Method for preparing cerium-activated yttrium aluminium garnet fluorescent powder

A technology of yttrium aluminum garnet and phosphor powder is applied in the field of phosphor powder to achieve the effects of changing sintering temperature, low production cost and shortened time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

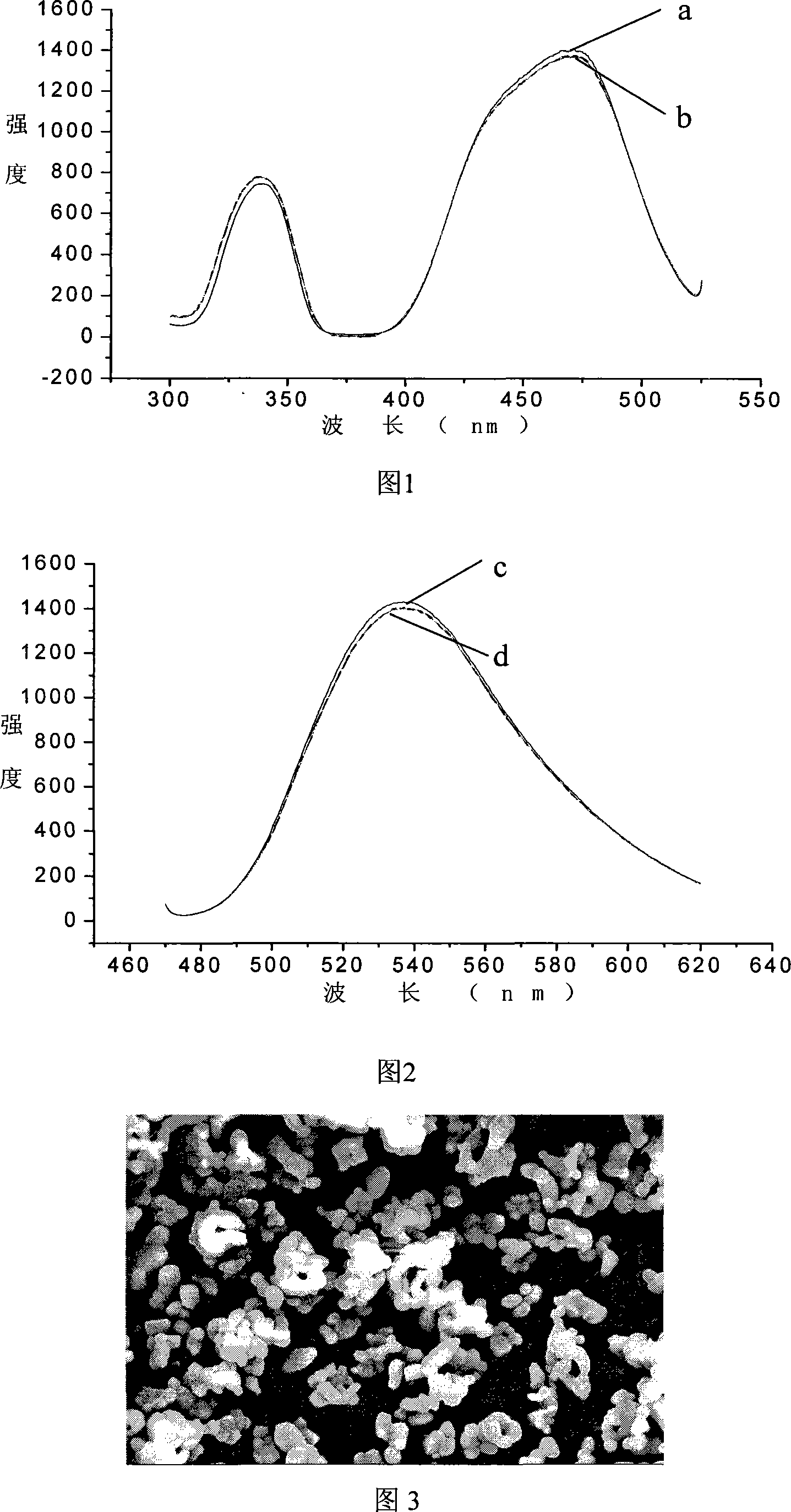

[0056] Example 1: Y 2.96 al 5 o 12 : Ce 0.04 Phosphor powder preparation

[0057] Take 3.342g Y 2 o 3 , added to a solution made of 6.1mL concentrated nitric acid and 100mL deionized water, heated to dissolve and remove slightly excess nitric acid; add 18.757gAl(NO) 3 9H 2 O and 0.174g Ce(NO) 3 ·6H 2 O, use deionized water to make a solution with a total concentration of metal ions of 0.4mol / L. Weigh 12.607g of oxalic acid and dissolve it in 200mL of deionized water, and adjust the pH value to 9.5 with ammonia water. Add the mixed solution of the metal salt dropwise into the composite precipitant under constant stirring, keep the solution temperature at 50°C, and the dropping rate is 2mL / min. After the dropwise addition, it was aged for 12 hours and then filtered, and the precipitate was washed with deionized water and absolute ethanol respectively, and then dried in an oven at 60°C for 12 hours. Add 4.5% of the target product mass as NaF as a flux, mix and grind. ...

Embodiment 2

[0058] Example 2: Y 2.94 al 5 o 12 : Ce 0.06 Phosphor powder preparation

[0059] Similar to Example 1, the difference is as follows:

[0060] (1) Raw material ratio is 3.319g Y 2 o 3 , 18.757g Al(NO 3 ) 3 9H 2 O and 0.261g Ce(NO 3 ) 3 ·6H 2 O; be made into a solution with a total concentration of metal ions of 0.3mol / L; the amount of oxalic acid is 20.171g, dissolved in 200mL of water, and the pH value is adjusted to 9 with ammonia water.

[0061] (2) flux consumption is 1.1% of target product quality, wherein BaF 2 and H 3 BO 3 Each accounts for 0.55%; the temperature of the solid phase reaction is 1200°C, and the temperature is kept for 1h.

[0062] (3) High-temperature sintering at 1500° C. for 4 hours.

Embodiment 3

[0063] Example 3: Y 2.94 al 4 GaO 12 : Ce 0.06 Phosphor powder preparation

[0064] Similar to Example 1, the difference is as follows:

[0065] (1) Raw material ratio is 3.319g Y 2 o 3 , 15.006gAl(NO 3 ) 3 9H 2 O, 2.841g GaCl 3 ·6H 2 O and 0.261gCe(NO 3 ) 3 ·6H 2 O; made into a solution with a total concentration of metal ions of 0.25mol / L.

[0066] (2) flux consumption is 2% of target product quality, wherein NaF accounts for 1.25%, H 3 BO 3 Accounting for 0.75%; the temperature of the solid phase reaction is 1200°C, and the temperature is kept for 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com