Pretreatment method for plate-frame pressure filtration of bloom-forming cyanobacteria

A technology of blooming blue-green algae and blue-green algae board, which is applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, sludge treatment, etc. It can solve the problems of unable to deal with water-blooming blue-green algae mud, and achieve a boost pressure filter effect, reduce cell elasticity, and reduce the effect of water-holding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

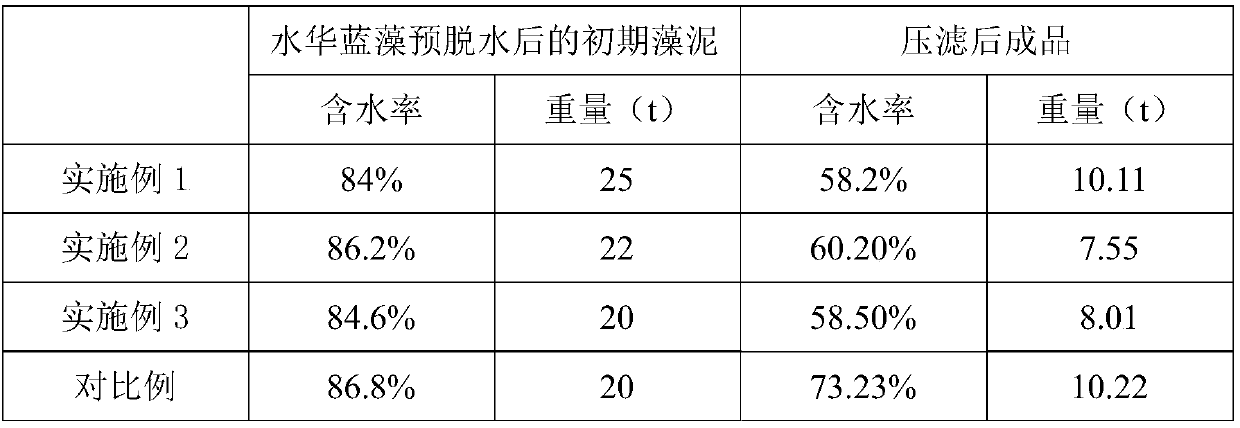

Embodiment 1

[0026] A pretreatment method for water bloom cyanobacteria plate and frame filter press, comprising the following steps:

[0027] Step 1, diluting and stirring the initial algae mud after pre-dehydration of the bloom cyanobacteria to an algae-water mixture with a water content of 95%;

[0028] Step 2, adding ferrous sulfate powder and hydrogen peroxide to the above-mentioned algae-water mixture in sequence, and fully stirring to obtain a mixture A;

[0029] In step 3, the polyaluminum ferric chloride agent and quicklime are sequentially added to the mixed solution A and stirred evenly to obtain a preconditioned water bloom cyanobacteria solution.

[0030] The water content of the initial algae mud after the pre-dehydration of the bloom cyanobacteria in the step 1 is 85-90%.

[0031] The initial algae mud after the pre-dehydration of the bloom cyanobacteria in the step 1 is diluted to a 95% algae-water mixture by adding water.

[0032] The adding quality of the ferrous sulfat...

Embodiment 2

[0039] A pretreatment method for water bloom cyanobacteria plate and frame filter press, comprising the following steps:

[0040] Step 1, diluting and stirring the initial algae mud after pre-dehydration of the bloom cyanobacteria to an algae-water mixture with a water content of 95%;

[0041] Step 2, adding ferrous sulfate powder and hydrogen peroxide to the above-mentioned algae-water mixture in sequence, and fully stirring to obtain a mixture A;

[0042] In step 3, the polyaluminum ferric chloride agent and quicklime are sequentially added to the mixed solution A and stirred evenly to obtain a preconditioned water bloom cyanobacteria solution.

[0043] The water content of the initial algae mud after the pre-dehydration of the bloom cyanobacteria in the step 1 is 85-90%.

[0044] The initial algae mud after the pre-dehydration of the bloom cyanobacteria in the step 1 is diluted to a 95% algae-water mixture by adding water.

[0045] The addition quality of the ferrous sulf...

Embodiment 3

[0052] A pretreatment method for water bloom cyanobacteria plate and frame filter press, comprising the following steps:

[0053] Step 1, diluting and stirring the initial algae mud after pre-dehydration of the bloom cyanobacteria to an algae-water mixture with a water content of 95%;

[0054] Step 2, adding ferrous sulfate powder and hydrogen peroxide to the above-mentioned algae-water mixture in sequence, and fully stirring to obtain a mixture A;

[0055] In step 3, the polyaluminum ferric chloride agent and quicklime are sequentially added to the mixed solution A and stirred evenly to obtain a preconditioned water bloom cyanobacteria solution.

[0056] The water content of the initial algae mud after the pre-dehydration of the bloom cyanobacteria in the step 1 is 85-90%.

[0057] The initial algae mud after the pre-dehydration of the bloom cyanobacteria in the step 1 is diluted to a 95% algae-water mixture by adding water.

[0058] The adding quality of the ferrous sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com