Energy-saving and environment-friendly rolling sand making machine

An energy-saving and environment-friendly sand making machine technology, which is applied in the direction of grain processing, etc., can solve the problems of uneven material size, easy clogging, and unsmooth discharge, and achieve the effect of smooth material discharge, not easy to clog, and lower cylinder speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments.

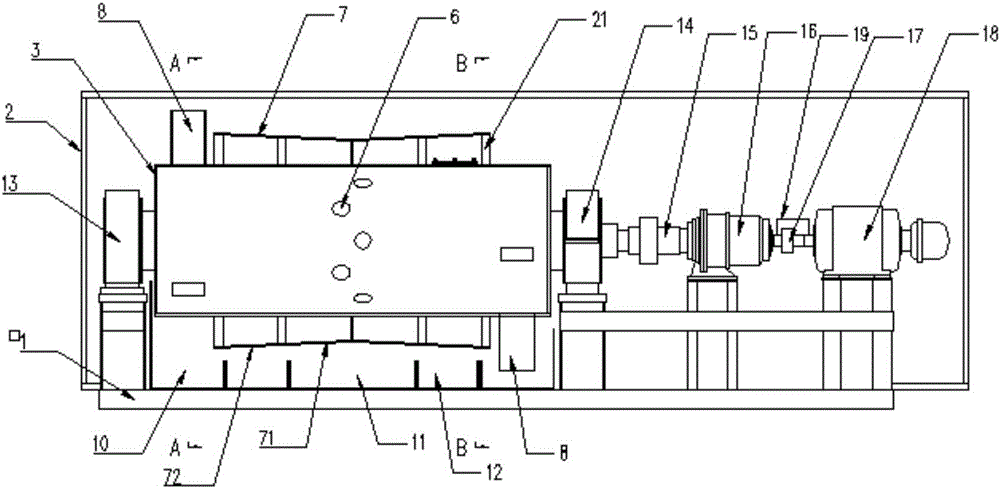

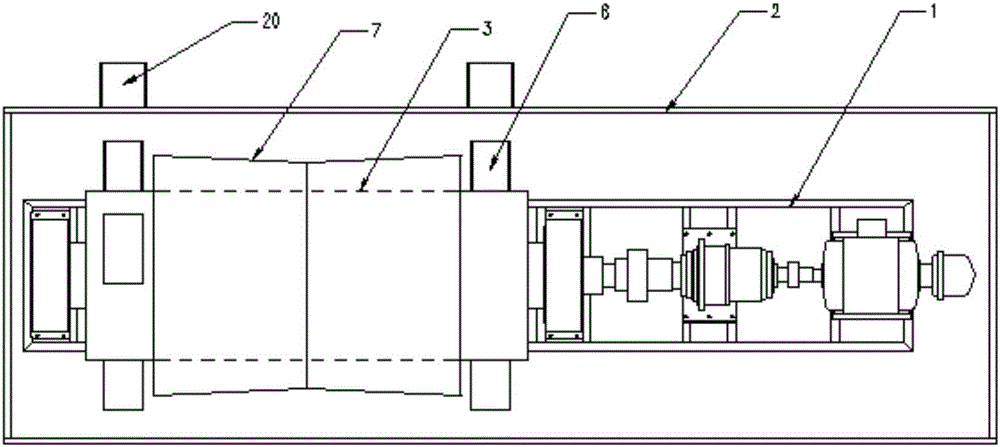

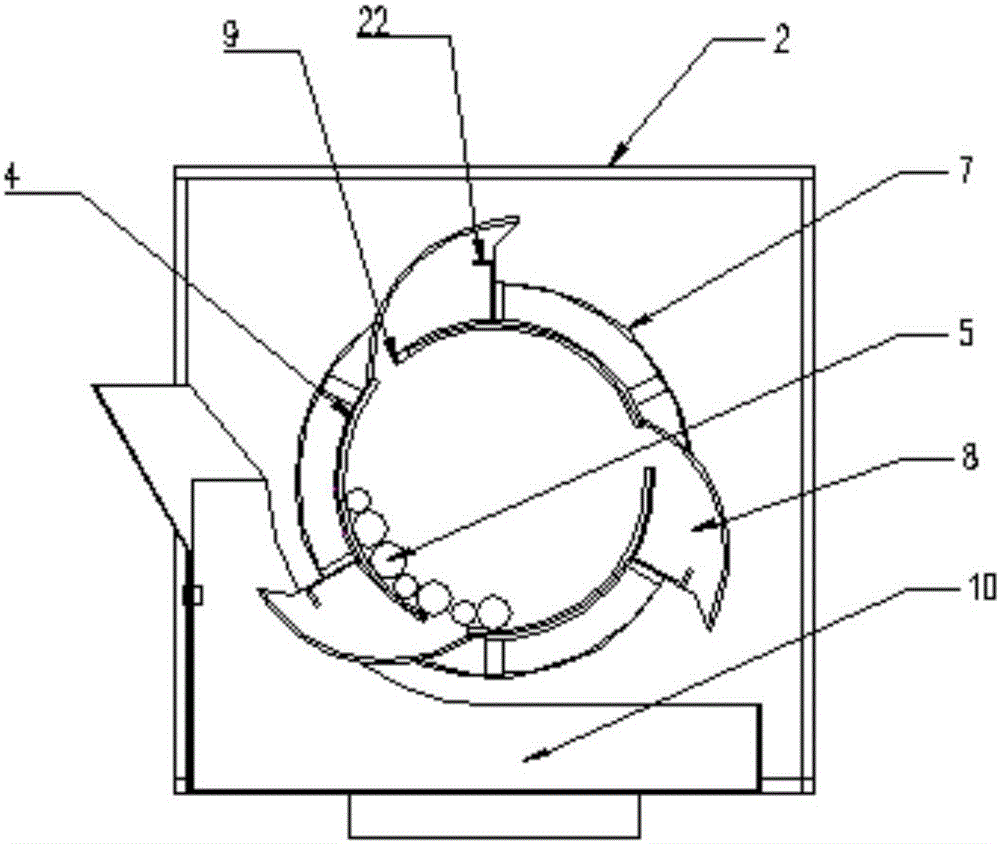

[0025] An energy-saving and environmentally friendly rolling sand making machine, comprising a frame 1, an outer frame 2, a cylinder 3 and a driving device, the cylinder 3 is provided with a lining plate 4 and a rolling medium 5, and the rolling medium 5 for gangbang. Both ends of the cylinder body 3 are provided with feeding buckets 8 , the middle of the cylinder body 3 is provided with a sand discharge hole 6 , and a screen 7 is provided outside the cylinder body 3 .

[0026] The feeding bucket 8 is provided with an L-shaped baffle plate 22 , and the cylindrical body 3 where the feeding bucket 8 is connected with the cylindrical body 3 is provided with a feeding port 9 . There are three feeding buckets 8 at both ends of the cylinder body 3 , which are distributed evenly along the outer wall of the cylinder body 3 , and the feeding buckets 8 at the left and right ends are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com