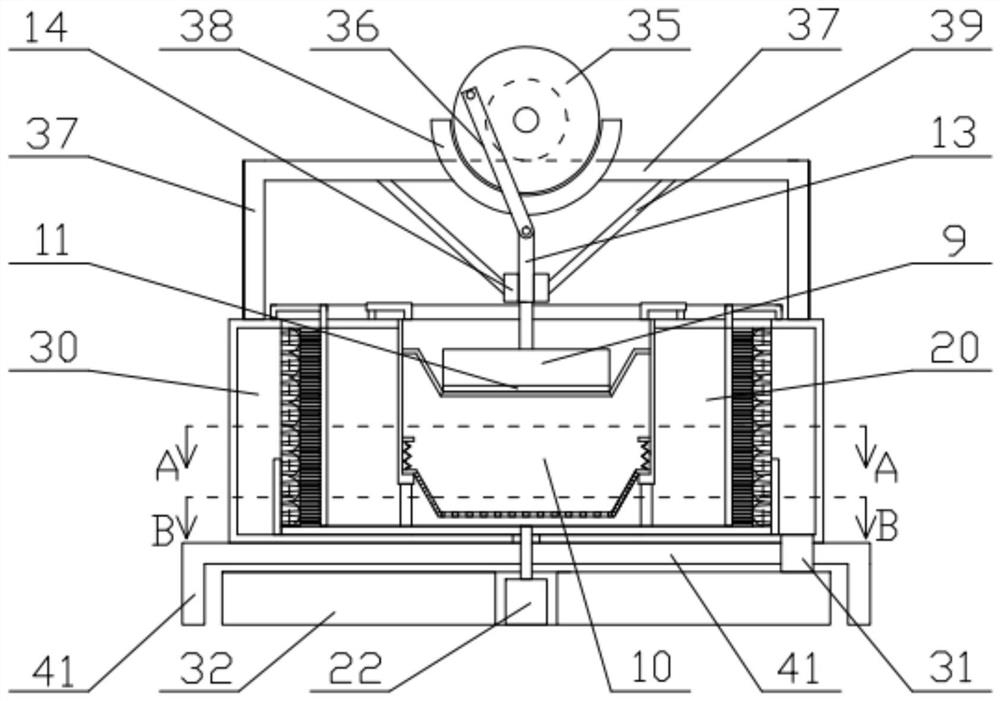

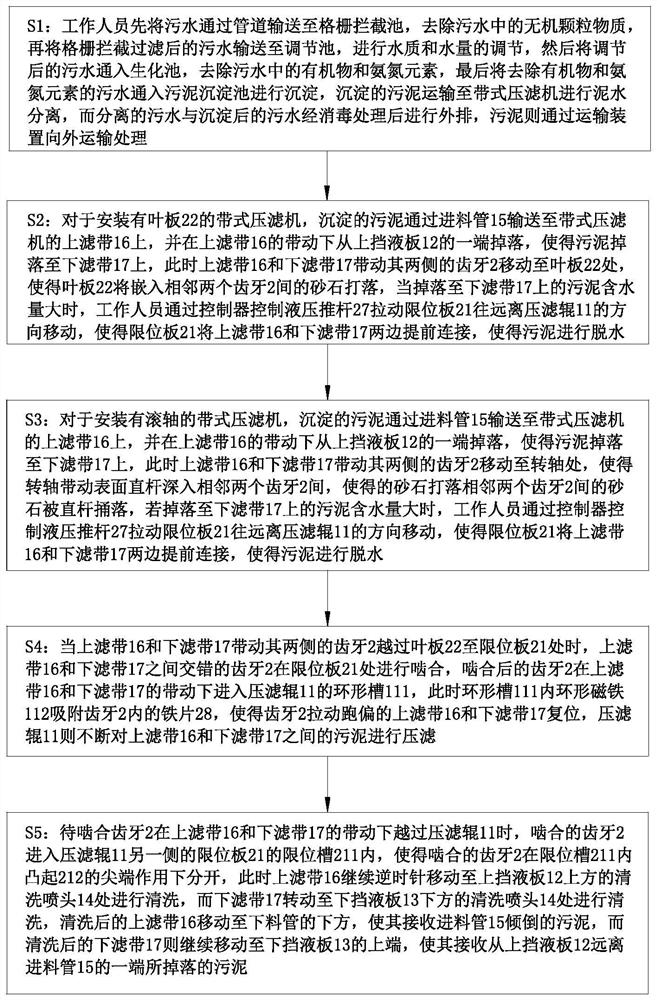

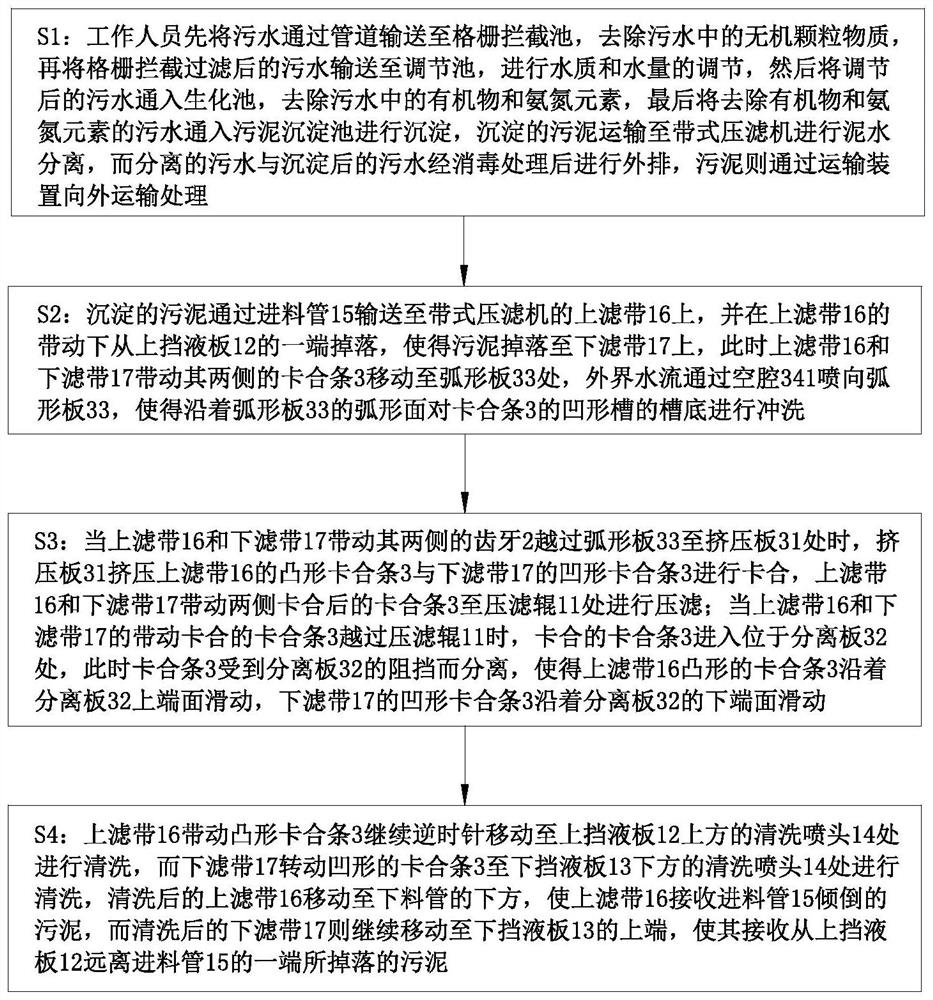

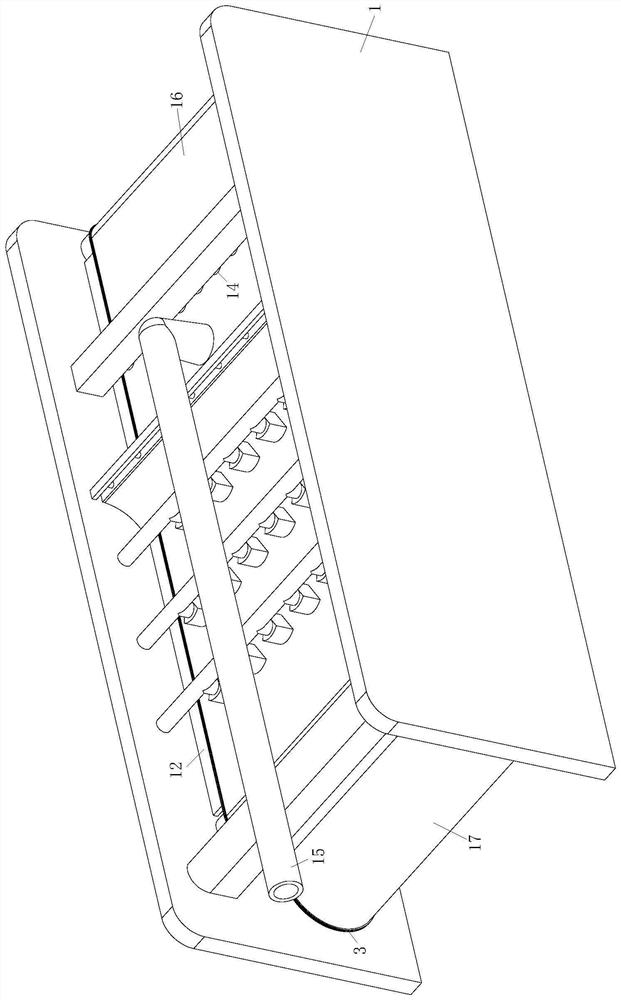

Divided-flow type sludge and sewage treatment system and treatment process

PendingCN114832481AImprove filter press effectImprove practicalitySludge treatmentSpecific water treatment objectivesWater treatment systemSludge

The invention belongs to the technical field of sludge and sewage treatment, and particularly relates to a flow dividing type sludge and sewage treatment system and process. The belt filter press comprises a rack, and a filter pressing roller is rotationally mounted on the rack; an upper liquid baffle is arranged above the filter pressing roller; a lower liquid baffle is arranged below the filter pressing roller; the upper liquid baffle and the lower liquid baffle are fixedly connected with the rack; cleaning nozzles are mounted above the upper liquid baffle and below the lower liquid baffle; through the arrangement of the sealing mechanism, the two sides of the upper filter belt and the lower filter belt are in sealed contact by the sealing mechanism at the positions, close to the filter pressing roller, of the upper filter belt and the lower filter belt, so that the upper filter belt and the lower filter belt are extruded by the filter pressing roller; sludge layers which are located between the upper filter belt and the lower filter belt and are extruded by the filter pressing rollers to flow to the two sides cannot overflow from the two sides of the upper filter belt and the lower filter belt under blocking of the sealing modules, so that the filter pressing effect of the filter belts on the sludge is improved, and the practicability of the device is improved.

Owner:王树

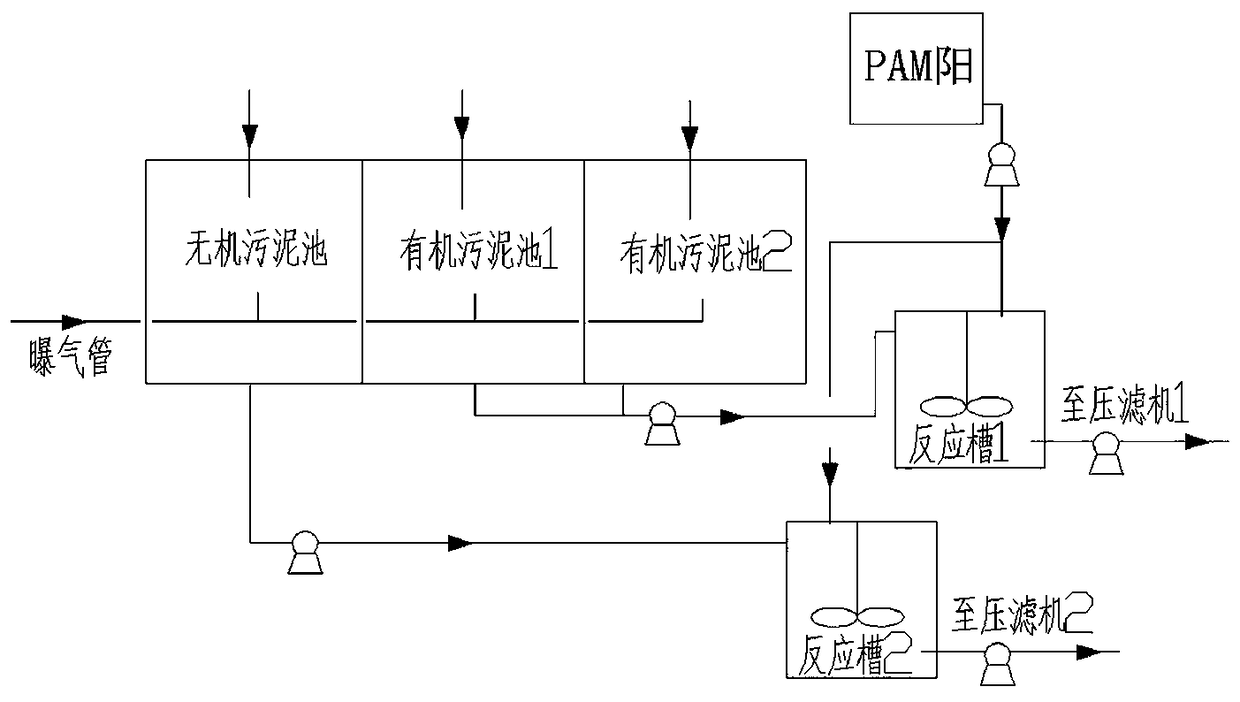

Treatment method of high oil content wastewater sludge

InactiveCN109020157AImprove filter performanceSimple processSludge treatment by de-watering/drying/thickeningPolyacrylamideOil content

The invention relates to a treatment method of high oil content wastewater sludge. The method comprises the steps of preparing a flocculant: injecting water and polyacrylamide (PAM) cations into a PAMdissolving tank in proportion, starting a solution stirrer for stirring, and evenly mixing to obtain a solution; preparing sludge: conveying high oil content organic sludge and inorganic sludge of coking wastewater into a sludge mixing tank; carrying out material transportation: transporting the sludge prepared in a sludge preparation tank into a sludge reaction tank, and conveying the flocculantsolution in the PAM cation dissolving tank into the sludge reaction tank; stirring and flocculating: starting an agitator of the sludge reaction tank, starting a sludge pump when the floc is found inthe sludge reaction tank, and transporting the flocculated material into a filter press; carrying out drying treatment: sending sludge settled by a flocculation reaction into the filter press and carrying out sludge-water separation, and the transporting the sludge, subjected to filter pressing, to a phenol cyanide stockyard for performing ore blending treatment. The method provided by the invention has the characteristics of being good in solid-liquid separation effect of the sludge, good in filter pressing performance, less in reagent consumption, and the like.

Owner:GUANGDONG HUAXIN ENVIRONMENTAL PROTECTION TECH CO LTD

Residual active sludge dehydration filter aid and application thereof

ActiveCN109879578AGood flocculation effectImprove dehydration effectSludge treatment by de-watering/drying/thickeningOther chemical processesChemical oxygen demandResource utilization

The invention discloses a residual active sludge dehydration filter aid and application thereof. The filter aid is selected from at least one of grafted puffed bagasse and sugarcane chaff. The filteraid provided by the invention can greatly improve the filter-press effect and efficiency, the water content of filter cake and the chemical oxygen demand (CODcr) of filtered liquid are lowered after dehydration, and the whole filter-press process is smooth, safe, easy in operation, needs simple equipment, and small investment, and has very good economical benefit and wide social benefit. The filter cake prepared by a dehydration method can be used for preparing a water body purifying material, so that the problem of residual active sludge in the sewage treatment process is transformed into a sewage treatment method, waste is changed into treasure, a closed loop is formed, and resource utilization of the residual active sludge is realized. The filter cake prepared by the dehydration methodcan also be used for preparing biological organic fertilizers, thereby realizing the resource utilization of the residual active sludge.

Owner:广东省科学院生物与医学工程研究所

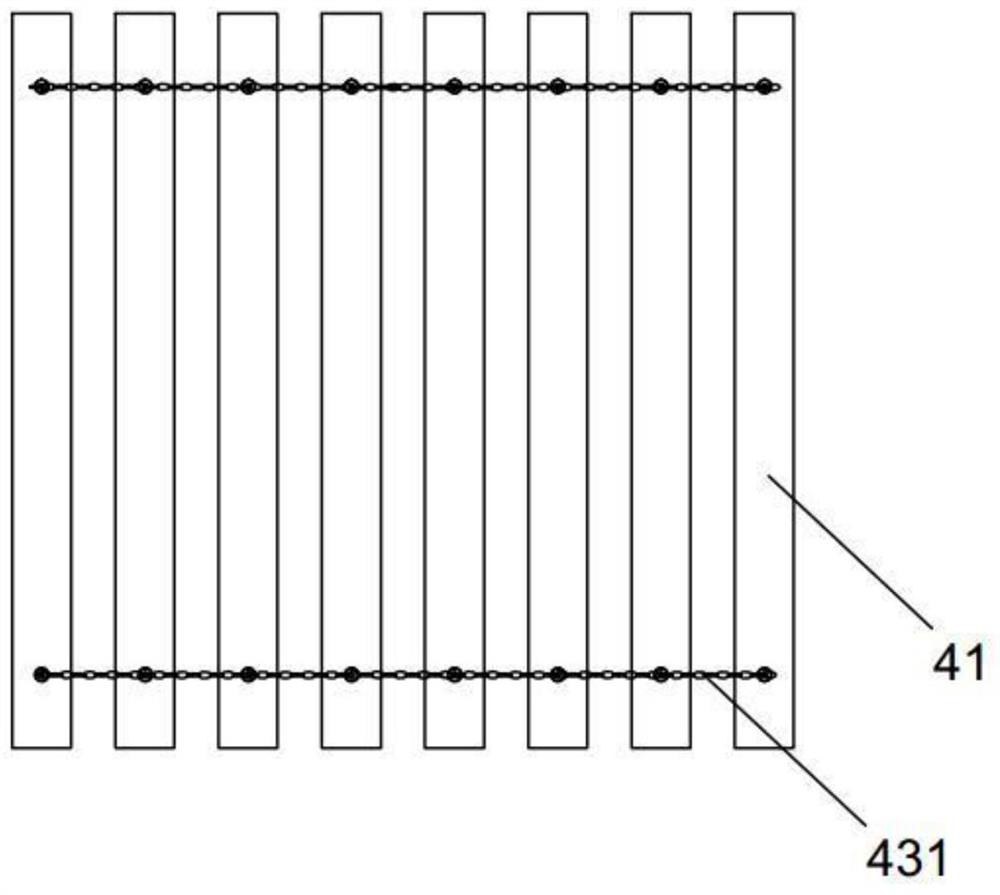

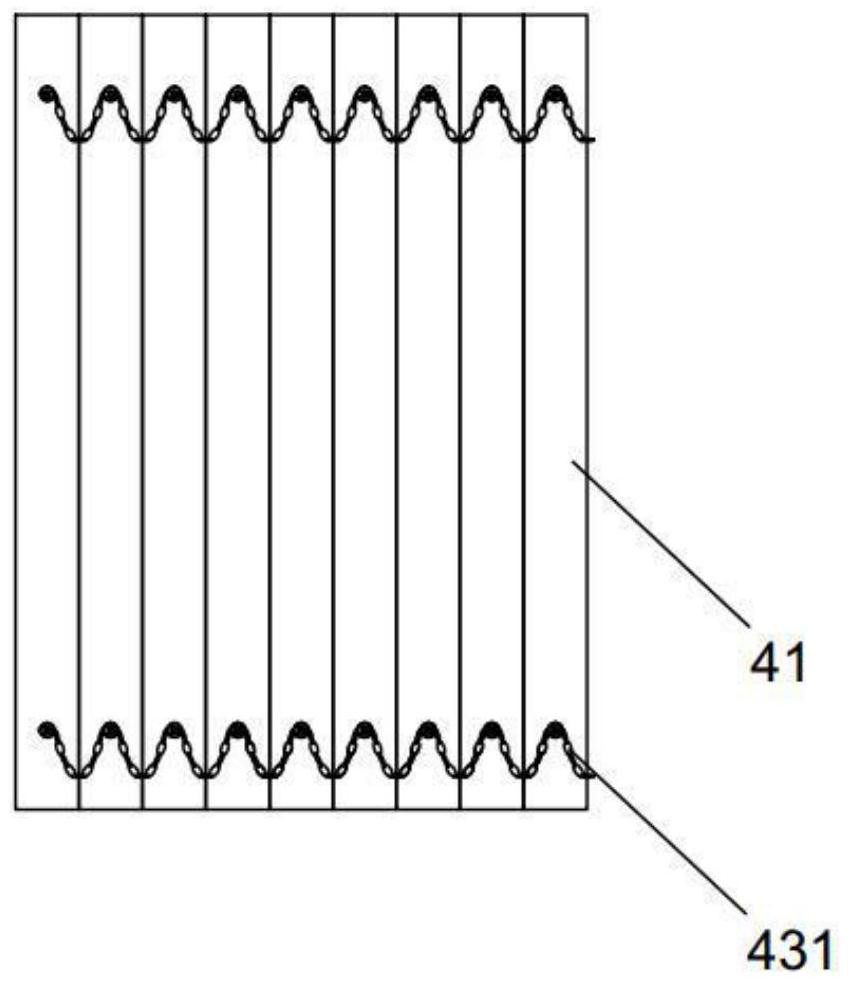

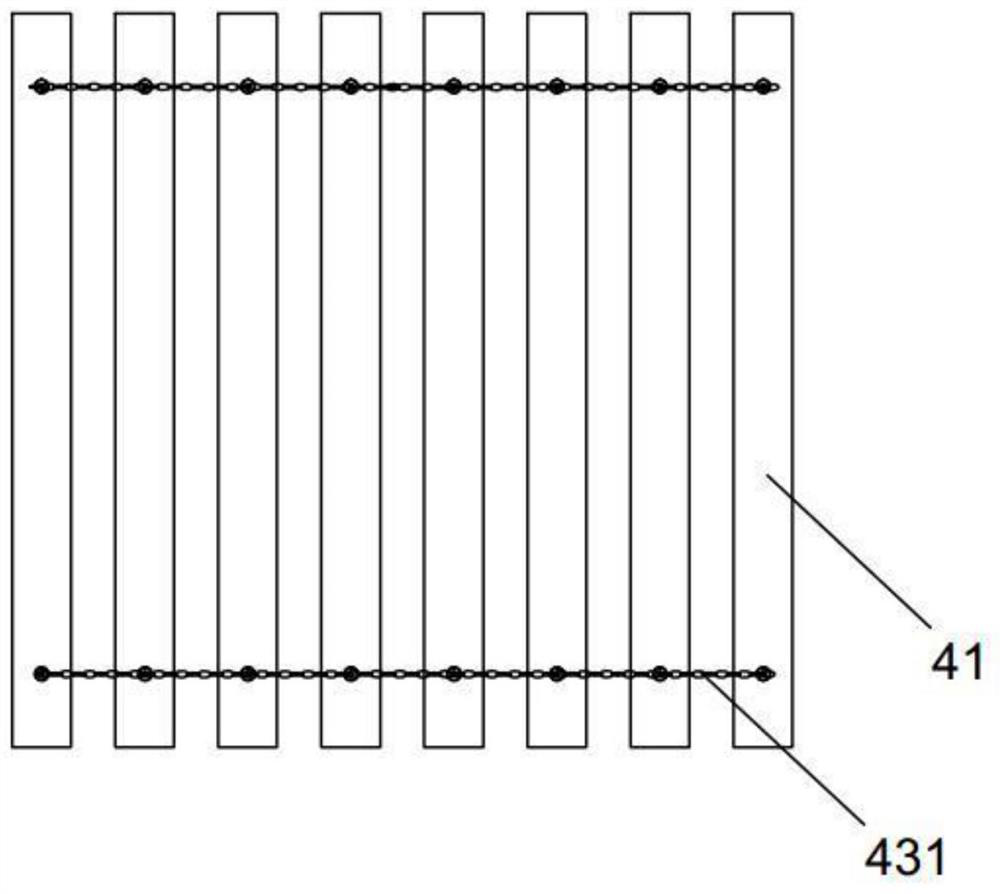

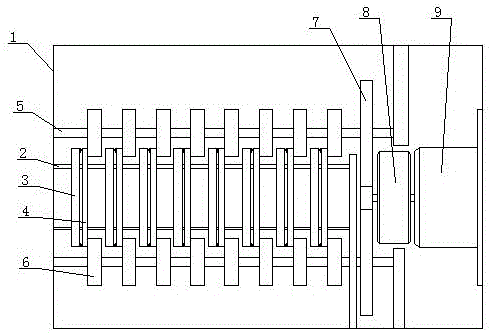

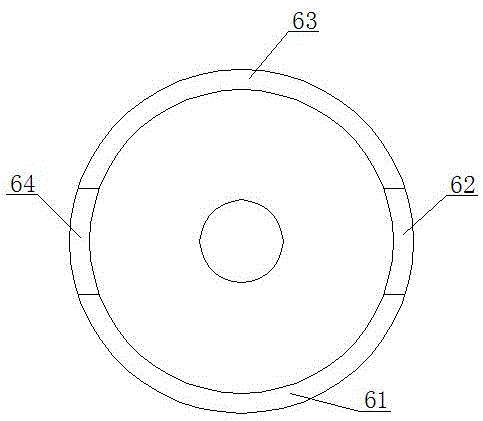

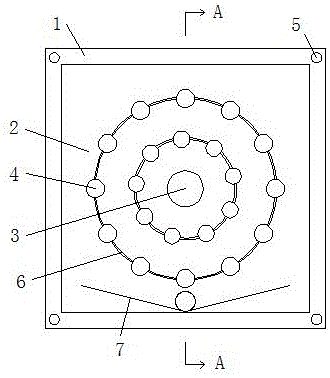

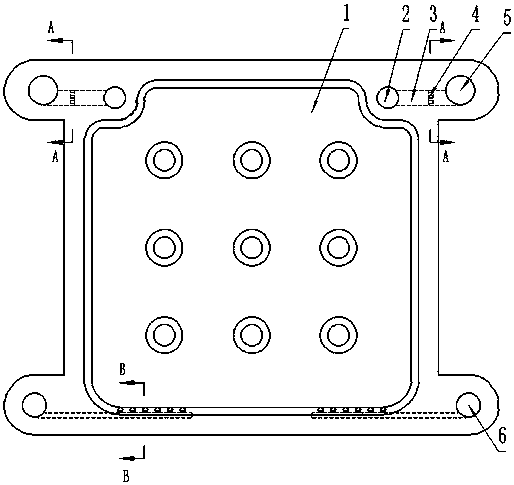

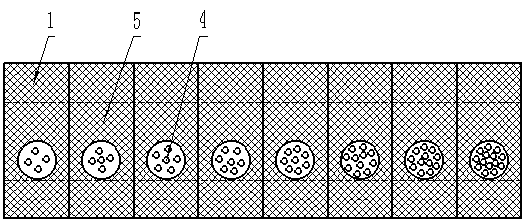

Double-feeding compartment type filter plate combination for fast and uniform feeding

The invention discloses a double-feeding compartment type filter plate combination for fast and uniform feeding. The double-feeding compartment type filter plate combination comprises a plurality of main boards and matching boards which are arranged alternately. The main boards and the matching boards have the same outer shape dimensions, and outer crossing lugs are correspondingly arranged on theupper and lower sides of the main boards and the matching boards symmetrically. Every two upper outer crossing lugs are provided with total feeding channels, and every two lower outer crossing lugs are provided with liquid outlet channels. Single-plate feeding channels perpendicular to the main feeding channels are arranged at the parts, outside filter chambers, on the main boards, and material splitting holes perpendicularly communicate with the single-plate feeding channels. The material splitting holes communicate with the filter chambers on both sides of the main boards. The single-platefeeding channels are internally provided with perforated partition plates, and the hole diameter and the number of holes of the perforated partition plates of the main boards which are sequentially arranged in the feeding direction are sequentially increased. The filter plate combination can realize fast and uniform feeding so as to achieve an ideal filter-pressing effect.

Owner:ZHONGDA BRIGHT FILTER PRESS

A method for deep dehydration of cyanobacteria

ActiveCN109553266BReduce moisture contentEasy to follow upSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationFiltrationCyanobacteria

The invention belongs to the technical field of environmental engineering, and particularly relates to a method for deep dehydration of cyanobacteria. The method comprises the steps: conditioning cyanobacteria produced by an algae-water separation station, performing filter pressing so as to obtain cyanobacteria algae gel with a water content of 60% or below, and treating filtered water through analkali liquid, an air floating pool, an AO biological pool and a sedimentation tank so as to meet the urban sewage discharge standard, wherein the alkali liquid is used for adjusting the pH value ofthe filtered water to neutrality or weak alkalinity, in the air floating pool, a coagulant and coagulant aids are utilized to perform a coagulation reaction with the filtered water, and after floc isformed, solid-liquid separation is conducted through an air floatation effect. The problem of high water content of the cyanobacteria algae gel is solved, and the water content of the cyanobacteria algae gel can be reduced effectively after conditioning and pressure filtration are performed, so that reduction of the cyanobacteria is achieved after salvage is performed, and subsequent treatment isfacilitated.

Owner:无锡市水务集团有限公司

Movable check valve of filter press

InactiveCN113457238ARealize automatic operationSimple structureStationary filtering element filtersSlurryFilter press

The invention discloses a movable on-off valve of a filter press. The movable on-off valve comprises a valve body and a valve core, the valve body is of a cylindrical structure and is slidably mounted in the filter press cylinder body, the valve body is driven by a reciprocating propelling device to move back and forth along the inner wall of the filter press cylinder body, and a detachable filter plate is mounted at the front end of the valve body. The valve element is driven by a valve element driver to move front and back, and an internal flow channel of the valve body is opened or closed. The check valve can move back and forth in the filter press cylinder body, and is coordinated and matched with a corresponding valve on the filter press cylinder body in the moving process; therefore, the flow direction of the filtrate and the internal pressure of the filter pressing cylinder body are controlled through on / off, and automatic operation of feeding, filter pressing of thick slurry, discharging of the filtrate and a filter cake and backwashing of a filter plate is realized. Besides, the structure is simple, the manufacturing cost is low, the filter pressing efficiency and effect are greatly improved, and time and labor are saved.

Owner:盛金平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com