Combined process for sludge treatment

A combined process and sludge treatment technology, applied in the direction of sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the difficulty and cost of treatment, reduce to 75%-85%, sludge dry basis weight gain etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a combined process for sludge treatment, including the following steps:

[0045] 1) Take 100kg (about 100L) of sludge with a moisture content of about 98.5%, and pour all into the conditioning tank;

[0046] 2) Adjust the pH of the sludge to 3 with 50% sulfuric acid, and add Fe 2+ , The addition amount is 35g / (kg dry sludge), after mechanical stirring for 5min, add H 2 O 2 , Add 30g / (kg dry sludge), mechanically stir for 30min, add CaO, add 100g / (kg dry sludge), stir for 5min; after treatment, the average particle size of sludge is 48.06μm, and the dry sludge matrix increases 10.6% weight.

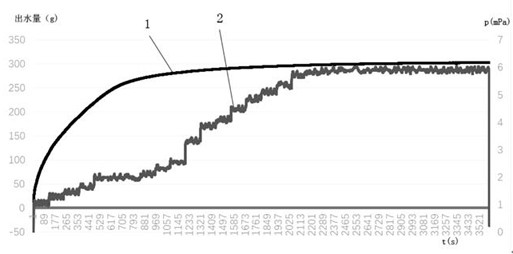

[0047] 3) Start the plunger pump to transport the sludge in the conditioning tank to the diaphragm plate and frame filter press. The inlet pressure is maintained at 1.6MPa for a duration of 1h; after all the sludge is delivered to the filter press, the press pump is started for compression Filter, the pressure is set to 2.5MPa, the filter pressure curve is as fig...

Embodiment 2

[0051] This embodiment provides a combined process for sludge treatment, including the following steps:

[0052] 1) Take 100kg (about 100L) of sludge with a moisture content of about 98.2%, and pour all into the conditioning tank;

[0053] 2) Adjust the pH of the sludge to 3 with 50% sulfuric acid, and add Fe 2+ , The dosage is 70g / (kg dry sludge), after mechanical stirring for 5min, add H 2 O 2 , Add 30g / (kg dry sludge), mechanically stir for 30min, add CaO, add 60g / (kg dry sludge), stir for 5min; the average particle size of the sludge after treatment is 46.05μm, and the dry sludge matrix increases It weighs 8.4%.

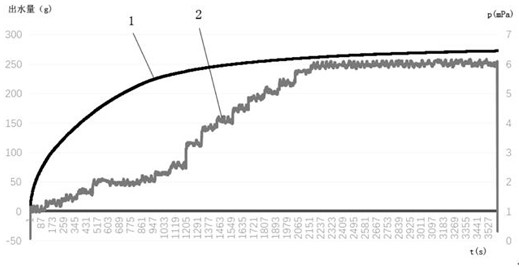

[0054] 3) Start the plunger pump to transport the sludge in the conditioning tank to the diaphragm plate and frame filter press. The inlet pressure is maintained at 1.6MPa for a duration of 1h; after all the sludge is delivered to the filter press, the press pump is started for compression Filter, the pressure is set to 2.5MPa, the filter pressure curve is as image 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com