Treatment method of high oil content wastewater sludge

A wastewater sludge and treatment method technology, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve poor flocculation effect, easy adhesion of filter belt, and flushing water volume Large and other problems, to achieve the effect of large sludge treatment capacity, improved filter press performance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with embodiment the present invention is further described.

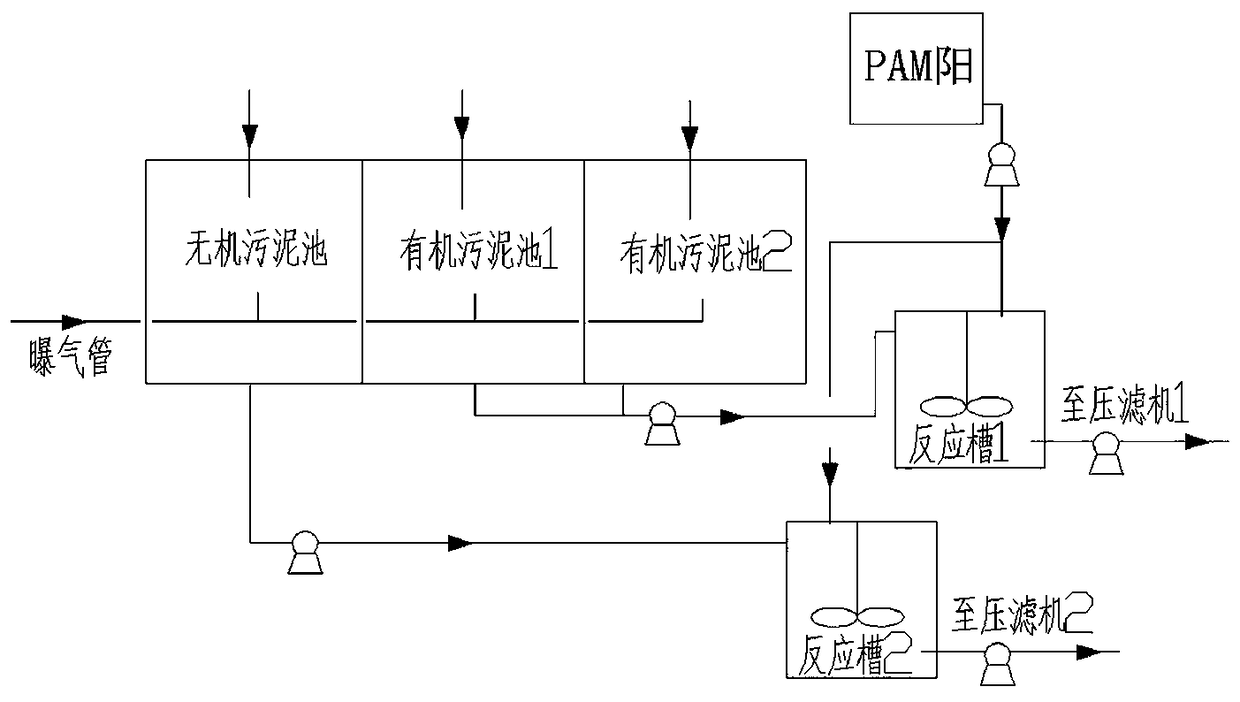

[0013] A treatment method for high oily wastewater sludge, comprising:

[0014] 1. Preparation of flocculant: Inject water and polyacrylamide cations into the PAM dissolution tank at a ratio of 1000:2-3, start the solution stirrer to stir at a speed of 63-85 rpm, and prepare the flocculant after stirring evenly. Become the solution that mass percent concentration is 0.2-0.3%;

[0015] 2. Sludge preparation: coking wastewater with high oil content organic sludge and inorganic sludge are transported to the sludge mixing tank at a ratio of 3:1, where they are mixed by aeration;

[0016] 3. Material transportation: The sludge prepared in the sludge mixing tank is transported to the sludge reaction tank at a flow rate of 10-15m³ / h through the sludge delivery pump, and at the same time, the flocculant solution in the PAM (cation) dissolution tank is passed through the PAM ( Cationic) delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com