Method for preparing melamine cyanurate with large particle size and wide distribution

A technology of melamine cyanurate and melamine, which is applied in the field of preparation of melamine cyanurate with large particle size and wide distribution, can solve the problems of process limitation, suction filtration and drying, increase the difficulty of mixing and extrusion processing, and product accumulation Low density and other issues, achieve excellent flame retardant effect, improve flame retardant effect and mechanical properties, and avoid equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 560.12kg of water to a 1500L reactor, add 80.59kg of cyanuric acid, heat up to 70°C and stir to dissolve, mix 75kg of melamine and 7.78kg of polyacrylamide evenly, add them, heat up to 98°C, and react at a constant temperature for 3 hours under stirring to obtain White slurry, convey the slurry into a filter press for dehydration to obtain a white filter cake, which is put into a flash dryer for flash drying, and then pulverized to obtain a white MCA powder with an average particle size of 22.6 μm.

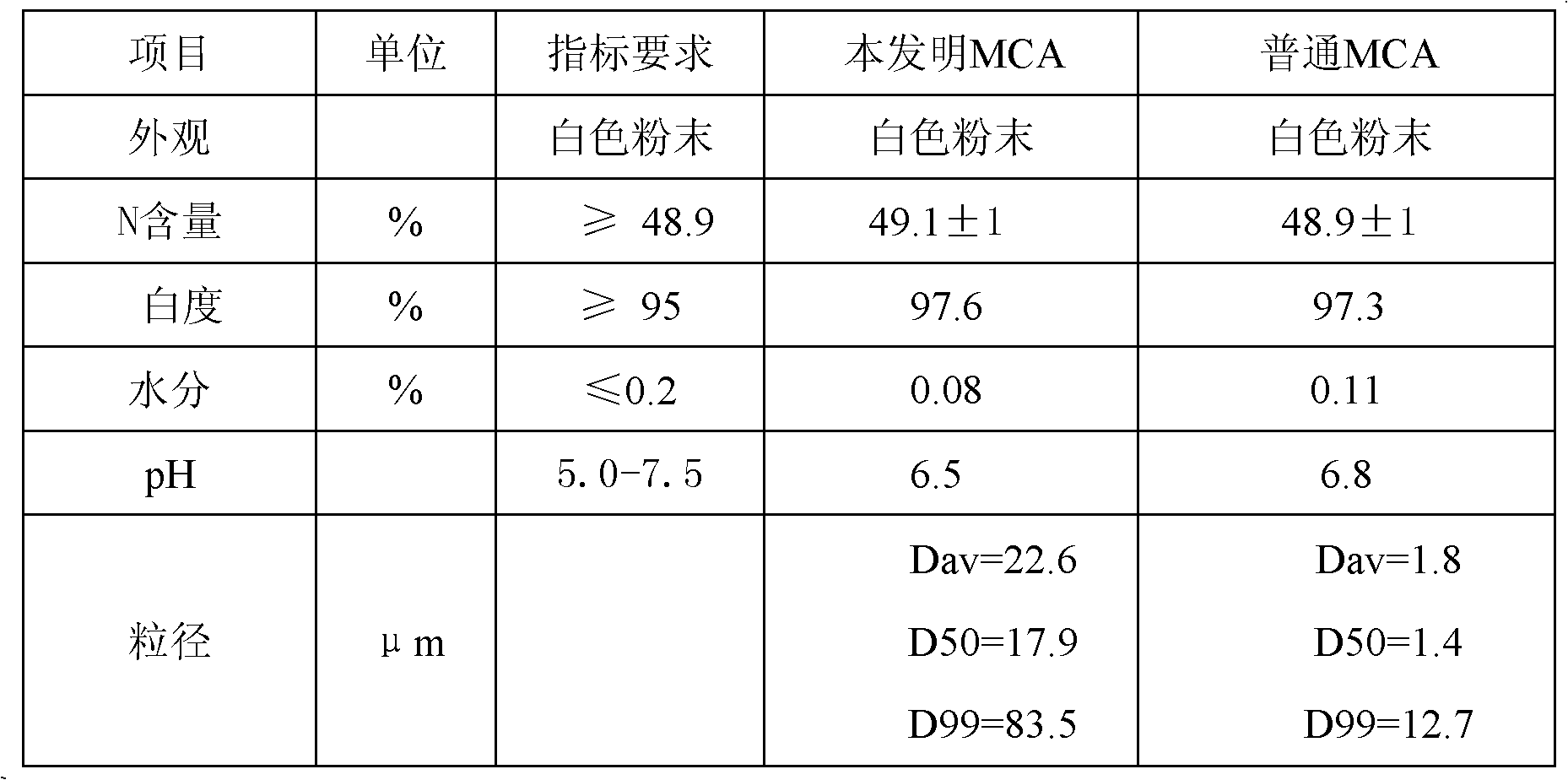

[0016] The comparison between the performance index of the product of this embodiment and the common MCA index is shown in Table 1 below.

[0017] Table 1 product of the present invention and common product performance index contrast

[0018]

[0019] It can be seen from the above table that the MCA prepared in this example fully meets the index requirements, and the average particle size is 22.6 μm, the median particle size is 17.9 μm, and the maximum particle size ...

Embodiment 2

[0021] Add 233.4kg of water into a 1500L reactor, add 20.15kg of cyanuric acid, heat up to 110°C and stir to dissolve, mix 18.75kg of melamine and 1.95kg of polyacrylamide evenly and add, stir and react at a constant temperature for 5 hours at 110°C to obtain white Slurry, the slurry is transported into a filter press for dehydration to obtain a white filter cake, which is sent to a flash dryer for flash drying, and then crushed to obtain a white MCA powder with a large particle size and a wide distribution.

Embodiment 3

[0023] Add 560.13kg of water into a 1500L reactor, add 96.71kg of cyanuric acid, heat up to 60°C and stir to dissolve, mix 90kg of melamine and 0.93kg of polyacrylamide evenly, add them, heat up to 95°C, and react at a constant temperature for 2 hours under stirring to obtain White slurry, the slurry is transported into a filter press for dehydration to obtain a white filter cake. The filter cake enters a flash dryer for flash drying and then crushed to obtain a white MCA powder with large particle size and wide distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com