Partition-plate-free open-close type filter chamber for sludge dewatering

A sludge dehydration, opening and closing technology, which is applied in water/sludge/sewage treatment, sludge treatment, filtration and separation, etc., can solve the problems of increasing labor consumption and single working hours, etc., to reduce the labor intensity of workers, Improve work efficiency and increase the effect of filter press effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

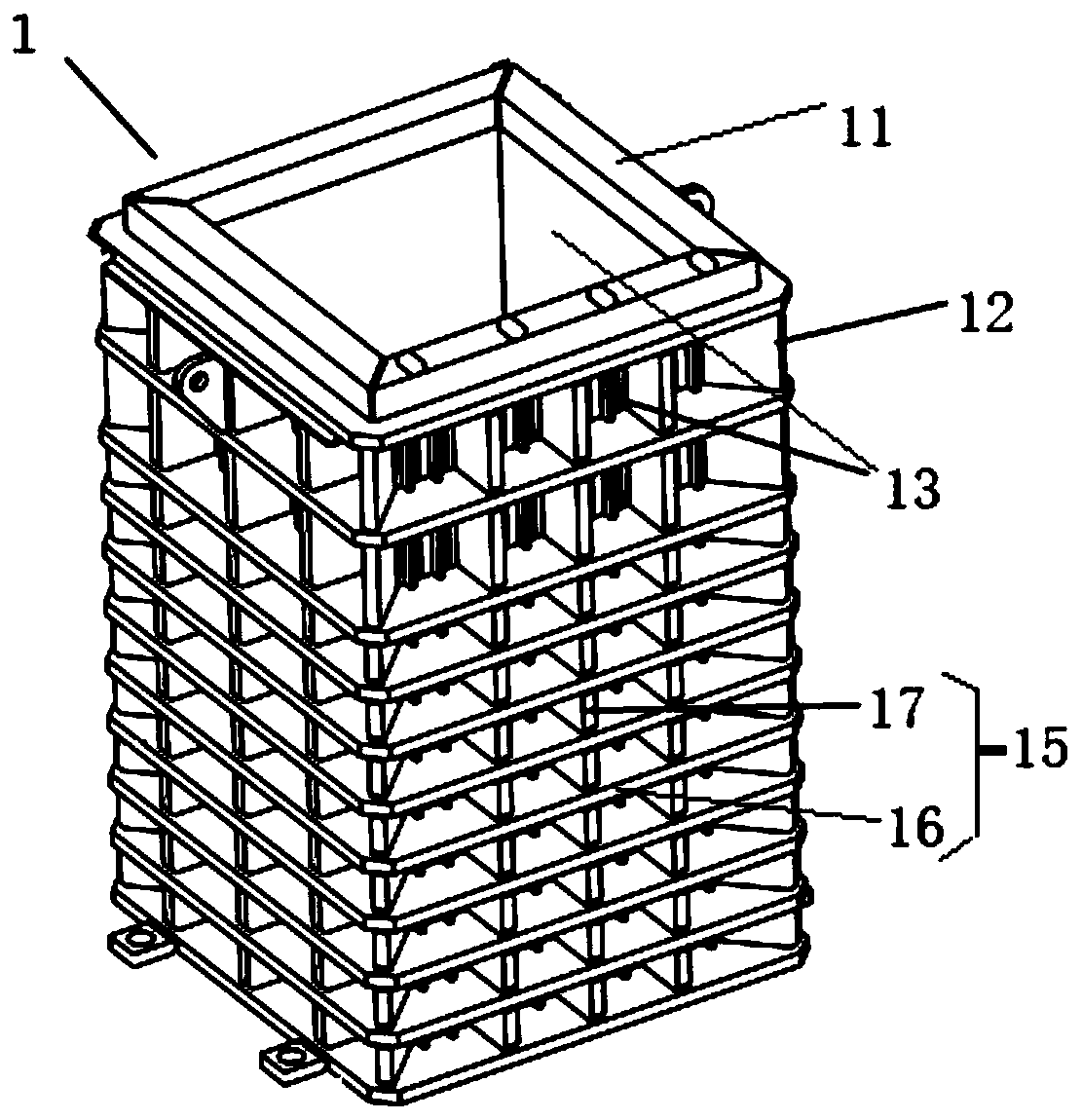

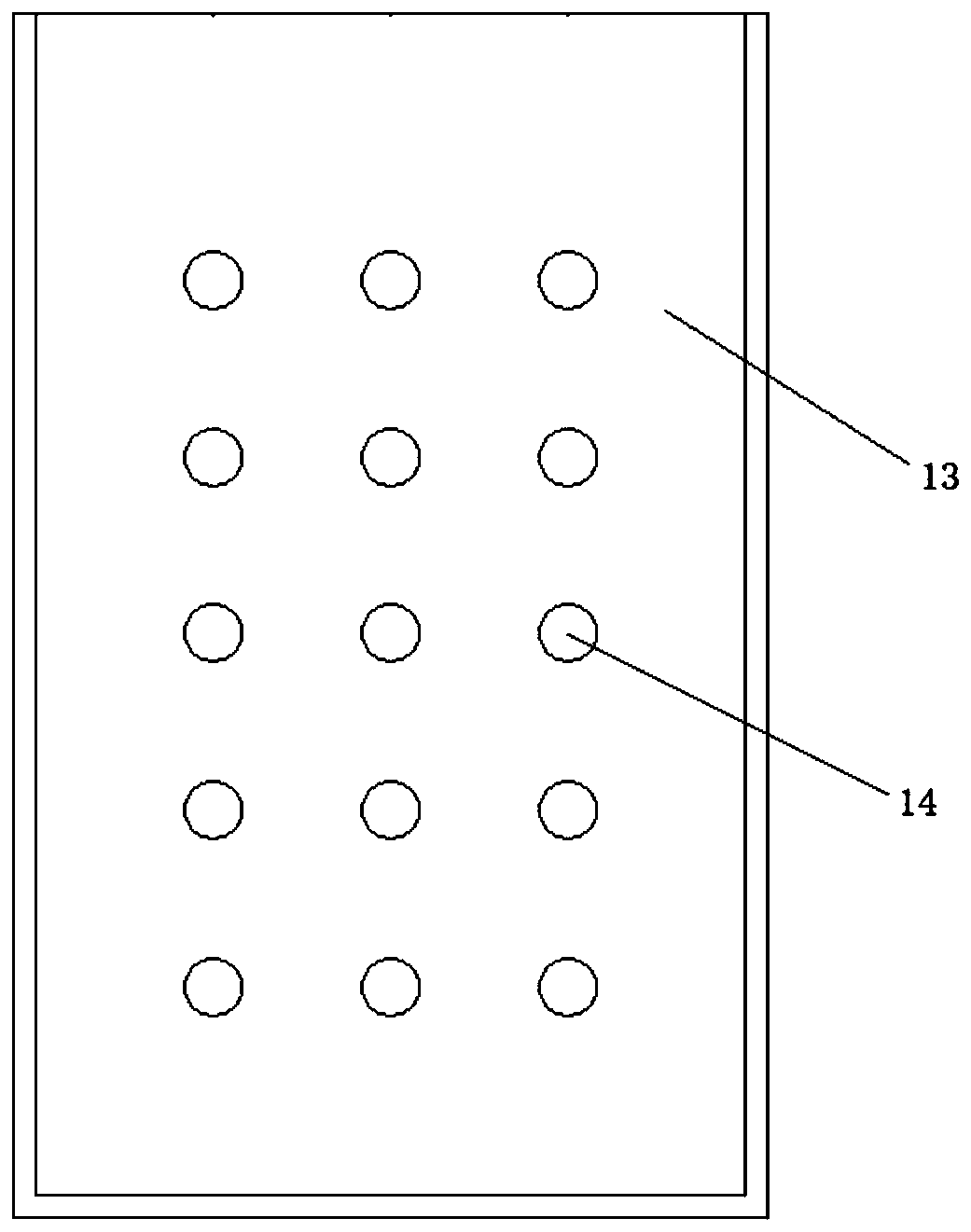

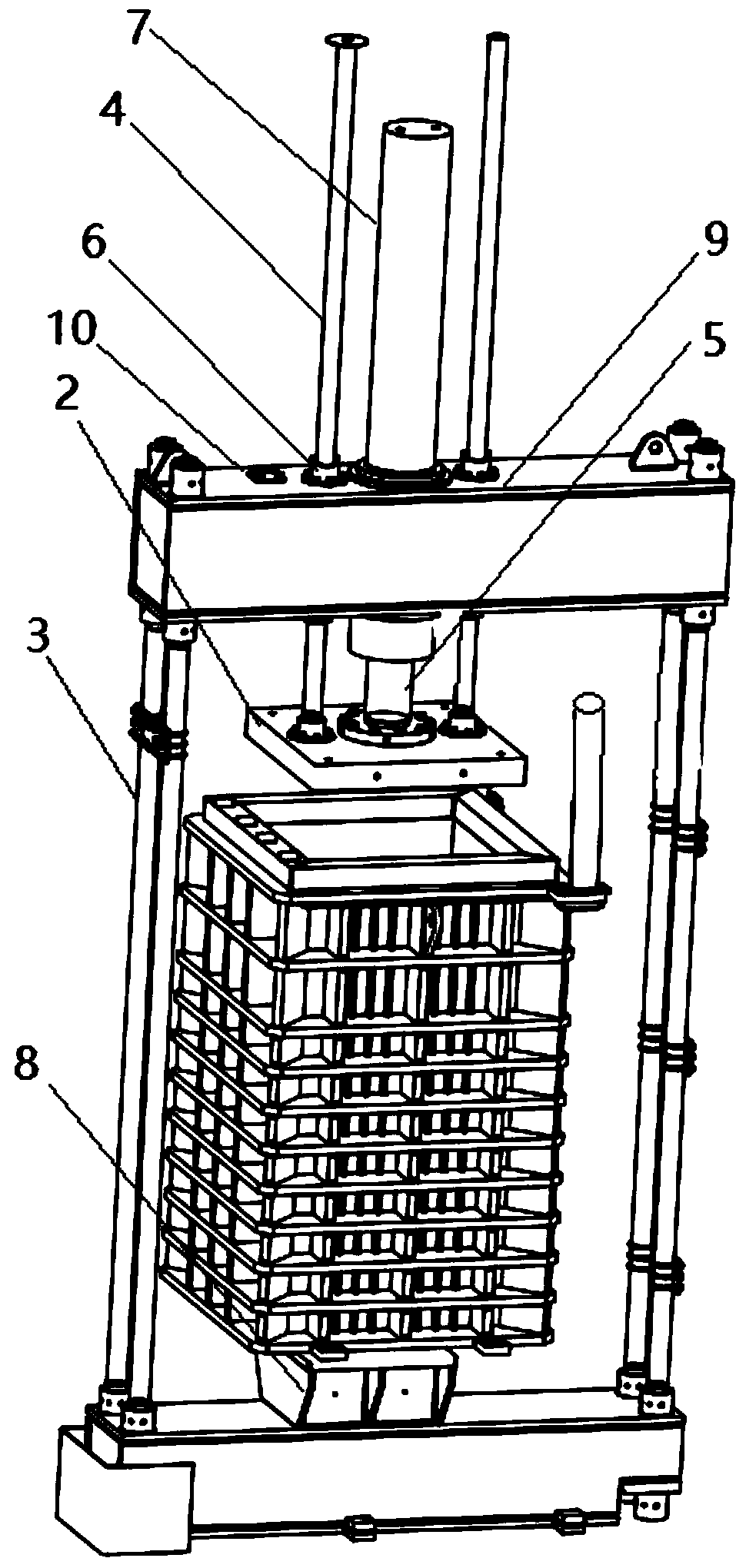

[0017] Example: such as figure 1 , figure 2 As shown, the present invention is used for sludge dewatering without a partition open-close filter chamber 1, including two rectangular frames 11 and four columns 12, a column 12 is respectively set between the four corners of the two rectangular frames 11, A three-dimensional frame is formed; a filter plate 13 is arranged between two adjacent columns 12 inside the three-dimensional frame, and a plurality of filter holes 14 are opened on the filter plate 13, and a filter chamber 1 is formed inside the filter plate 13, and a filter chamber 1 is formed outside the three-dimensional frame. The filter plate 13 adjacent to the two columns 12 is provided with a reinforcing rib plate 15 supporting the filter plate 13, and one side of the filter chamber 1 is an open-close structure to form a filter chamber door, and one side of the filter chamber door The column connected to it is connected by rotation, and the other side is closed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com