Municipal sludge reduction method

A municipal sludge and sludge thickening tank technology, applied in sludge treatment, biological sludge treatment, chemical instruments and methods, etc., can solve problems such as unfavorable drying, difficult sludge dehydration, long drying time, etc., to achieve Change the water existence status, the effect of sludge reduction is good, and the effect of improving the dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

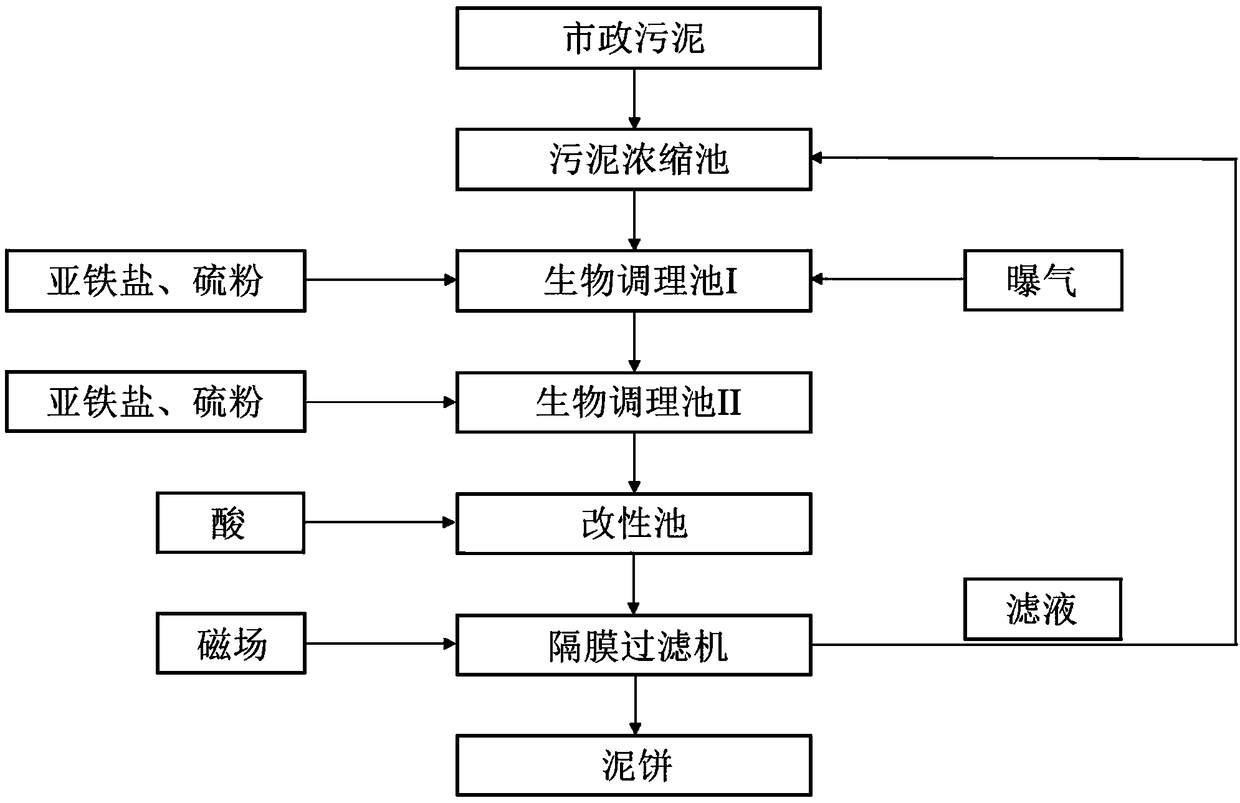

[0052] A kind of municipal sludge reduction method (technical process such as figure 1 shown), the steps are as follows:

[0053] 1) Pass municipal sludge (municipal sludge produced by a municipal sewage treatment plant in Hunan, with a water content of 99.2%) into the sludge concentration tank, concentrate for 13 hours, and return the supernatant to the front end of the sewage treatment plant;

[0054] 2) Pass the municipal sludge treated in step 1) into biological conditioning tank I, add ferrous sulfate (addition amount is 2g / L) and sulfur powder (addition amount is 2g / L), stir, aerate, 25 ℃ Conditioning for 2 days;

[0055] 3) Pass the municipal sludge treated in step 2) into biological conditioning tank II, add ferrous sulfate (addition amount is 1g / L) and sulfur powder (addition amount is 2g / L), stir, and condition at 30°C for 2 sky;

[0056] 4) Pass the municipal sludge treated in step 3) into the modification tank, add dilute sulfuric acid with a mass fraction of 15...

Embodiment 2

[0060] A kind of municipal sludge reduction method (technical process such as figure 1 shown), the steps are as follows:

[0061] 1) Pass municipal sludge (municipal sludge produced by a municipal sewage treatment plant in Hunan, with a water content of 99.5%) into the sludge concentration tank, concentrate for 13 hours, and return the supernatant to the front end of the sewage treatment plant;

[0062] 2) Pass the municipal sludge treated in step 1) into biological conditioning tank I, add ferrous sulfate (addition amount is 4g / L) and sulfur powder (addition amount is 2g / L), stir, aerate, 30 ℃ Conditioning for 2 days;

[0063] 3) Pass the municipal sludge treated in step 2) into biological conditioning tank II, add ferrous sulfate (addition amount is 1g / L) and sulfur powder (addition amount is 2g / L), stir, and condition at 30°C for 2 sky;

[0064] 4) Pass the municipal sludge treated in step 3) into the modification tank, add dilute sulfuric acid with a mass fraction of 15...

Embodiment 3

[0068] A kind of municipal sludge reduction method (technical process such as figure 1 shown), the steps are as follows:

[0069] 1) Pass municipal sludge (municipal sludge produced by a municipal sewage treatment plant in Hubei, with a water content of 99.0%) into the sludge concentration tank, concentrate for 12 hours, and return the supernatant to the front end of the sewage treatment plant;

[0070] 2) Pass the municipal sludge treated in step 1) into biological conditioning tank I, add ferrous sulfate (addition amount is 4g / L) and sulfur powder (addition amount is 4g / L), stir, aerate, 25 ℃ Conditioning for 2 days;

[0071] 3) Pass the municipal sludge treated in step 2) into biological conditioning tank II, add ferrous sulfate (addition amount is 2g / L) and sulfur powder (addition amount is 4g / L), stir, and condition at 25°C for 3 sky;

[0072] 4) Pass the municipal sludge treated in step 3) into the modification tank, add dilute sulfuric acid with a mass fraction of 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com