Filter press with movable check valve and use method of filter press

A mobile, filter press technology, applied in separation methods, chemical instruments and methods, fixed filter element filters, etc., can solve the problems of low filter press efficiency and effect, filter cake reprocessing, clogging, etc. Achieve the effect of saving manpower and material resources, good sealing performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

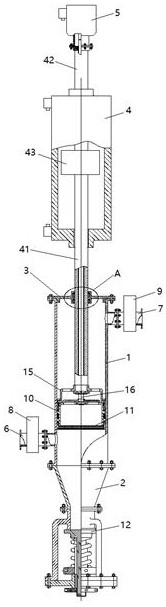

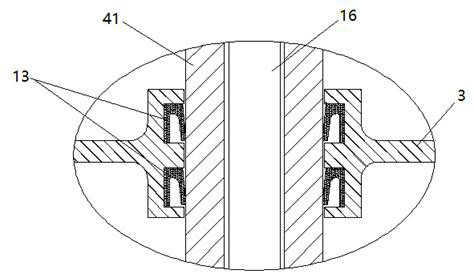

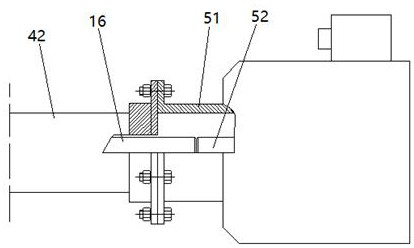

[0041] See Figure 1-8 A filter machine with a moving stop valve, including the cylinder 1, the front end of the cylinder 1, and fixedly connected to the pressing chamber 2 with which the cylinder 1 is fixedly connected to the sealing cover. 3, the rear of the cylinder 1 is provided with a reciprocating propulsion device 4 and a spool of the core driver 5, and the cylinder 1, respectively, the side walls of the rear end are respectively provided with a concentrated slurry inlet 6 and the filler outlet 7, a thick paste inlet 6 and the filtrate The outlet 7 corresponds to the feed valve 8 and the discharge valve 9; the inside of the cylinder 1 is slidably mounted, and the stop valve 10 includes a valve body 101 and passage of movable before and after the inner wall of the cylinder 1. The spool 102 of the inner flow channel of the valve body 101 is attached to the front end of the valve body 101, and the reciprocating propulsion device 4 drives the valve body 101 to move before and af...

Embodiment 2

[0061] See Figure 9 , 10 In this embodiment, the valve body 101 is a cylindrical structure, and the push rod connecting bracket 15 is also a cylindrical structure, and the outer diameter of the valve body 101 and the push rod connecting bracket 15 is slightly smaller than the inner diameter of the cylinder 1, and pushes the rod connection. The inner diameter of the front port of the bracket 15 is smaller than the inner diameter of the port of the valve body 101, thereby forming a valve seat stop structure at the front port of the push rod connection bracket 15; in addition, the rear end of the push rod connection bracket 15 is a hollow structure.

[0062] The spool 102 is located inside the valve body 101, and the spool 102 moves forward or backward on the drive of the spool driver 5. When moving backward, the spool 102 is pressed outside the front port of the propeller connection bracket 15. The end face (the valve seat stop is at the interior flow channel of the cutoff valve bod...

Embodiment 3

[0065] See Figure 11 , 12In this embodiment, the structure of the elastic damper 12 'is different from the elastic damper 12 structure in the first embodiment, which includes a throat 121' with a front end of the compression chamber 2 and can be sealed in the throat 121. The top of the front port of the front port is fixed to the outer wall of the L-shaped bracket 123 ', the vertical portion of the L-shaped bracket 123', the L-shaped bracket 123 ', and the horizontal tube 124' It is provided with the horizontal axis 125 ', the lateral axis 125', and the lateral axis 125 'can be passed before and after, respectively, and the passage of the rear end is respectively, and the horizontal axis 125' is located at the horizontal tube 124. The exterior of the part of the part is inherently inherently spring seat 126 'and the outer portion of the rosk 127', the outer spring seat 126 'and the spring seat 127' is set with a spring 128 '. In the through hole of the rear end of the transverse t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com