Patents

Literature

128results about How to "Avoid normal operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic vehicle carrying and transferring method and system, and application

InactiveCN109403690AExcellent input costEnsure the cost of waitingParkingsTransfer systemSoftware system

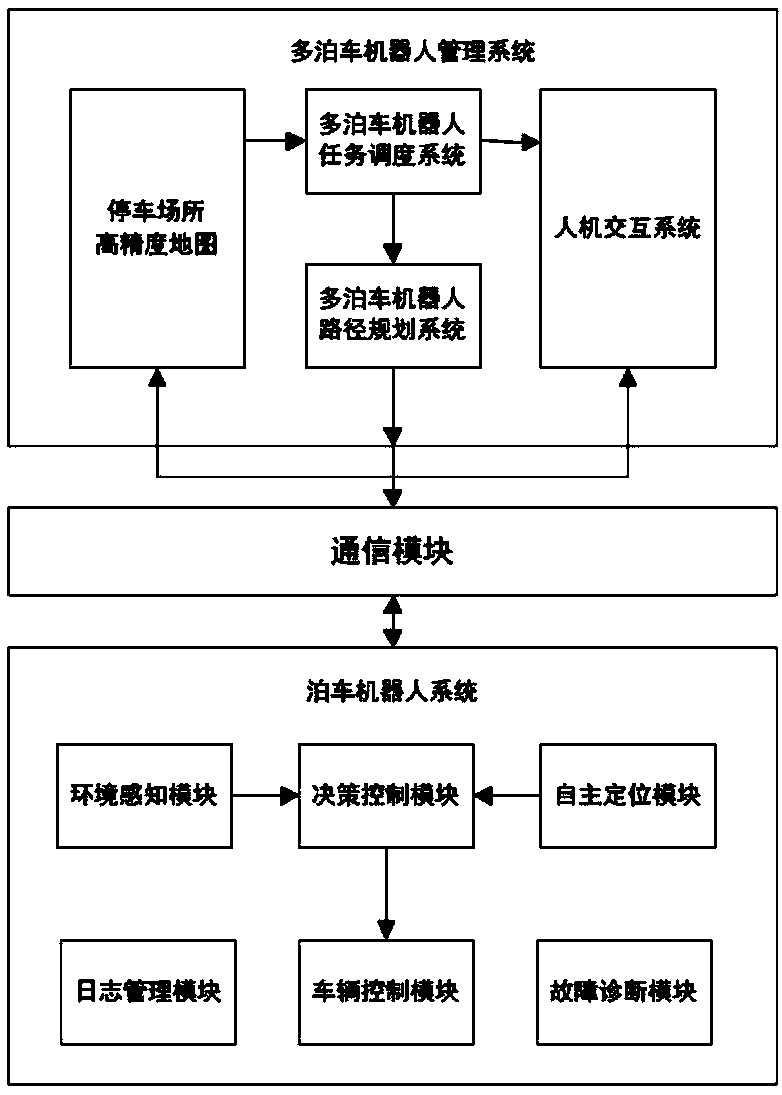

The invention discloses an automatic vehicle carrying and transferring method and system. The automatic vehicle carrying and transferring method comprises the following steps that the interactive relation is established with a user; the parking request of the user is obtained, and a loading and transporting device for loading and transporting a vehicle of the user is dispatched to the parking position of the user; the loading and transporting device automatically loads and transports the vehicle of the user to be parked on a designated parking position; the pick-up request of the user is obtained, and the loading and transporting device for loading and transporting the vehicle of the user is dispatched to the designated parking position; and the loading and transporting device automatically loads and transports the vehicle of the user to be parked on a designated pick-up position. The automatic vehicle carrying and transferring system comprises the loading and transporting device, a multiple loading and transporting device task scheduling system, a loading and transporting device vehicle-mounted automatic navigation hardware platform and software system, a vehicle transferring station system and a man-machine interaction subsystem, wherein the loading and transporting device is a parking robot. The comfort of vehicle parking and picking-up of the user is improved, the operationefficiency is improved, the space utilization rate is increased, the construction cost is lowered, and complicated and tedious operation and maintenance are relatively avoided.

Owner:TONGJI UNIV

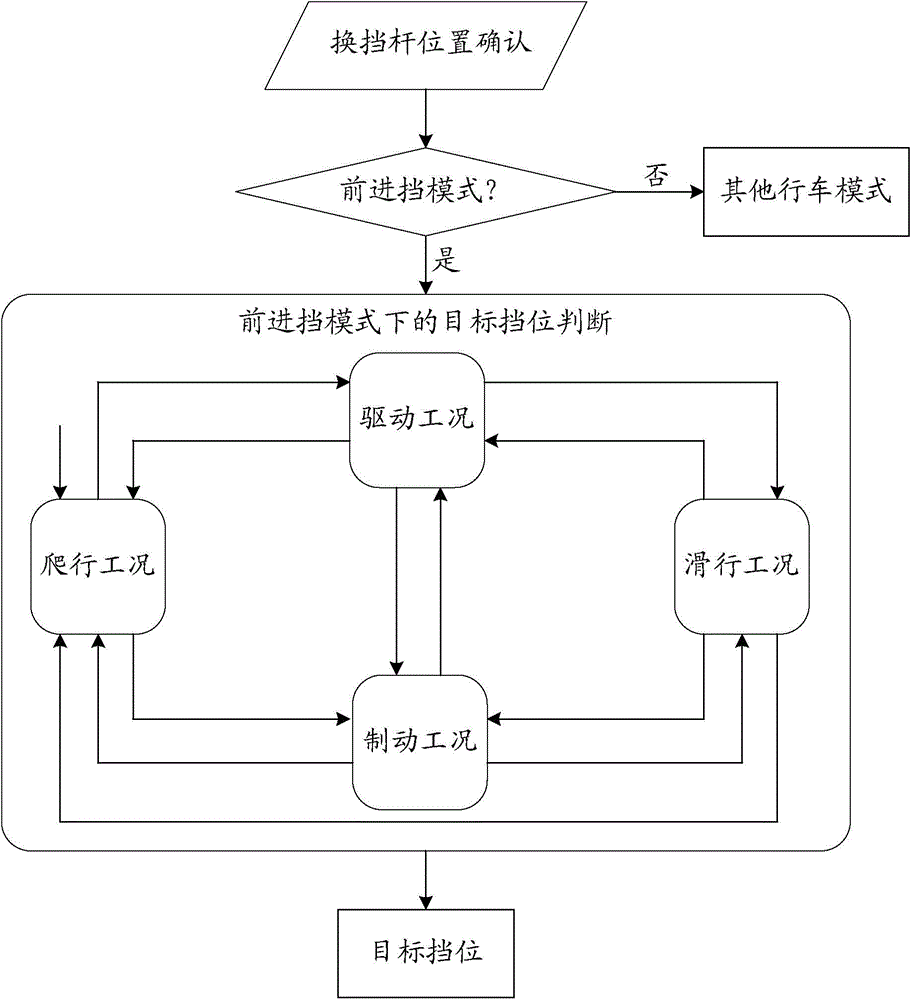

Method and device for controlling automatic gear shifting of automobile

ActiveCN105276156AImprove recycling efficiencyAffect powerGearing controlEnergy recoveryProcess control

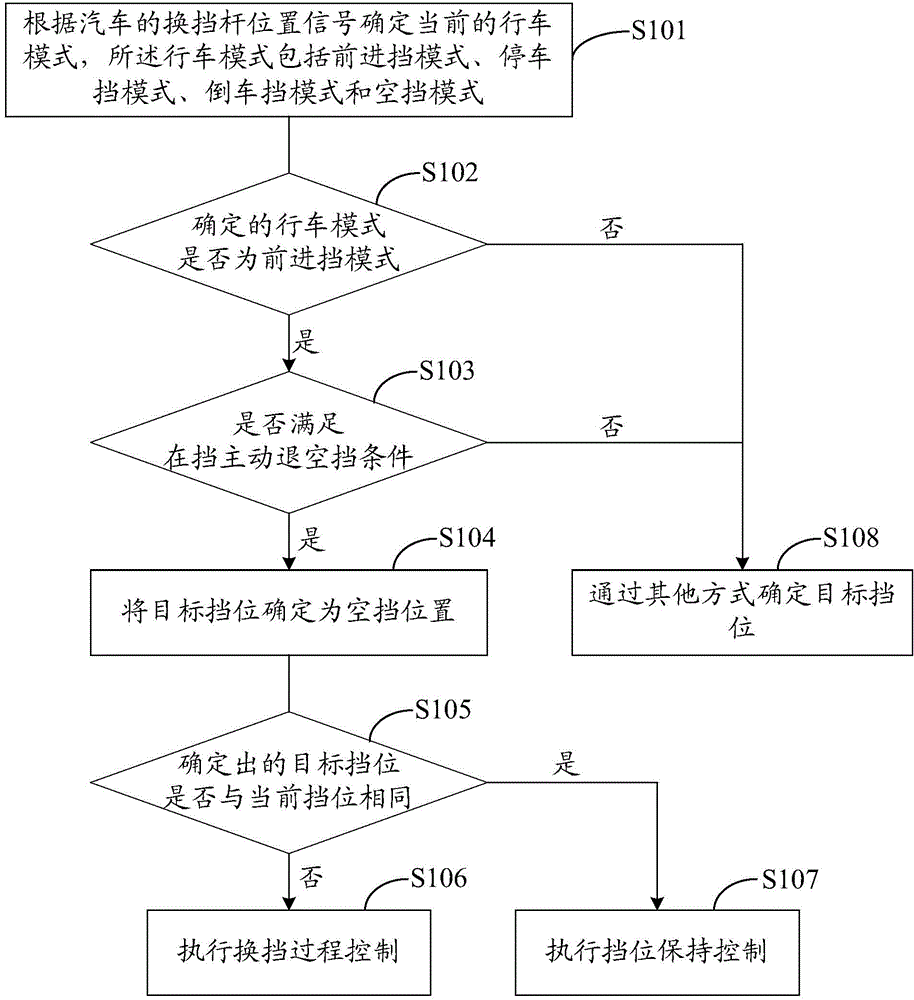

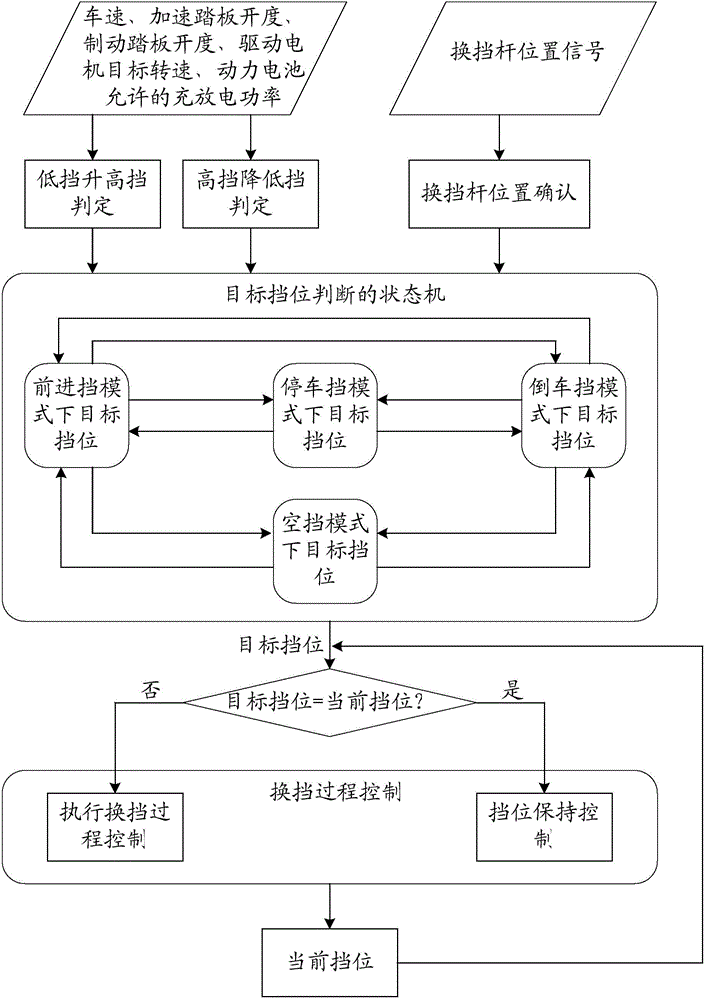

The invention provides a method and device for controlling automatic gear shifting of an automobile. The method comprises the steps that the current running mode is determined according to position signals of a shift lever of the automobile, and the running modes comprise the forward gear mode, the parking gear mode, the reverse gear mode and the neutral gear mode; if the running mode is determined to be the forward gear mode, the target gear is determined according to different running working conditions of the automobile; the running working conditions comprise the sliding working condition, the step of determining the target gear according to the different running working conditions of the automobile comprises the substep of determining the target gear to be the neutral gear if active gear-to-neutral-gear conditions are met, and the active gear-to-neutral-gear conditions comprise the conditions that the running working condition of the automobile is the sliding working condition, the accelerated speed of the automobile is smaller than or equal to zero, and the time interval between gear-to-neutral-gear operations is larger than a threshold value; and when the determined target gear is different from the current gear, control over the gear shifting process is executed. According to the scheme, the brake energy recovery efficiency and the dynamic property of running of the whole automobile can be both considered, and the energy utilization efficiency of the whole automobile is improved.

Owner:SAIC MOTOR

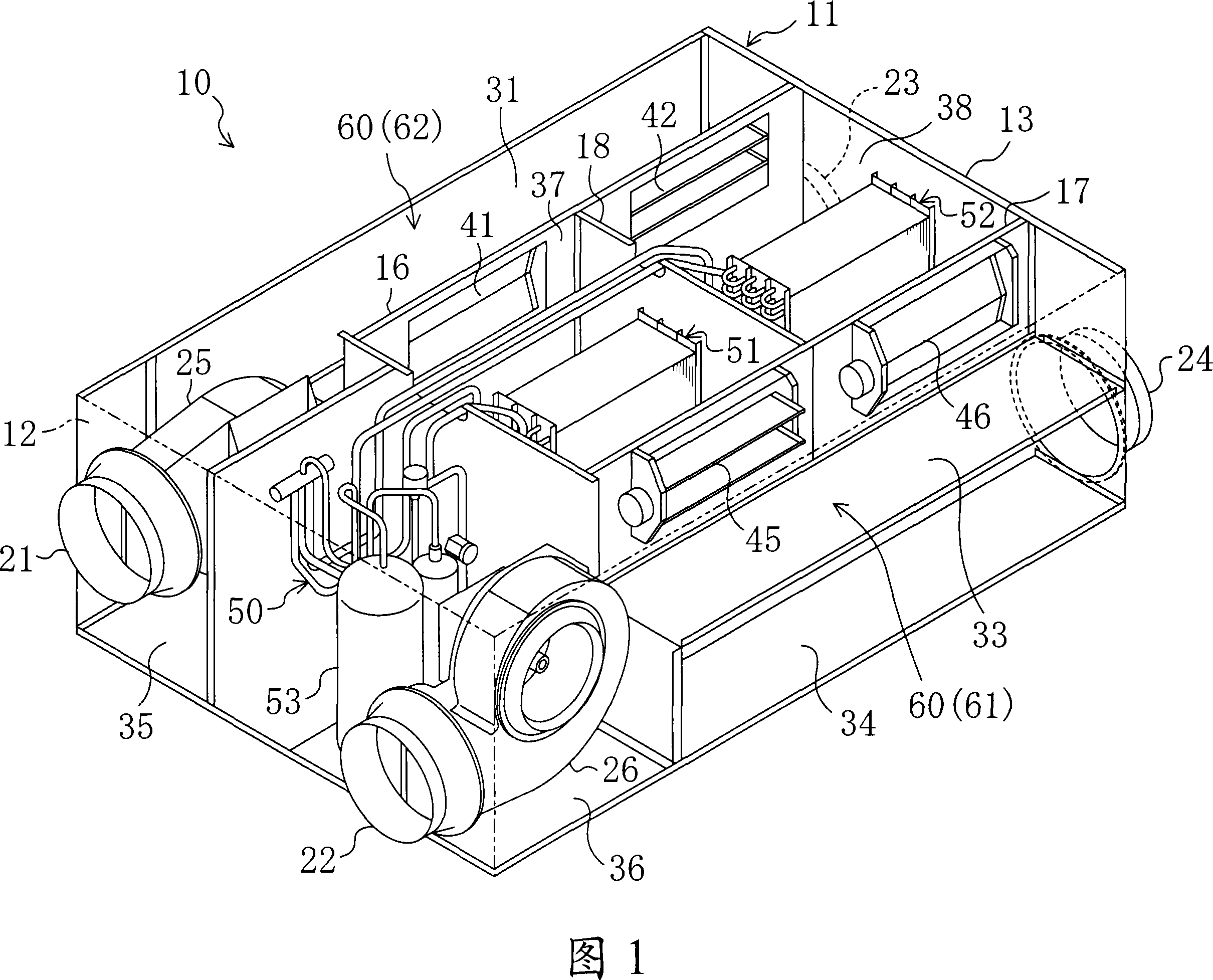

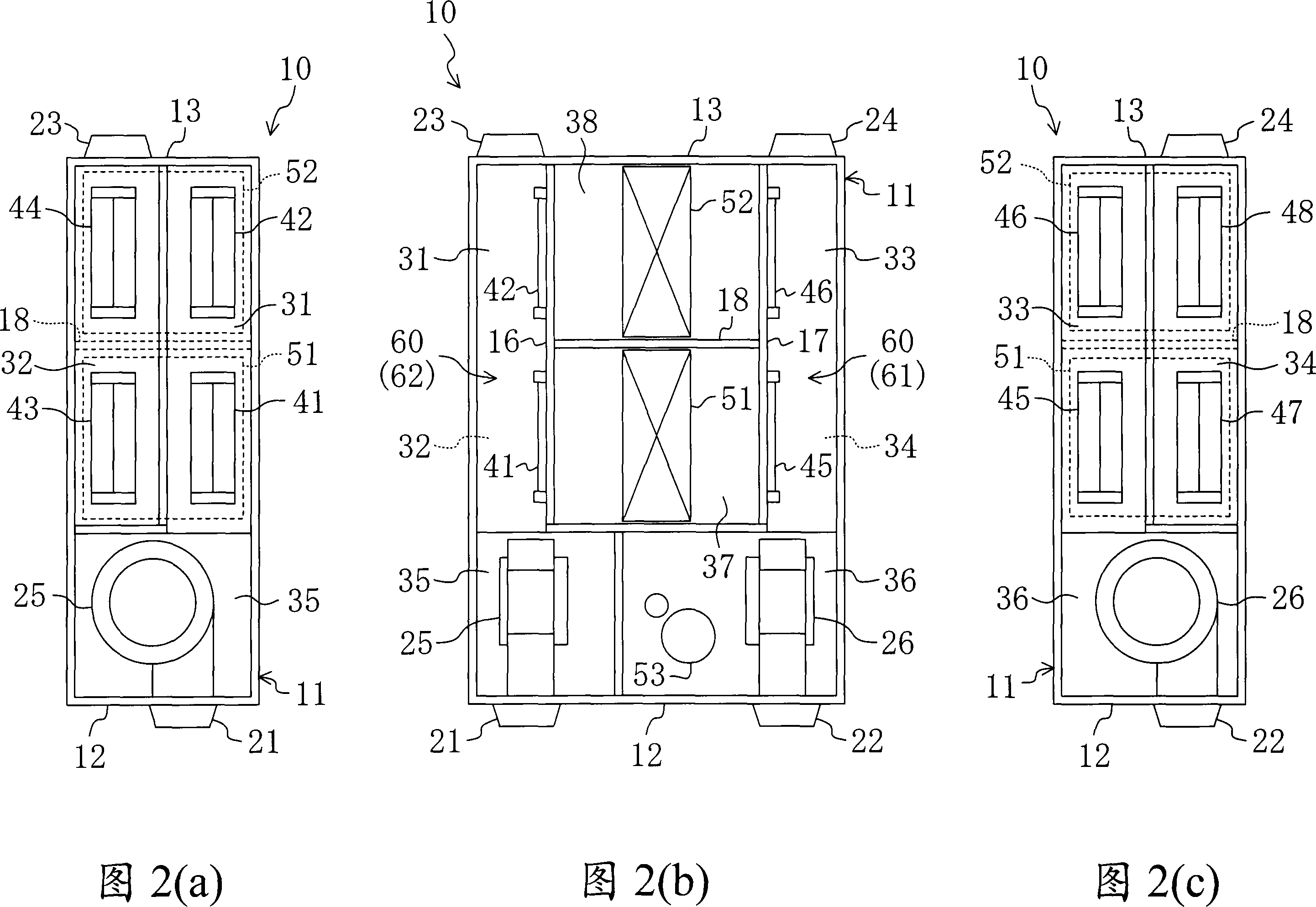

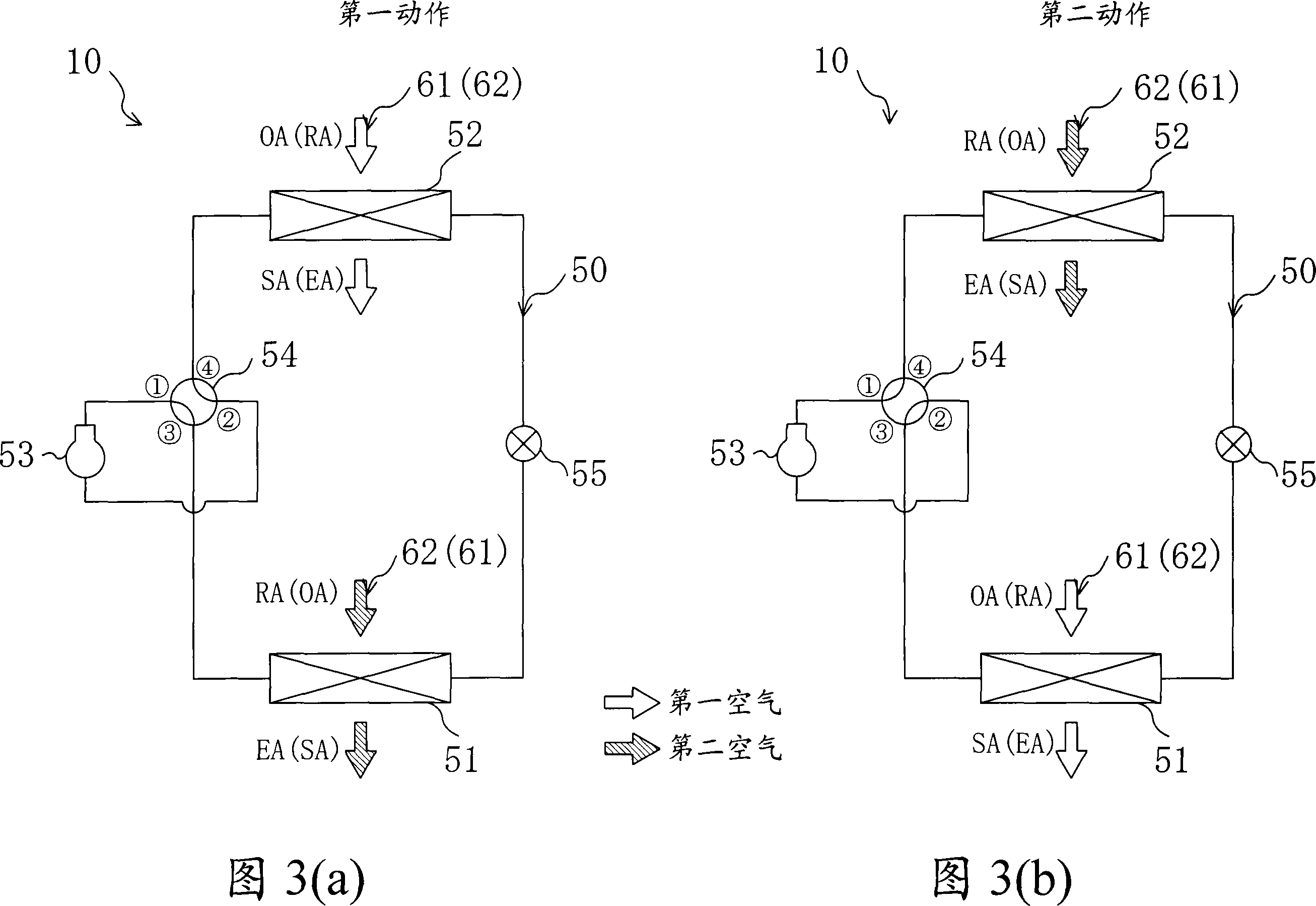

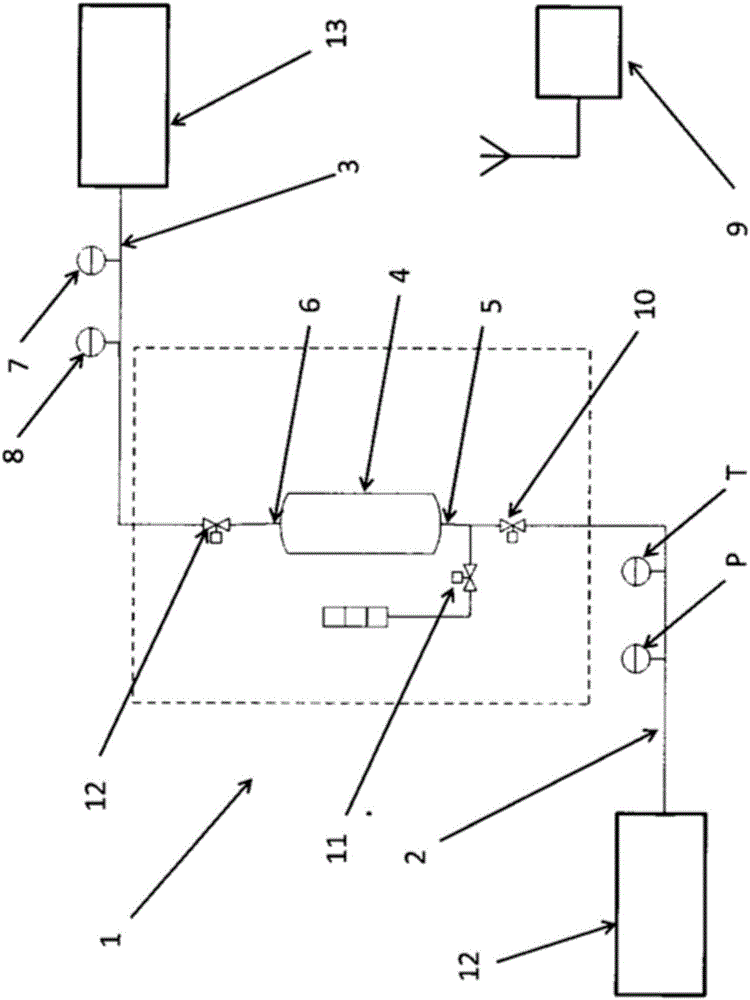

Air conditioning system

ActiveCN101184957ARunning properlyPrevent rustMechanical apparatusSpace heating and ventilation safety systemsOperation modeEngineering

Heat exchangers of a refrigerant circuit 50 are constructed of a first adsorption heat exchanger 51 and a second adsorption heat exchanger 52, both of which have an adsorbent supported thereon, and are constructed so as to be switched into an evaporator and a condenser. An air passage 60 is constructed so as to be switched into states in which air flowing from the outside of a room to the inside of the room and air flowing from the inside of the room to the outside of the room flow through either of the first adsorption heat exchanger 51 and the second adsorption heat exchanger 52. A dehumidifying operation mode and a humidifying operation mode can be performed by switching the flow of refrigerant and the flow of air at specified intervals, a cooling operation mode and a heating operation mode can be performed without switching the flow of refrigerant and the flow of air, and an ventilating operation mode can be performed by flowing air through the air passage 60 in a state where the refrigerant circuit 50 is stopped.

Owner:DAIKIN IND LTD

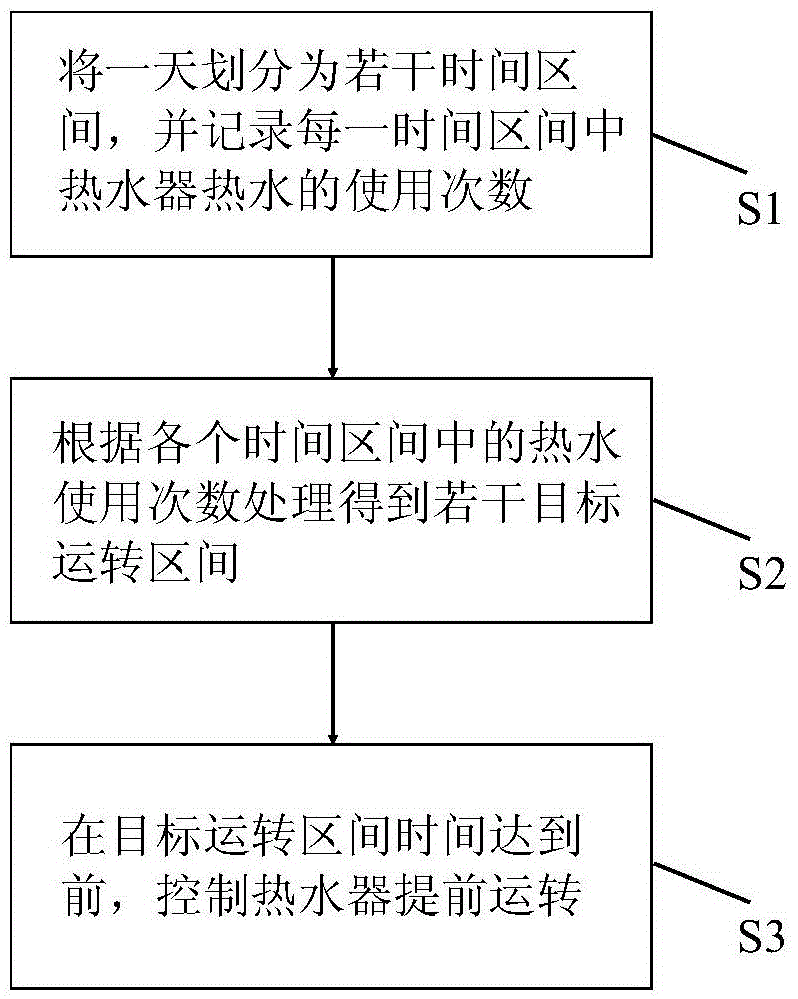

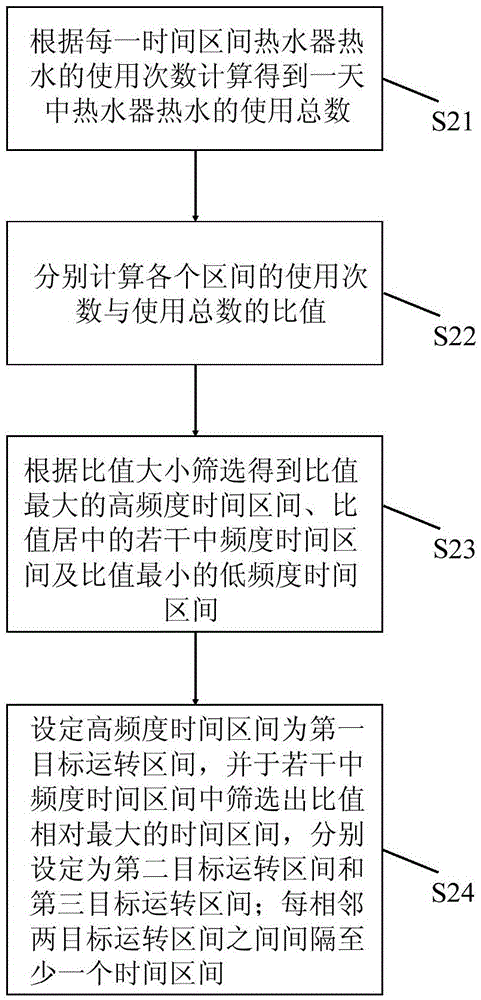

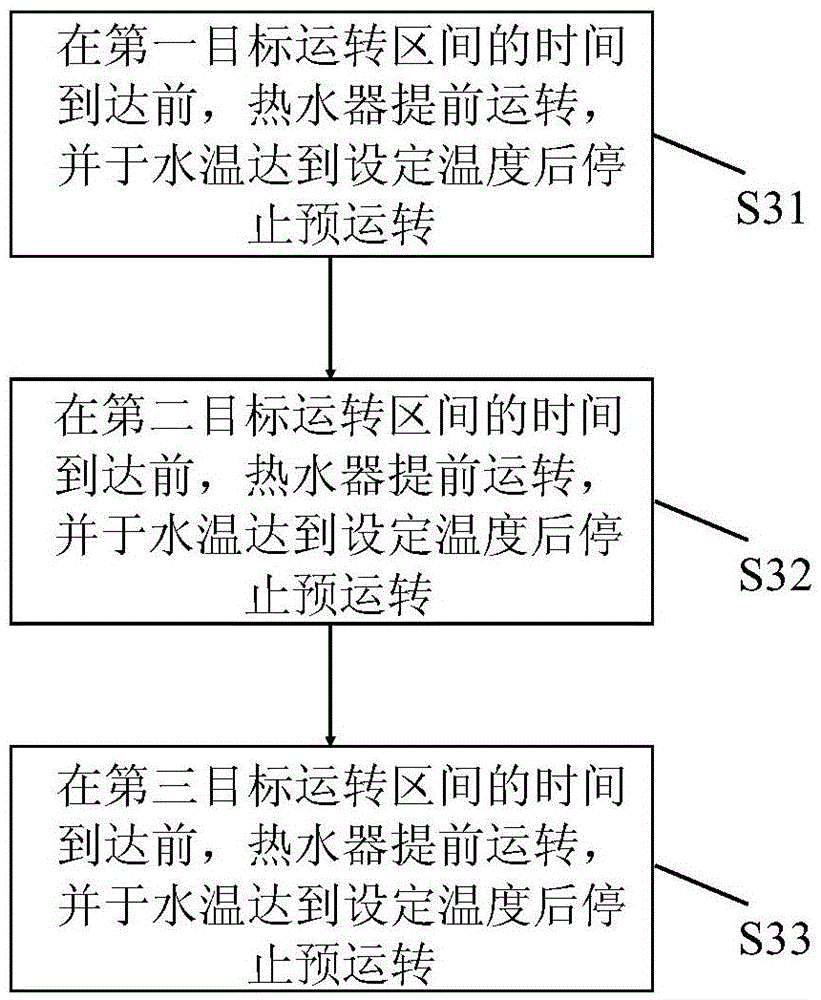

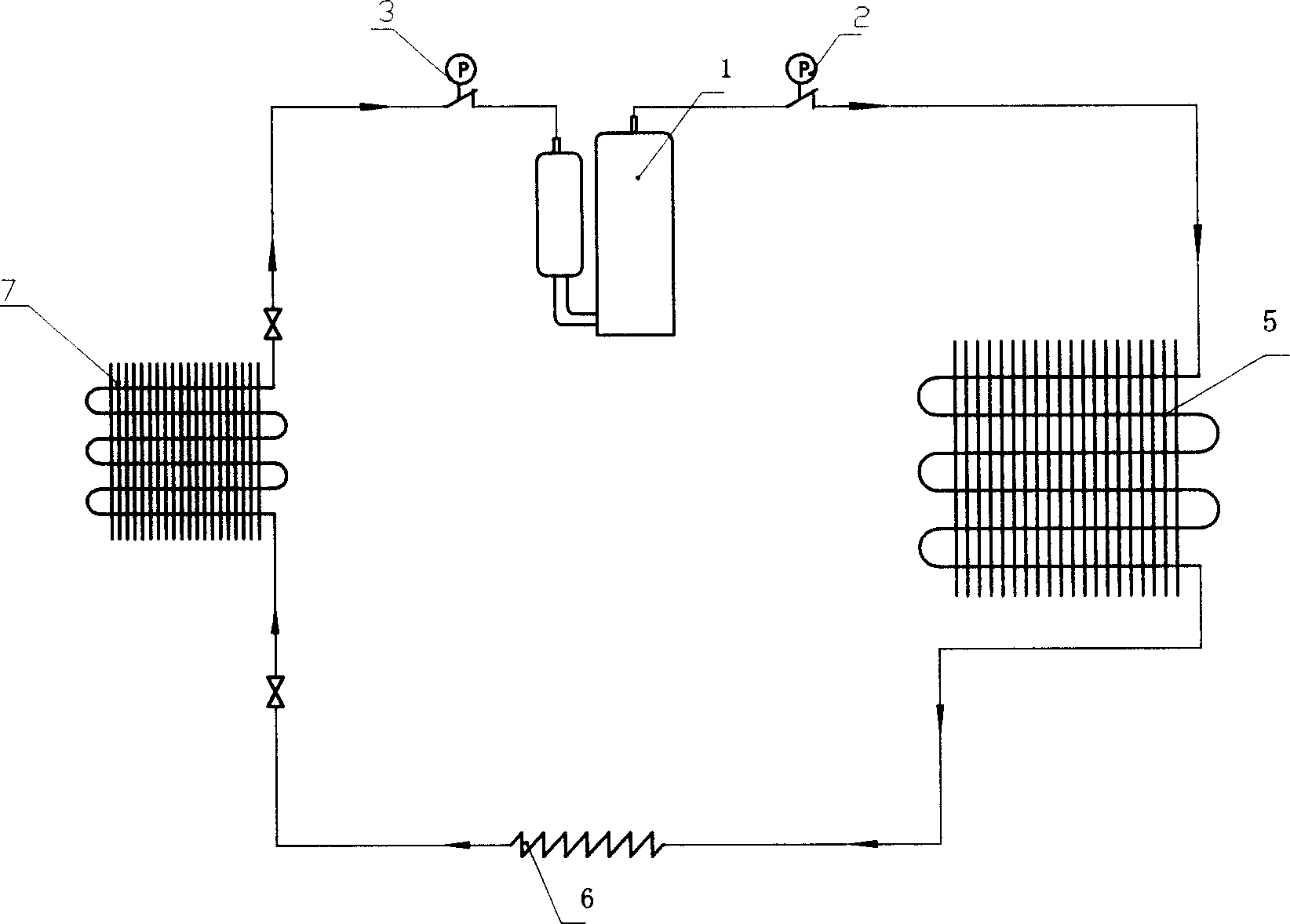

Control method for pre-operation of water heater

ActiveCN105605791AImprove timelinessMeet the needs of large amounts of waterFluid heatersWater useEngineering

The invention relates to a control method for pre-operation of a water heater. The method comprises the following steps that one day is divided into a plurality of time intervals, and a hot water use frequency of the water heater in each time interval is recorded; a plurality of target operation intervals are obtained according to the treatment of the hot water use frequency in each time interval; the water heater is controlled to operate in advance before the time of each target operation interval reaches. Compared with the prior art, the control method disclosed by the invention has the advantages that the water heater is subjected to pre-operation control according to a hot water use habit of a user, so that the operation of manually starting the water heater by the user in a timing manner is unnecessary, and the heating timeliness of the water heater is improved, therefore the water heater is more intellectualized and humanized, the demand for a large amount of water of the user is also met at the same time, and the use experience of the user is improved.

Owner:PANASONIC HOME APPLIANCES AIR CONDITIONING GUANGZHOU CO LTD

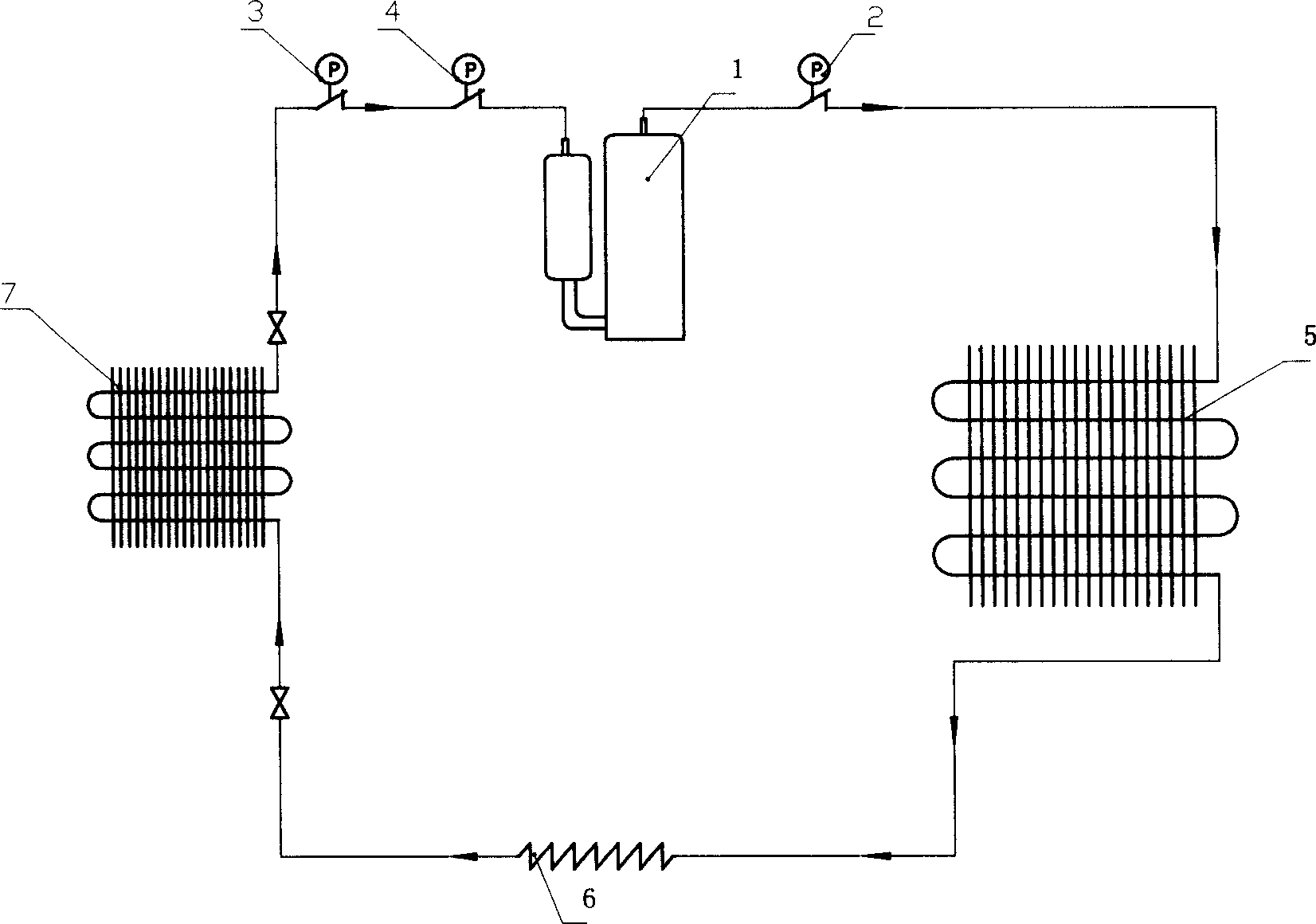

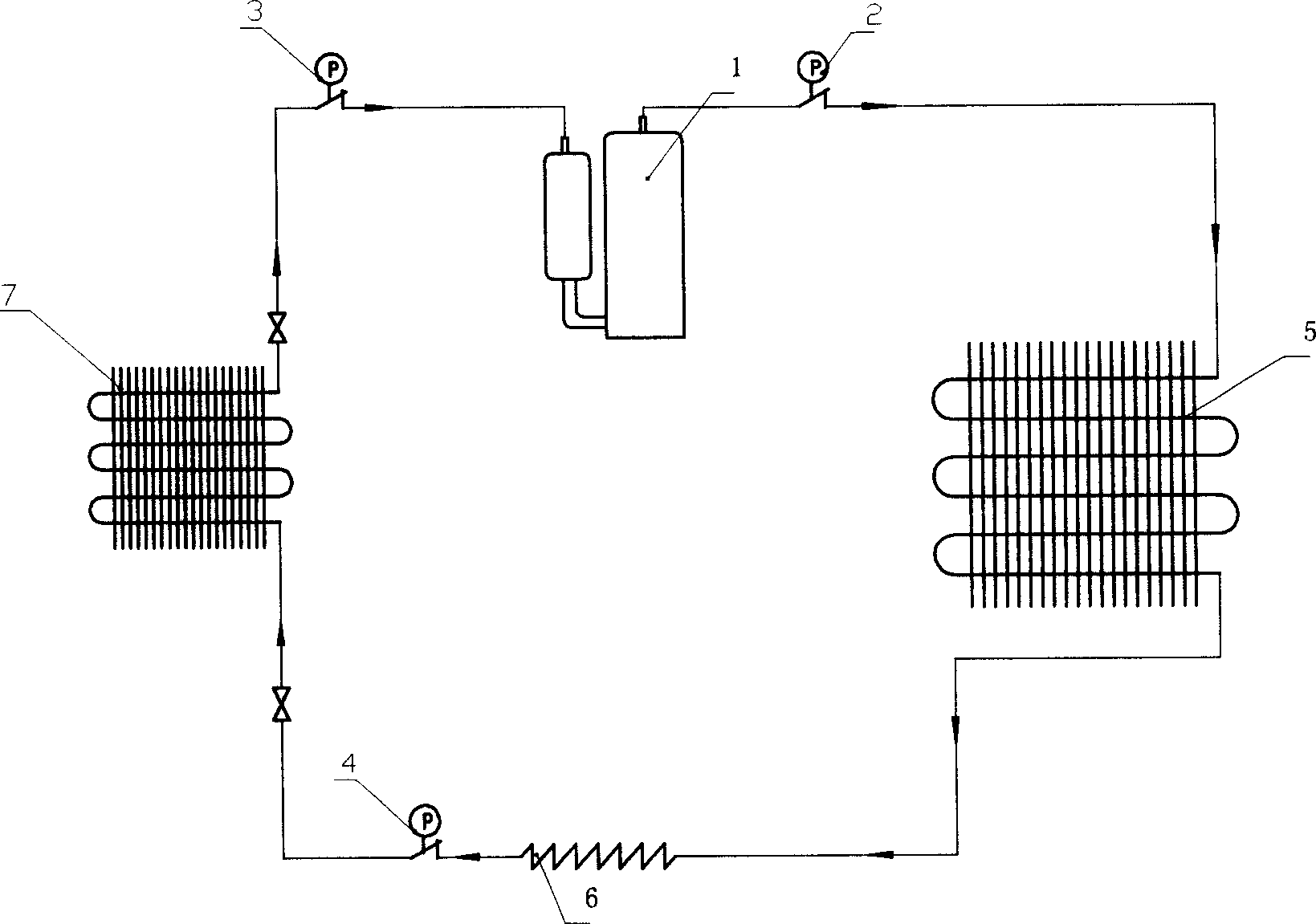

Safety prealarming device of refrigerating system

InactiveCN1710359AAvoid normal operationExtended use timeRefrigeration safety arrangementElectricityControl system

A safety pre-alarm device on refrigerating system consists of pre-alarm low pressure valve and control circuit for transmitting electric signal, the input end of control circuit is electrically - connected to pre-alarm low pressure valve. It can remind or request the operator to stop air conditioner and to carry out relative detection when refrigerant leakage is occurred on refrigerating loop to cause loop return air pressure drop to meet pre-alarm pressure value of pre-alarm low pressure valve.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

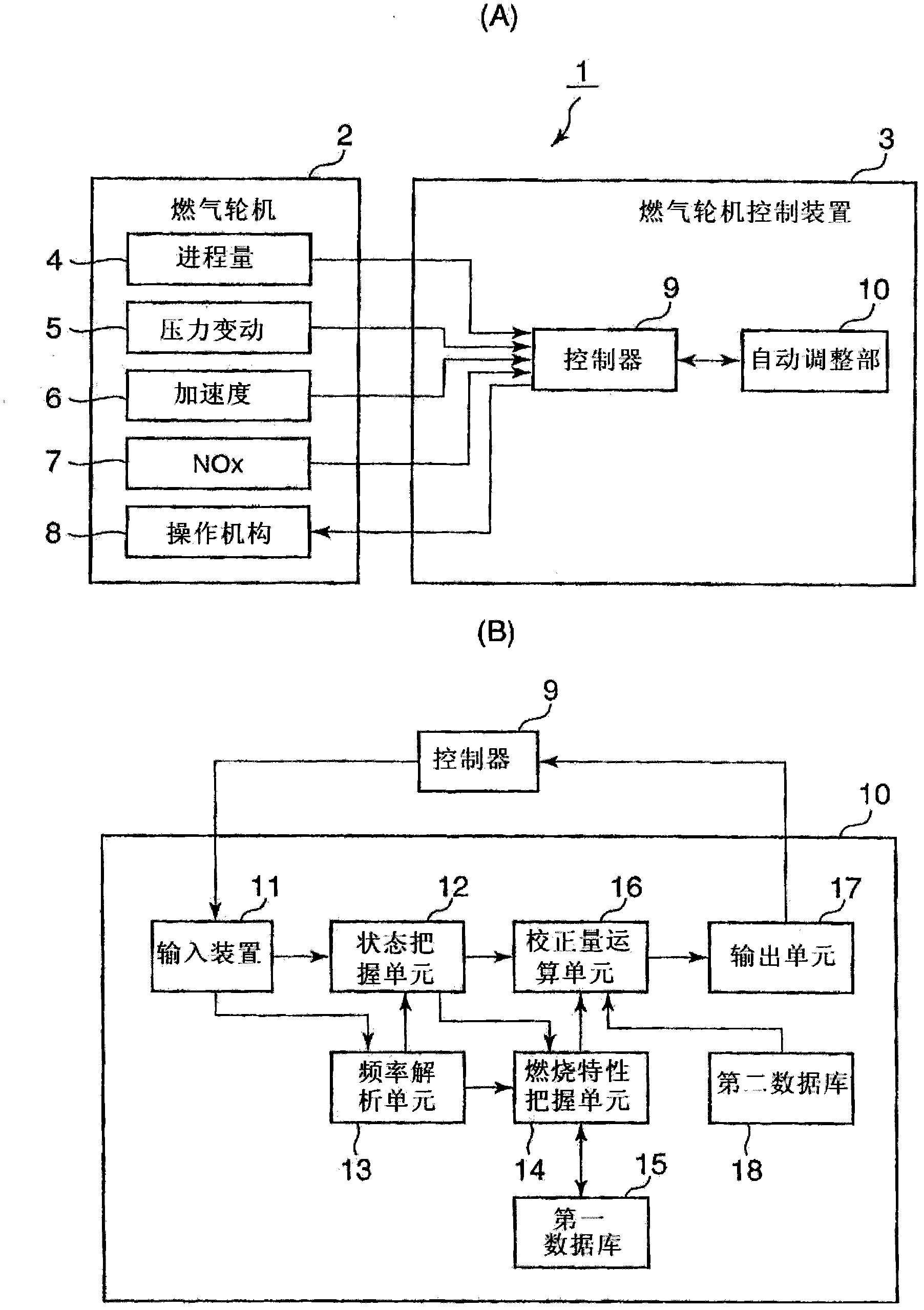

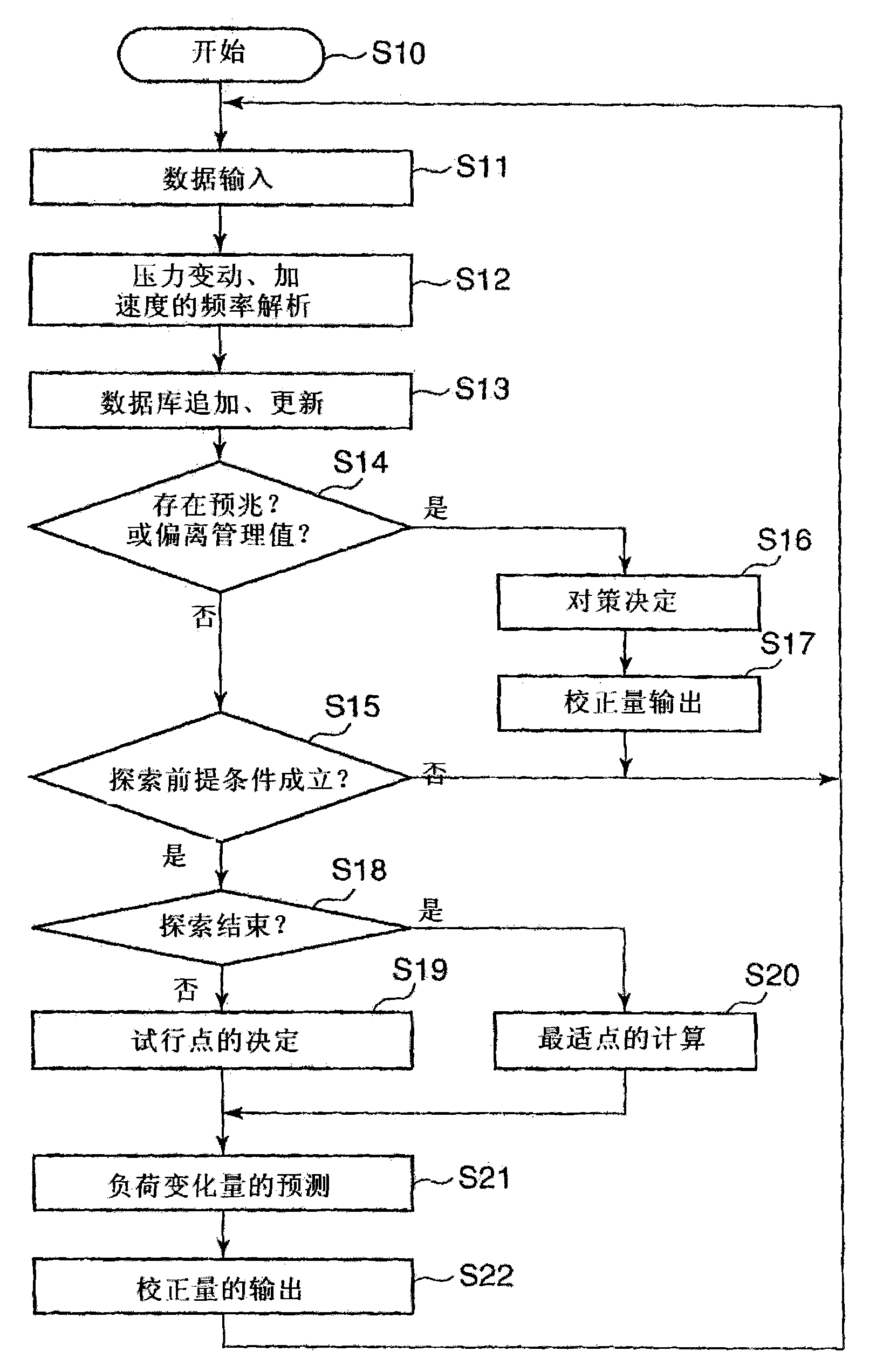

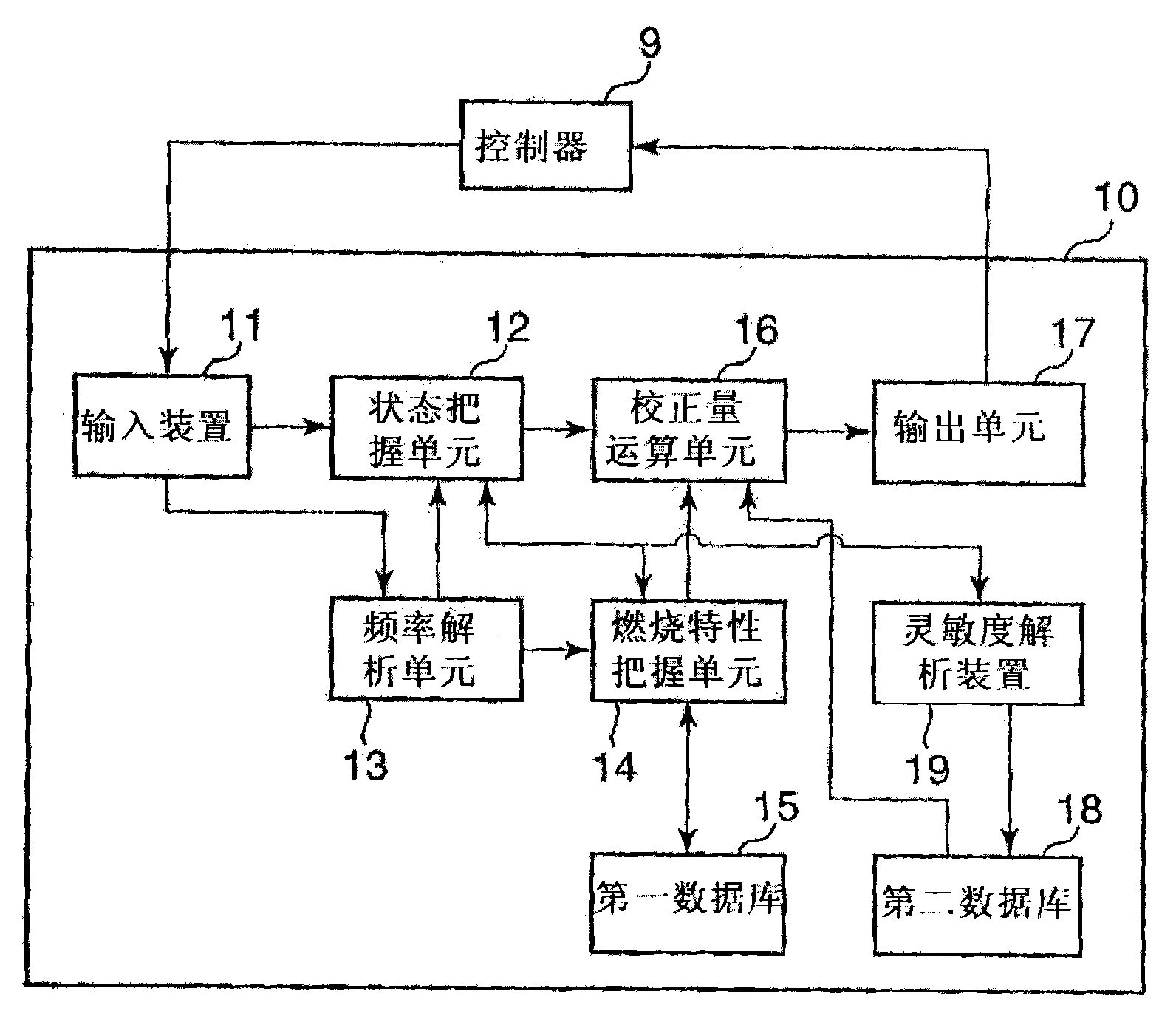

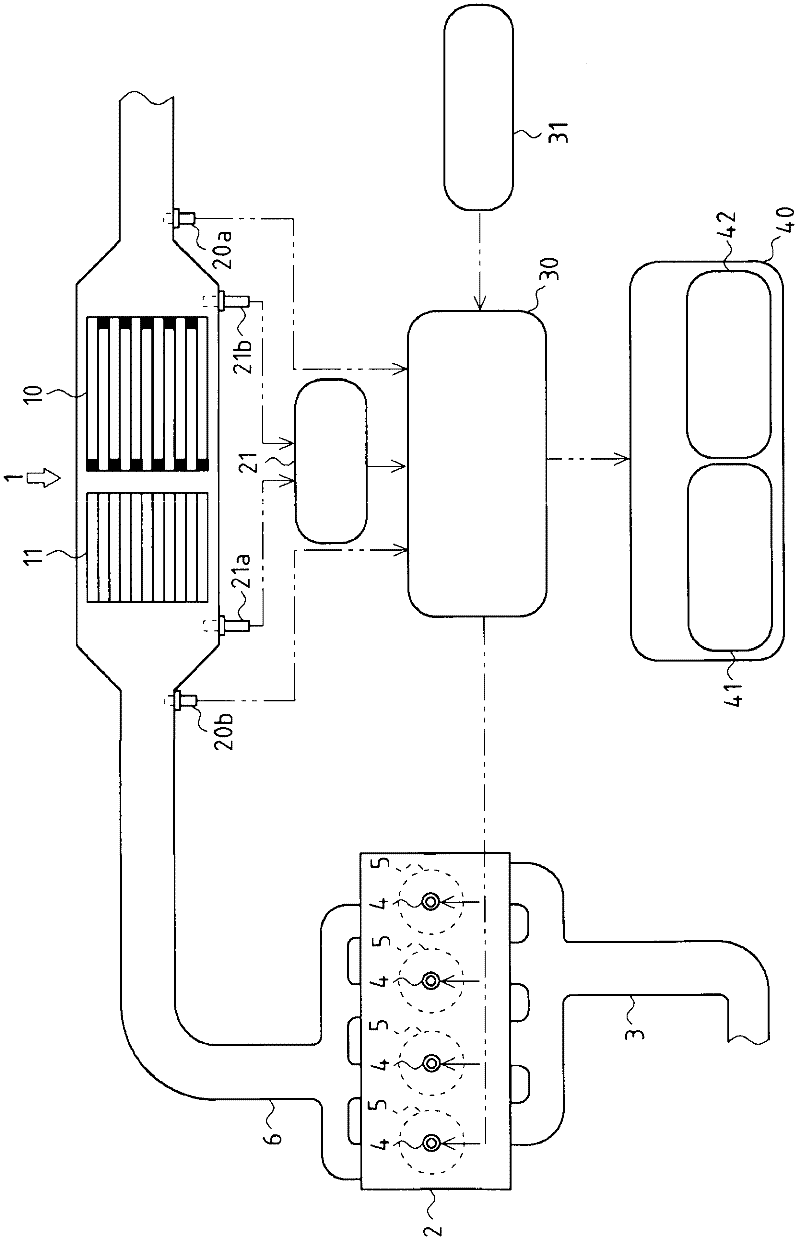

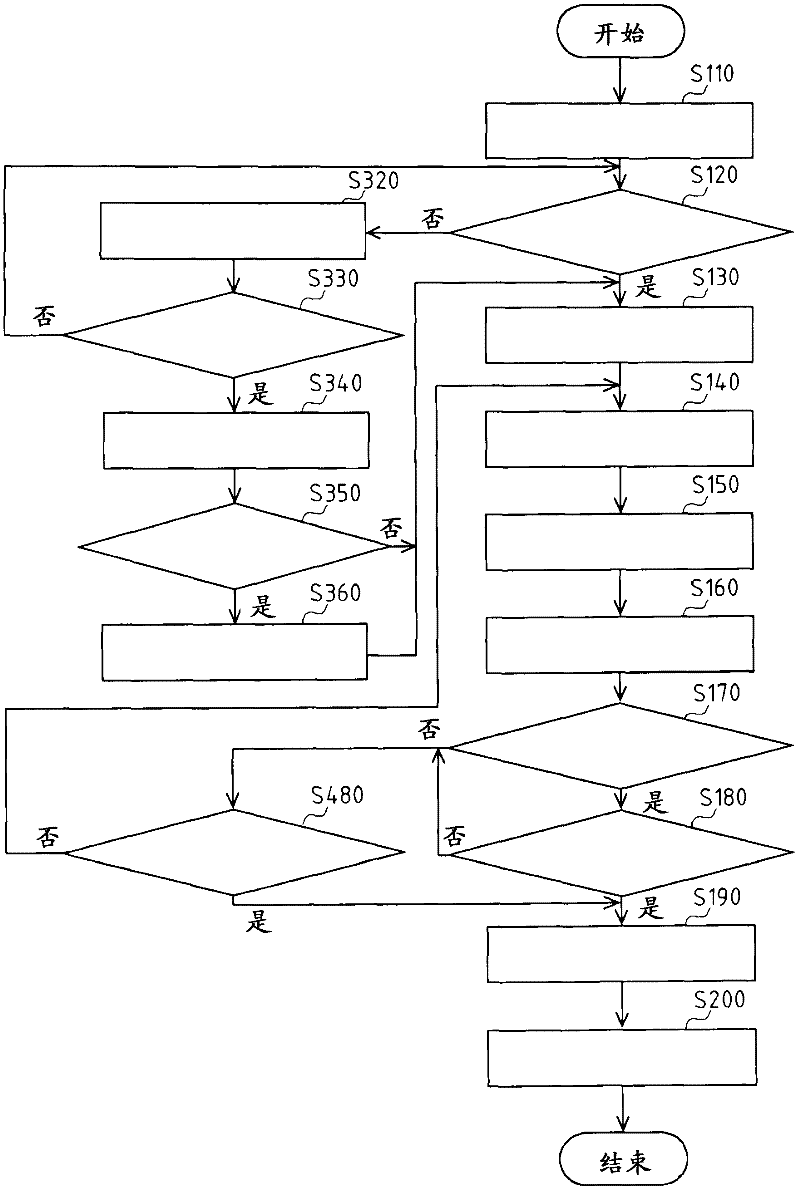

Gas turbine control method and controller

ActiveCN101981294AAvoid normal operationImprove combustion stabilityTurbine/propulsion fuel controlMachines/enginesTraffic capacityCombustor

Provided is gas turbine control method and controller whereby a design performance and an operating state based on ideal fuel flow rate and air flow rate assumed at the time of designing can be maintained by preventing an operation deviated from an operating state that is based on ideal fuel flow rate and air flow rate assumed by initial design values, in a gas turbine control method designed to search optimal operating conditions automatically using control inputs such as a pilot ratio. The gas turbine controller comprises a second database that stores load sensitivity, i.e. the correlation between the load amount of a gas turbine and control inputs such as a fuel flow rate, air flow rate, pilot fuel ratio, and top hat fuel ratio in the gas turbine, wherein the amount of load variation for at least one of control inputs, a fuel flow rate or an air flow rate supplied to a combustor is predicted according to operational conditions obtained by searching using the load sensitivity, regulation is made according to the prediction results, and the regulation results are stored in the second database.

Owner:MITSUBISHI POWER LTD

Exhaust purification device for internal combustion engine

InactiveCN102356219AAvoid normal operationElectrical controlInternal combustion piston enginesParticulatesReference Period

Owner:YANMAR POWER TECHNOLOGY CO LTD

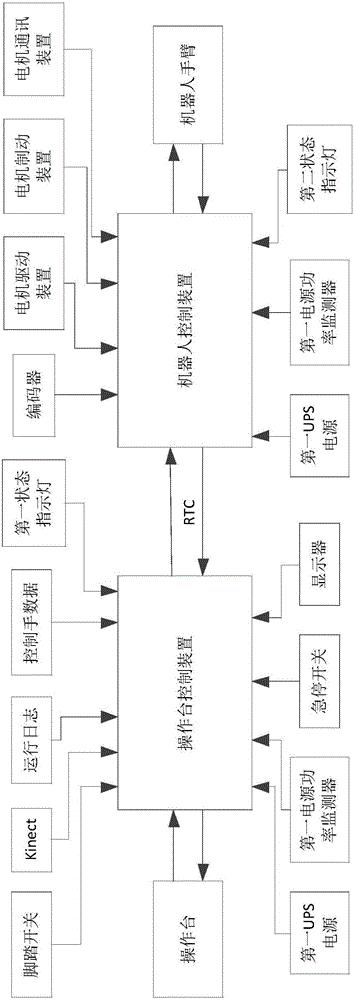

Minimally invasive surgery robot and control device thereof

InactiveCN105943163AEnsure safetyImprove securityDiagnosticsSurgical robotsRobot controlInvasive surgery

The invention discloses a minimally invasive surgery robot and a control device thereof. The control device comprises a console control device and a robot control device, and the console control device and the robot control device are connected, a monitoring device and a display are arranged on the console control device, and the robot control device is provided with an encoder. The console control device and the robot control device control states of a console and arms of the robot respectively, and by connection of the console control device and the robot control device, information establishment and feedback can be realized to enable operators to operate the arms of the robot to perform an operation. By the monitoring device, the display and the encoder, operating parameters of the arms of the robot and the console can be monitored in an operation process, and monitoring information is shown to the operators. Therefore, accuracy in operation of the arms of the robot is improved, and safety in operation is guaranteed.

Owner:CHONGQING JINSHAN SCI & TECH GRP +1

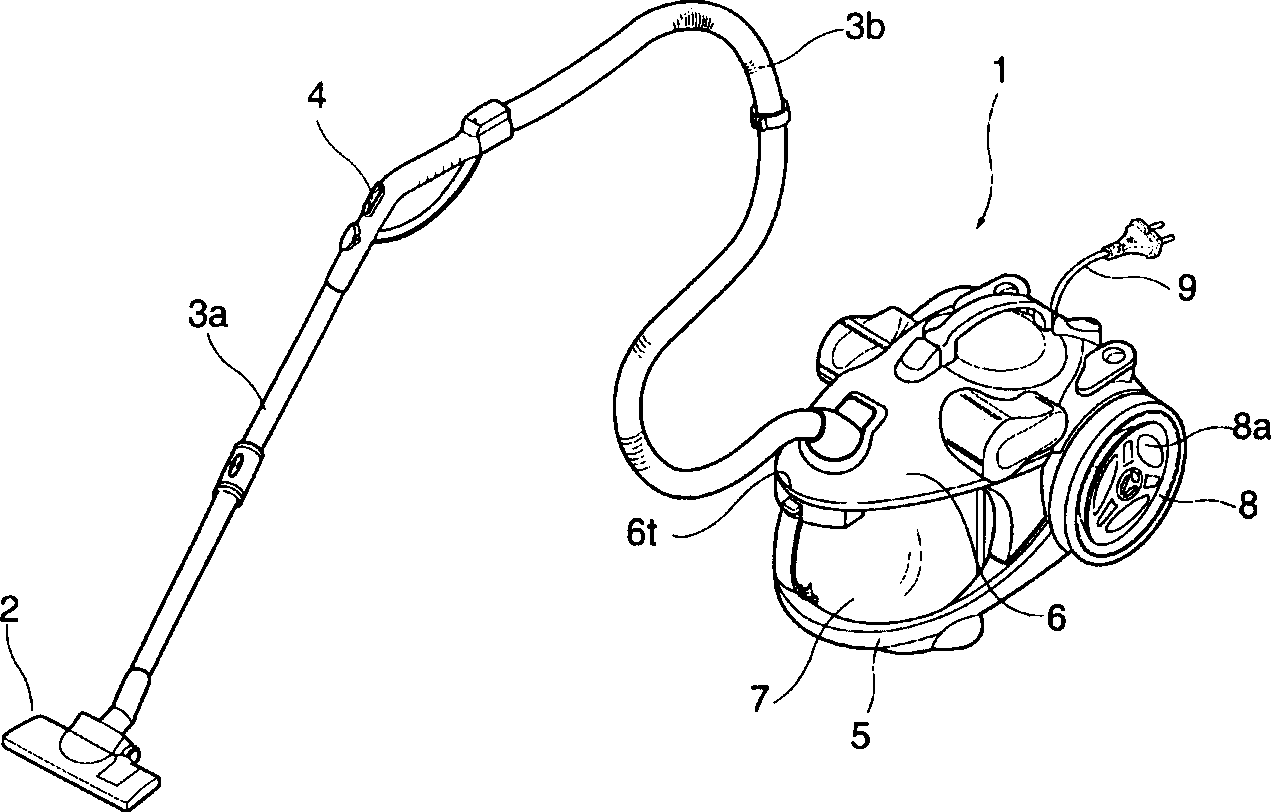

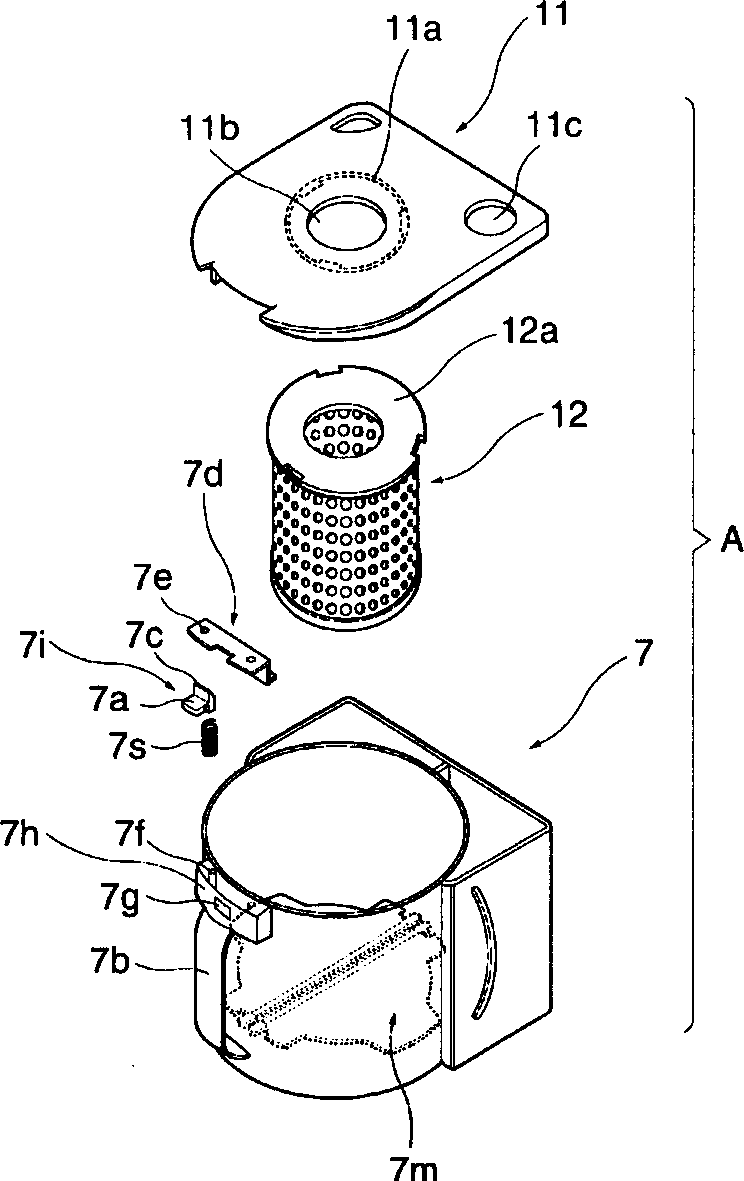

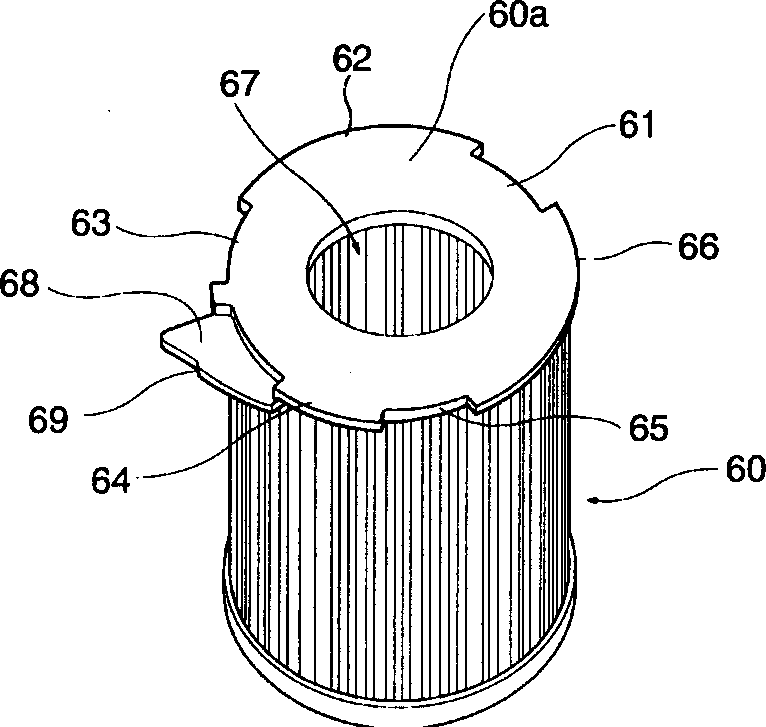

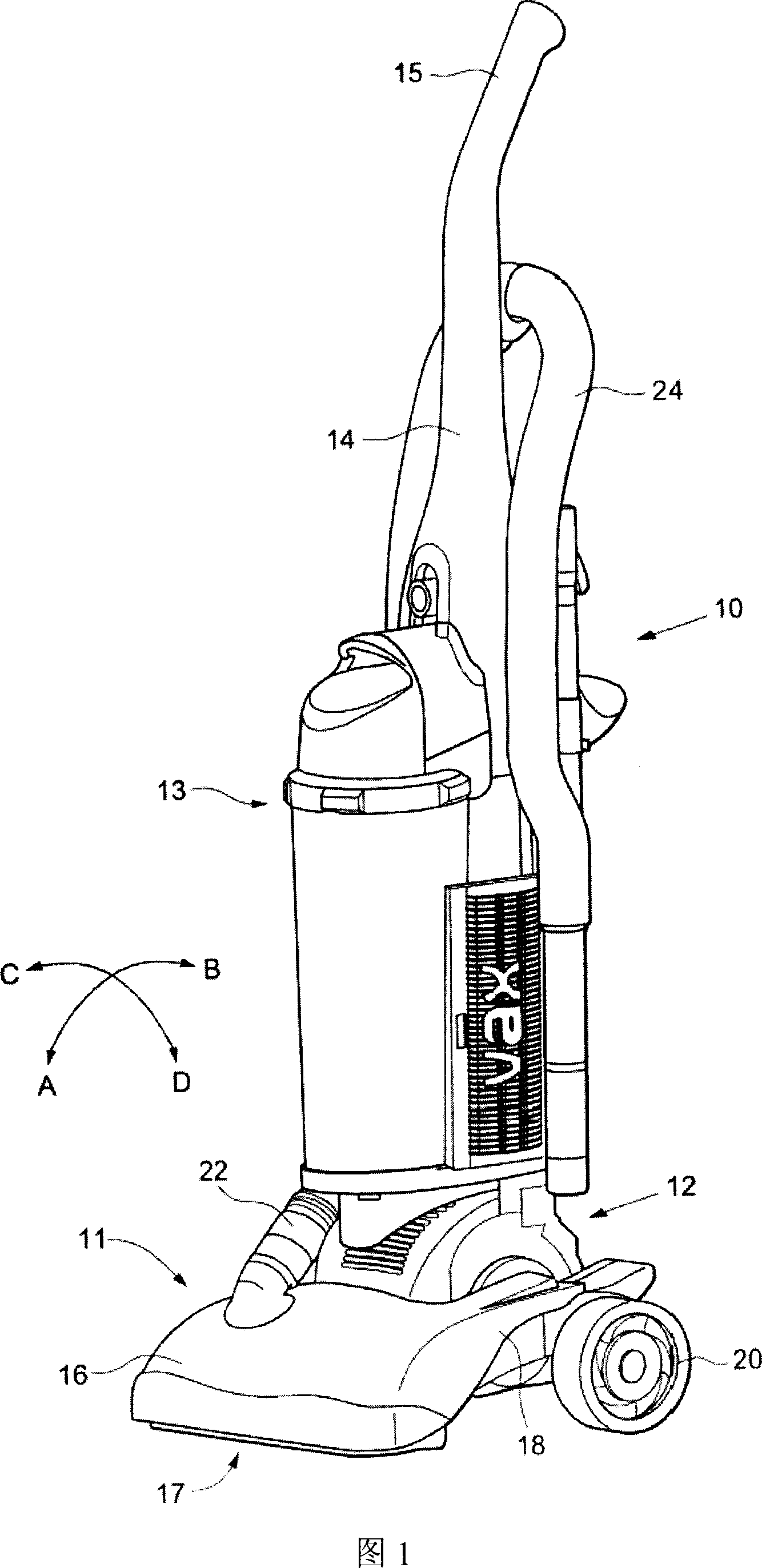

Filter installation device for vacuum cleaner

The present invention relates to a structure for confirming as to whether a filter is mounted into a vacuum cleaner. The structure for a vacuum cleaner according to the present invention comprises a cover (40) including a discharging port (44) for discharging air from which foreign materials are removed, a movable member (50) of which positions are changed depending on coupling states thereof, and a support portion (45) for moving the movable member (50); and a filter (60) including a coupling means (60a) having a plurality of protrusions (62,64,66) coupled to the support portion (45) of the cover (40), a plurality of indented portions (61,63,65) formed between the plurality of the protrusions (62,64,66), and an engagement piece (68) formed to be spaced apart from the protrusions (62,64,66) for changing the position of the movable member (50). The filter (60) is detachably mounted to the support portion (45). According to the present invention, unless the filter (60) having a function of removing fine dusts from the air is coupled to the cover (40), the movable member (50) hinders a dust collecting casing (20) from being perfectly covered with the cover (40). That is, since the cover (40) of the dust collecting casing (20) is positioned higher, by a height of the movable member (50), than a space formed in a main body of the cleaner for allowing the dust collecting casing (20) to be received therein, the dust collecting casing (20) cannot be received within the main body of the cleaner.

Owner:LG ELECTRONICS INC

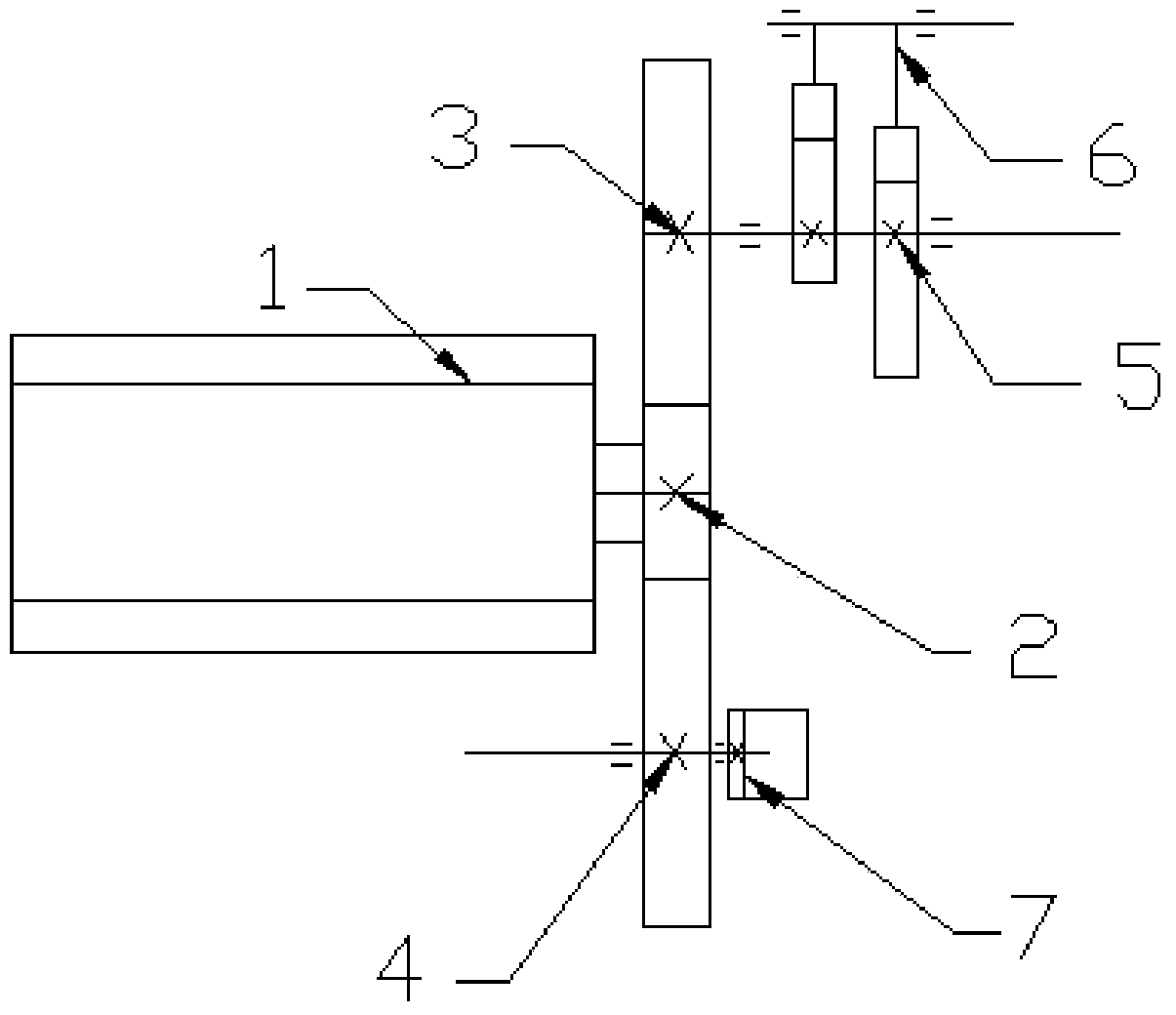

Power device for air jet loom

InactiveCN103966731AHigh transmission efficiencySimple structureLoomsElectric machineryAerospace engineering

The invention discloses a power device for an air jet loom. The power device for the air jet loom comprises a servo motor, wherein a primary driving gear is arranged on the output shaft of the servo motor and is in mesh transmission with a beating-up transmission gear and an open transmission gear simultaneously, the open transmission gear is arranged on an open transmission gear shaft, a power-off brake is arranged on the open transmission gear shaft, the beating-up transmission gear is arranged on a transmission shaft, and a beating-up conjugate cam is arranged on the transmission shaft. By means of the gear transmission structure formed by the primary driving gear, the beating-up transmission gear and the open transmission gear, transmission efficiency is increased, the structure is simplified, and regulation and maintenance are convenient.

Owner:HANGZHOU CHUANGXING WEAVING EQUIP TECH

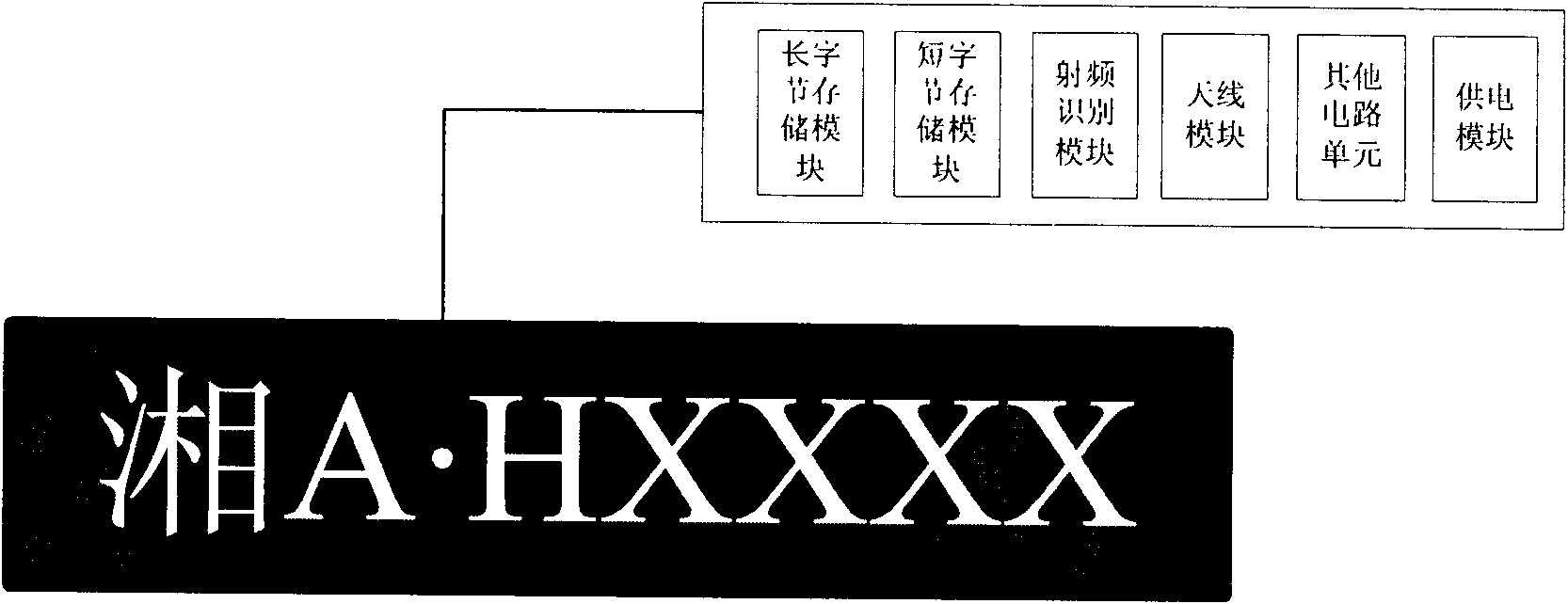

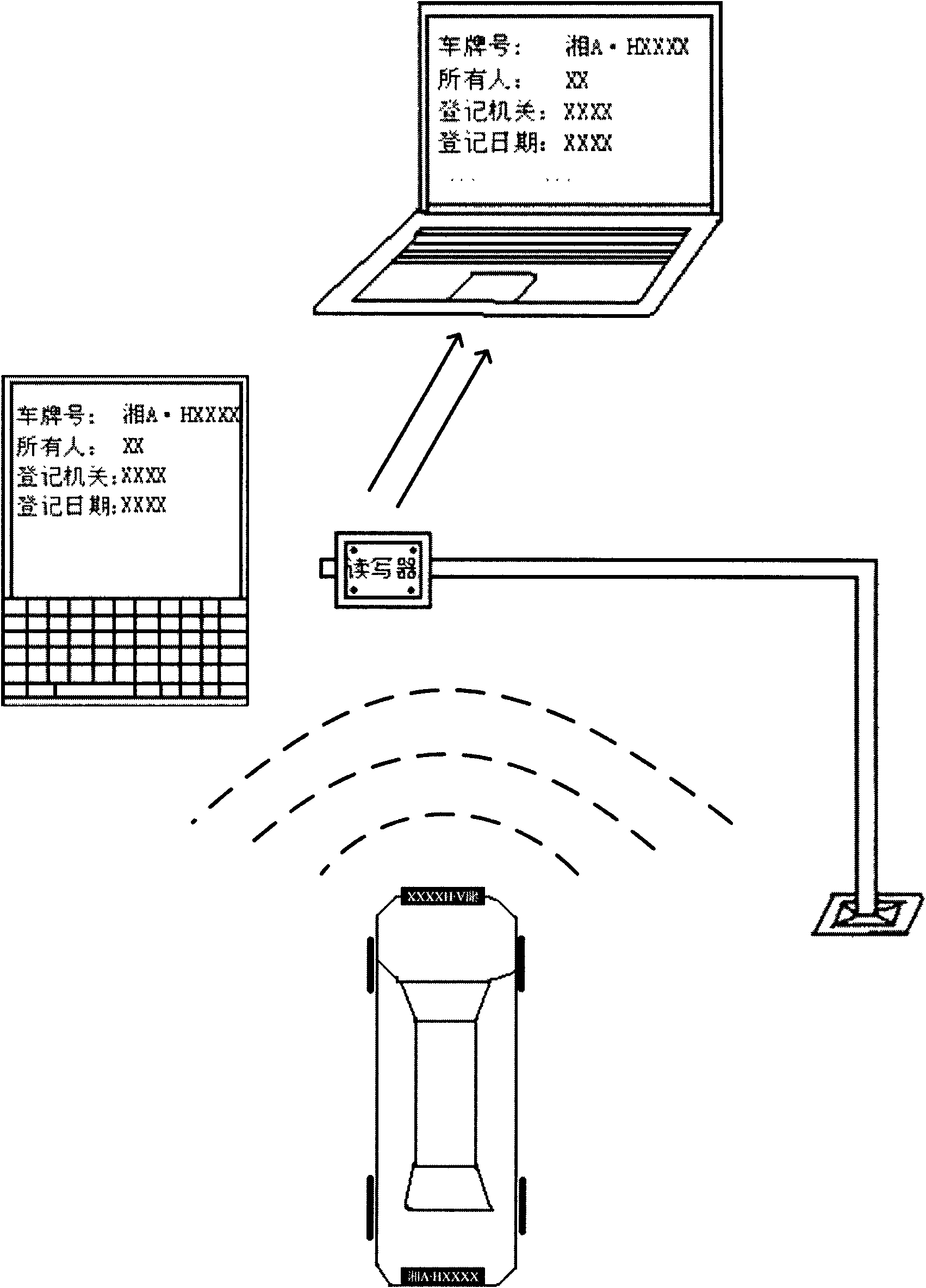

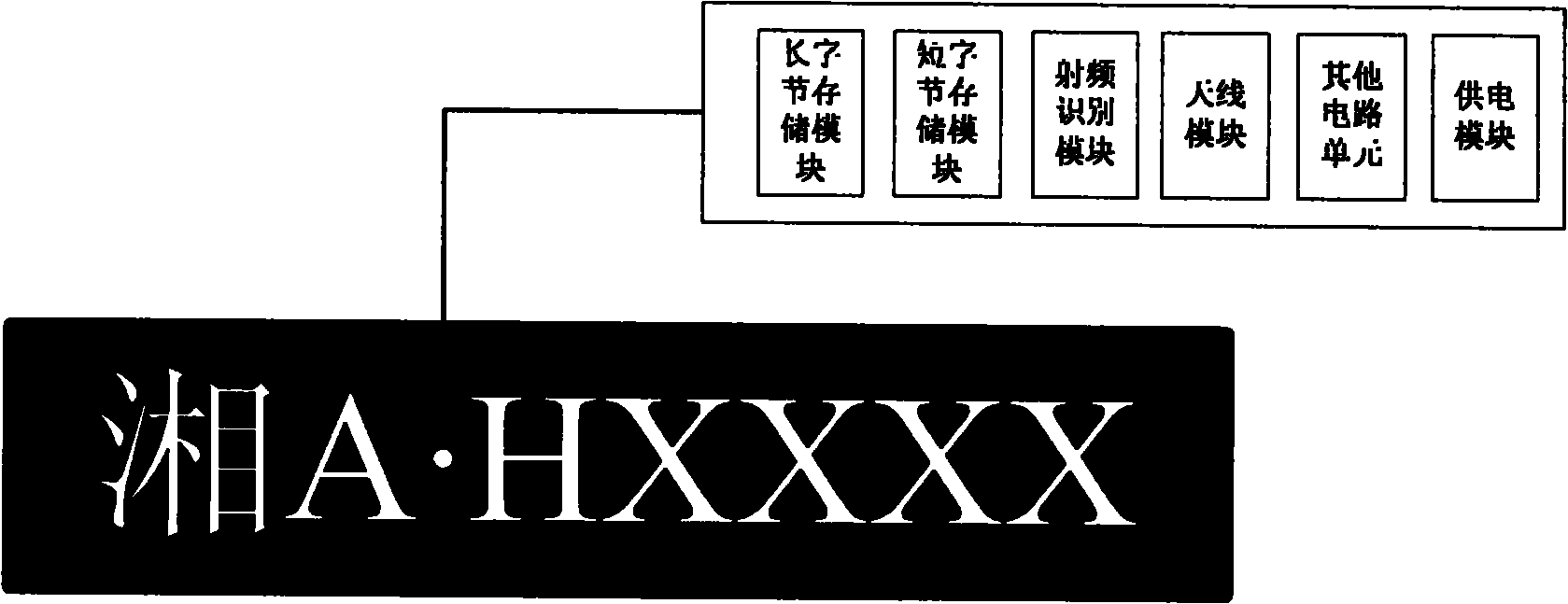

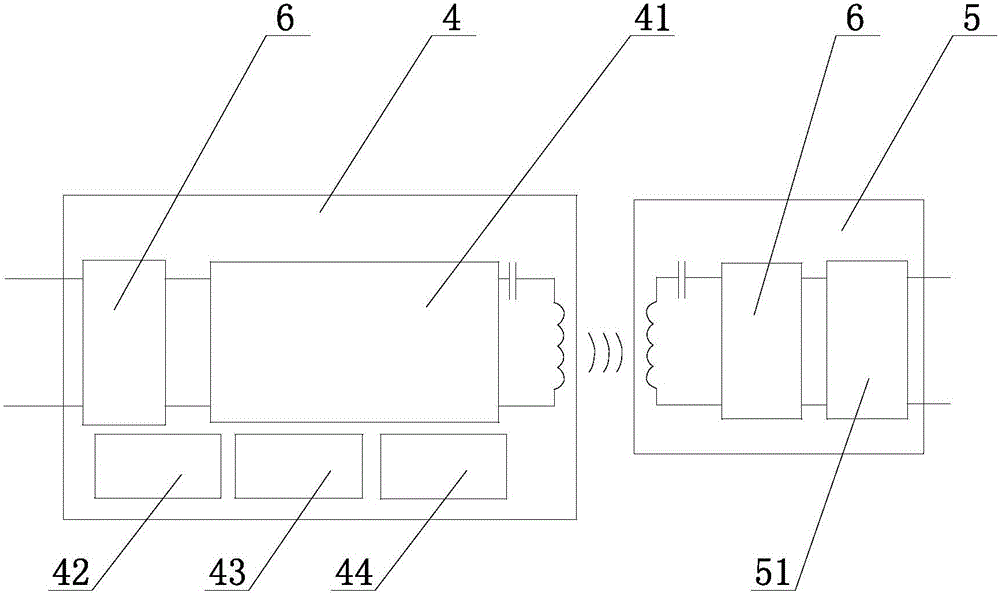

Intelligent electronic number plate with double storage modules

InactiveCN101976371AImprove securityImprove real-time performanceRecord carriers used with machinesEngineeringShock resistance

The invention provides an intelligent electronic number plate with double storage modules, which comprises a physical printed number plate and a built-in electronic chip. The invention is characterized in that the electronic chips containing double storage modules is arranged in the physical number plate. The electronic number plate designed in such a way has the advantages of complete airtightness, strong environment resistance, uniqueness, constant unique position performance and the like, and can prevent illegal demounting. The built-in electronic chip comprises a radio-frequency identification module, an antenna module, other circuit units, a power supply module, a short byte storage module and a long byte storage module. The radio-frequency identification module in the built-in electronic chip works in an active mode when in use. The main components (assemblies) related to the radio-frequency identification module comprise a radio-frequency identification tag, a reader-writer, an antenna and a management application system. The intelligent electronic number plate can authenticate the unique identity of the vehicle without any additional influence on the appearance of the vehicle, has dual data protection functions and a certain shock resistance, and has the characteristics of strong anti-theft performance and easy realization.

Owner:刘海涛

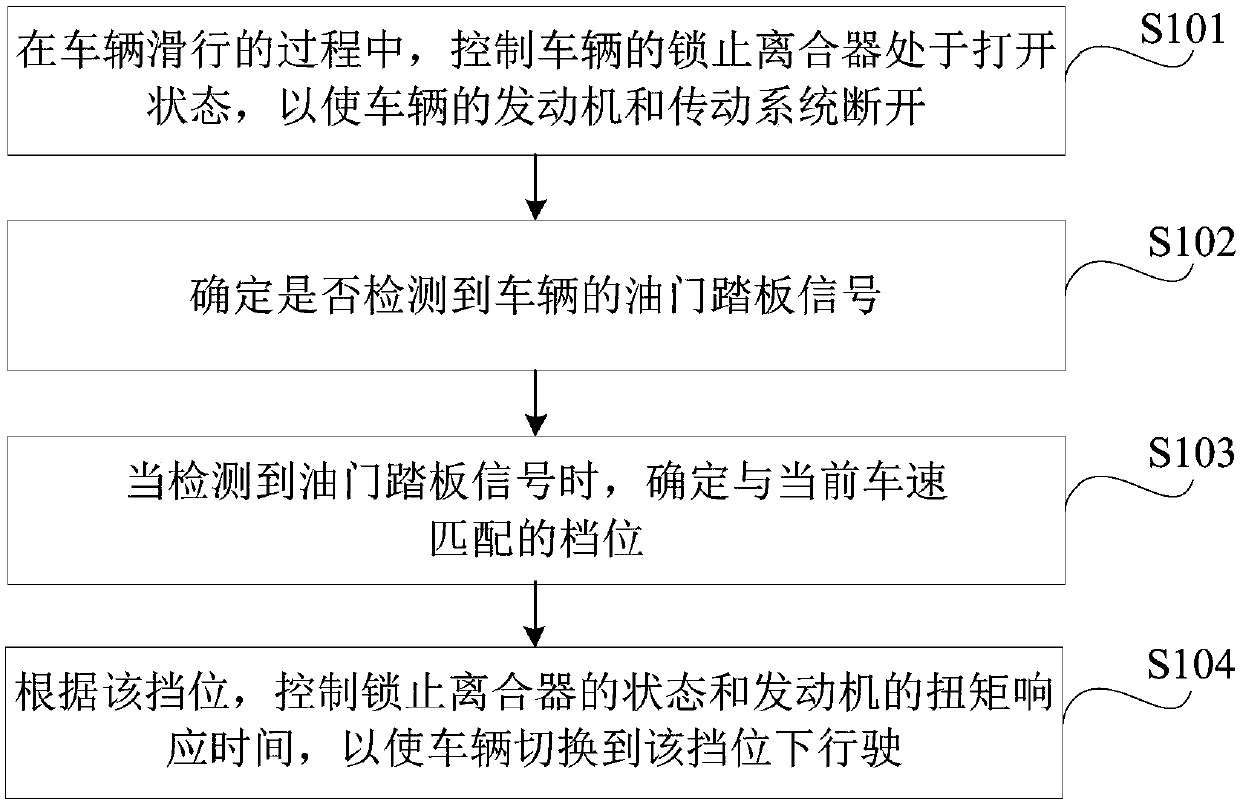

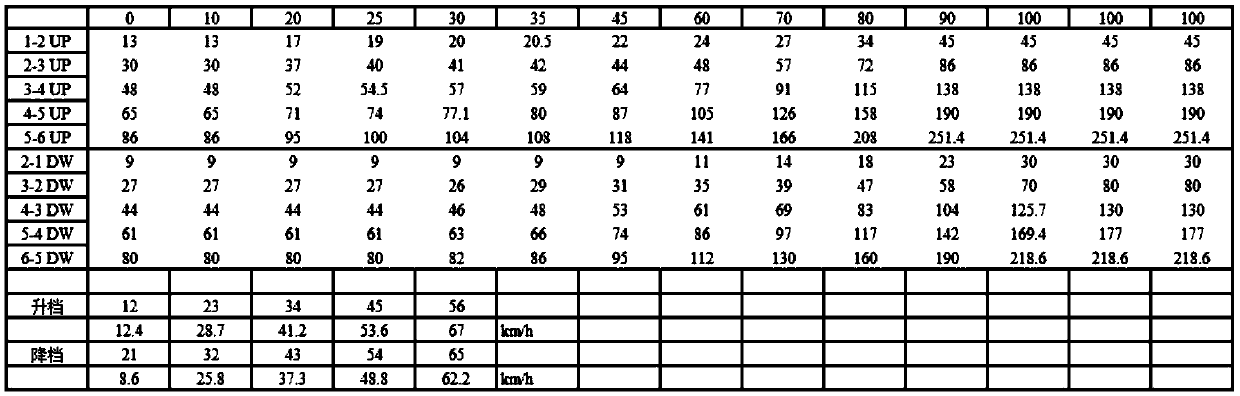

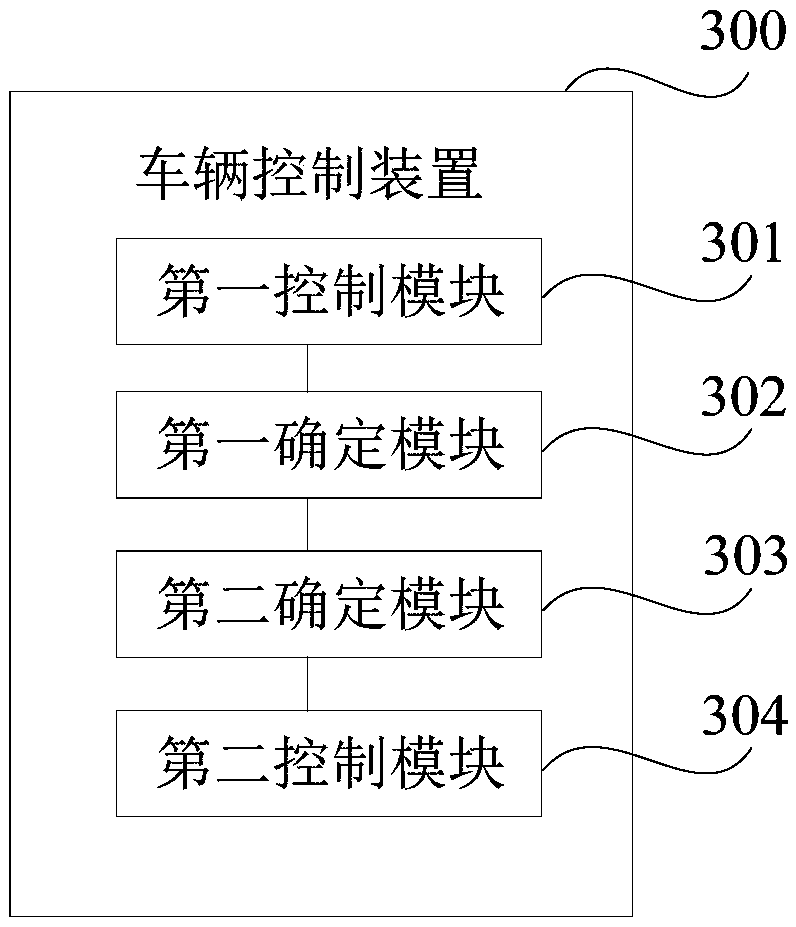

Vehicle control method, vehicle control device and vehicle

The invention relates to a vehicle control method, a vehicle control device and a vehicle, and aims to increase a coasting distance of the automatic transmission vehicle and reduce a sense of abruptness generated when a driver presses an accelerator to accelerate during deceleration and downshifting. The vehicle control method comprises the steps of controlling a lock-up clutch of the vehicle to be in an open state during coasting of the vehicle so as to disconnect an engine of the vehicle from a transmission system, judging whether an accelerator pedal signal of the vehicle is detected, determining a gear position which matches a current vehicle speed when the accelerator pedal signal is detected, and controlling a state of the lock-up clutch and a torque response time of the engine according to the gear position so as to enable the vehicle to shift to the gear position and travel in the gear position.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

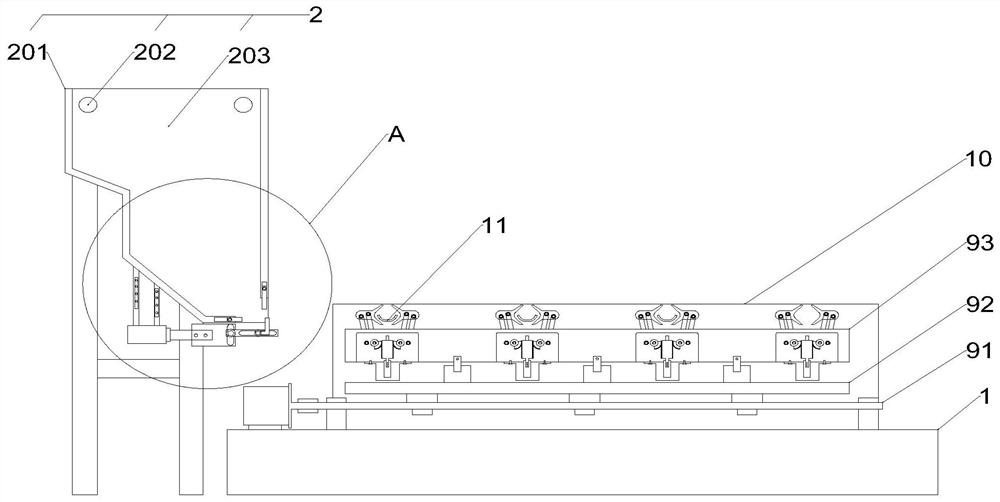

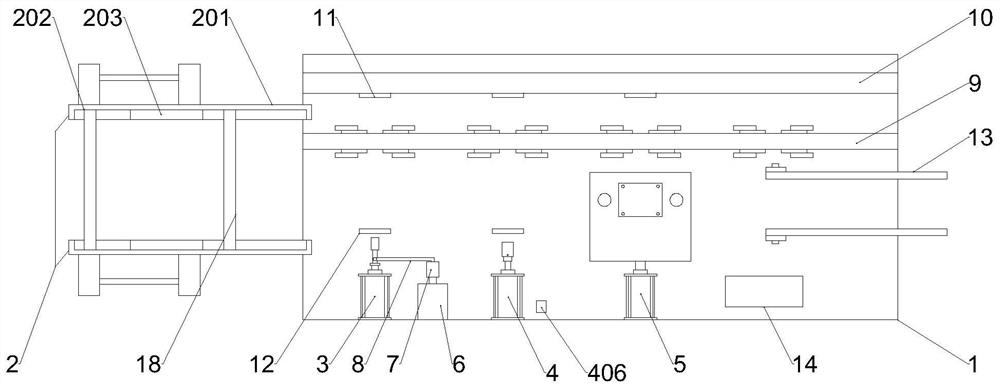

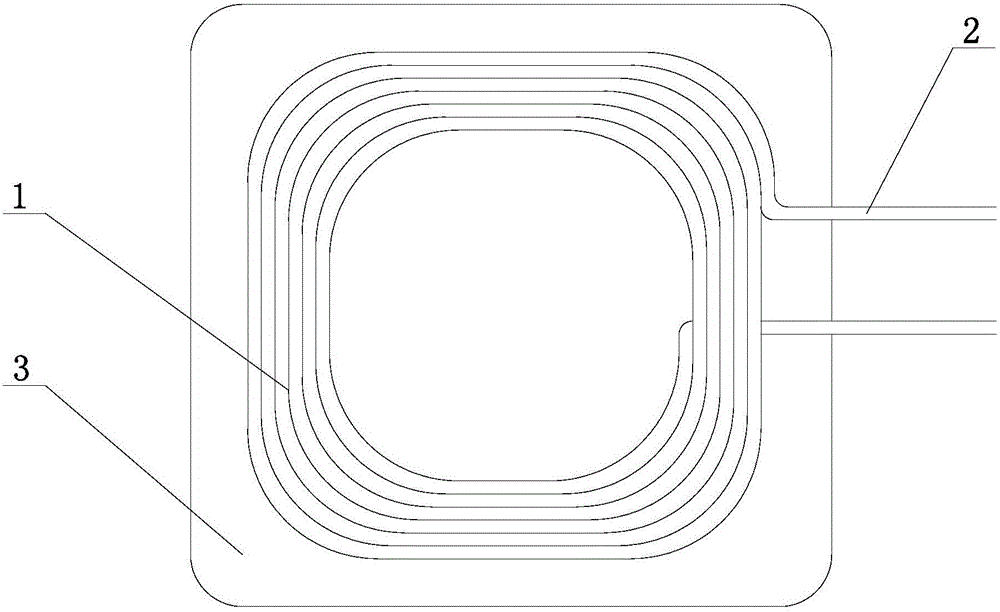

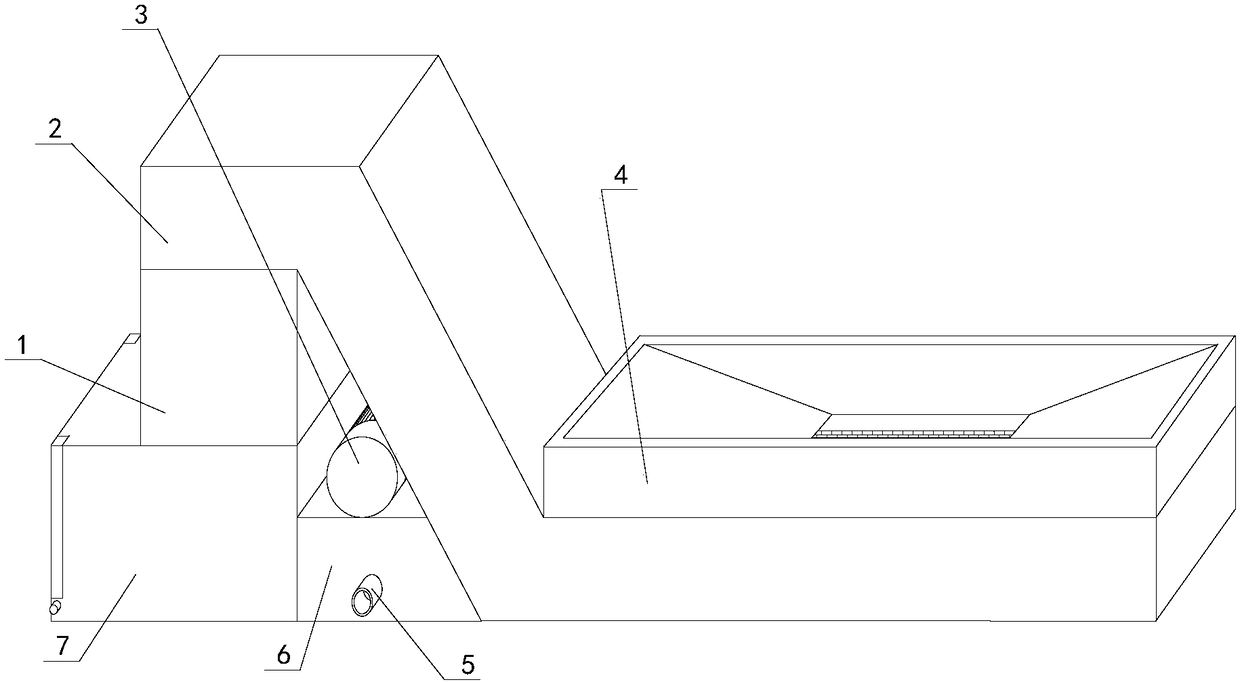

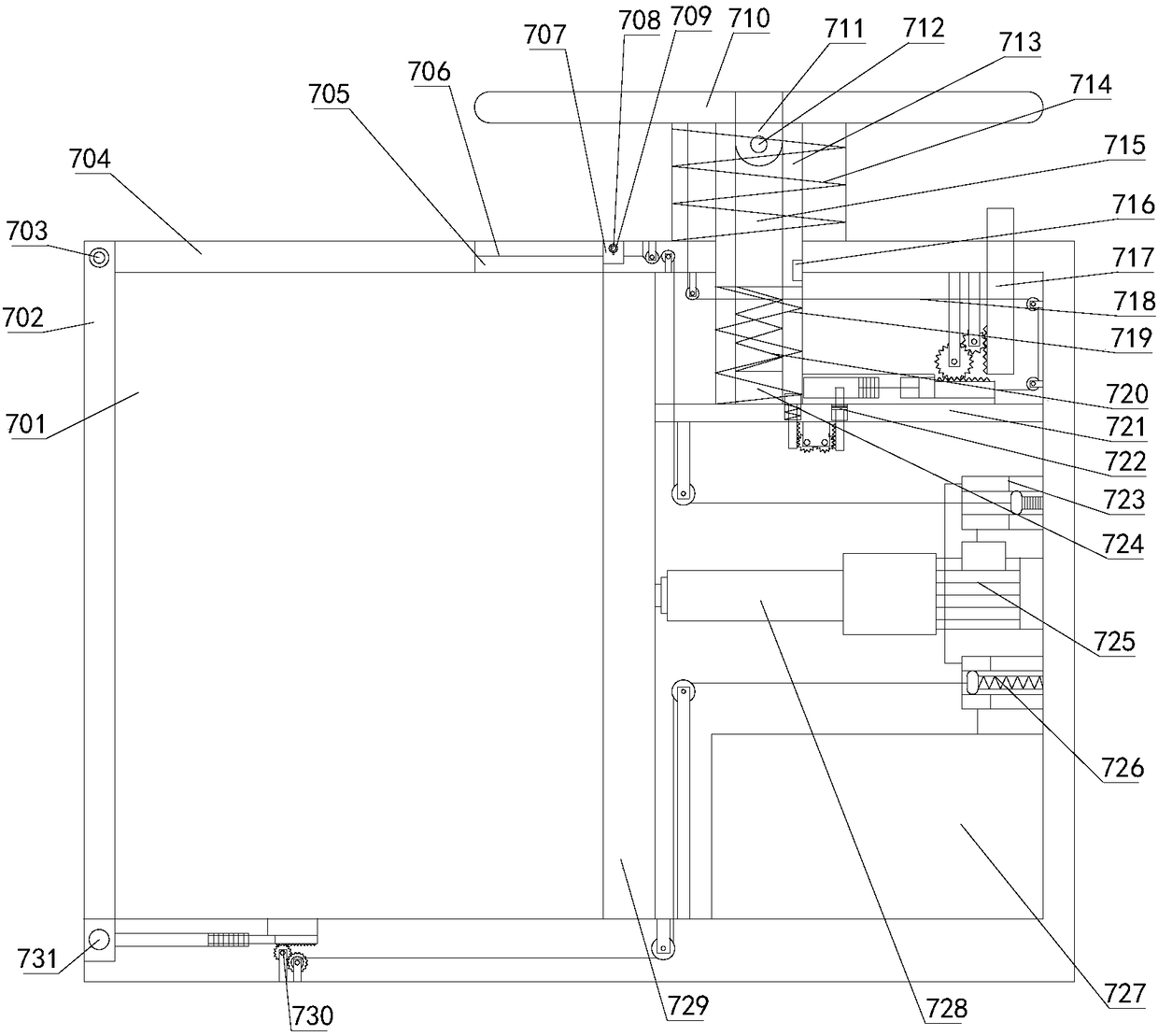

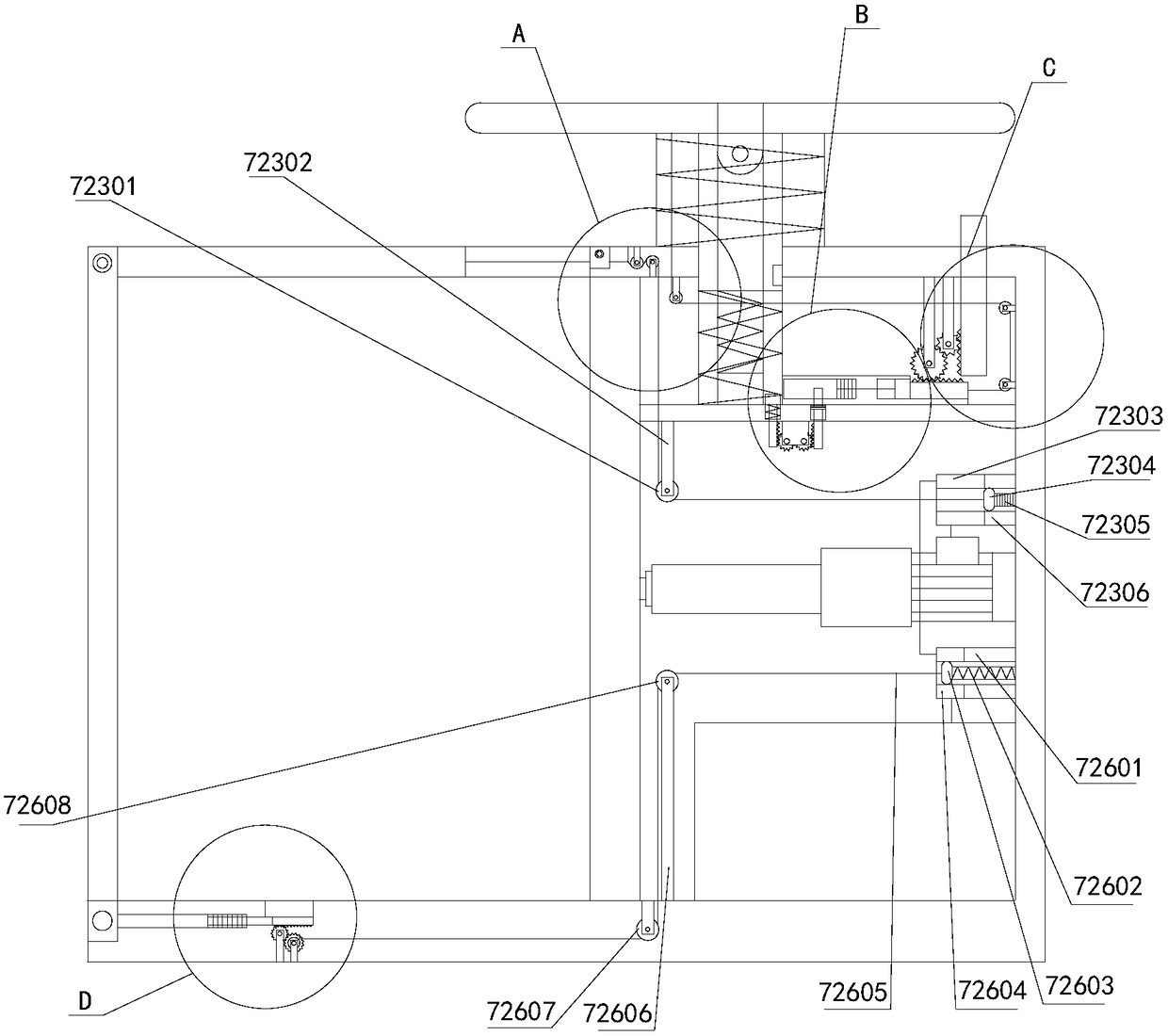

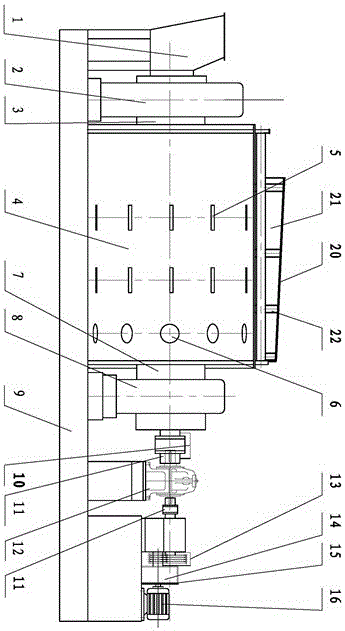

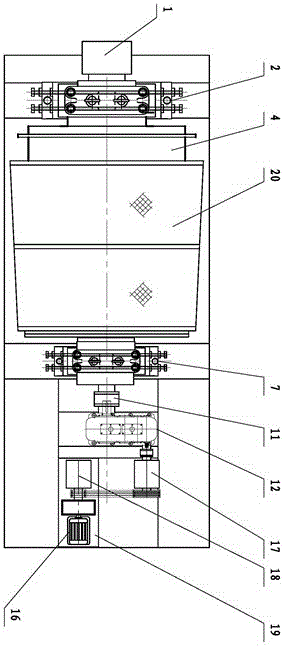

Full-automatic pipe fitting flaring machine

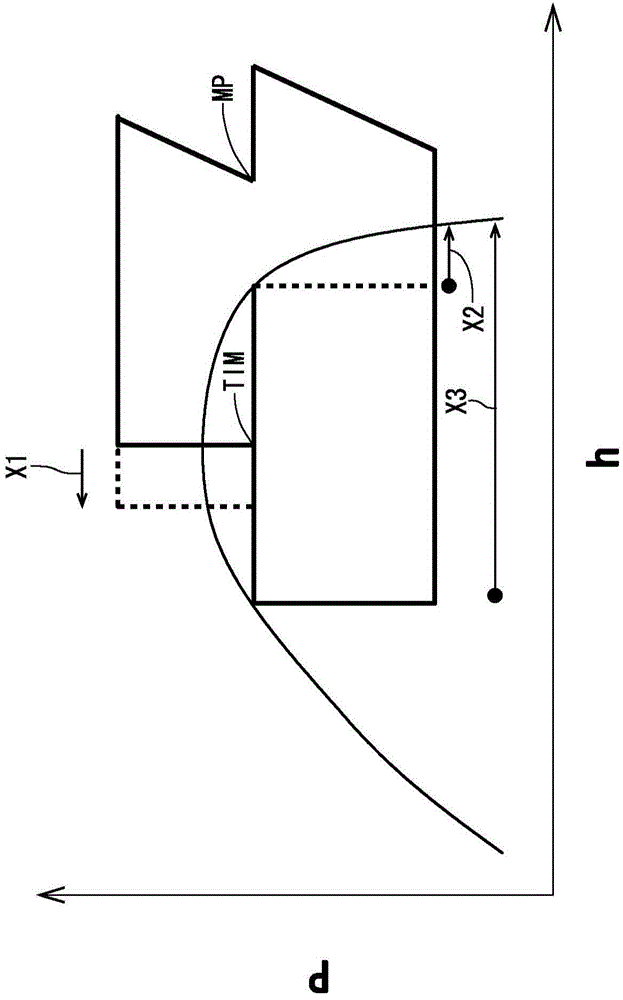

ActiveCN112222306AAvoid normal operationExpand the scope of processingShaping toolsMetal-working feeding devicesMachinePipe

The invention relates to the technical field of pipe fitting flaring, and discloses a full-automatic pipe fitting flaring machine. The machine comprises a workbench, wherein a pipe storage box is arranged on the left side of the workbench, a lubricating smearing assembly, a heating assembly, a flaring assembly and a discharging guide rail are sequentially arranged at the top of the workbench fromleft to right, and an oil storage tank and a micro oil pump are arranged between the lubricating smearing assembly and the heating assembly. According to the machine, the pipe storage box can store alarge number of pipes according to the pipes with different lengths or different pipe diameters, the pipe storage box can automatically send out the pipes and automatically cooperates with a clampingconveying assembly for processing, clamping assemblies can clamp pipe fittings with the different pipe diameters, the machine is wide in processing range, the whole process is automatic, the labor cost is reduced, large-batch processing can be completed through one-time material storage, a plurality of kinds of machining work such as lubricating treatment, heating treatment and flaring are automatically conducted on the pipe fittings at the same time, the production efficiency is improved, the yield is increased, the equipment structure layout is simple and reasonable, and later maintenance and repair are facilitated.

Owner:无锡金羊管件有限公司

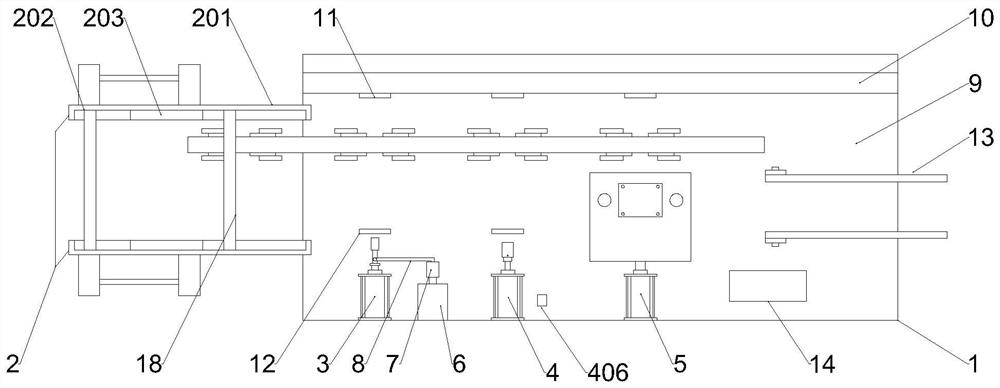

Flat coil, fabrication method thereof and flat coil wireless charger

InactiveCN105896682AReduce permeabilityLow magnetic permeabilityBatteries circuit arrangementsTransformers/inductances coils/windings/connectionsElectromagnetic interferenceUltimate tensile strength

The invention relates to a flat coil. The flat coil is a single-layer coil formed by winding a single self-adhered enameled wire form inside to outside, two wiring ends are led out of the single-layer coil, one side of the single-layer coil is in fixed contact with a magnetic shielding plate, the induction intensity of the flat coil is utilized to the greatest extent, the loss is relatively low, particularly, the flat coil is relatively high in environmental adaptability and stable is performance, and the normal operation of an electromagnetic interference device is prevented. The invention also provides a fabrication method of the flat coil and a flat coil wireless charger employing the flat coil.

Owner:WUXI JINGLEI ELECTRONICS

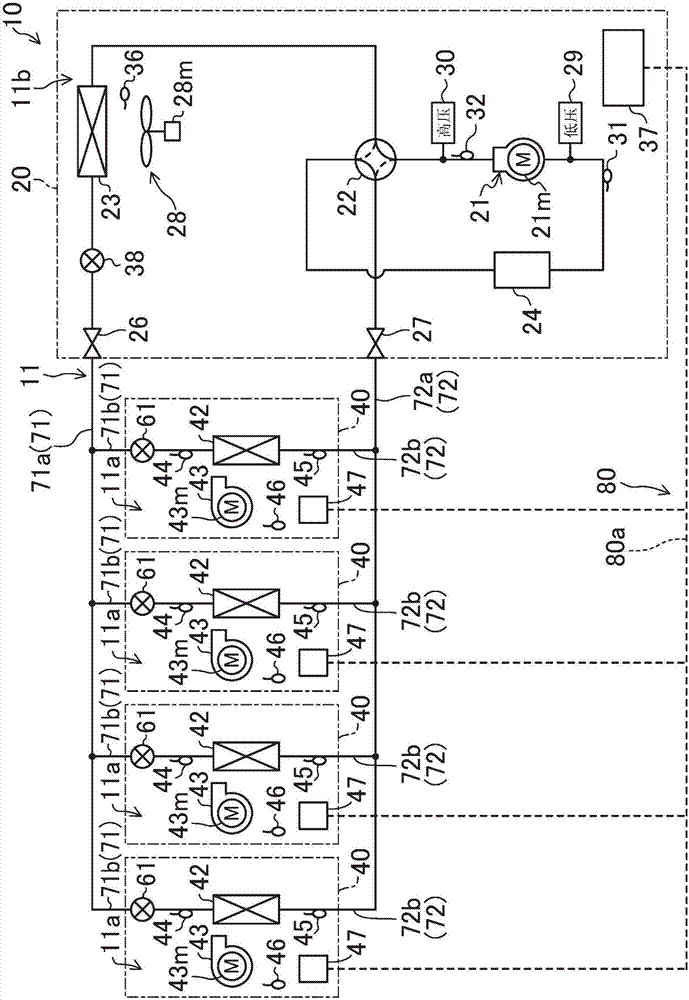

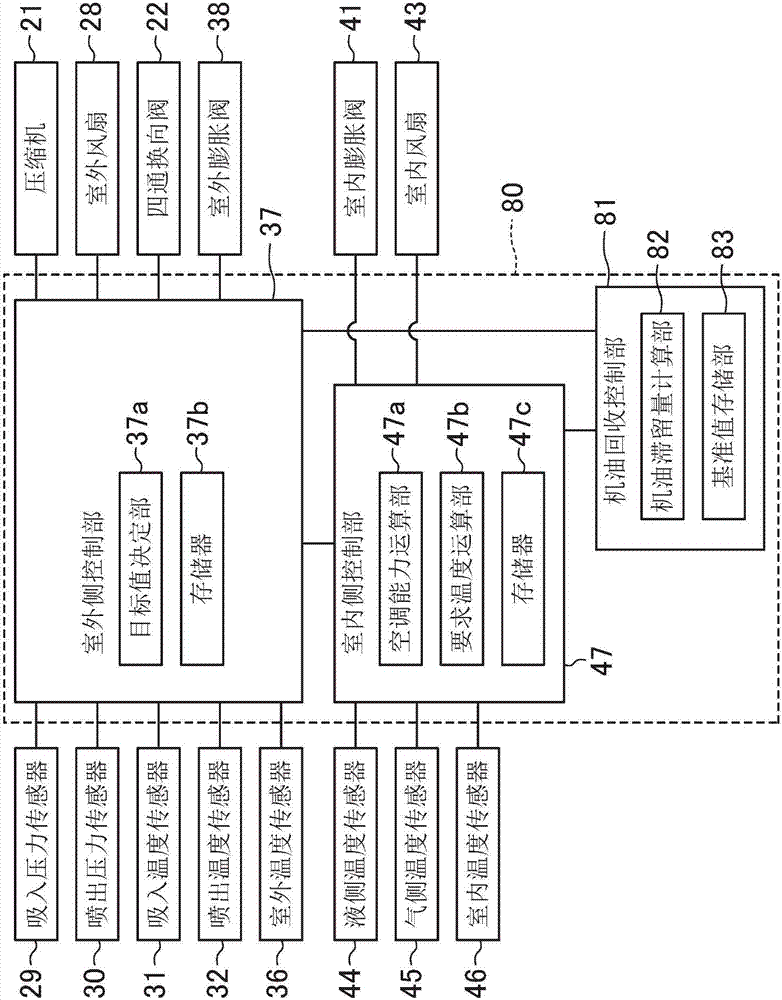

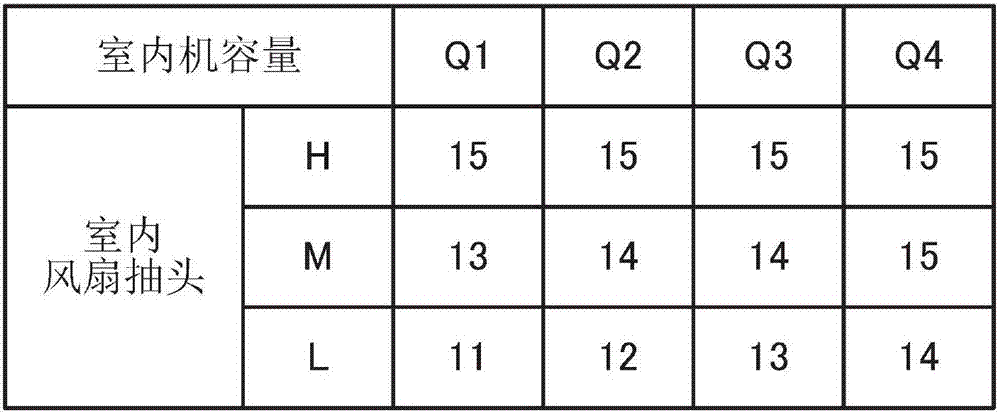

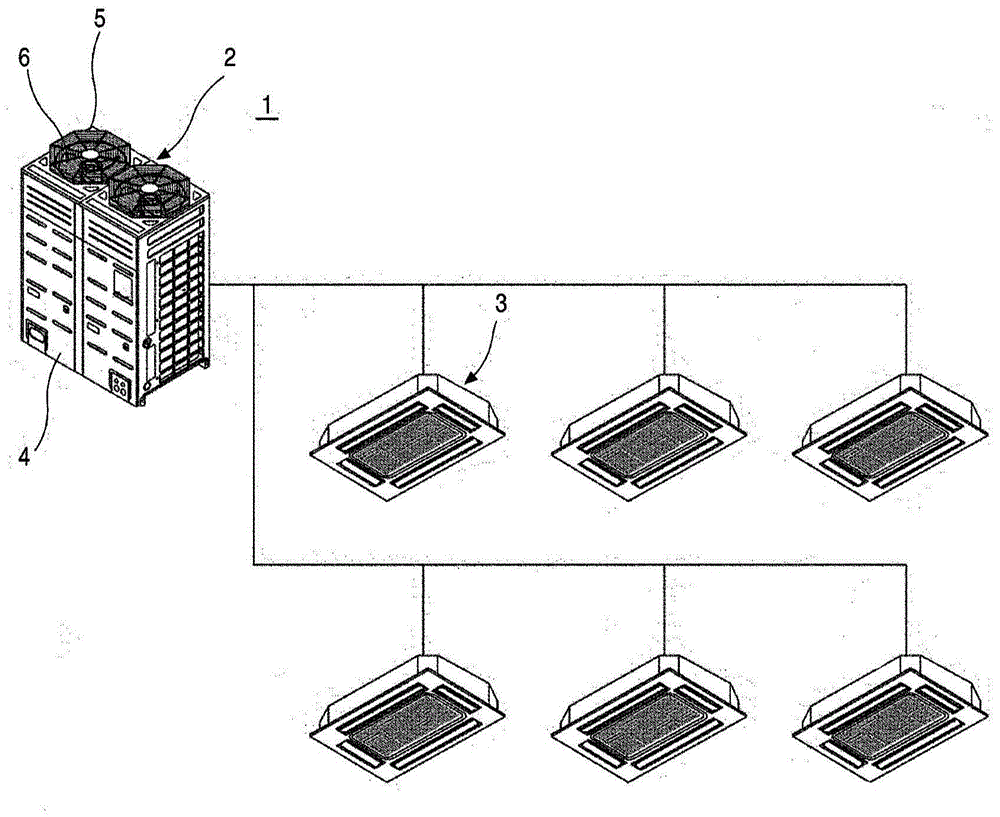

Air conditioning device

ActiveCN107208938AAvoid normal operationSuppression of poor lubricationMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringAir conditioning

Provided is an air conditioning device (10) in which an outdoor unit (20) and a plurality of indoor units (40) are connected and wherein the accumulated amount of refrigeration oil in gas-side main piping (72a) is calculated when the gas refrigerant flow rate in the gas-side main piping (72a) is slower than a main pipe flow rate lower threshold value, the accumulated amount of oil in gas-side branch piping (72b) is calculated if the gas refrigerant flow rate of the gas-side main piping (72a) is faster than the main pipe flow rate lower threshold value but slower than a branch pipe flow rate lower threshold value, and, if the total value of said accumulated amounts surpasses a set amount, oil recovery operation is carried out so that oil recovery is performed at an appropriate timing and defective lubrication is prevented in a compressor (21).

Owner:DAIKIN IND LTD

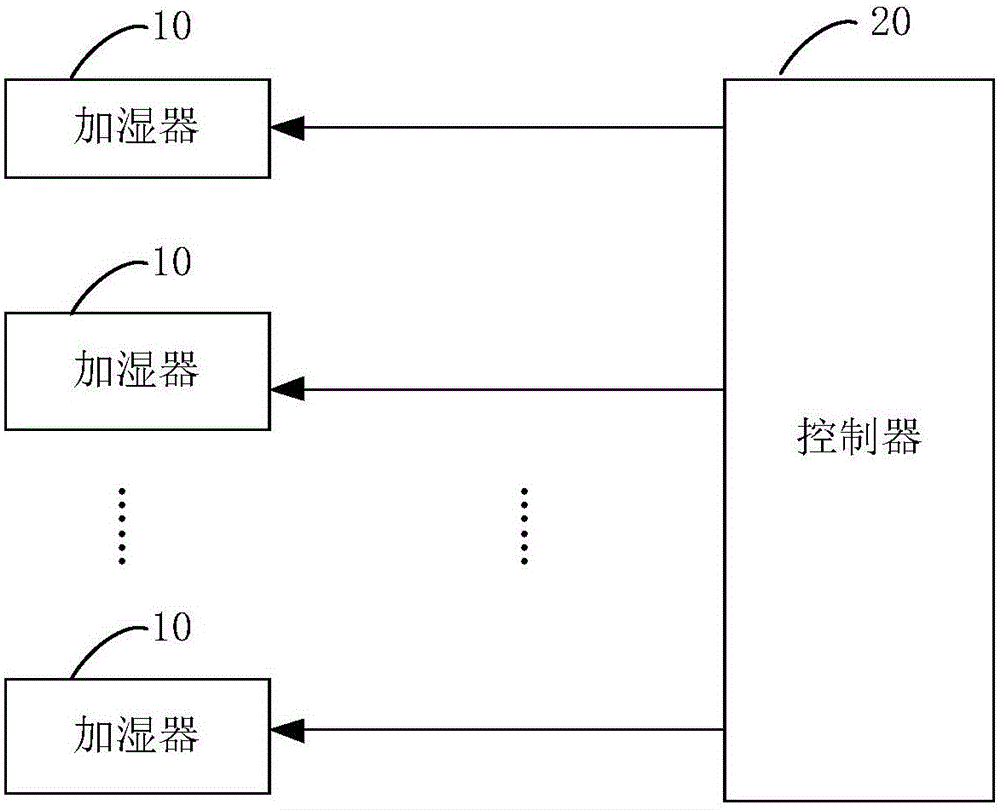

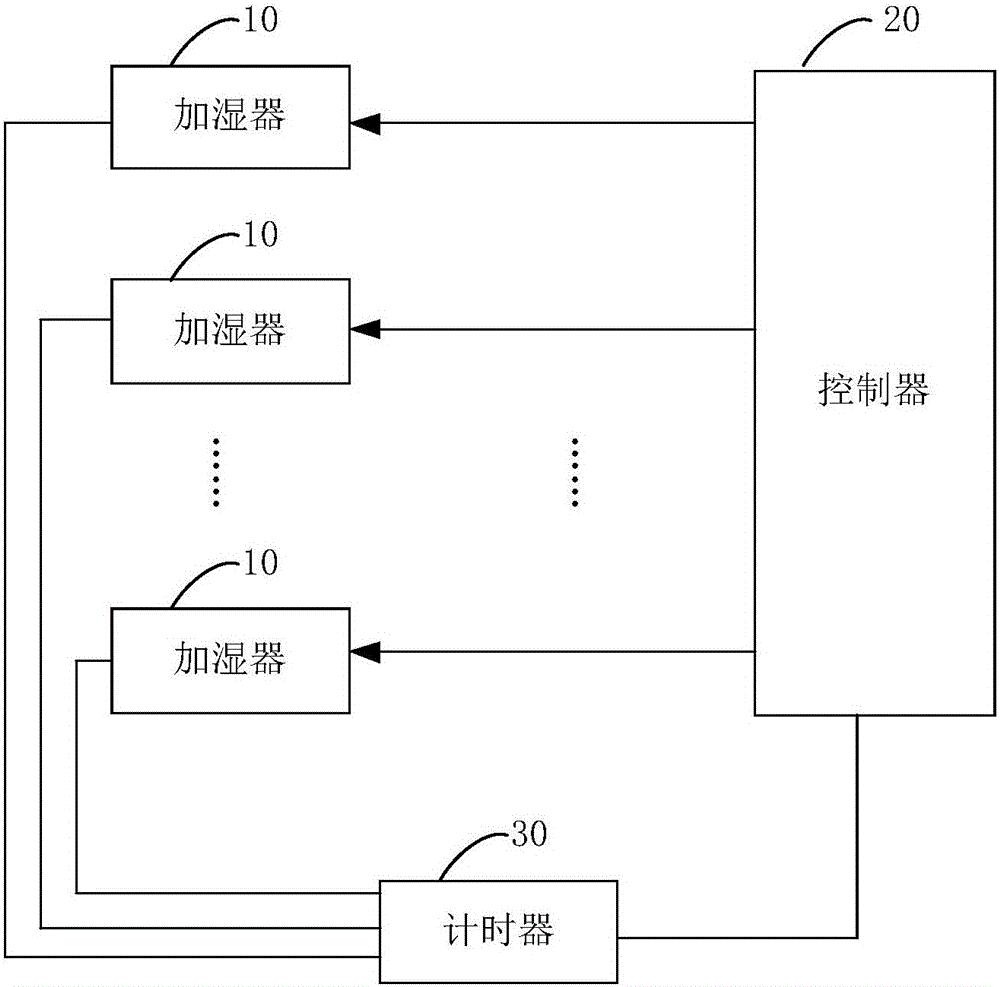

Air conditioner and control method thereof

InactiveCN106679029AExtended service lifeAvoid normal operationMechanical apparatusSpace heating and ventilation safety systemsMoisture sensorHumidifiers

The invention relates to the field of household electric appliances and discloses an air conditioner and a control method thereof. The air conditioner comprises a plurality of humidifiers, a humidity sensor used for sensing the environment humidity, and a controller used for controlling the humidifiers for humidification based on the sensed environment humidity. By adoption of the air conditioner and the control method thereof, the service lives of the air conditioner humidifiers can be prolonged.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

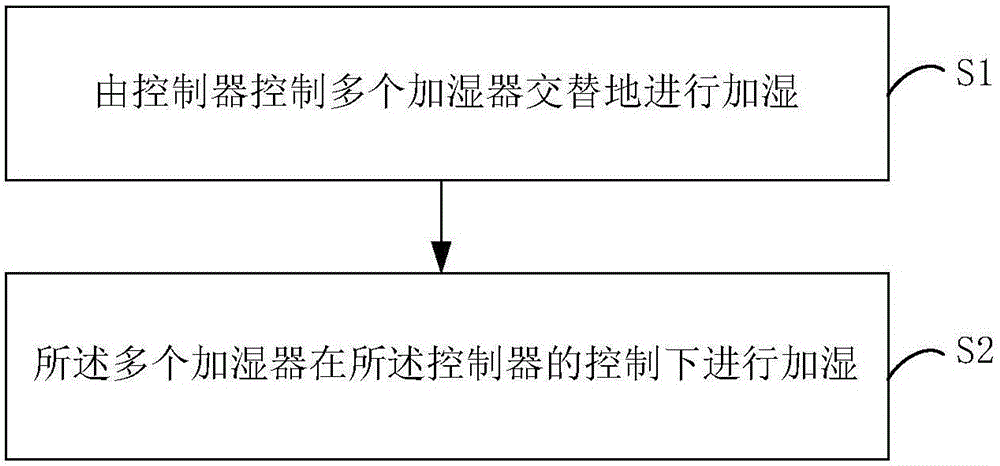

Upright-type cleaning appliances

InactiveCN101044964AAvoid normal operationMechanical suction controlMachine detailsEngineeringFuselage

Owner:VAX LTD

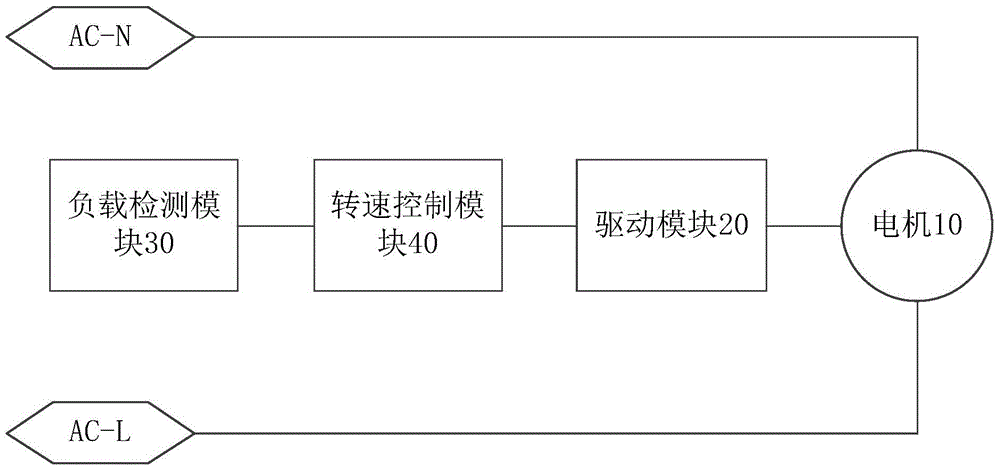

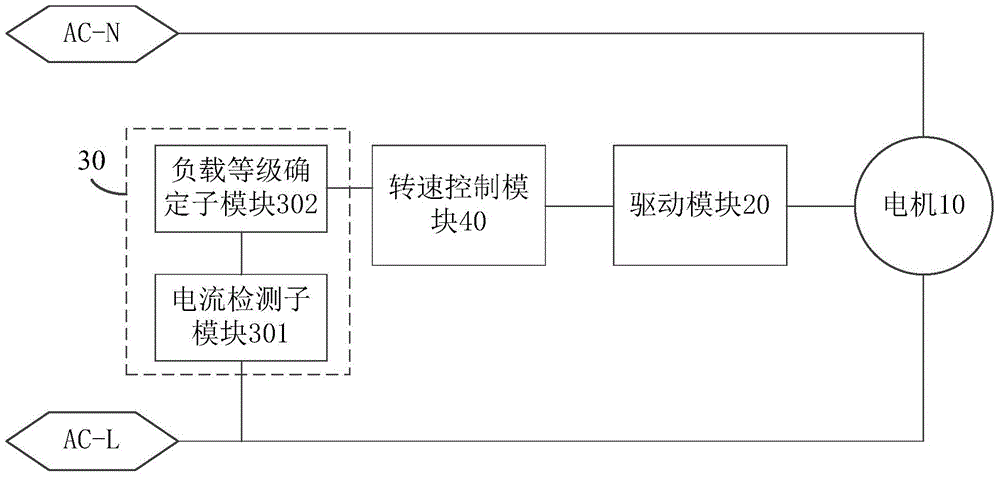

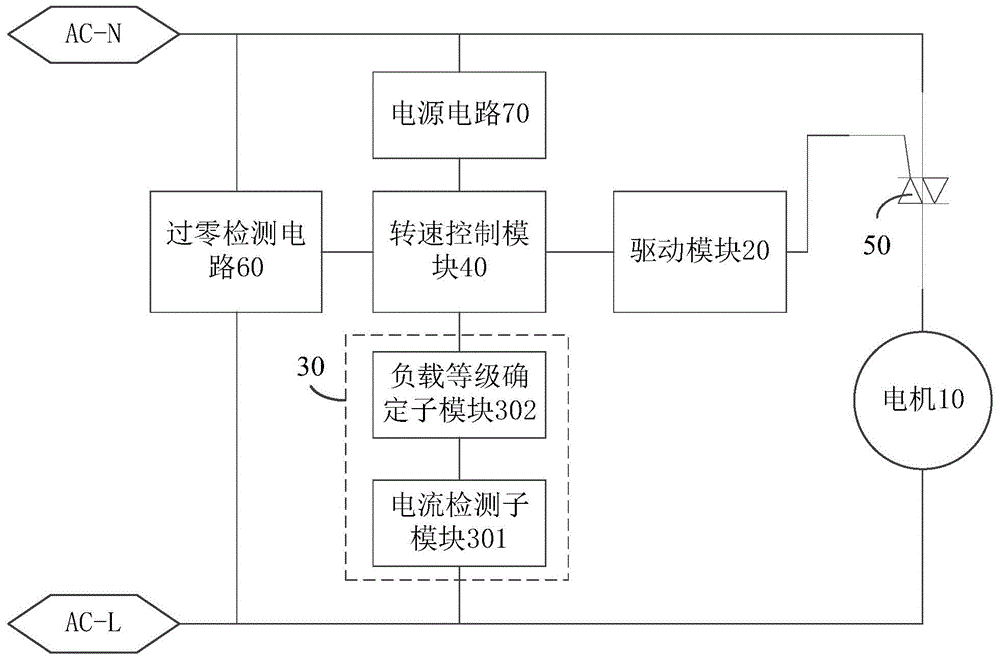

Food processor and motor rotation speed control device and method for food processor

PendingCN106612090AReduce speedReduce noiseAC motor controlKitchen equipmentComputer moduleControl theory

The invention discloses a food processor and a motor rotation speed control device and a method for a food processor. The device comprises a first input end, a second input end, a motor connected with the first input end and the second input end, a driving module for driving the motor, a load detection module for detecting the load grade of the food processor and a rotation speed control module connected with the load detection module and the driving module for controlling the rotation speed of the motor according to the load grade. Thus, in the case of a low load grade, the rotation speed of the motor is reduced, continuous high-speed rotation of the motor is avoided, noise during the rotation process of the motor can be effectively reduced and the experience of the user is enhanced.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

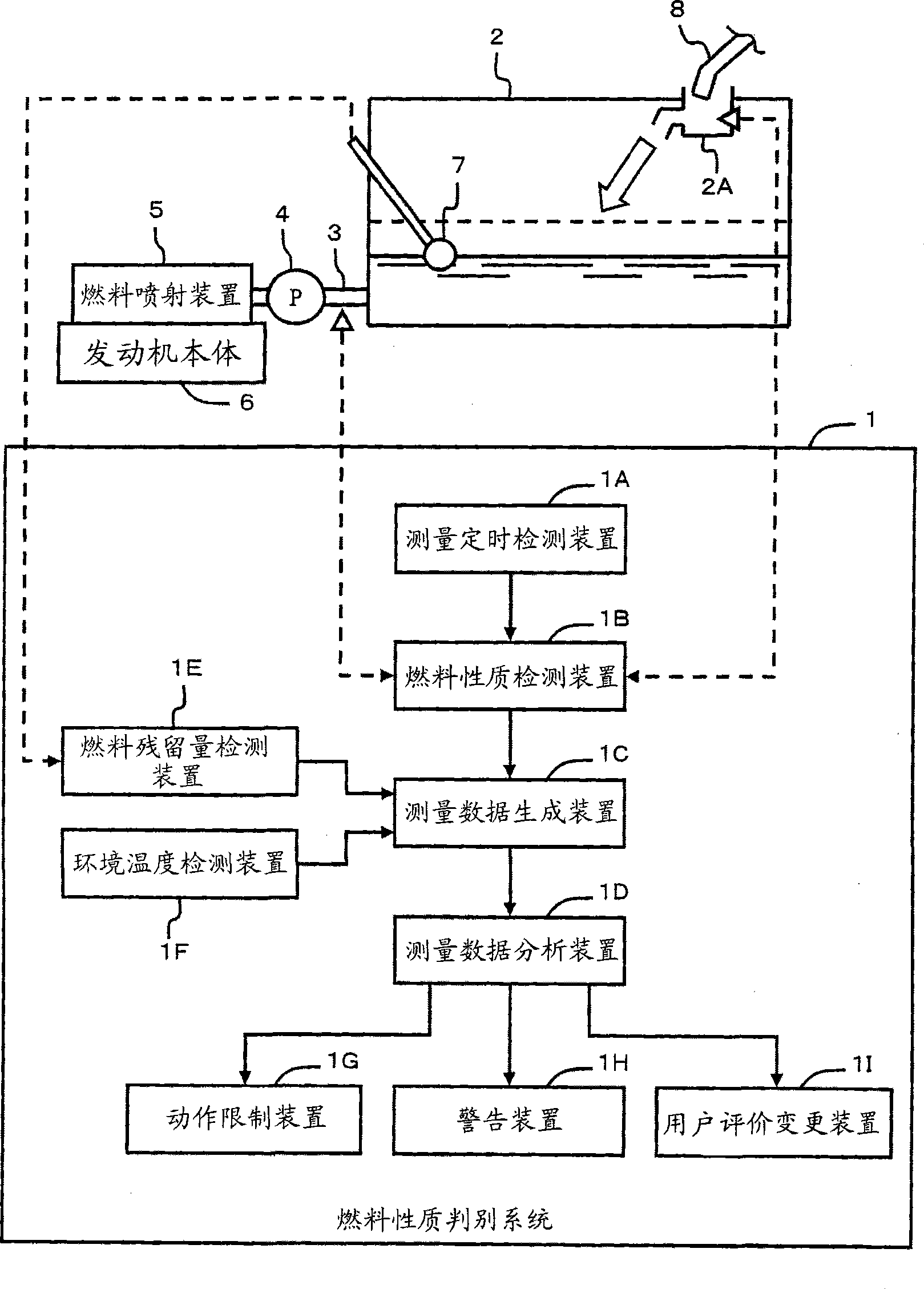

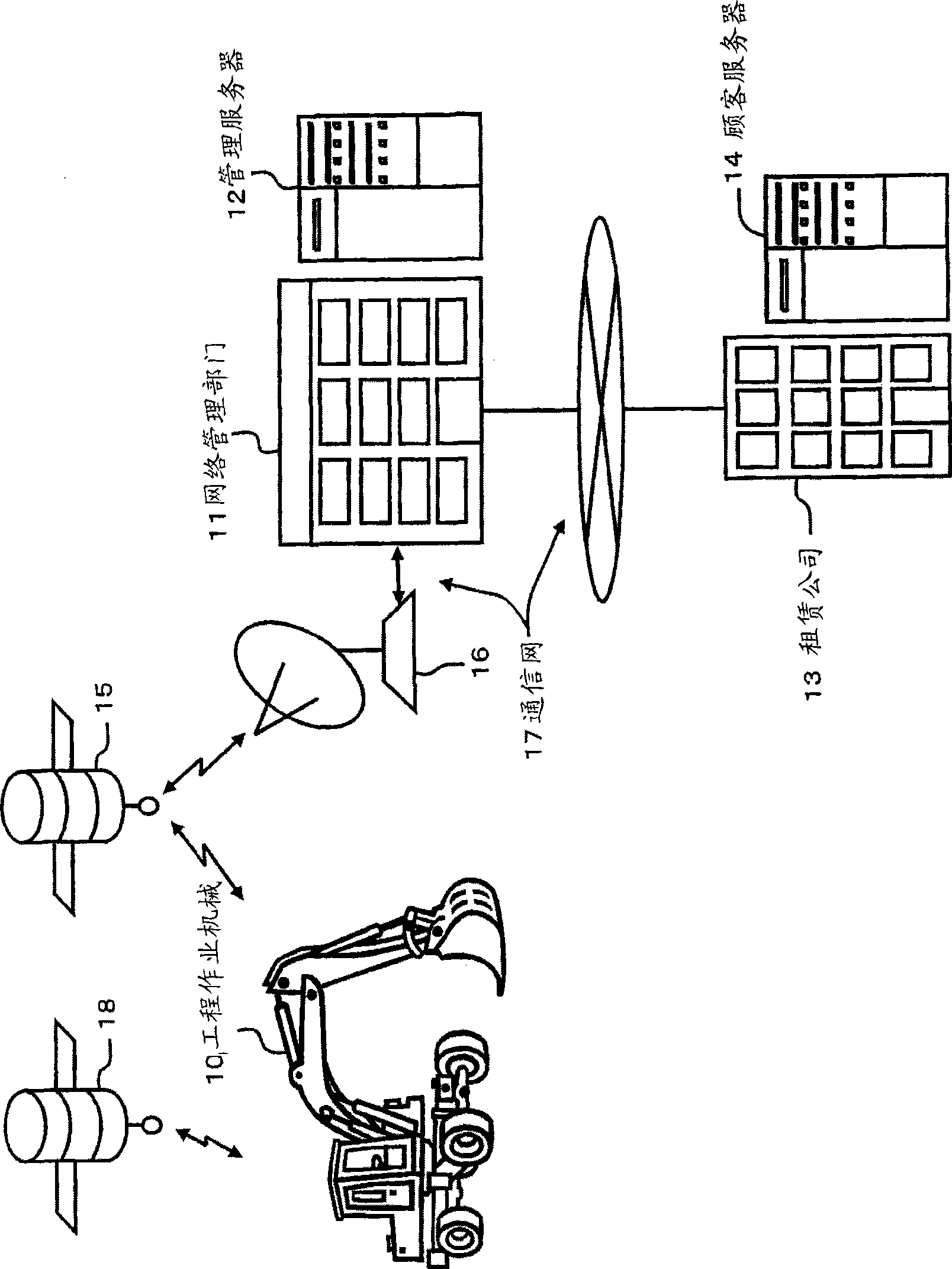

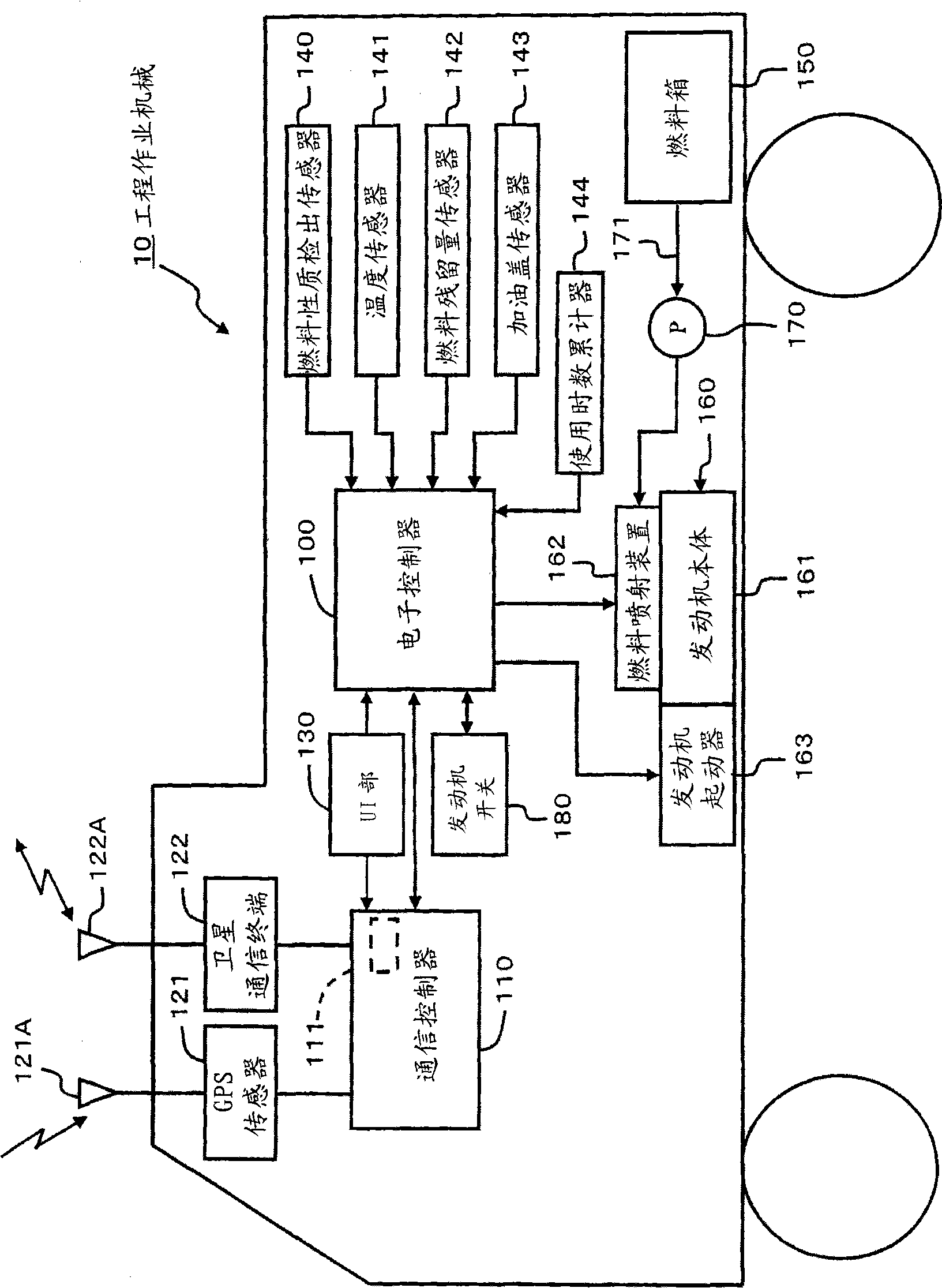

Fuel nature discriminating system for working machines, and fuel nature discriminating method for working machines

InactiveCN101484681AControl speedDeter inappropriate behaviorElectrical controlInternal combustion piston enginesControl engineeringFuel tank

Owner:KOMATSU LTD

Milling machine waste collector

InactiveCN108058062AAvoid normal operationCompressed and collectedMaintainance and safety accessoriesWaste managementScrap

The invention discloses a milling machine waste collector. The milling machine waste collector comprises a discharging receiving groove, a lifter, a pumping motor, a collection base, a discharge outlet, a pumping base and a collection and compression box; the lifter is shaped like a Z, the collection base is welded to the right side of the top, the discharging receiving groove is welded to the left side of the bottom, the bottom of the discharging receiving groove is vertically locked to the right side of the top of the collection and compression box in a locked mode, the pumping base is locked to the right end, the right end of the pumping base is welded to the lifter, and the pumping motor is locked to the top; when a user uses the equipment, the equipment can automatically conduct solid-liquid separation on waste by means of a mechanism composed of a gear, a stay cord, an ejector rod, a spring and the like, quantitative solid accumulation is conducted, and then the waste can be discharged into the compression box to be controlled to be compressed, the compression box of the equipment can be compressed and controlled to be deenergized when a box cover is opened and feeding is conducted, the safety in use is guaranteed, the equipment can compress and collect the waste better, danger caused by vibration spill is prevented, and use is facilitated.

Owner:孙培宗

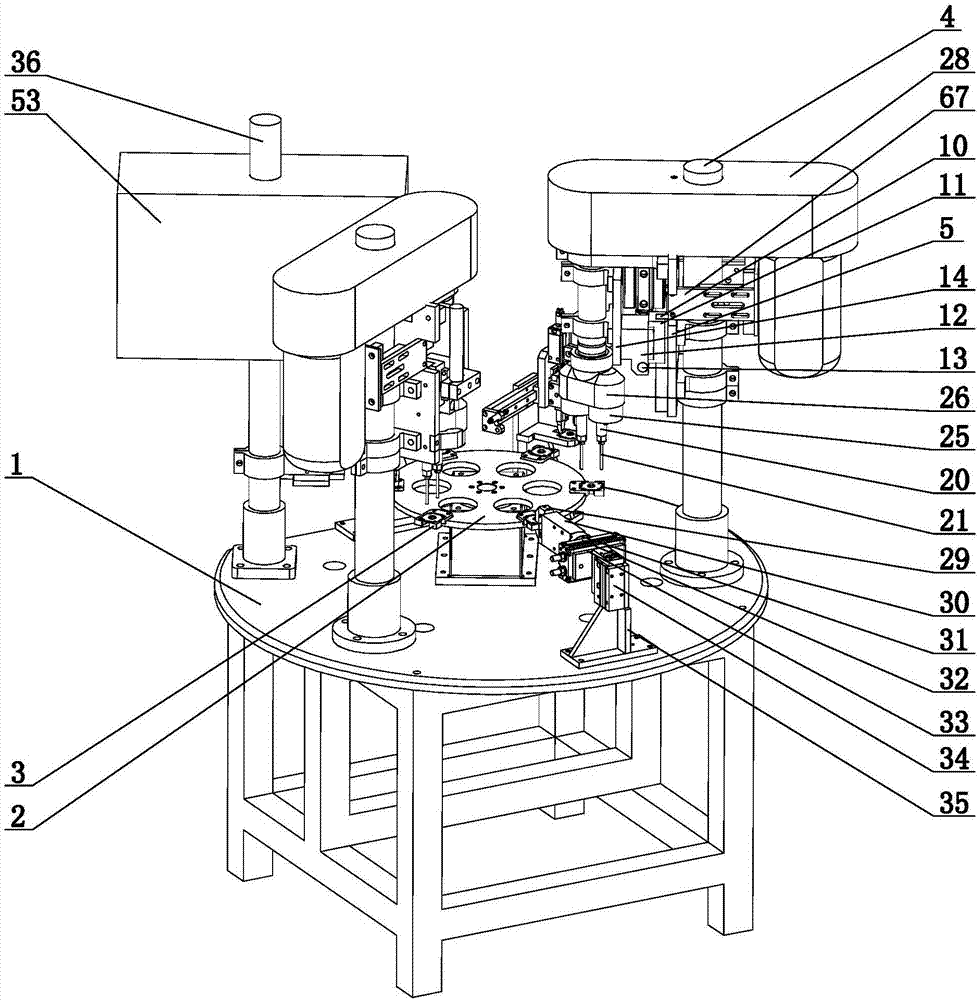

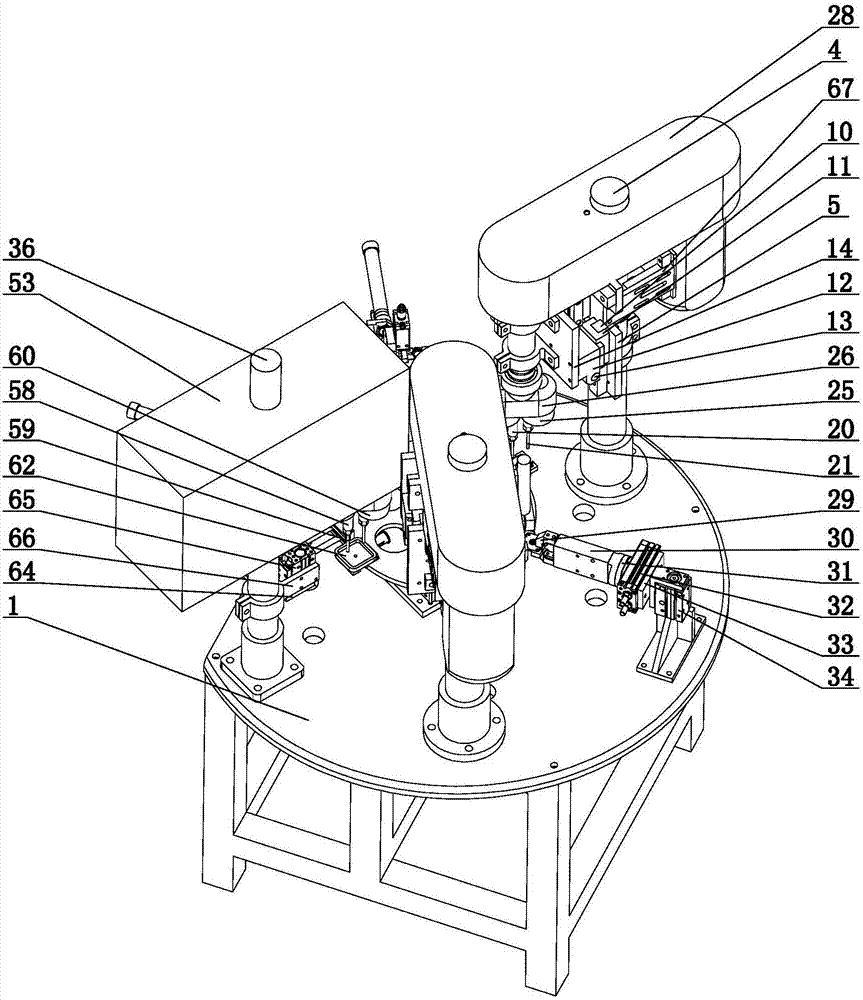

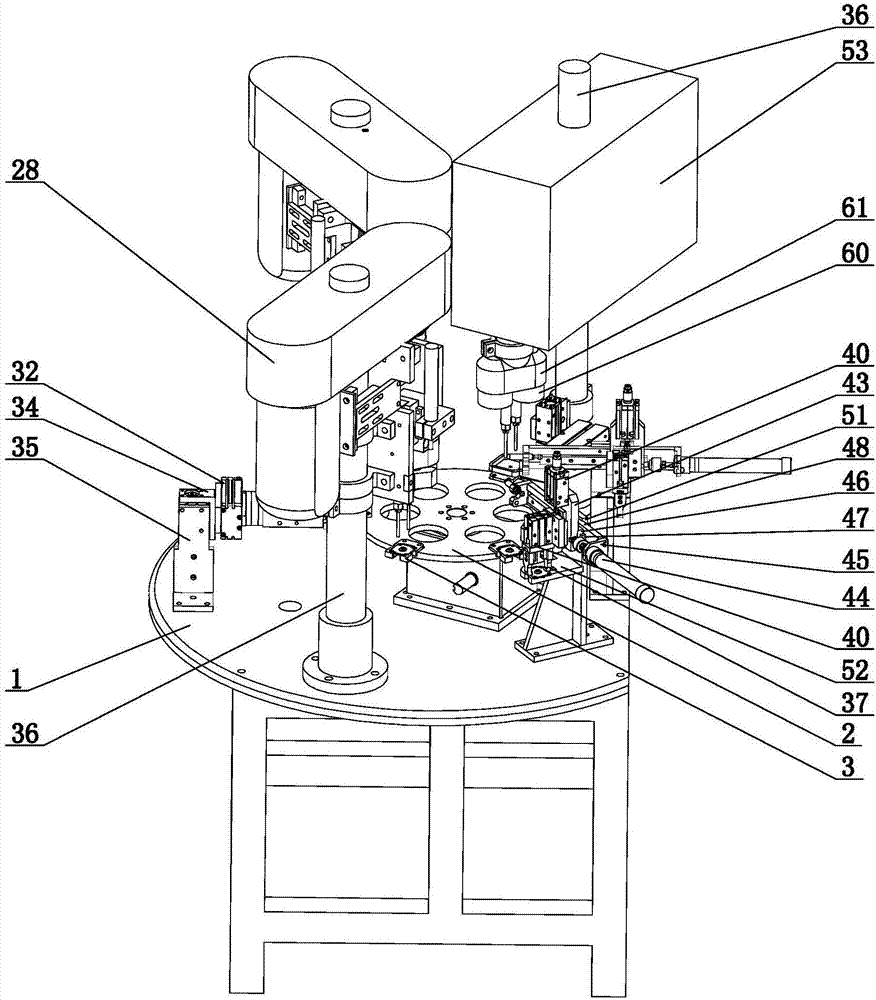

Chamfering and tapping machine for cover plate

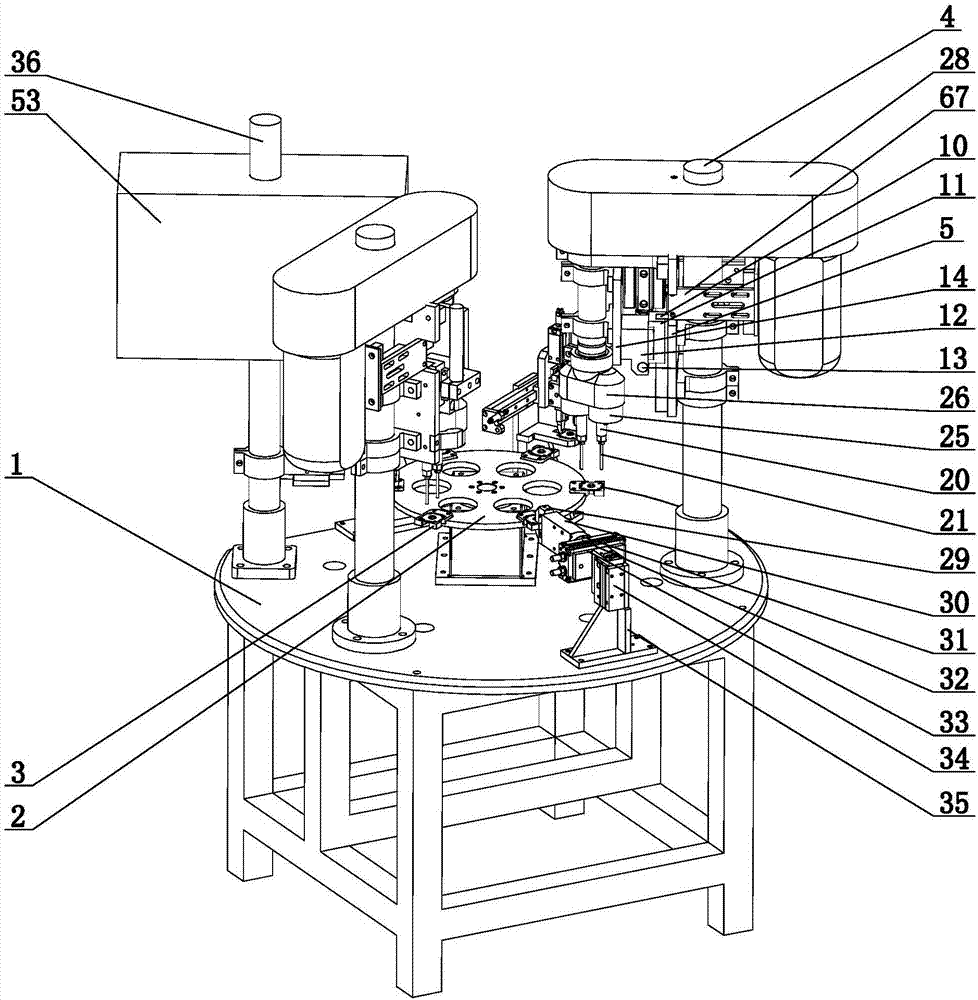

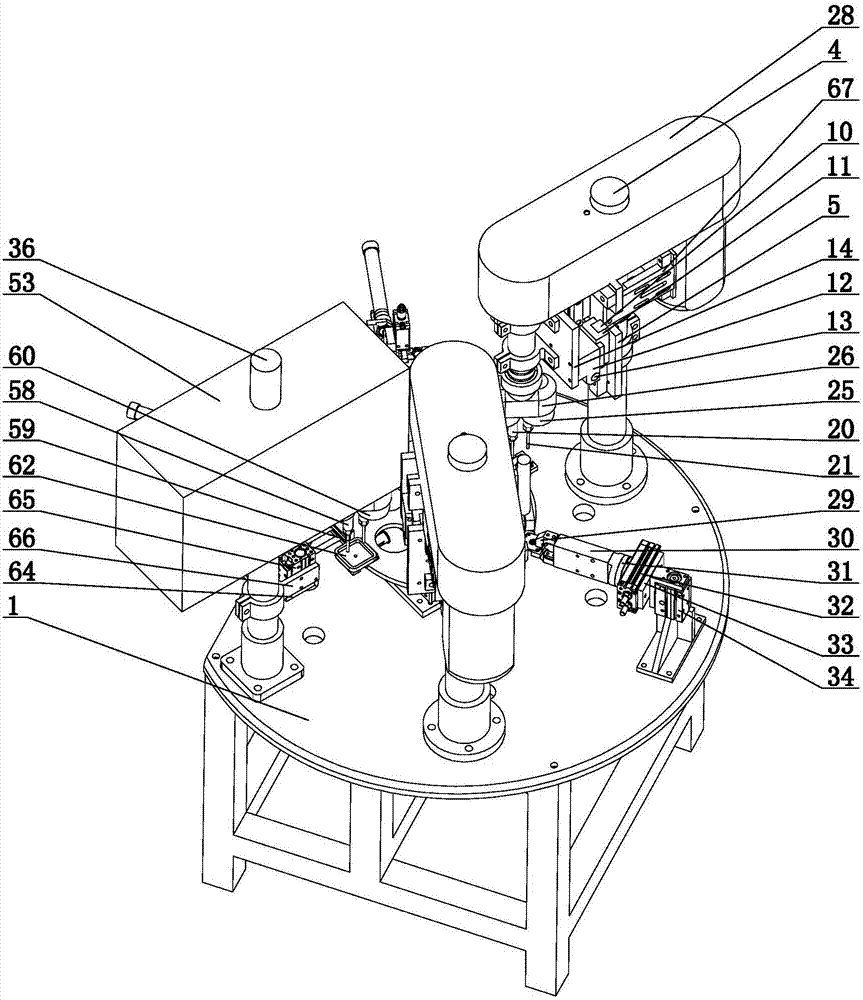

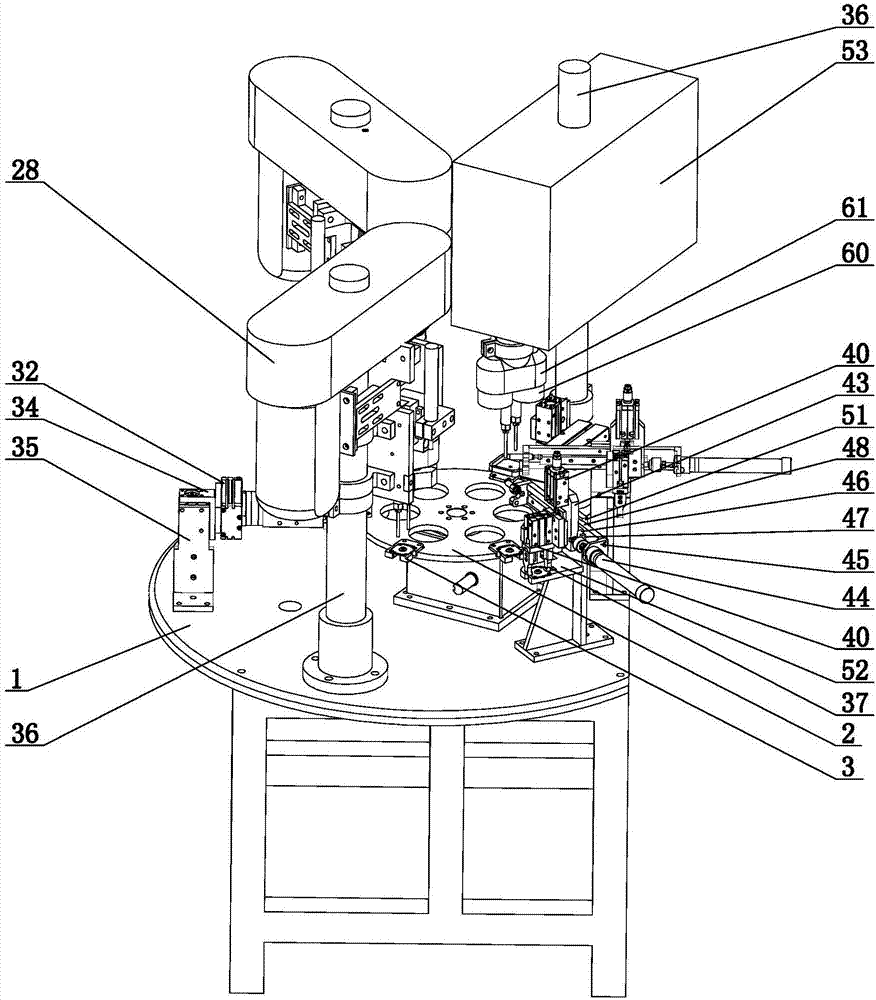

ActiveCN107378496AEliminate repairsEliminate scrappingOther manufacturing equipments/toolsMachineWorkstation

The invention relates to the field of processing of gas components, in particular to a chamfering and tapping machine for a cover plate. The chamfering and tapping machine for the cover plate comprises a bottom table, wherein a rotating plate mechanism is arranged in the middle of the surface of the bottom table and comprises a rotating plate and a divider; the rotating plate is rotatably arranged on the divider; six square cover plate fixing seats are uniformly distributed on the surface of the edge of the rotating plate; the surfaces of the cover plate fixing seats are inwards recessed to form a cover plate accommodating groove; and a first workstation, a second workstation, a third workstation, a fourth workstation, a fifth workstation and a sixth workstation are successively arranged on the periphery of the rotating plate clockwise. The chamfering and tapping machine for the cover plate has the beneficial effects that the structure is novel, the design is skillful, chamfering processing and tapping processing are finished in a process, chamfering, tapping, turning and the like do not need to be carried out independently artificially, the labor cost is low, and the processing efficiency is high.

Owner:CIXI TIANXING ELECTRIC

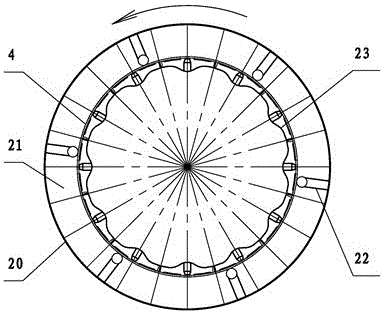

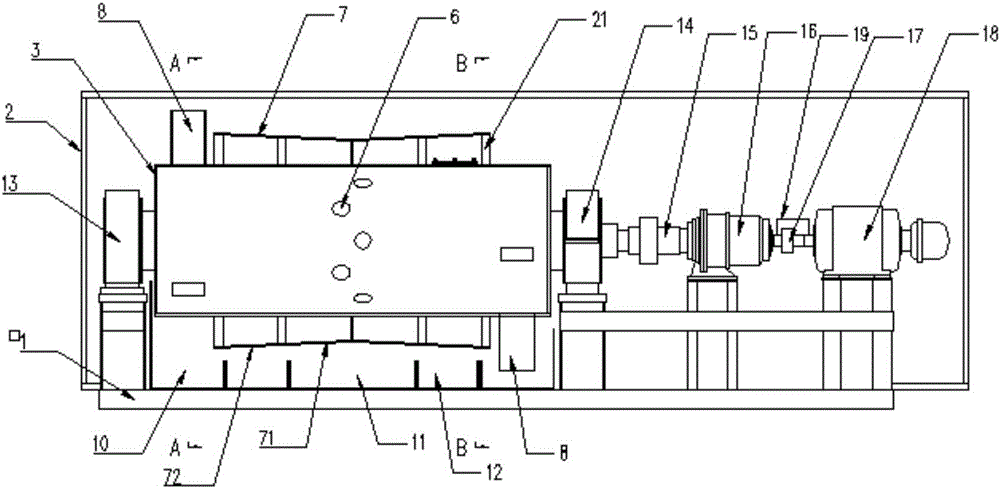

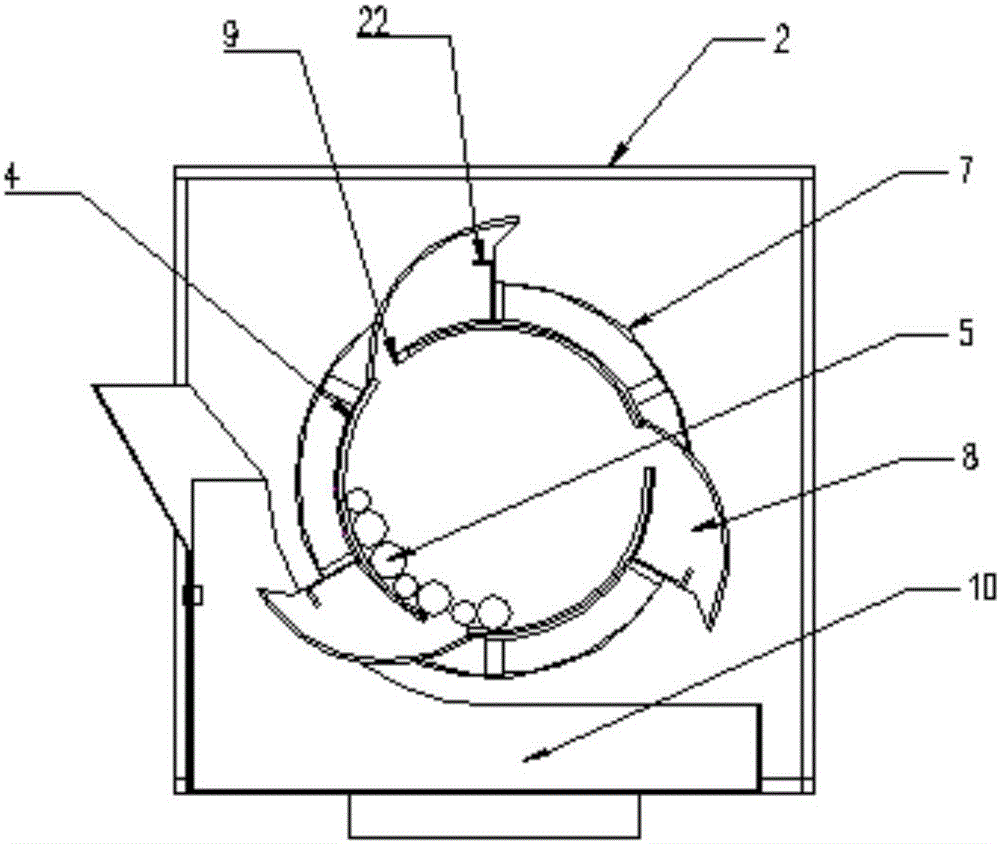

Energy-saving and environment-friendly milling screening machine

The invention relates to the technical field of grinding equipment, in particular to an energy-saving and environment-friendly milling screening machine. The energy-saving and environment-friendly milling screening machine comprises a material feeding portion, a barrel body and a driving device, wherein a lining plate is arranged in the barrel body, the material feeding portion is connected with the barrel body through a hollow shaft, the barrel body is connected with the driving device through a transmission shaft, a barrel opening, away from the material feeding portion, of the barrel body is in a sealed shape, a material discharging hole is formed in the barrel body, a screen is arranged outside the barrel body, surrounds the outside of the barrel body, and is arranged in a barrel shape, a screening portion is formed between the screen and the barrel body, one end of the screening portion is open, the other end of the screening portion is closed, and the closed end of the screening portion and the closed end of the barrel body are connected with each other, and are located at the same side. According to the energy-saving and environment-friendly milling screening machine disclosed by the invention, milling and screening integrated production is realized without arranging a plurality of sets of equipment; energy consumption of equipment for screening and conveying can be reduced; the accumulation of materials can be effectively avoided as a strong exhaust hole is formed, and therefore the yield and production efficiency are increased, finer grinding phenomena can be reduced, and the pick-up rate of finished products is increased; moreover, the milling and screening in both dry and wet manners can be realized, so that production adaptability is enhanced, and the wet-type operation can also solve the problem of flying dust.

Owner:樊日宏 +1

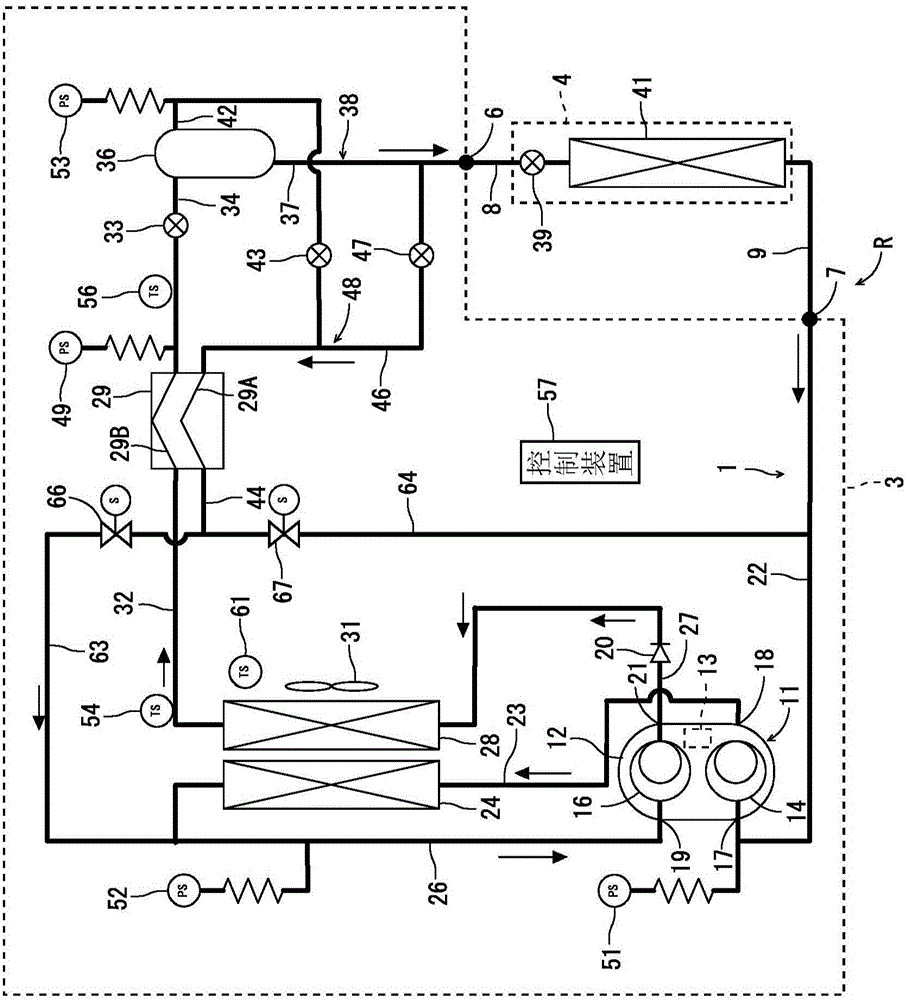

Freezing apparatus

ActiveCN104833123AImprove freezing effectReduced compression workloadMechanical apparatusCompression machines with non-reversible cycleGas coolerHigh pressure

The invention provides a freezing apparatus. When the high pressure side is up to a critical pressure, a steady freezing capacity can be guaranteed. The freezing apparatus comprises an electric expansion valve (33) that is connected to the downstream side of an air cooler (28) and the upstream side of an electric expansion valve (39); a liquid storing device (36) that is connected to the downstream side of the electric expansion valve (33) and the upstream side of an electric expansion valve (39); a heat exchanger (29) that is set at the downstream side of the air cooler and the upstream side of an electric expansion valve (33); an auxiliary circuit (48) that helps a refrigerant in the liquid storing device flows from electric expansion valves (43,47) into a first path (29A), and then back to a compressor (11); and a main circuit (38) that helps the refrigerant flows from the air cooler into a second path (29B) , and flows into the electric expansion valve (33) after heat exchange with the refrigerant flows in the first path, and makes the refrigerant flows from the lower part of the liquid storing device into the electric expansion valve (39); and electromagnetic valves (66,67) that are switched selectively, and make the refrigerant flows out of the first path back into the middle pressure part of the compressor or back to a low pressure part.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Chamfering and tapping machine

ActiveCN107344290AEliminate scrappingAvoid reworkFeeding apparatusOther manufacturing equipments/toolsEngineeringMachine

The invention relates to the field of gas part machining and particularly relates to a chamfering and tapping machine. The chamfering and tapping machine comprises a bottom platform; a turntable structure is arranged on the middle position of the surface of the bottom platform; the turntable structure comprises a turntable and a splitter; the turntable is rotatably arranged on the splitter; the surface of the edge of the turntable is uniformly distributed with six square cover plate fixing seats; the surfaces of the cover plate fixing seats are inwards sunken to form cover plate accommodating slots; and the periphery of the turntable is sequentially and clockwise provided with a first working position, a second working position, a third working position, a fourth working position, a fifth working position and a sixth working position. The chamfering and tapping machine has the beneficial effects of novel structure, artful design, capability of finishing chamfering and tapping in the one process, no need of manual independent chamfering, tapping and turnover, low labor cost and high machining efficiency.

Owner:CIXI TIANXING ELECTRIC

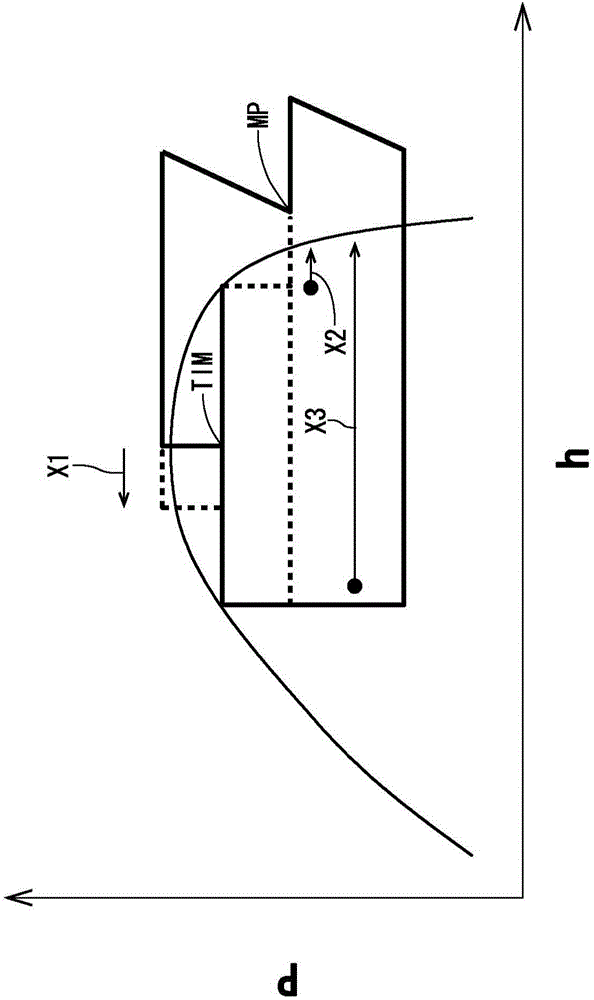

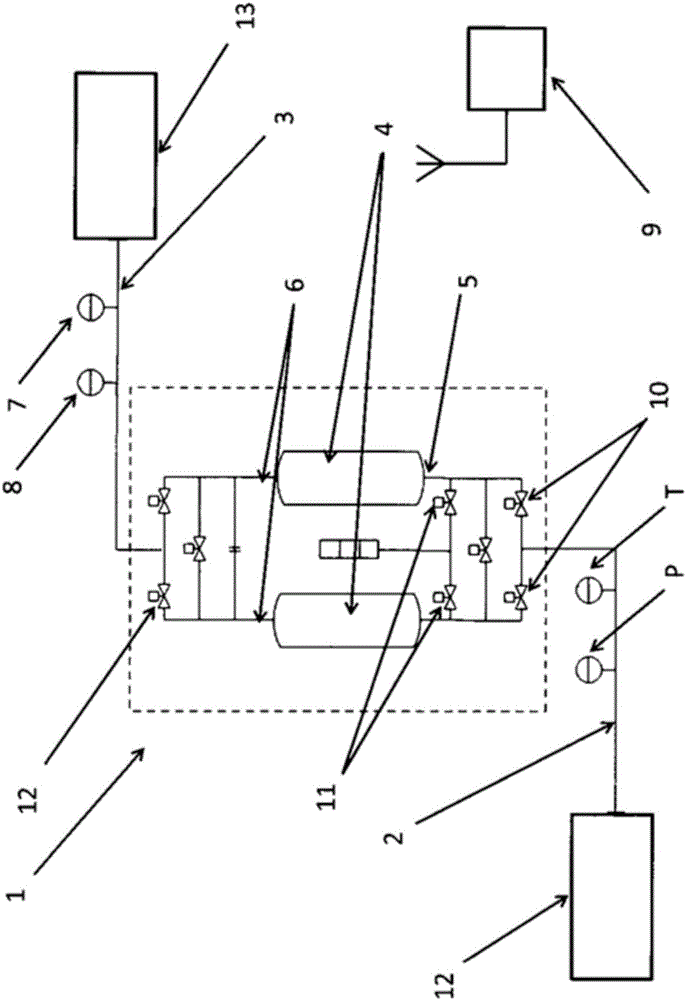

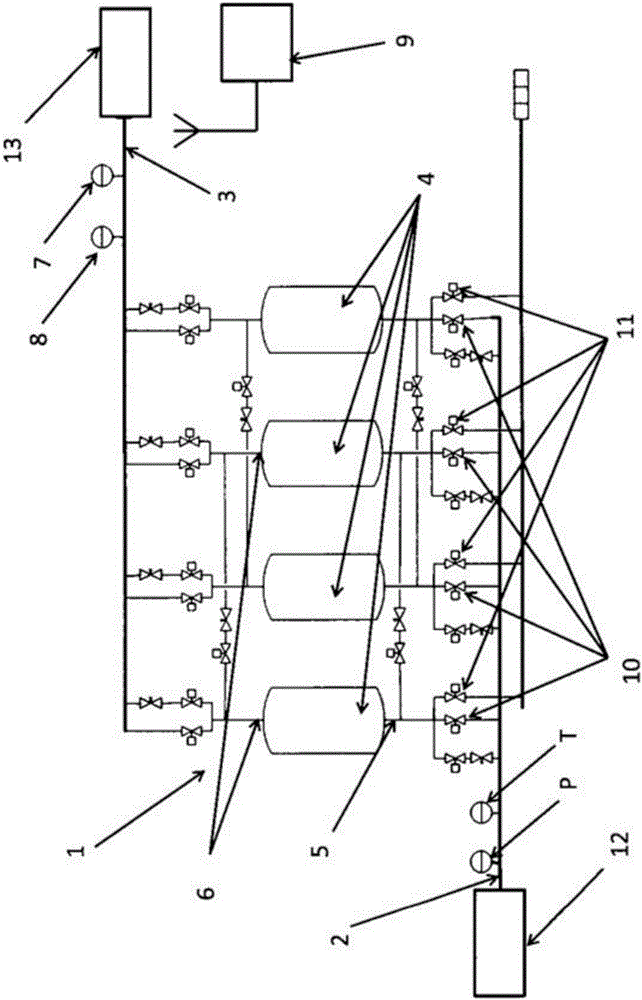

Method for controlling an adsorption phase of a gas generator and a gas generator applying such a method

ActiveCN106237784AGuaranteed to workAvoid saturationGas treatmentDispersed particle separationPhysical chemistryEngineering

A method for controlling an adsorption phase of a gas generator, said generator comprising an adsorbent medium capable of selectively adsorbing a first gaseous component from an inlet gas flow comprising a gaseous mixture, and allowing an outlet gas flow mainly comprising a second gaseous component, said method comprising the steps of: directing the inlet gas flow through an inlet of said gas generator; measuring the outlet gas flow; determining the concentration of said second gaseous component at the outlet of said vessel,; wherein the method further comprises the steps of: A9) calculating the capacity of the generator; A10) comparing the measured outlet gas flow with the calculated capacity; All) if the measured outlet gas flow is lower than the calculated capacity, and if the determined concentration is higher than or equal to a set value, maintaining the generator in adsorption phase for a predetermined time interval, Deltas; subjecting the generator to a regenerating cycle after said predetermined time interval, Delta s.

Owner:ATLAS COPCO AIRPOWER NV

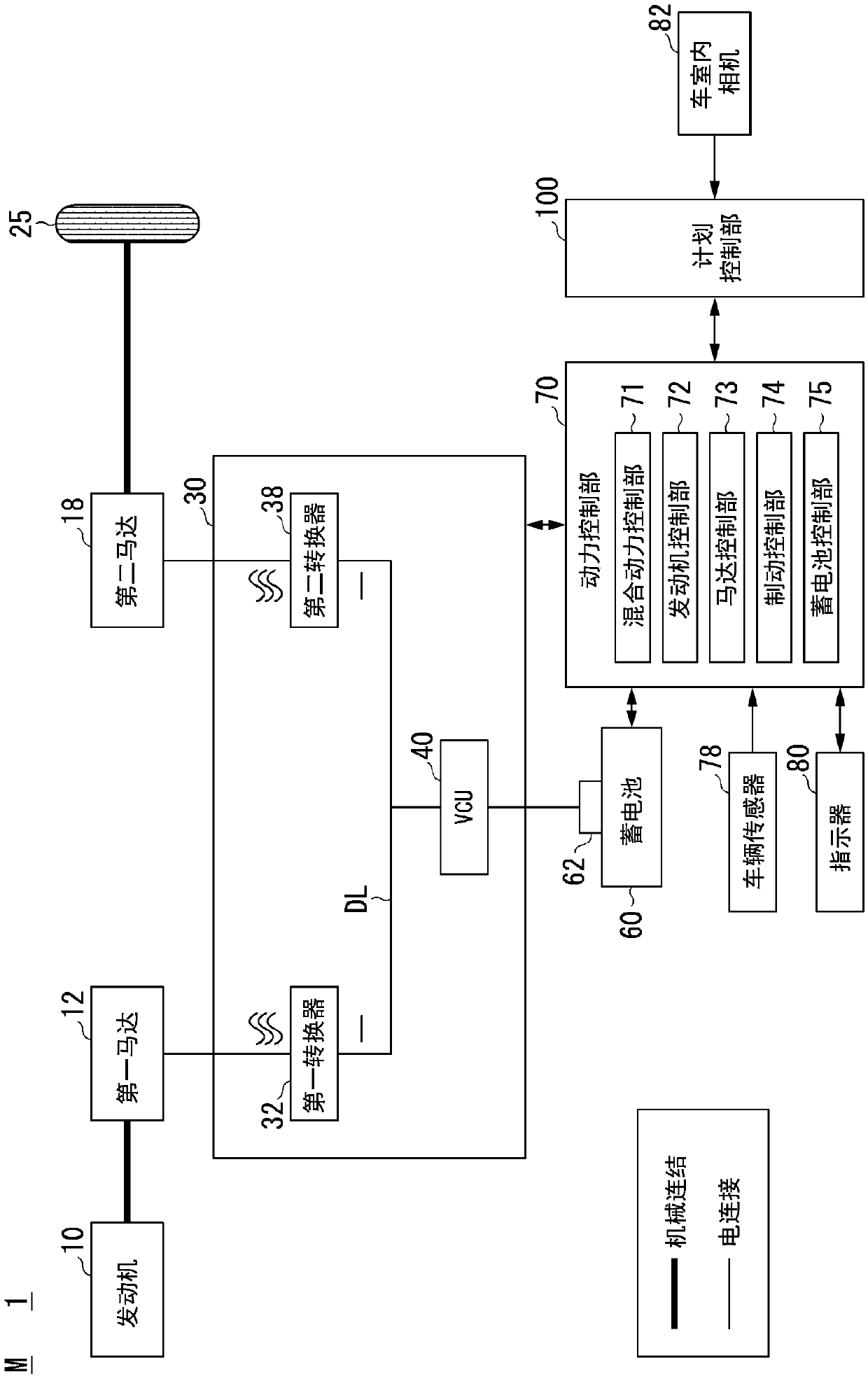

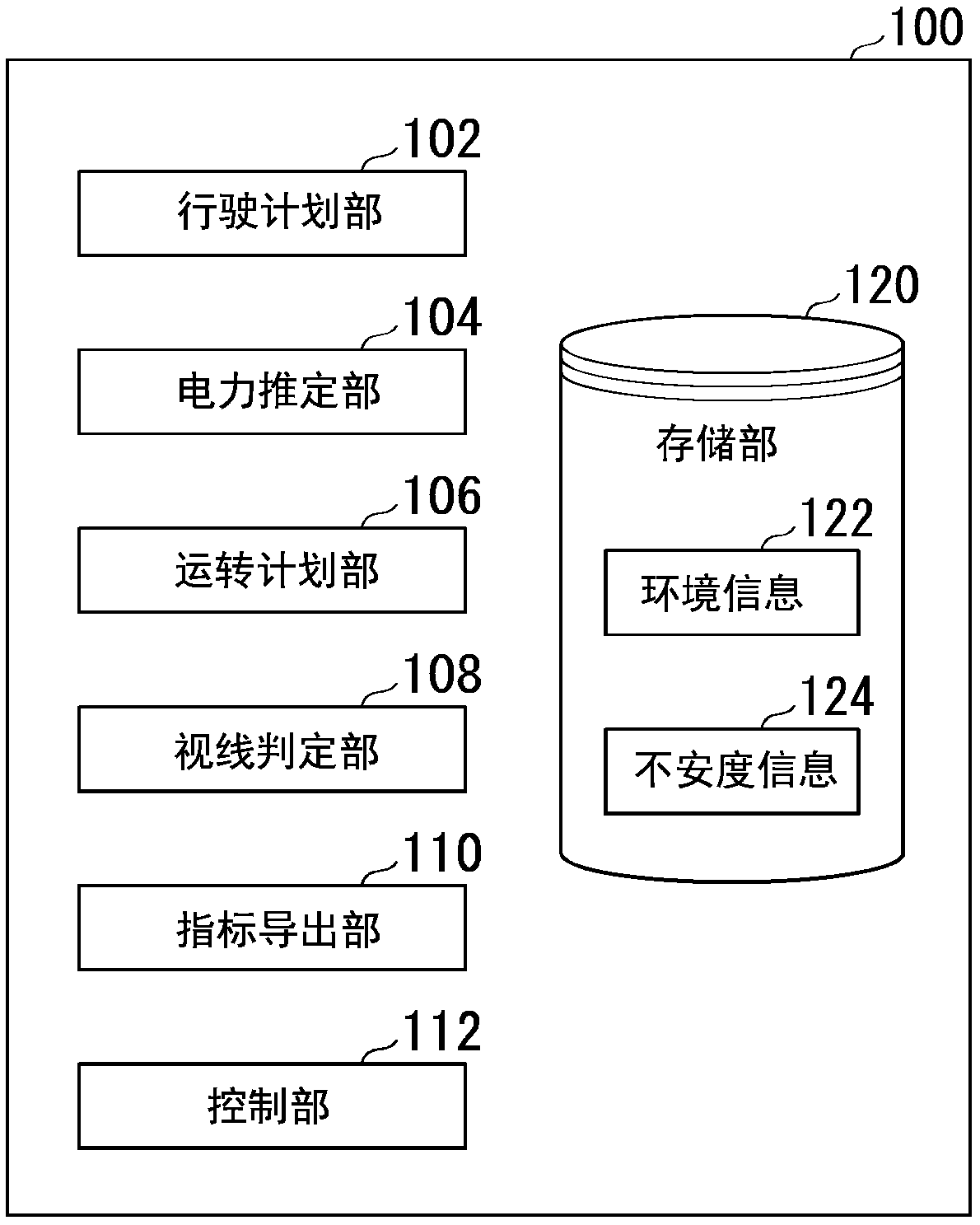

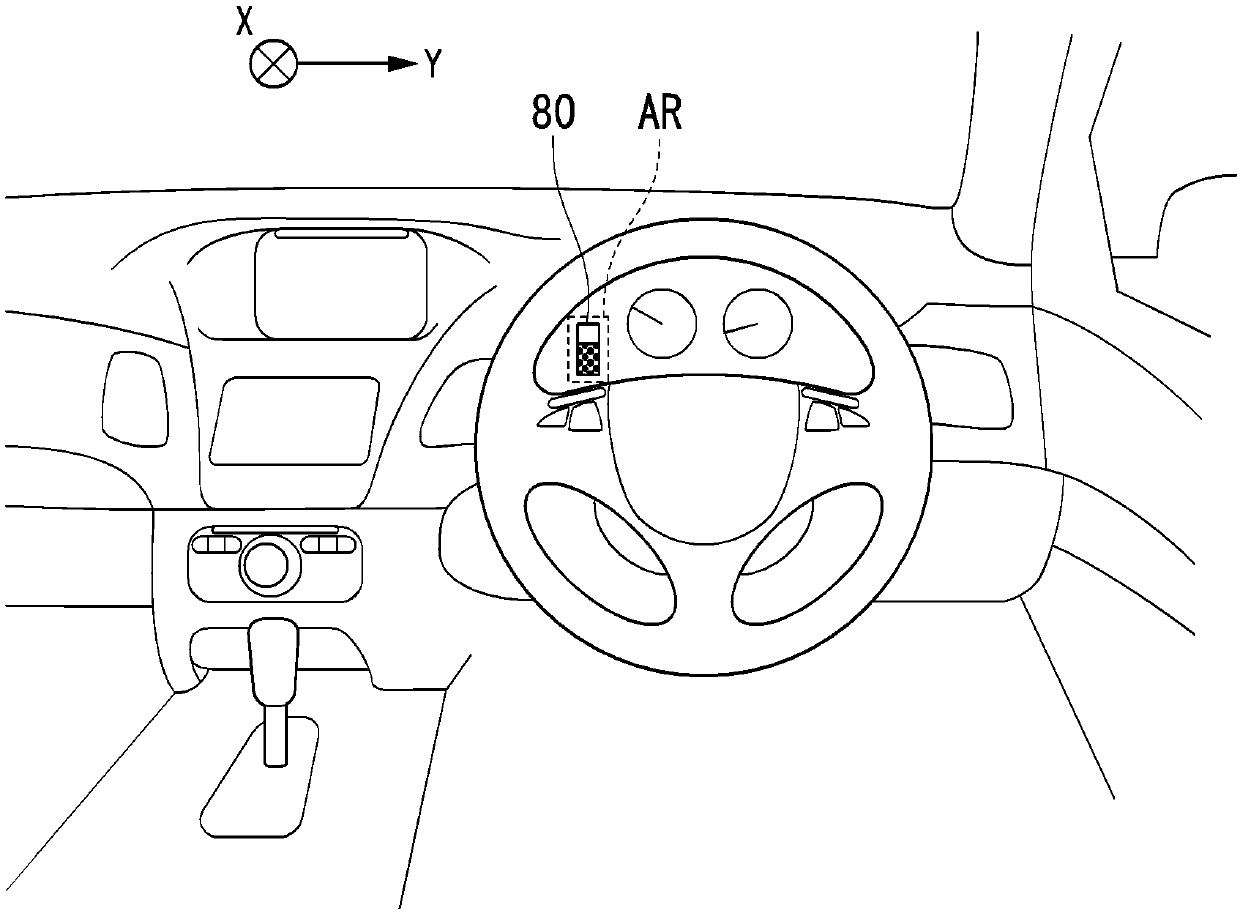

Vehicle control system, vehicle control method, and storage medium

ActiveCN109878506ARestorationAlleviate uneasinessHybrid vehiclesBatteries circuit arrangementsDrive wheelControl system

Owner:HONDA MOTOR CO LTD

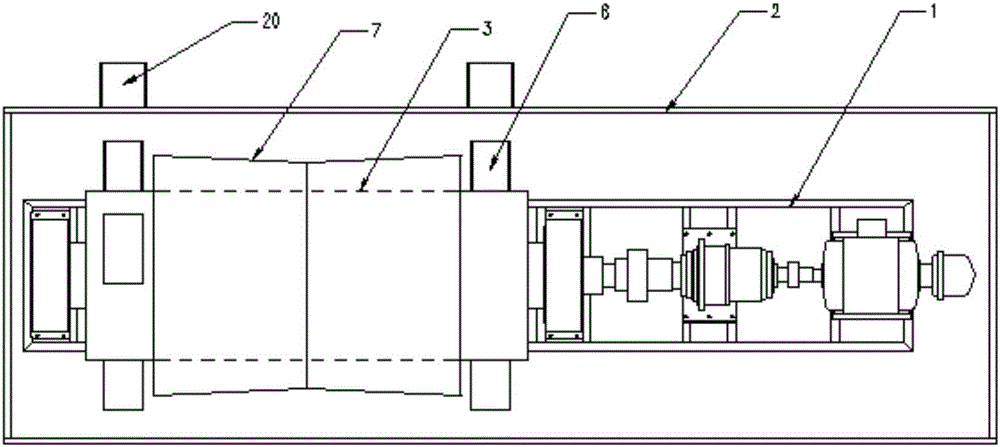

Energy-saving and environment-friendly rolling sand making machine

ActiveCN106391213ASmooth dischargeAvoid normal operationGrain treatmentsEnergy consumptionLarge particle

The invention belongs to the field of rolling equipment and particularly relates to an energy-saving and environment-friendly rolling sand making machine. The energy-saving and environment-friendly rolling sand making machine comprises a rack, a cylinder and a driving device; a lining plate and rolling media are arranged in the cylinder; each of two ends of the cylinder is provided with feeding buckets; sand discharging holes are formed in the middle of the cylinder; and a screen is arranged outside the cylinder, is arranged along the circumference of the cylinder, is opened at two ends and is connected with the cylinder through connecting columns. Materials are fed from two ends of the rolling sand making machine and are discharged from the middle of the rolling sand making machine, so that the processing efficiency is greatly increased; in addition, the materials are more smoothly discharged, so that the blocking phenomenon is not easily caused, the condition that qualified materials operate in the cylinder for a long term can be avoided, the energy consumption of equipment is reduced, and the production continuity is improved; meanwhile, the screen is mounted outside the cylinder, and rolling and screening are simultaneously performed, so that the equipment investment is reduced; and the rolled materials are screened in a classifying way, and the materials with relatively large particles return to a feeding chute, so that self-closed cycle is realized, and the automation capacity of the equipment is improved.

Owner:樊日宏 +2

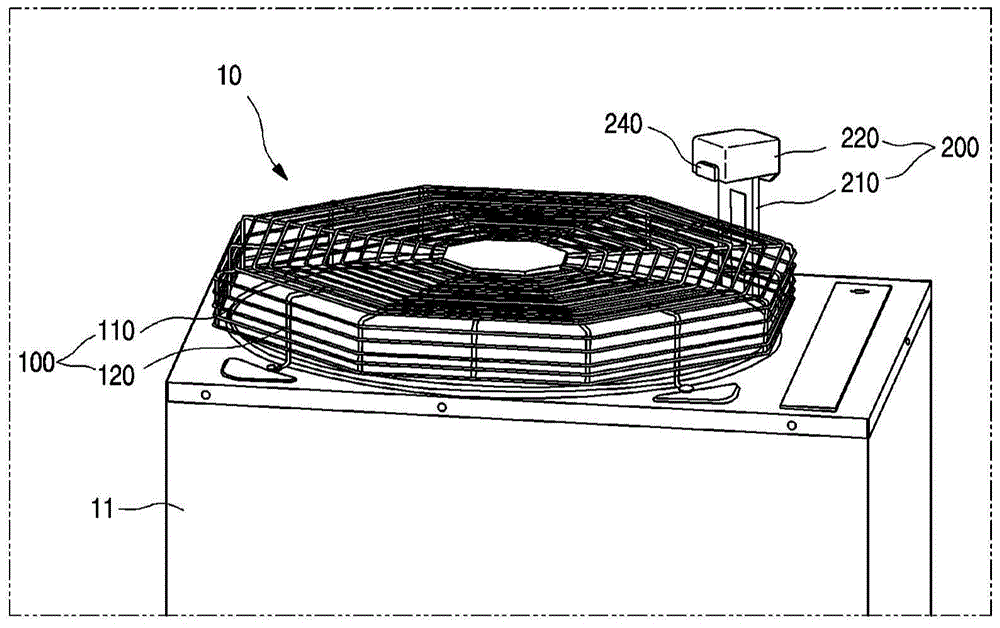

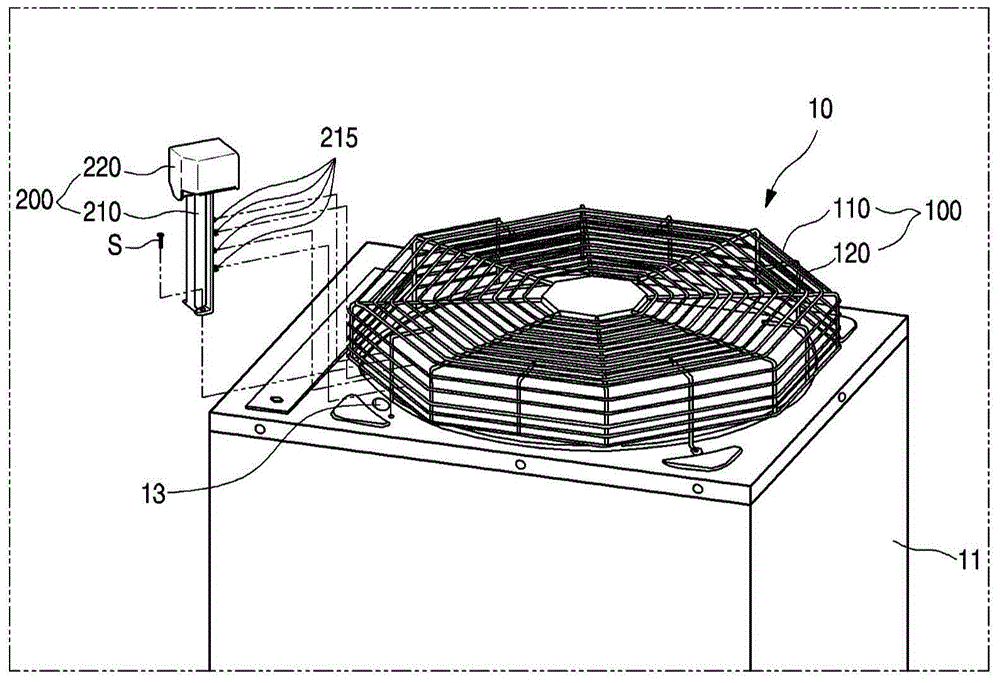

Air conditioner and method for controlling the same

ActiveCN105091212AEasy to fixAvoid damageMechanical apparatusSpace heating and ventilation safety systemsElectrical and Electronics engineeringSnow

Provided are an air conditioner and a method for controlling the same. The air conditioner has a structure in which a snowfall detection device is fixed to a grill and a case, and an amount of snow accumulated on the grill is detected in a noncontact manner to control an operation of the air conditioner. Thus, the snowfall may be more stably and reliably detected, and also the air conditioner may more stably and reliably operate.

Owner:LG ELECTRONICS INC

Biologic protein feed and preparation method thereof

The invention discloses a biologic protein feed used for feeding livestock and a preparation method thereof. The biologic protein feed is prepared from 89-95 parts by weight of feed for livestock, 5-10 parts by weight of mixed bacterial suspension and 0.01-1 part by weight of Chinese medicinal herb condiment; and the preparation method thereof comprises the following steps of: 1) preparing activated bacterial suspension; 2) preparing the mixed bacterial suspension; 3) preparing the Chinese medicinal herb condiment; and 4) preparing the finished product. The biologic protein feed used for feeding livestock can prevent various diseases, improve reproduction rate and survival rate of livestock and enhance the quality and yield of livestock products; green, healthy and safe products are produced, and adverse effects of mould and harmful materials in the feed on livestock can be eliminated in use. The biologic protein feed disclosed by the invention has the advantages of low cost and stable performance, is convenient to use and is safe and reliable; moreover, the preparation method is simple.

Owner:王克洲 +2

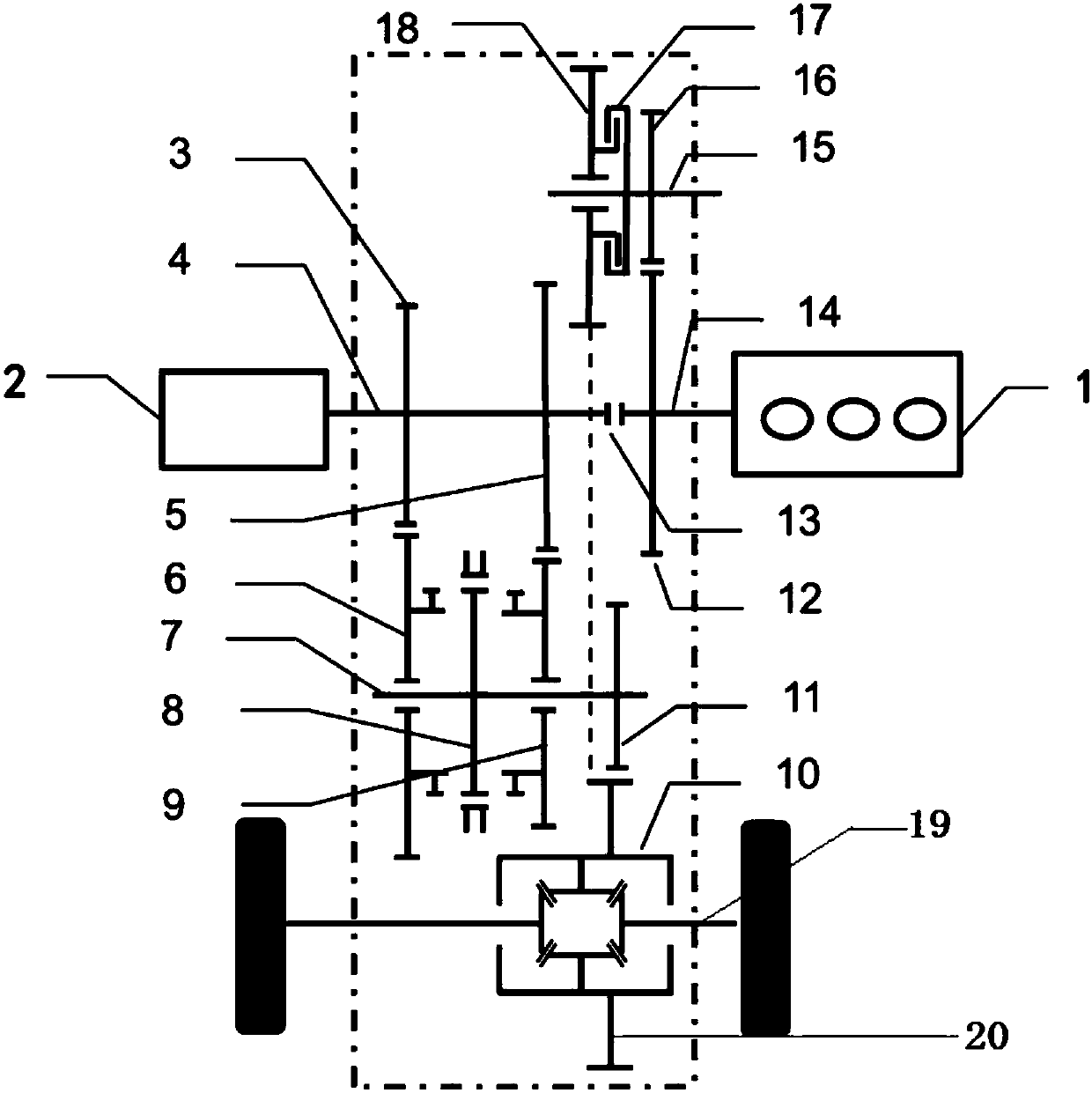

Multimode power transmission structure of hybrid electric vehicle

ActiveCN107554274AAvoid normal operationImprove fuel economyHybrid vehiclesGas pressure propulsion mountingGear driveReduction drive

The invention discloses a multimode power transmission structure of a hybrid electric vehicle. A first clutch is connected between a motor input shaft and an engine input shaft; an engine input gear is fixedly connected to the engine input shaft, a reducer gear is fixedly connected to a main reducer, a first-gear driving gear and a second-gear driving gear are fixedly connected to the motor inputshaft, the first-gear driving gear and the second-gear driving gear transmits power to the reducer gear through an engine output gear set, and an engine input gear transmits power to the reducer gearthrough an engine output gear set. The mass of a power assembly and cost of the power assembly are reduced by canceling an electric generator; both the engine and the electric generator can work in ahigh efficiency interval; the ability of starting, accelerating and climbing a slope of the vehicle is improved, and the maximum rotating speed of a motor is reduced, so that cost of the motor is reduced; no power interrupt occurs on the engine and the motor in the gear shifting process; and the transmission device is small in size, compact in whole structure, and convenient to arrange.

Owner:DONGFENG MOTOR CORP HUBEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com