Tool load waveform mode based tool switching detection method

A pattern detection and tool technology, applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing mechanical parts, etc., to avoid changes, omit additions, and omit hardware configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

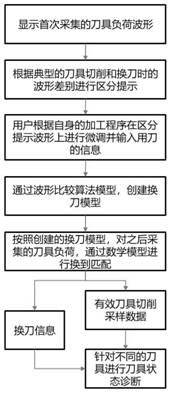

[0022] The tool switching method is detected based on the tool load waveform mode, which includes the following steps:

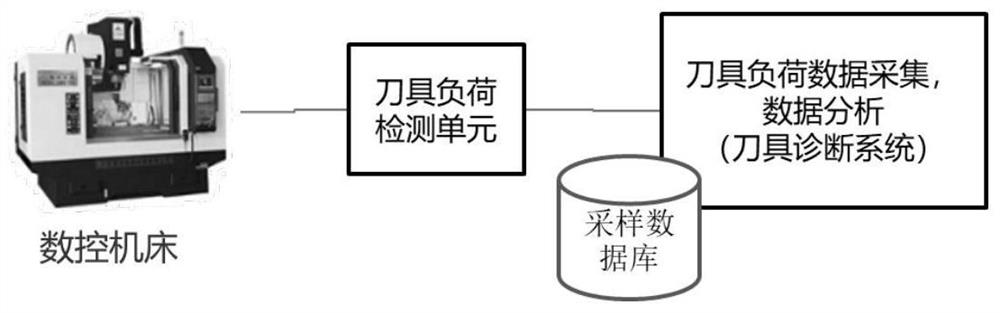

[0023] A. Use the existing tool load data acquisition system to collect the load data of the CNC machine tool during work without interruption;

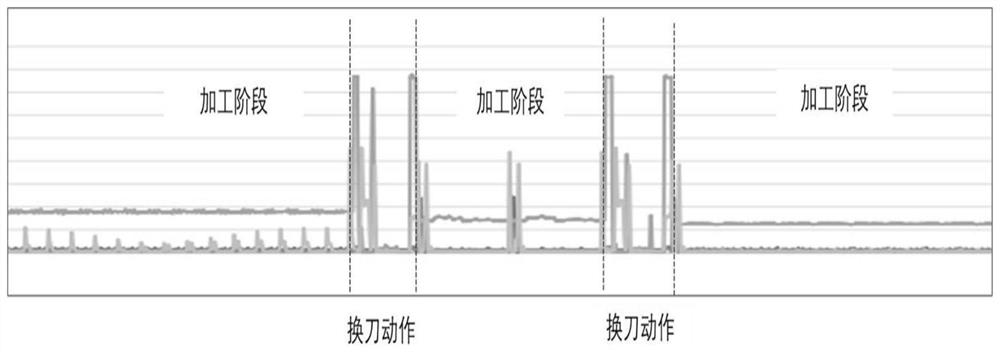

[0024] B. Classify and mark the waveform difference corresponding to the load of typical tool cutting and tool changing;

[0025] C. Screen out the effective data during cutting and tool change, and establish the tool change model by the tool diagnosis system for the tool load during cutting, and separate the effective tool cutting load data;

[0026] D. According to the created tool change model and tool information, for the tool load collected after the tool change model is created, through the in-depth data analysis of the mathematical model in the diagnosis system, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com