Composite non-phosphorus scale inhibitor

A technology of compound scale inhibitor and scale inhibitor, which can be used in descaling and water softening, natural water treatment, special treatment targets, etc., can solve the problem of poor scale inhibition effect, etc. Scaling performance, easy compounding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

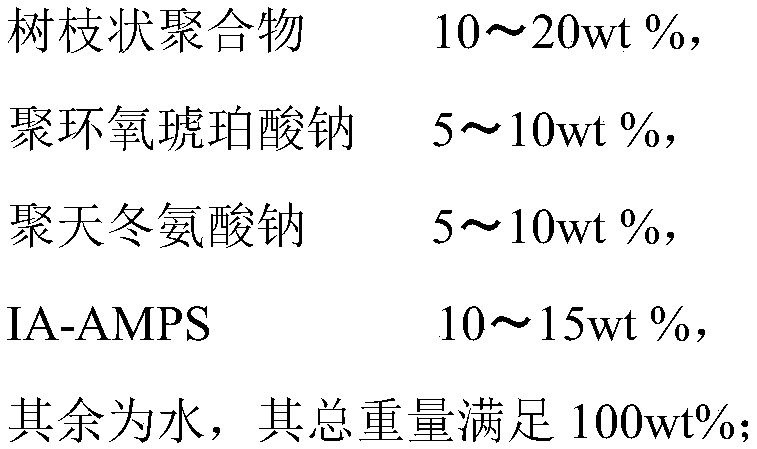

Embodiment 1

[0050] Get the 1.0 generation EDA-PAMAM 20g that comparative example 2 prepares, add 12.5g solid content and be 40% polyepoxysodium sodium succinate (PESA), 12.5g solid content is 40% polyaspartic acid sodium (PASP) , 25g of IA-AMPS with a solid content of 40% and 30g of deionized water, stirred evenly to obtain 100g of a composite scale inhibitor with a solid content of 40%. In the prepared composite antiscalant, the content of 1.0 generation EDA-PAMAM is 20%, and the content of PESA is 5%. The content of PASP was 5%, and the content of IA-AMPS was 10%. The compound antiscalant prepared above was subjected to the performance test experiment of inhibiting silicon scale and calcium scale. The scale inhibition results are shown in Table 2.

Embodiment 2

[0052] Get the 1.0 generation EDA-PAMAM 15g that comparative example 2 prepares, add 12.5g solid content and be 40% polyepoxysodium sodium succinate (PESA), 12.5g solid content is 40% polyaspartic acid sodium (PASP) , 37.5g of IA-AMPS with a solid content of 40% and 22.5g of deionized water, stirred evenly to obtain 100g of a composite antiscalant with a solid content of 40%. In the prepared composite antiscalant, the content of 1.0 generation EDA-PAMAM is 15%, and the content of PESA is 5%. The content of PASP was 5%, and the content of IA-AMPS was 15%. The compound antiscalant prepared above was subjected to the performance test experiment of inhibiting silicon scale and calcium scale. The scale inhibition results are shown in Table 2.

Embodiment 3

[0054] Get the 1.0 generation EDA-PAMAM 10g that comparative example 2 prepares, add 25g solid content and be 40% polyepoxysodium sodium succinate (PESA), 25g solid content is 40% polyaspartic acid sodium (PASP), 25g IA-AMPS with a solid content of 40% and 15 g of deionized water were stirred evenly to obtain 100 g of a composite scale inhibitor with a solid content of 40%. In the prepared composite antiscalant, the content of 1.0 generation EDA-PAMAM is 10%, and the content of PESA is 10%. The content of PASP was 10%, and the content of IA-AMPS was 10%. The compound antiscalant prepared above was subjected to the performance test experiment of inhibiting silicon scale and calcium scale. The scale inhibition results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com