Patents

Literature

294results about How to "Not prone to clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

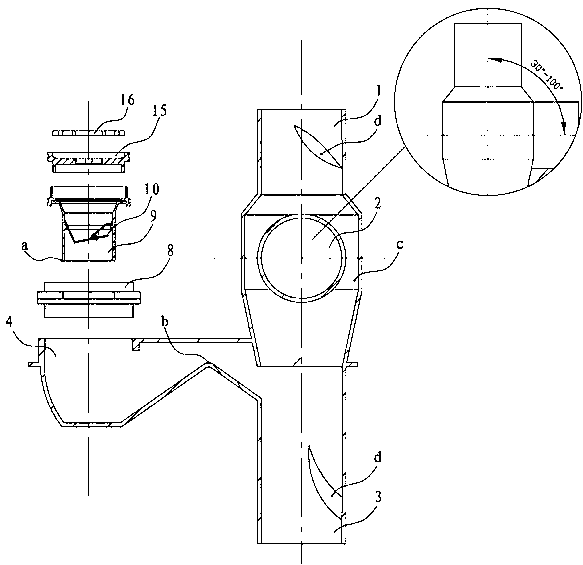

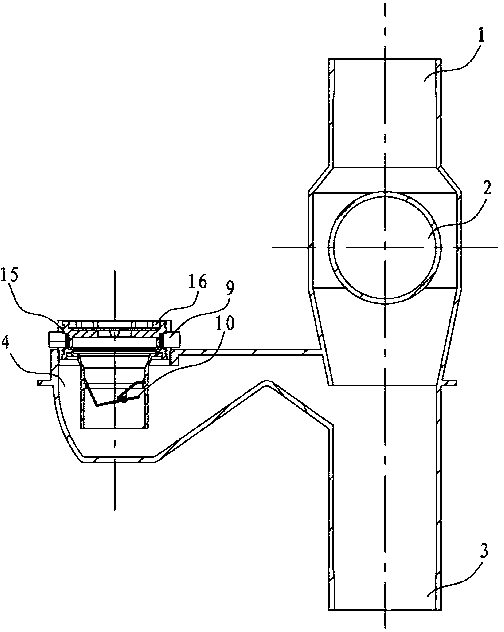

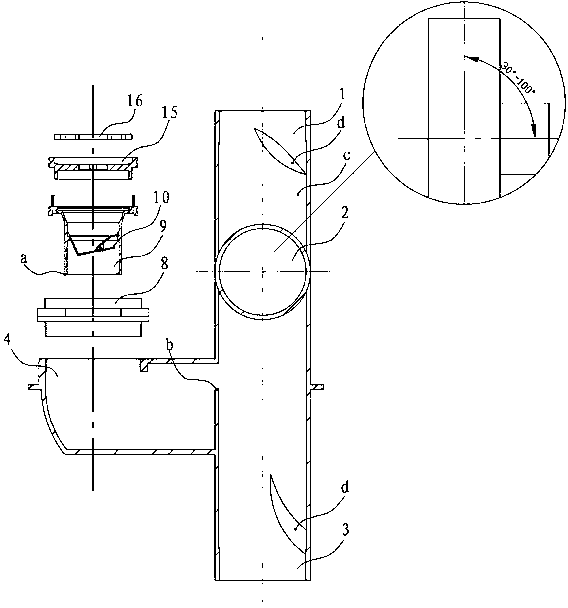

Same floor draining joint for building

InactiveCN102839724AIncrease drainage flowTo achieve the separation effectDomestic plumbingToiletCivil engineering

The invention relates to a same floor draining joint for a building, in particular to a same floor draining joint for a toilet, which consists of an upper vertical pipe draining port, a lower vertical pipe draining port and at least two transverse pipe draining ports; the upper vertical pipe draining port is communicated with the upper end and the lower end of the lower vertical pipe draining port; the at least two transverse pipe draining ports are staggered in position and are arranged between the upper vertical pipe draining port and the lower vertical pipe draining port; the orientation of the inlet of at least one of the transverse pipe draining ports is equal to or nearly equal to the orientation of the upper vertical pipe draining port, and the orientation of the inlet of at least one of the transverse pipe draining ports forms an included angle of 30-100 degrees with the orientation of the upper vertical pipe draining port. The same floor draining joint is rational and scientific in structure, and is capable of realizing the same floor draining and the same floor maintenance when the draining joint is adopted in the same floor draining of the non-falling plate or falling plate; the draining is more safe; the water is not easy to accumulate in the falling plate layer even the way of the falling plate is adopted, and the accumulated water is safely and completely discharged, so as to avoid the foreign smell in the room.

Owner:KUNMING QUNZHIYING TECH

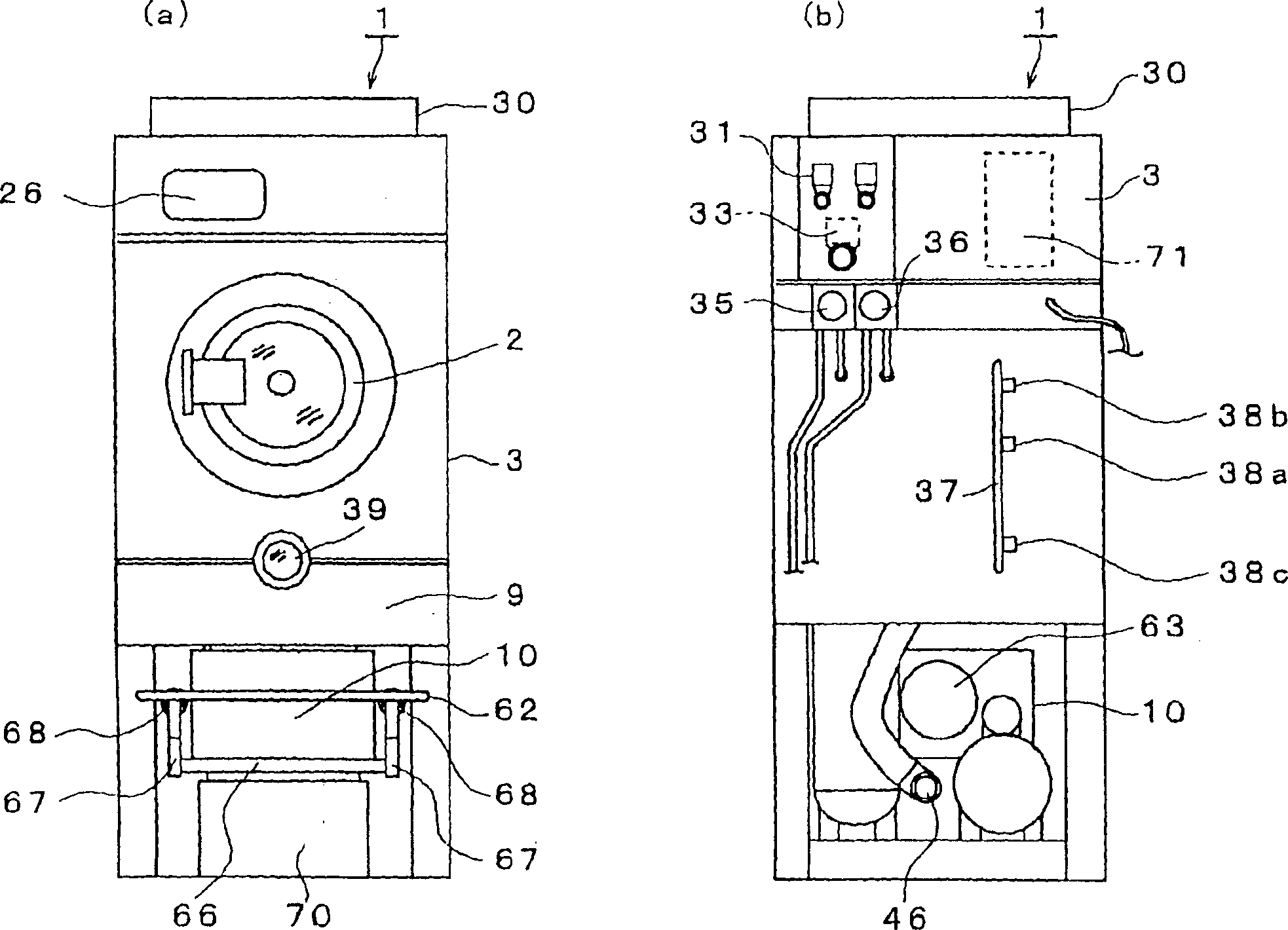

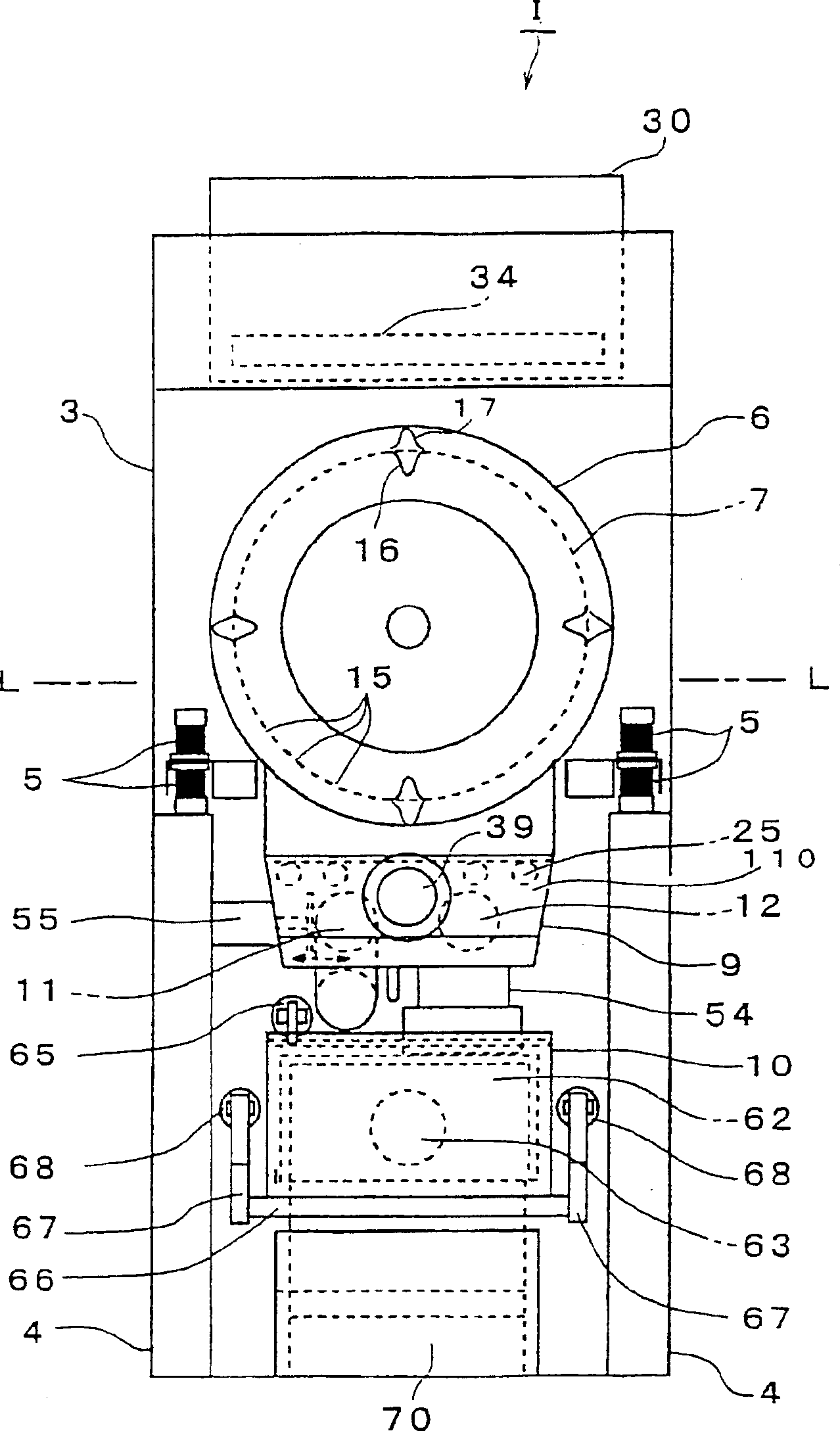

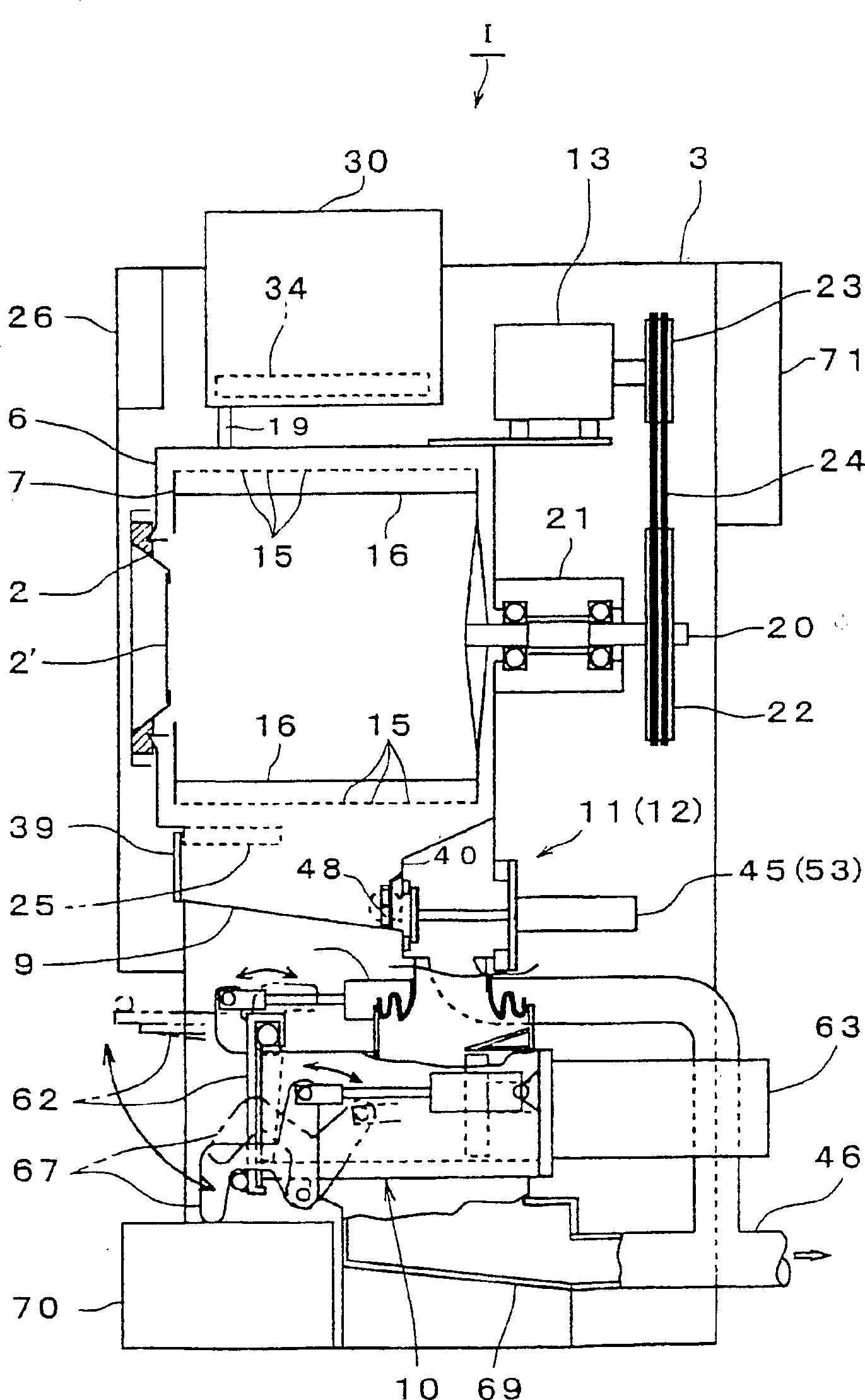

Used paper diaper processing method and used paper diaper processing device

InactiveCN1525890AImprove cleaning efficiencyEfficient separationSolid waste disposalPlastic recyclingPulp and paper industryAbsorbent material

Owner:NIPPON ASAHI KIKO HANBAI

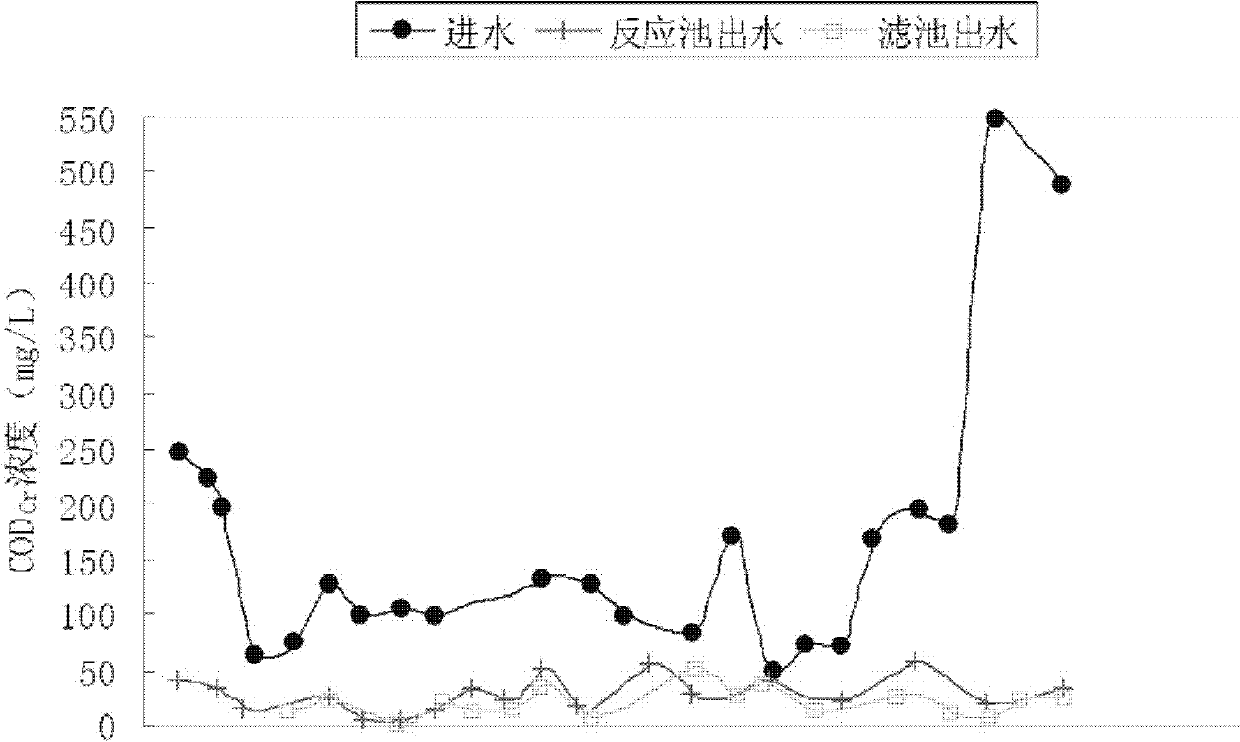

Aeration type sewage treatment device and method

InactiveCN106698823AStrong storageAvoid cloggingTreatment using aerobic processesSpecific water treatment objectivesHazardous substanceSewage

The invention mainly discloses an aeration type sewage treatment device and method. The technical scheme is as follows: the device comprises a primary sedimentation tank, a biodegradation tank and a disinfection tank, wherein a filtering device is arranged in the primary sedimentation tank and comprises a filtering plate and a collection box; the biodegradation tank comprises a facultative tank, an aerobic tank and a clarifying tank in mutual connection; a biological packing frame is arranged in the facultative tank; an aeration device is arranged in the aerobic tank and comprises a lifting cylinder, a spiral aerator and a rotating disk; the spiral aerator is mounted on the upper side of the lifting cylinder; a rotating shaft of the spiral aerator penetrates the rotating disk; and aerobic microbial packing is arranged on the rotating disk. Particle impurities of sewage are removed by the primary sedimentation tank, and then the sewage enters the biodegradation tank for reacting and finally is subjected to disinfection treatment. In the invention, through multi-stage treatment of the sewage, harmful substances in the sewage are separated and degraded better, the blocking phenomenon does not happen frequently, the treatment efficiency is high while the effect is good, and the treated sewage reaches the national discharge standard.

Owner:ZHEJIANG BUSINESS TECH INST

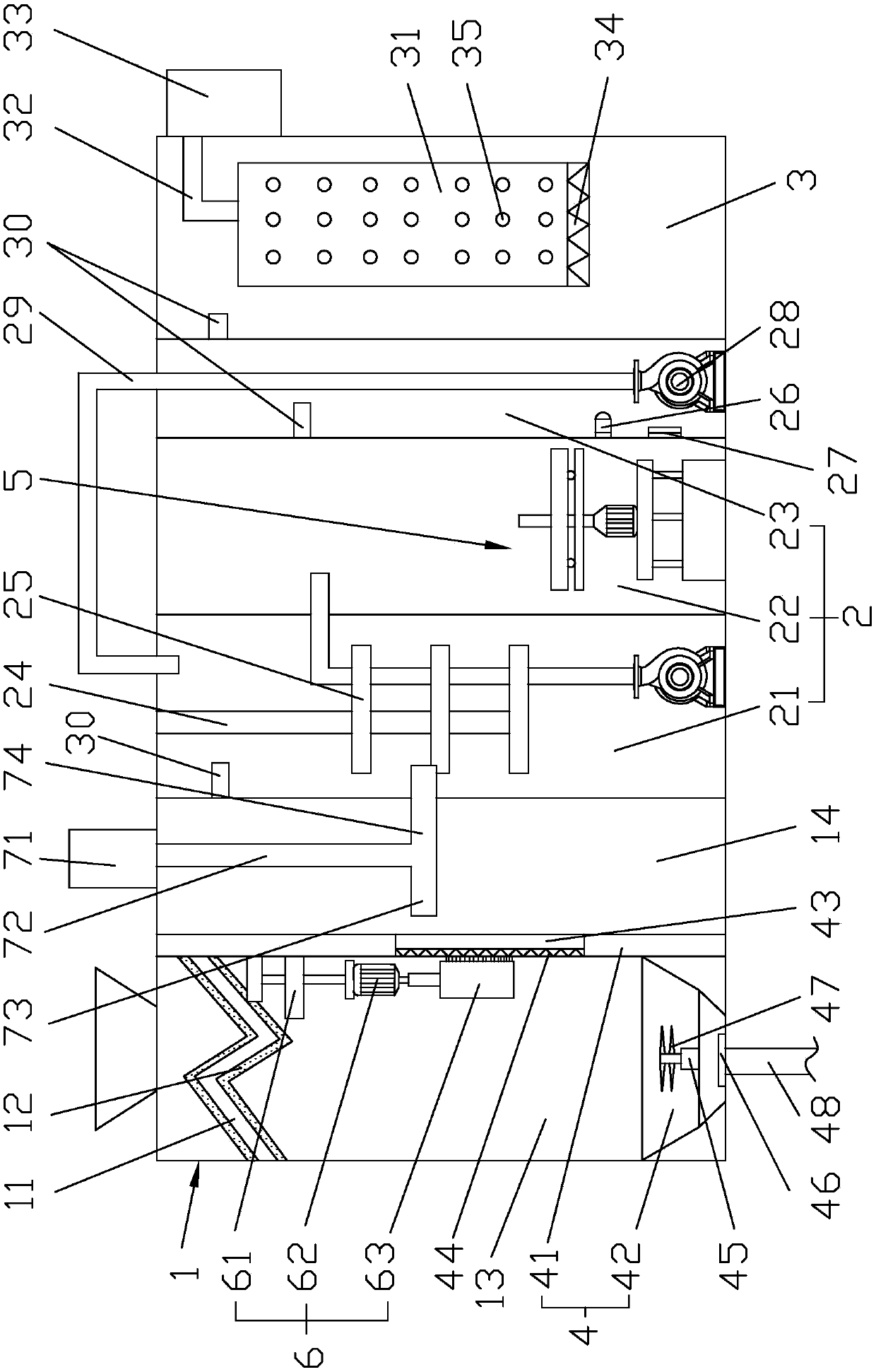

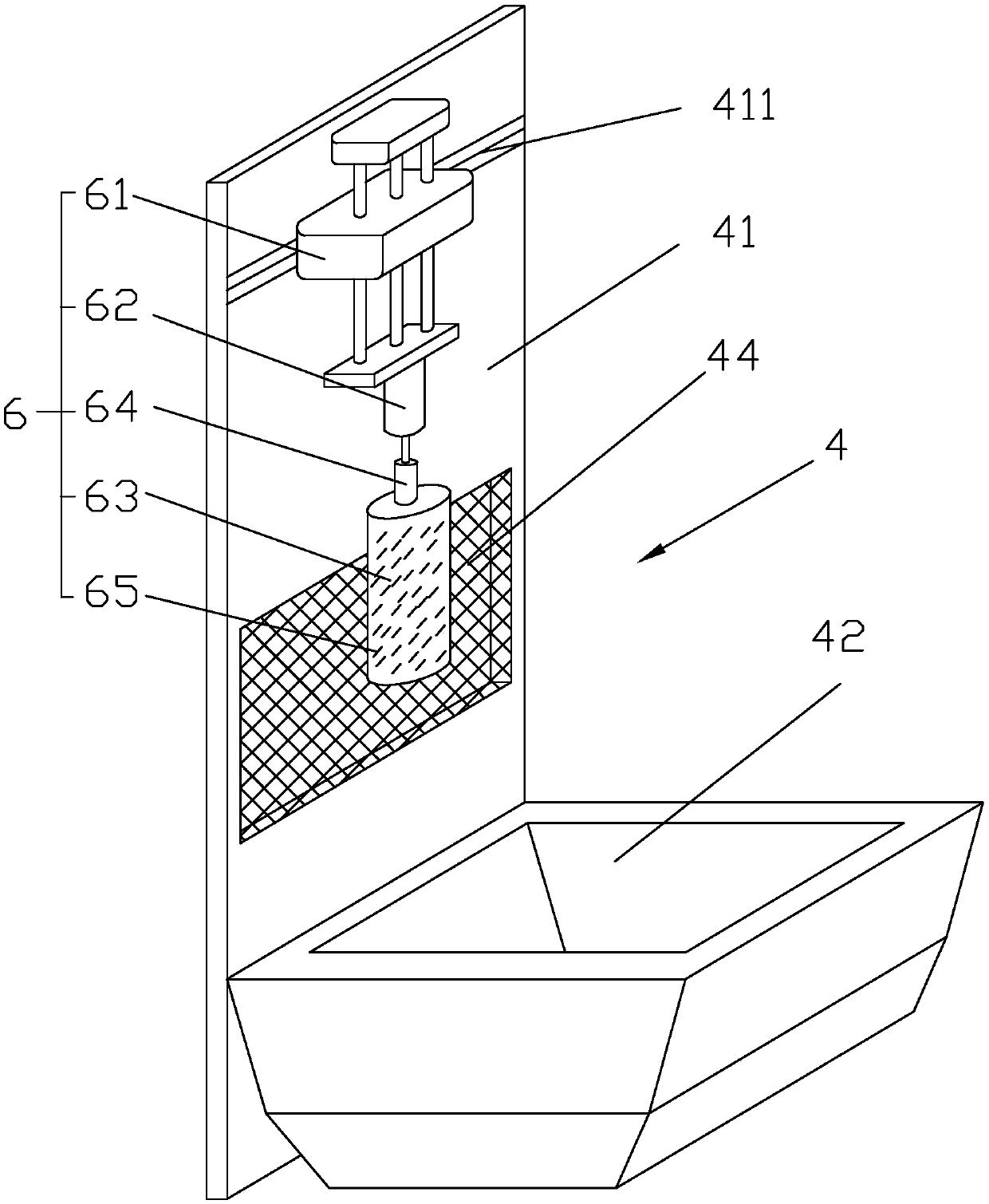

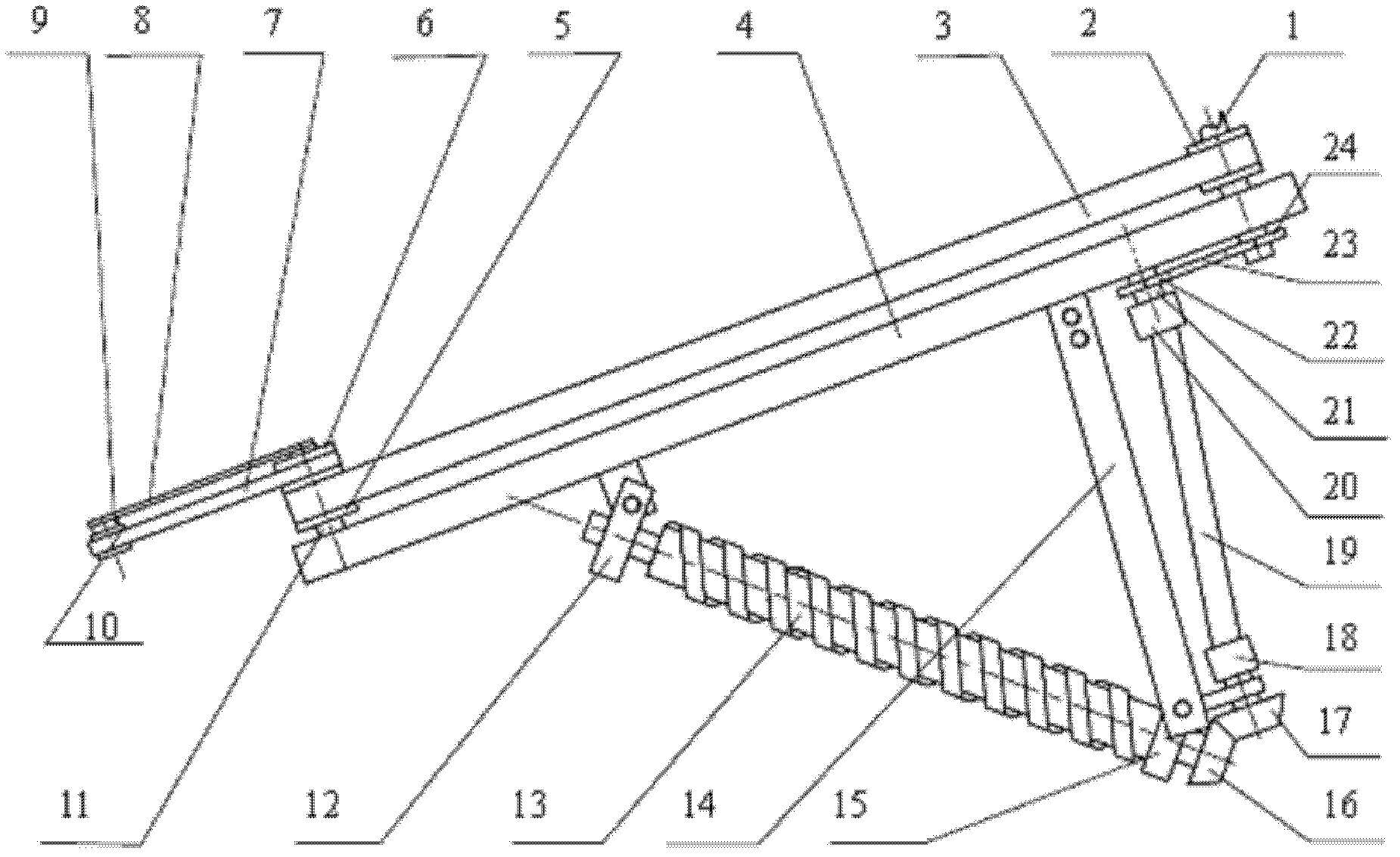

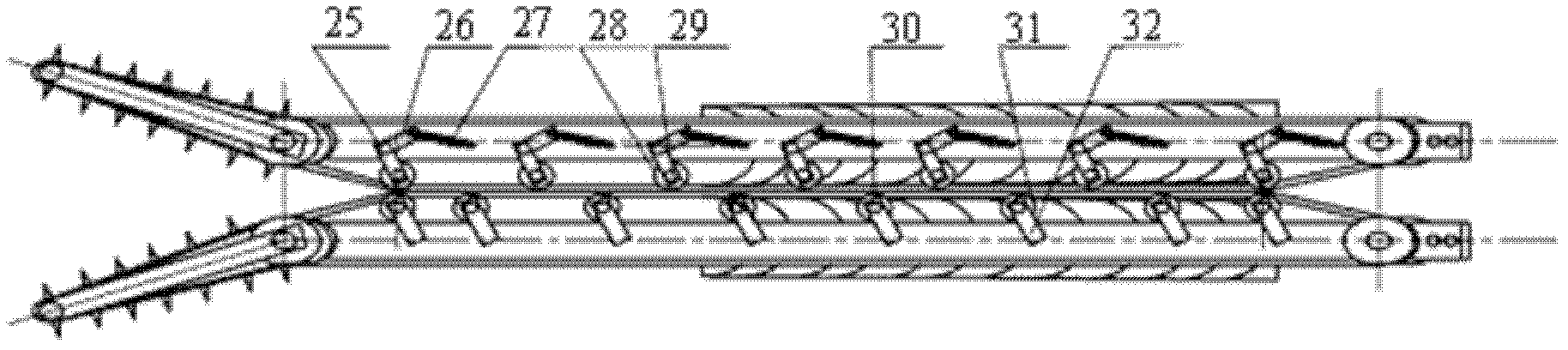

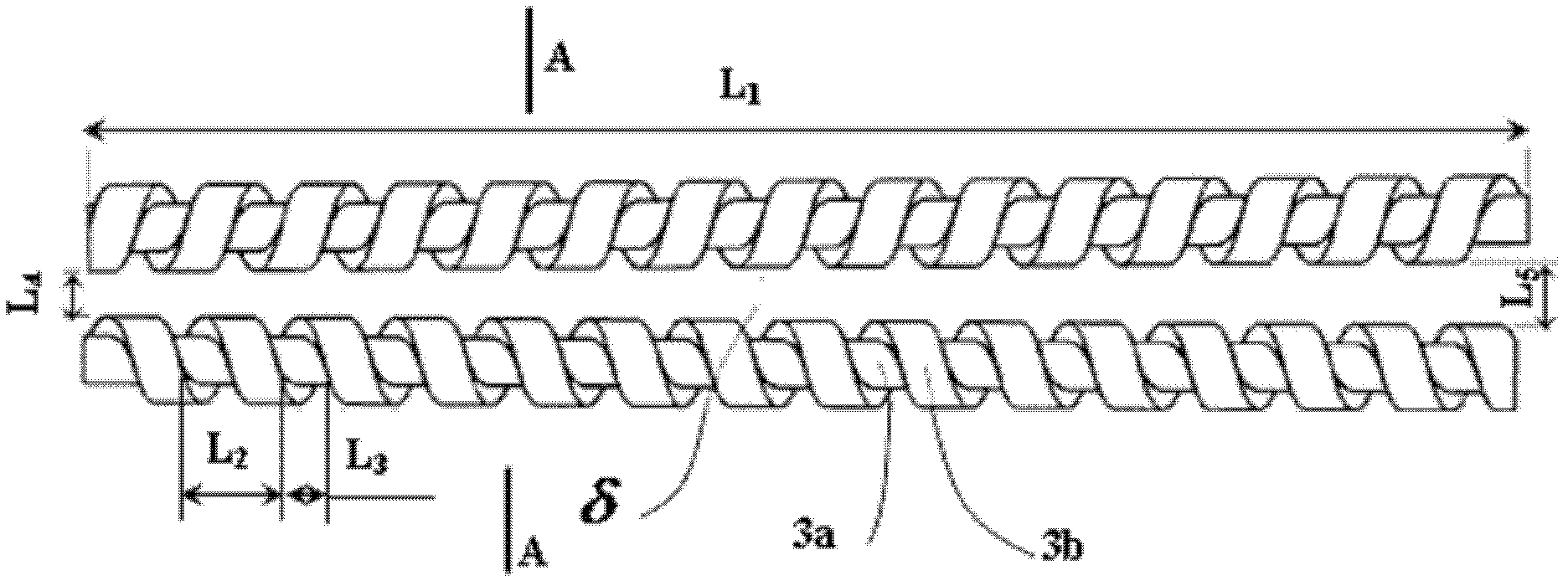

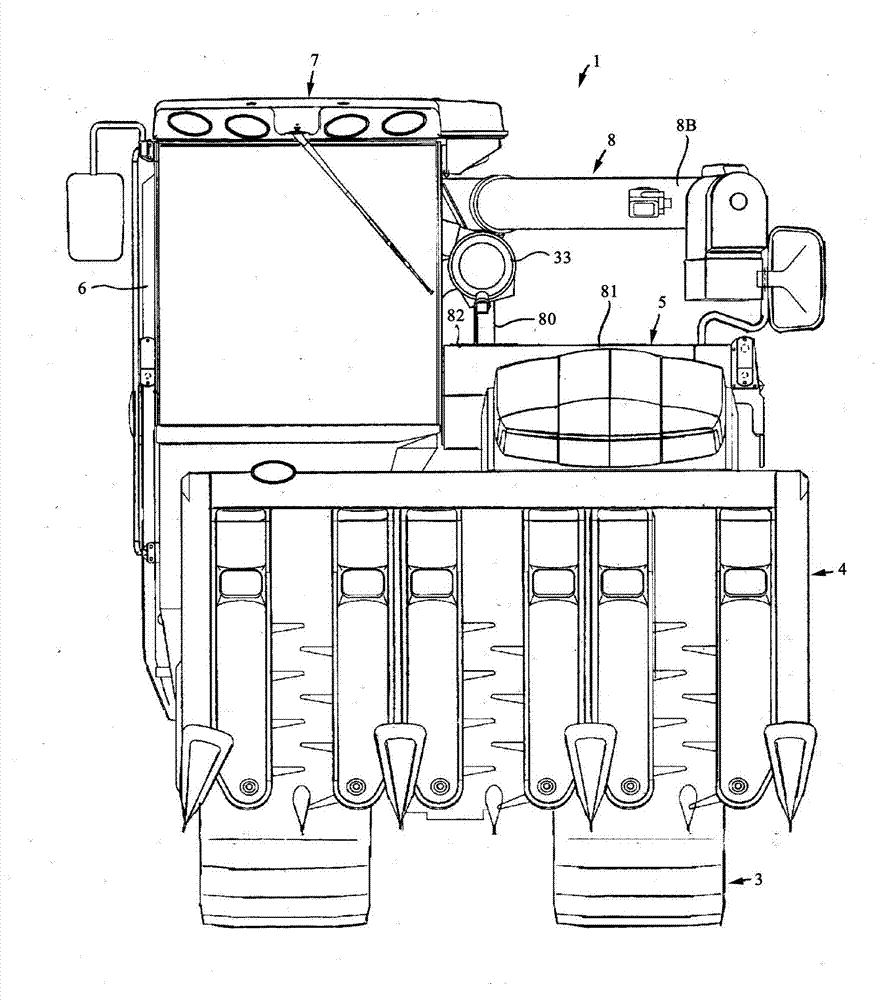

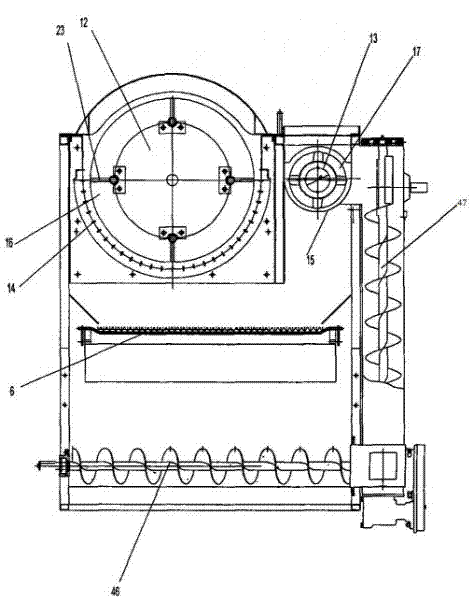

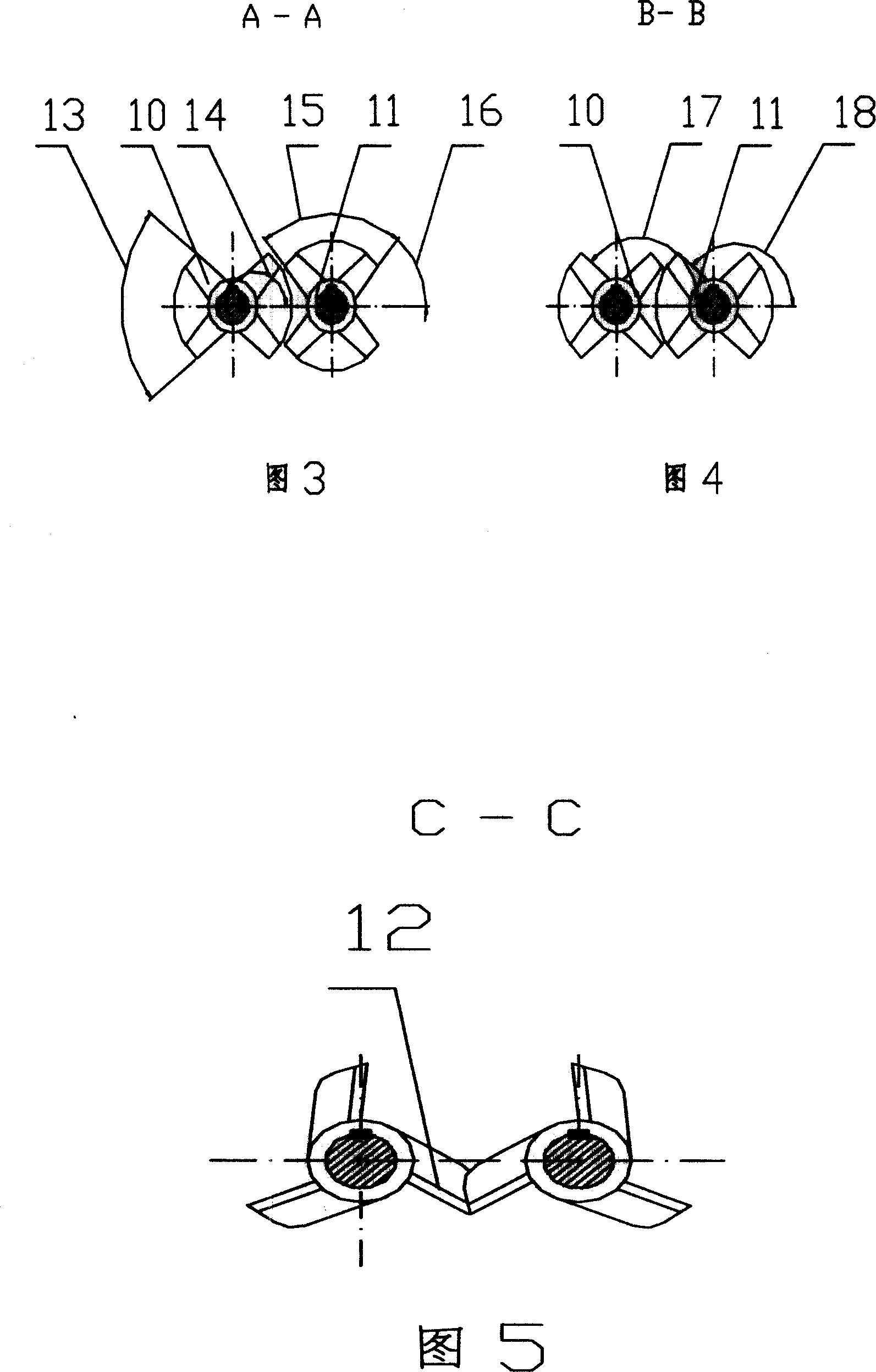

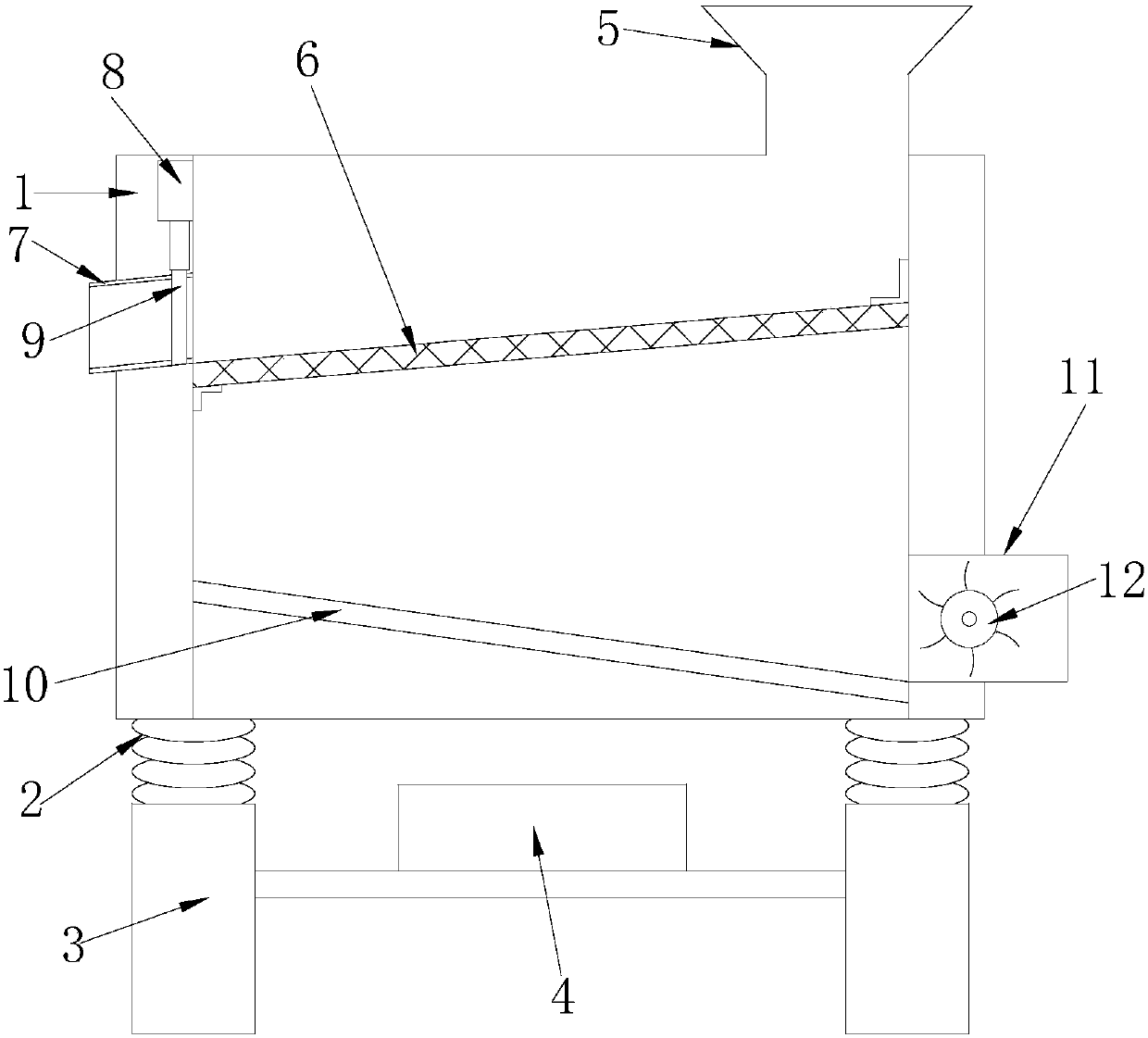

Corn bionic picker and picking method

The invention discloses a corn bionic picker and a picking method and relates to a corn picker suitable to arrange on a corn harvester and a corn picking method. The corn bionic picker comprises a rack (4), a clamping conveying mechanism and a picking mechanism. The rack (4) is fixedly connected with a rack of a harvesting mechanism and is bilaterally and symmetrically arranged in an inclined state with a low front part and a high rear part relative to the ground. The clamping conveying mechanism is formed by a pair of adjacent closed-loop conveying belts (3) arranged in parallel above the rack (4) and a pair of closed-loop grain lifting guide tapes (7) which are arranged at the front ends of the conveying belts (3) and extend towards both sides. The picking mechanism is formed by a pair of picking rollers (13) which are arranged below the rack (4), are obliquely crossed with the rack (4) and are provided with high front ends and low rear ends. A gap between the pair of picking rollers (13) and a gap between the pair of conveying belts (3) are on the same vertical plane. According to the invention, the bending and breaking principle of manually picking corn ears is simulated and the problem of damage to corns, which is caused by the existing stretching and squeezing method, can be fundamentally solved.

Owner:JILIN UNIV

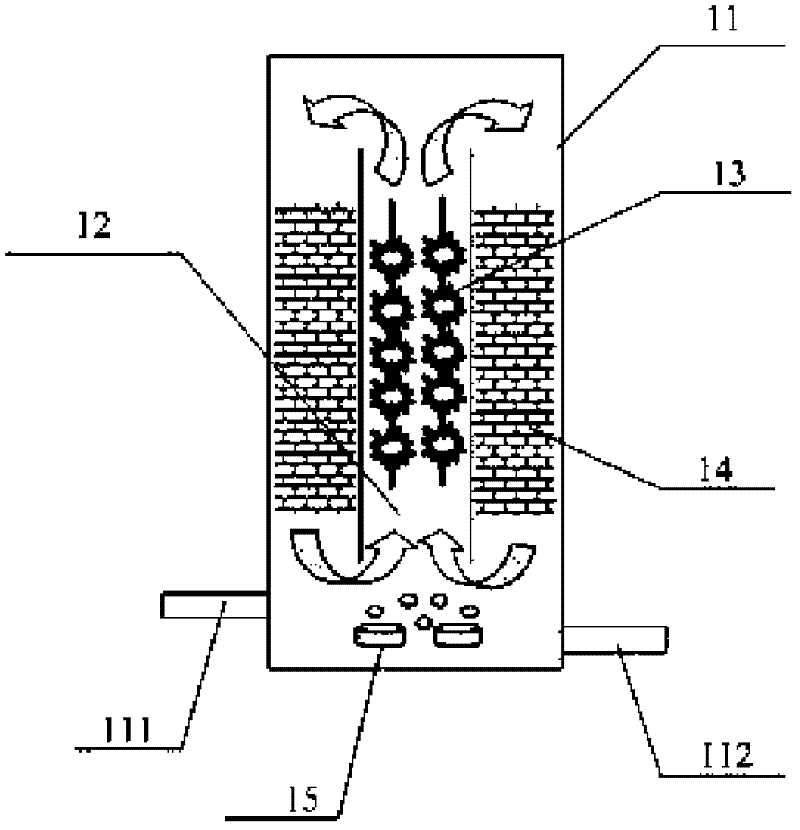

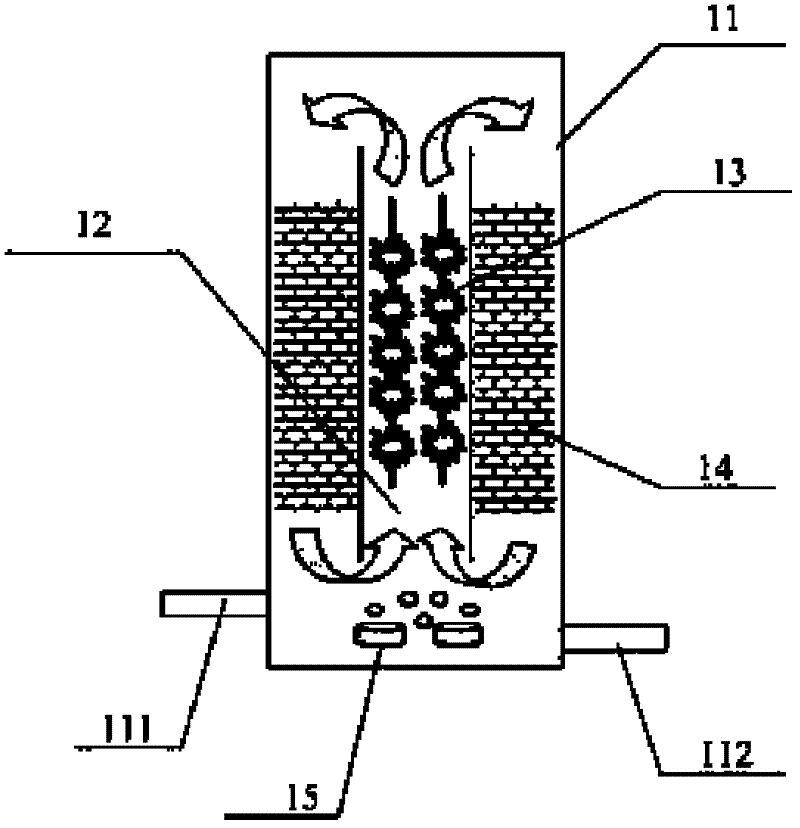

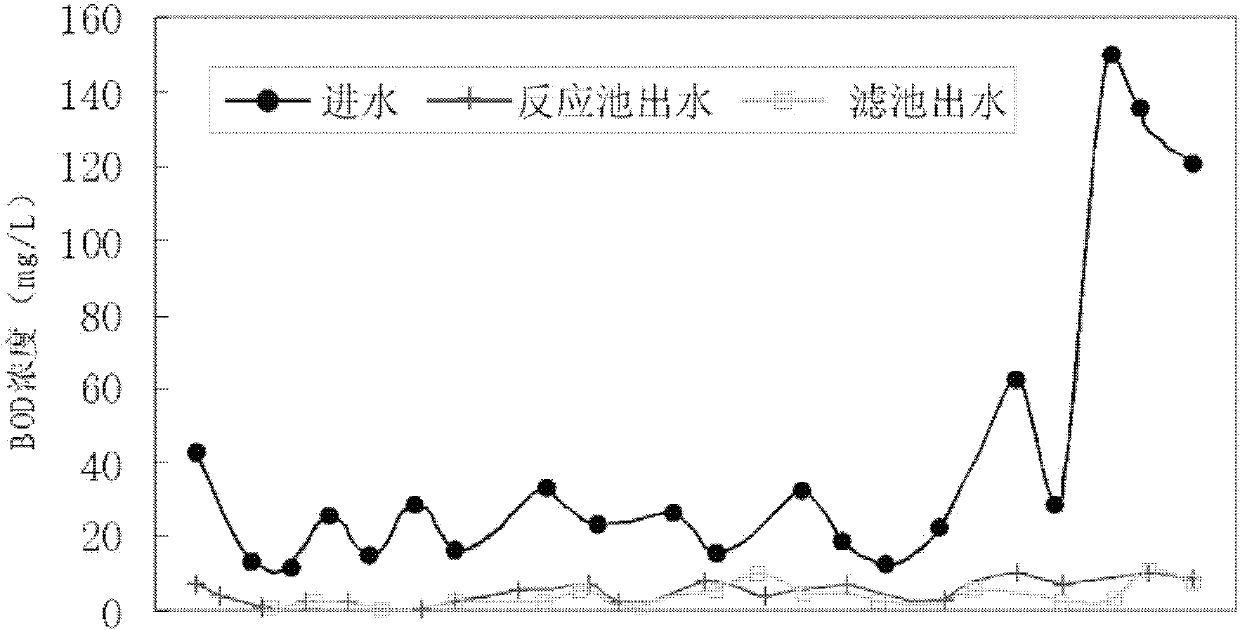

Biomembrane reactor, waste water treating system and method for treating waste water

ActiveCN102225803AReduce pollutant contentNot easy to blockTreatment using aerobic processesSustainable biological treatmentPromotion effectFilter material

The invention provides a biomembrane reactor, which comprises an outer cylinder with a water inlet and a water outlet provided at the bottom part; an inner cylinder arranged in the outer cylinder, two ends of the inner cylinder are communicated with the outer cylinder, the top of the inner cylinder is lower than the top of the outer cylinder; a filling material used for filling a bio-contact oxidation tank of the inner cylinder; a filter material used for filling the biological filter tank between the inner cylinder and the outer cylinder; an aeration apparatus provided at the bottom of the outer cylinder, the aeration apparatus is communicated with the inner cylinder. The invention provides a waste water treating system and a method for treating waste water. The biomembrane reactor provided in the invention has the functions of the bio-contact oxidation tank and the biological filter tank, waste water forms a circulation between the inner cylinder and the outer cylinder under the promotion effect of the aeration apparatus, and waste water passes through the filling material used for bio-contact oxidation tank and the filter material used for biological filter tank for a purifyingprocess, thereby the effect of treating waste water can be improved.

Owner:UNIV OF SCI & TECH OF CHINA

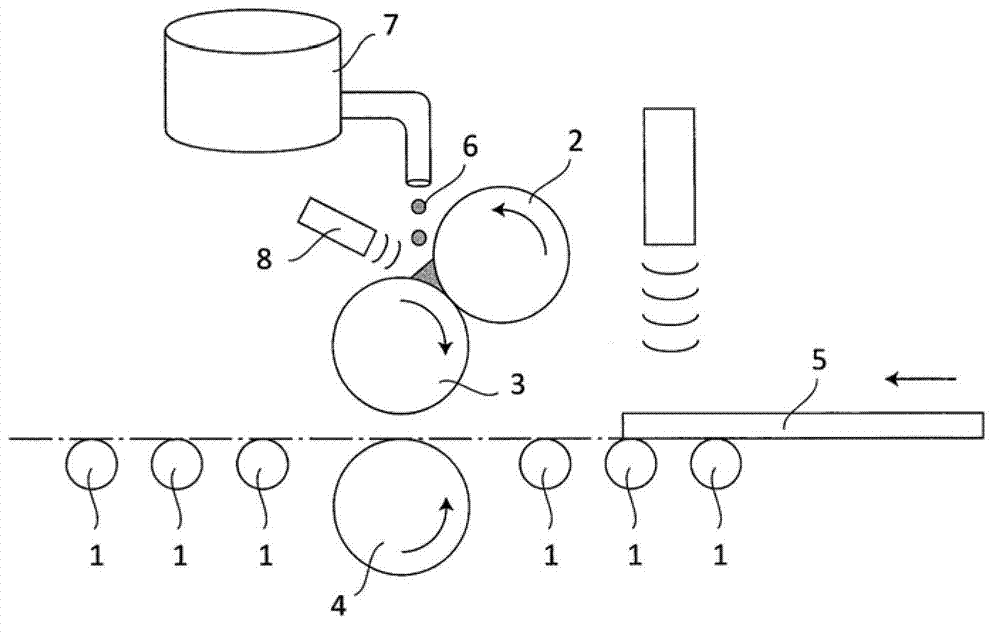

Method for coating material application to substrate and device for coating material application

ActiveCN103203304ACoating operation is easyImprove productivityLiquid surface applicatorsSuperimposed coating processMetallurgyCoating materials

The invention relates to a method for coating a material application to a substrate and a device for coating the material application. In order to thinly, uniformly and highly-efficiently coat the material application to surfaces of single or continuous glass or resin films, sheets and plates, the method and the device are provided. The method comprises providing the material application to a coating roll and then coating the material application to the surfaces of the conveying substrate through rotation of the coating roll, wherein the substrate is single or continuous. In a coating roll and a coating amount control roll in rotary contact with an outer surface of the coating roll, at least the coating amount control roll enables hydrophilic DLC film to form a film on surface of the roll. The coating amount control roll or a scraper is contacted with the coating roll, so as to coat the material application on the outer surface of the coating roll to be uniform and thin; and the outer surface is contacted with the conveying substrate through rotation of the coating roll, thereby coating the uniform and thin material application on the coating roll onto the substrate.

Owner:MIYAKO ROLLER IND

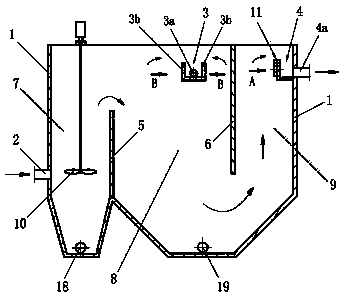

Kitchen wastewater oil-water separation device

ActiveCN103754985AEasy to separateAchieve secondary separationFatty/oily/floating substances removal devicesLiquid separationWater pipeGas separation

The invention relates to a kitchen wastewater oil-water separation device. The shell is provided with a water inlet pipe; a first vertical plate (5) and a second vertical plate (6) are arranged in the shell to sequentially constitute a first oil-water separation region (7), a second oil-water separation region (8) and a water collection region (9); the upper part of the first oil-water separation region is communicated with the upper part of the second oil-water separation region; the lower part of the second oil-water separation region is communicated with the lower part of the water collection region; a stirring component (10) is arranged in the first oil-water separation region, an oil collection tank is arranged on the upper part of the second oil-water separation region, and the upper part of the water collection region is provided with a water collection tank; side plates of the water collection tank are weir plate components (11) capable of adjusting waterflow liquid level; mobile weir plates (13) in the weir plate components (11) can move horizontally along fixed weir plates (12); the mobile weir plates can be moved to adjust the waterflow liquid level; and a sloping plate component (17) is arranged in the second oil-water separation region. The kitchen wastewater oil-water separation device has primary and secondary oil-water separation, has the characteristics of simple structure and high operation stability, can lower the manufacturing cost and is convenient for maintenance and cleaning.

Owner:CHINA MACHINERY INT ENG DESIGN & RES INST

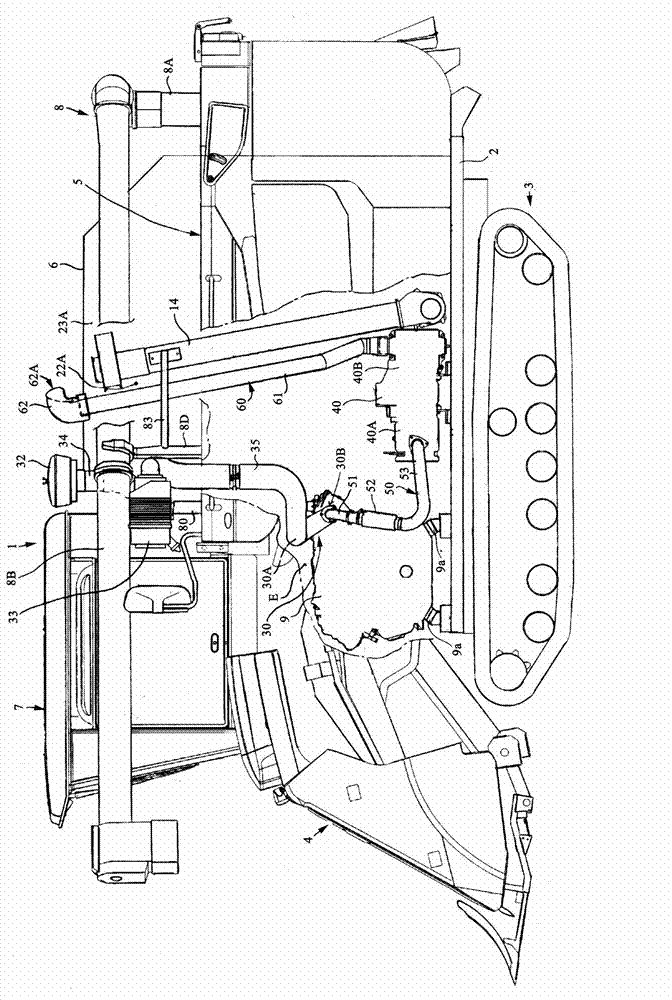

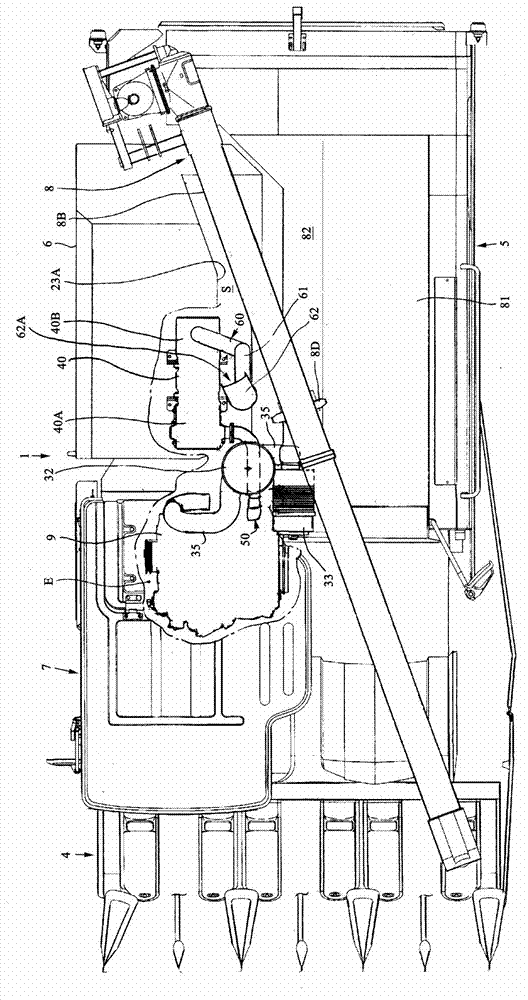

Combine

The task of the invention is to improve the durability of a pipeline at an exhaust influx side of an exhaust purification device and is not apt to generate metal fatigue, and to enable high-temperature exhaust gas exhausted from an upper end part of an exhaust pipe is difficult to be toward rice crumbs accumulated at a lower part of a machine body. The solution of the invention is that an inclined wall (23B) which is inclined upwards toward a threshing device (5) is arranged at the bottom of a grain container (6), an exhaust purification device (40) which removesparticle-shaped substances from exhausts of an engine (9) is configured in a space under the inclined wall (23B), an influx port of the exhaust purification device (40) is connected to an exhaust manifold (30B) through a connecting pipe (50) having flexibility, an outflux port of the exhaust purification device (40) is connected to a lower end part of an exhaust pipe (61) which guides gas exhausted from the outflux port to outside the machine, and the exhaust pipe (61) is arranged in an upward extending manner along a winnow device (14).

Owner:ISEKI & CO LTD

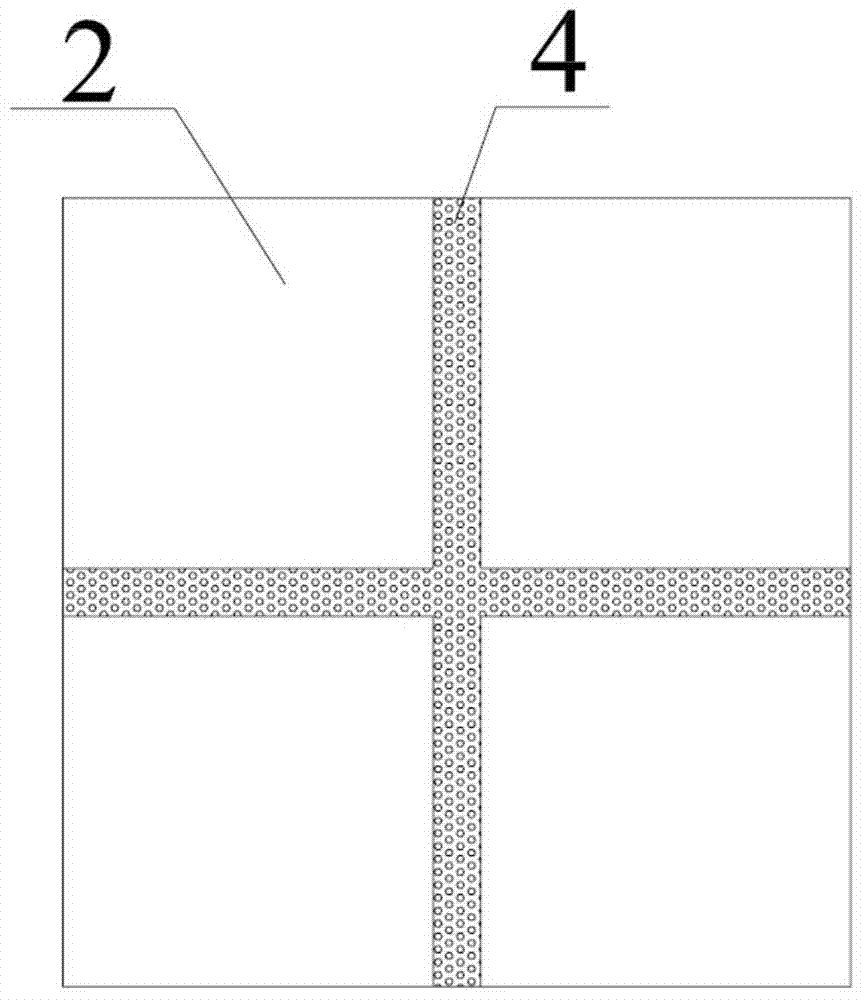

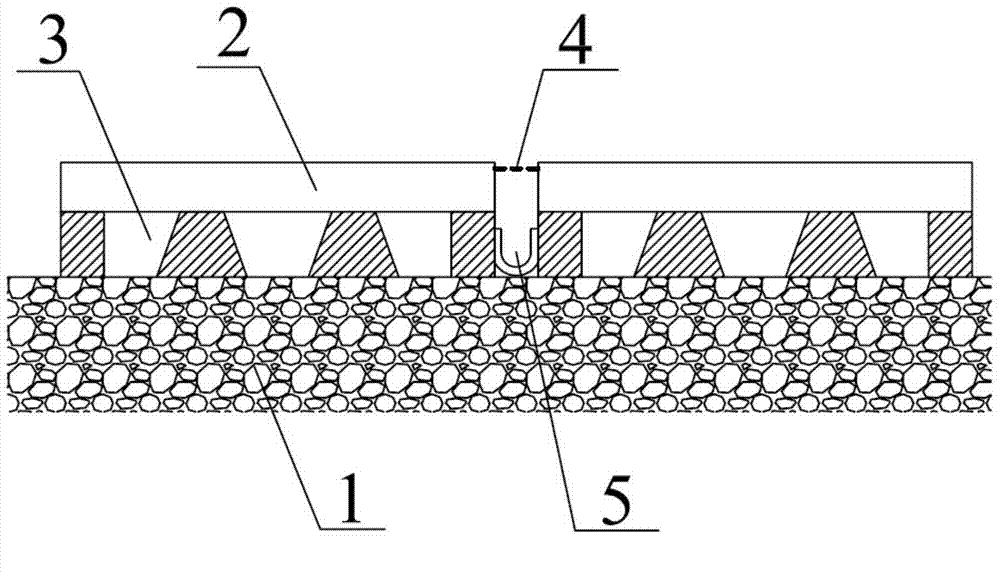

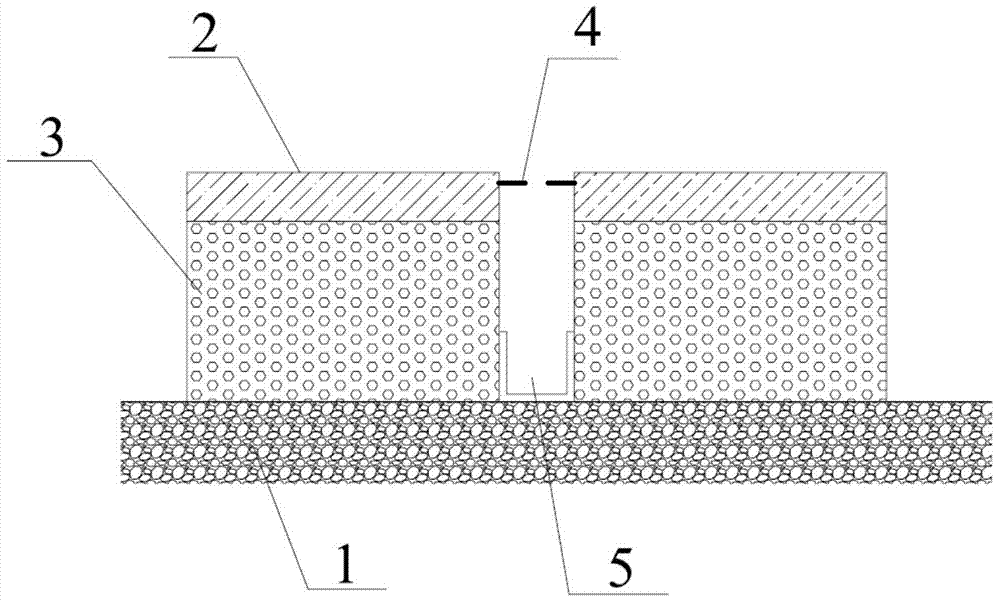

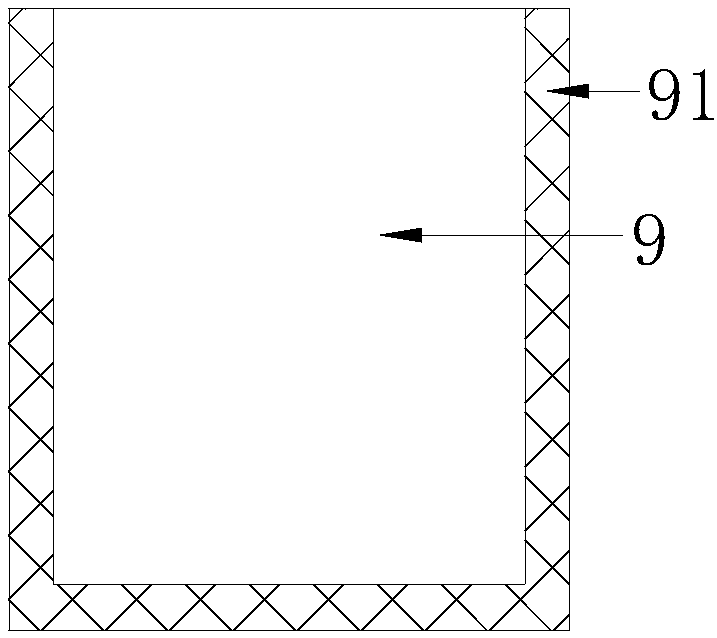

Water-permeable ground system and pavement method

ActiveCN104727201ASmooth water seepageExtended service lifePaving detailsRoads maintainenceSurface layerGround system

The invention provides a water-permeable ground system which comprises a water-permeable base layer. Multiple decoration modules are arranged on the water-permeable base layer; each decoration module comprises a decorative surface layer, the bottom of each decorative surface layer is provided with a support layer, a gap is arranged between each two adjacent decoration modules, a water-permeable module is arranged in each gap and comprises a water-permeable strip, each water-permeable strip comprises multiple water-permeable holes, and the water-permeable holes are through non-bent holes. According to the water-permeable ground system provided by the invention, water is infiltrated downwards through the water-permeable holes, and the water-permeable holes are just formed in the water-permeable strips, so that the stroke is short; the water-permeable holes are straight holes, so that a jamming phenomenon is unlikely to occur; impurities can be precipitated and stored in the gaps; if the water-permeable holes are jammed, the problem can be solved just by sweeping or cleaning by using water; impurities in the gaps are regularly cleaned or the water-permeable strips are regularly replaced, so that a jamming phenomenon caused by impurity accumulation after the system is used for a long time can be avoided. The water-permeable ground system has the characteristics of long service life and smooth water permeation.

Owner:吕国兵

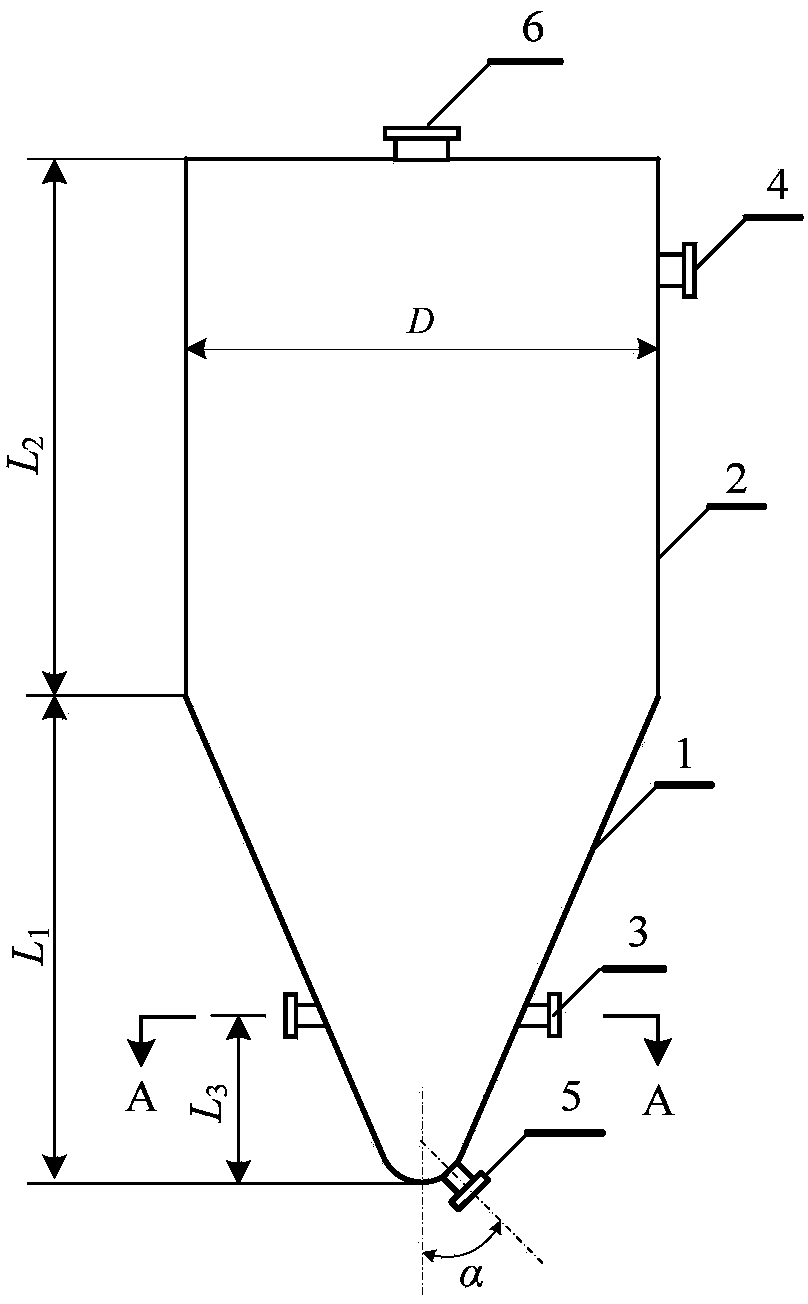

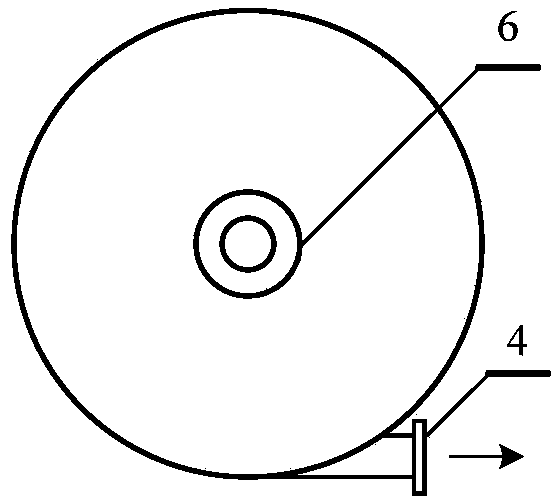

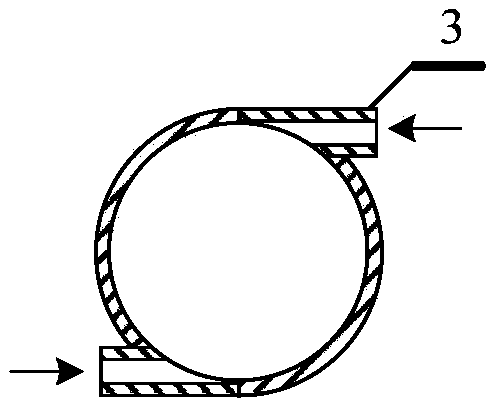

Rotational flow type fluidized bed crystallizer

InactiveCN104162288AEvenly dispersedNo fragmentationSolution crystallizationFluidized bedEngineering

The invention discloses a rotational flow type fluidized bed crystallizer. The rotational flow type fluidized bed crystallizer comprises a bed body, wherein the bed body is formed by combining a cylinder and a cone cylinder; the inner diameter of the large end of the cone cylinder is equal to that of the cylinder; the cone top of the cone cylinder is of a circular arc shape; the cone cylinder is positioned below the cylinder; the large end of the cone cylinder is connected with the lower end of the cylinder; the upper end of the cylinder is closed; a seed crystal adding opening is formed in the end surface of the upper end of the cylinder; at least two feeding pipes for adding material liquid are arranged on the side wall of the lower section of the cone cylinder and are uniformly distributed around the cone cylinder at the same height; each feeding pipe is positioned in the horizontal tangential direction of the cone cylinder; a crystal outlet is formed in the cone top of the lower end of the cone cylinder; a discharging pipe for outputting mother liquid is arranged on the side wall of the upper part of the cylinder and is positioned in the horizontal tangential direction of the cylinder, and an outlet of the discharging pipe is in accordance with the rotational direction of rotational flow formed by the material liquid. In order to meet requirements of a clearance crystallization process, a cooling jacket can be arranged on the basis of the structure.

Owner:SICHUAN UNIV

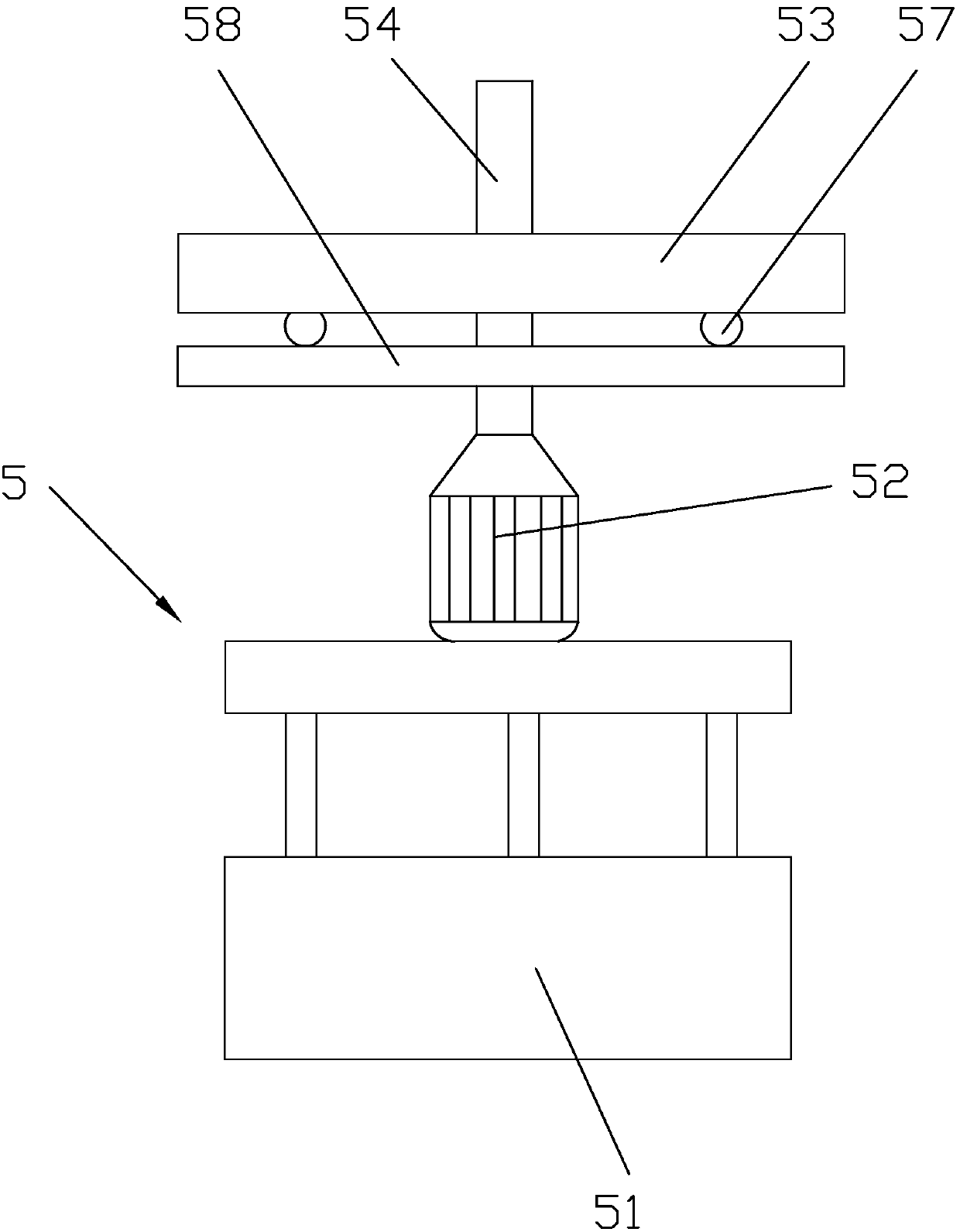

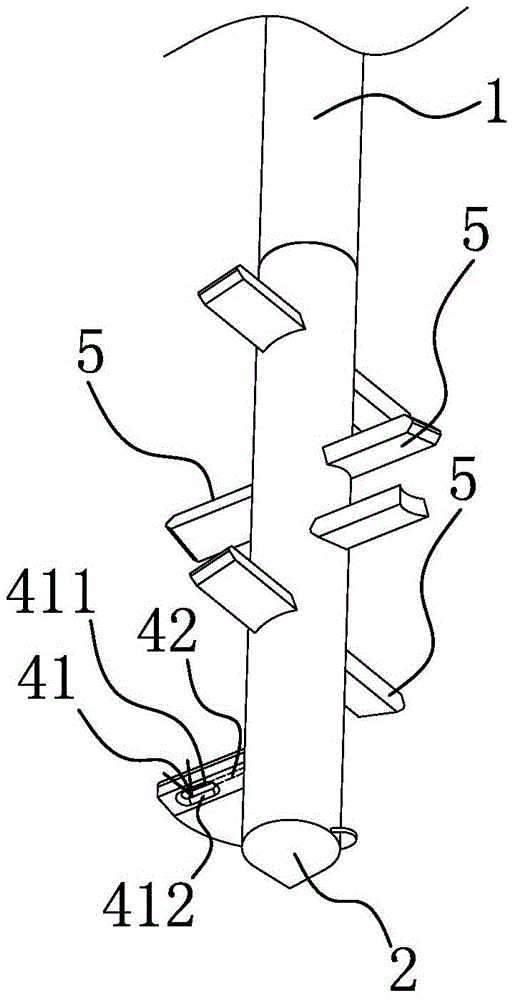

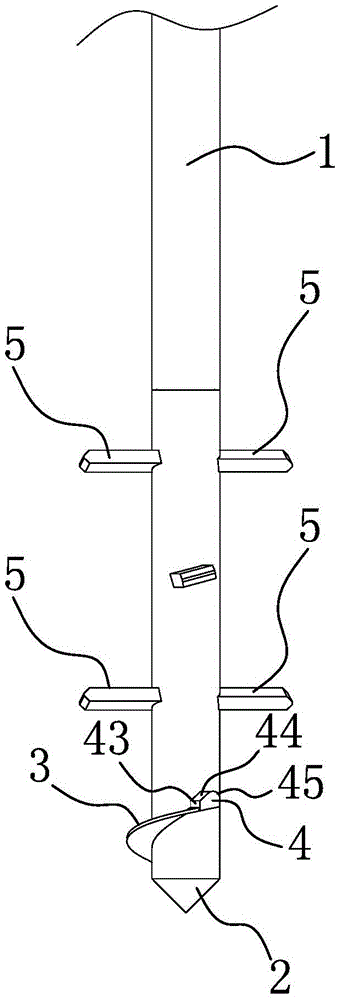

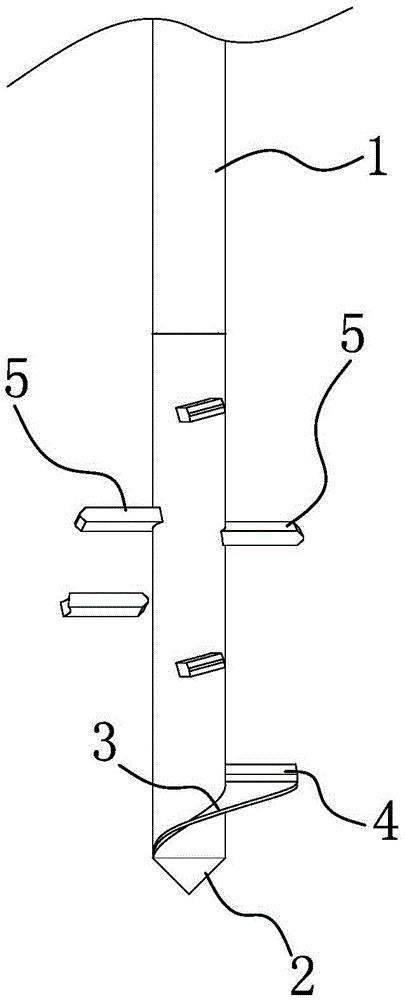

Drill rod assembly of pile driver

The invention belongs to the technical field of construction equipment and in particular relates to a drill rod assembly of a pile driver, aiming at solving the problem of an existing pile driver that a grout spraying area is small and the like. The drill rod assembly comprises a hollow drill rod body, wherein a drill bit pointed-cone-shaped part is arranged at one end of the drill rod body; a spiral drill bit blade, which is arranged in a spiral shape, is arranged at the circumferential outer side of one end, provided with the drill bit pointed-cone-shaped part, of the drill rod body; one end of the spiral drill bit blade extends to the drill bit pointed-cone-shaped part and the other end of the spiral drill bit blade is connected with a grout spraying seat which is arranged at the outer side of the drill rod body in the radial direction; at least one grout spraying hole connected with the inner part of the drill rod body is formed in one side, toward the drill bit pointed-cone-shaped part, of the grout spraying seat; the hole diameter of each grout spraying hole is gradually increased from inside to outside. The drill rod assembly of the pile driver has the advantages that a blocking phenomenon does not easily occur in a grout spraying process; the grout spraying area is large, and slurry is sprayed out in a sector shape; the grout spraying effect is good; the drill rod has good stability when rotating in the peripheral direction, and a swinging phenomenon does not easily occur; the efficiency of drilling the hole by the drill rod is improved and drill rods are not easy to be mutually interfered.

Owner:浙江兆弟技术有限公司

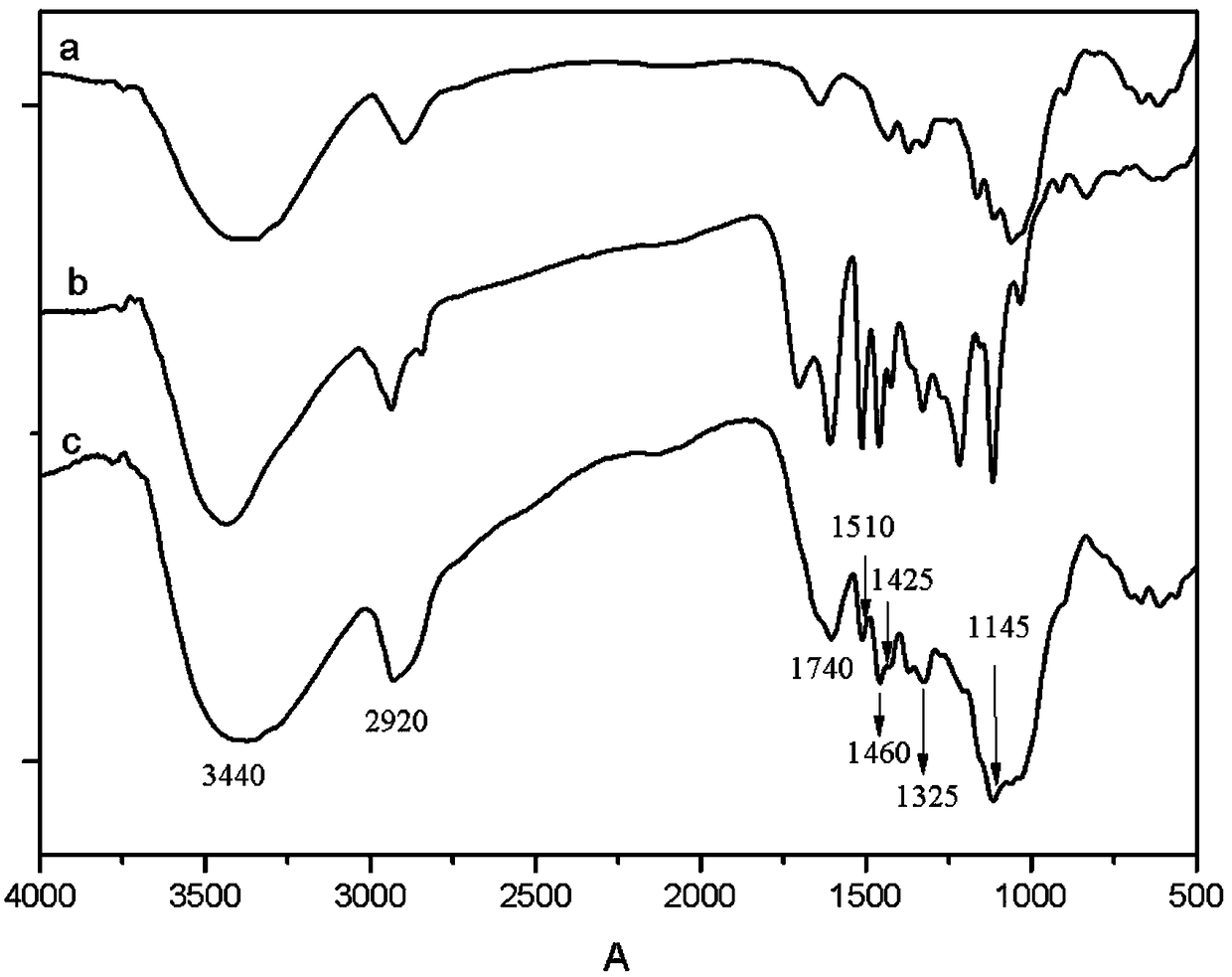

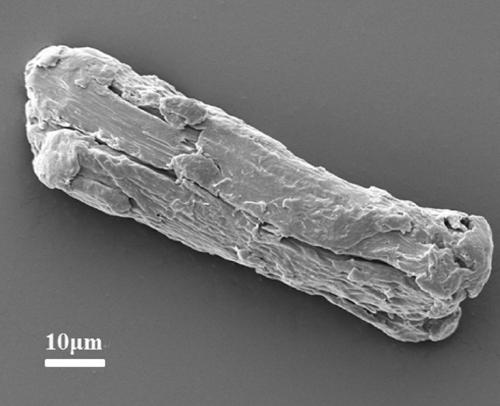

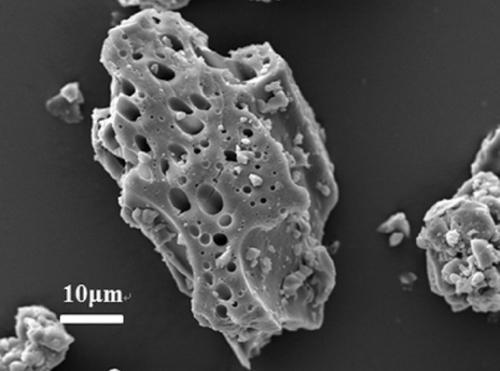

Lignin/microcrystalline cellulose complex, reinforced polylactic acid 3D printing material and preparation method thereof

ActiveCN109054323AGood compatibilityGood thermoplasticityAdditive manufacturing apparatusPlasticizerMicrocrystalline cellulose

In order to overcome the defects and shortcomings of poor compatibility between cellulose and a polymer matrix, frequent hole blocking in printing, difficulty in printing of lignin / polymer 3D printingmaterial and the like, common cellulose is subjected to acidolysis by using an inorganic acid solution; then the cellulose is modified by a silane coupling agent and lignin in an alcohol solution, toobtain the lignin / microcrystalline cellulose compound. The compound serving as a reinforcing material and PLA serving as a base material are blended with an inorganic nano material, a toughening agent, a plasticizer and the like, and the reinforced polylactic acid 3D printing material with good mechanical property and 3D printing property is prepared by melt extrusion blending and wiredrawing moulding. The mechanical property of the 3D printing material provided by the invention is better than that of common polylactic acid printing materials; according to a test by an FDM type 3D printer, the 3D printing material is completely applicable to the FDM rapid prototyping technology, and the printed product has high glossiness and wood-texture appearance and can be applied to the printing of furniture, toys, artwork, model design and the like.

Owner:SOUTH CHINA AGRI UNIV +1

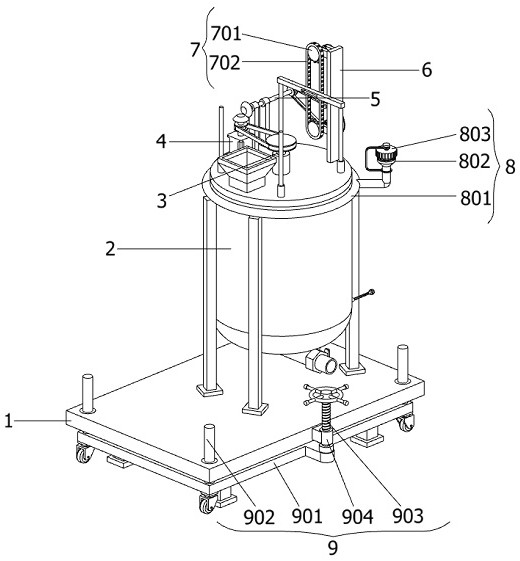

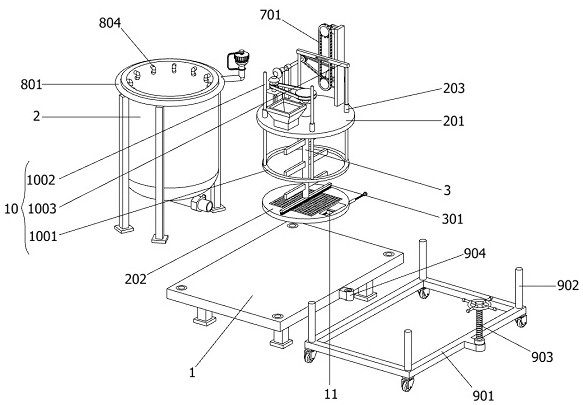

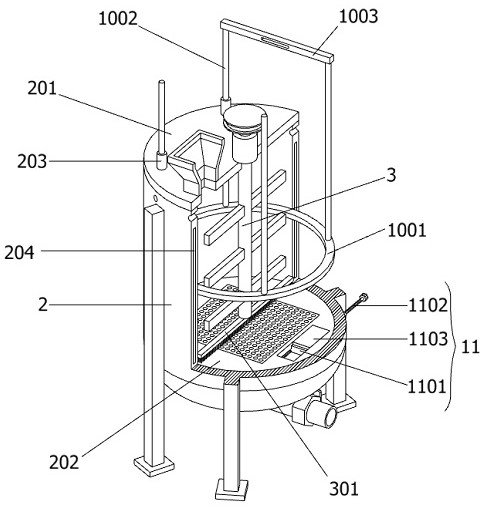

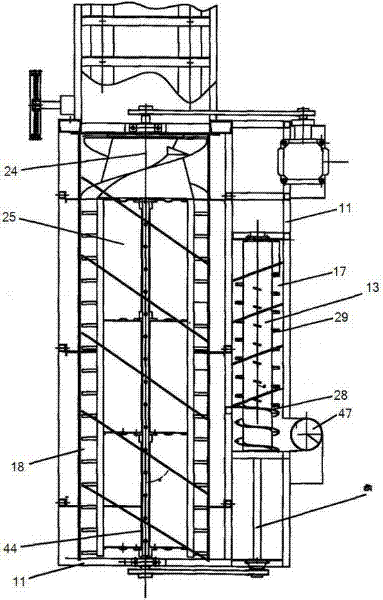

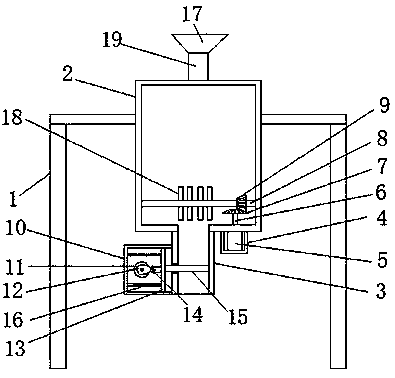

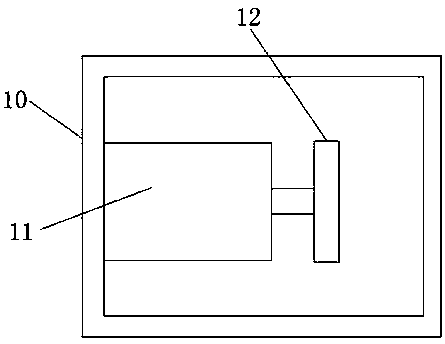

Bio-organic fertilizer raw material stirring device capable of uniformly stirring

InactiveCN112808145ANot prone to cloggingDoes not reduce heating effectRotary stirring mixersTransportation and packagingElectric machineryProcess engineering

The invention provides a bio-organic fertilizer raw material stirring device capable of uniformly stirring, belongs to the technical field of stirring devices, and aims to solve the problem that the heating effect of heating sheets on the inner wall of a tank body is reduced when thick organic fertilizer raw materials are attached to the inner wall of the stirring device, the bio-organic fertilizer raw material stirring device comprises a movable base, and the tank body is mounted on the right side of the upper end surface of the movable base; the center part of the tank body is rotationally connected with a stirring shaft; and a driving motor is mounted on the rear side of the top of the tank body, and the driving motor is rotationally connected with a driving belt wheel and a bevel gear through a rotating shaft. A rotating shaft of a driving motor drives a driving belt wheel and a bevel gear to rotate, and then the driving belt wheel drives a driven belt wheel at the upper end of a stirring shaft to rotate through a belt, so that the stirring shaft drives external stirring blades to perform stirring operation in a tank body; and in the rotating process of the stirring shaft, the upper surface of the filter screen on the filter plate is rotationally cleaned through the cleaning brush at the lower end of the stirring shaft, so that the upper surface of the filter screen on the filter plate can be cleaned at the same time.

Owner:周华梅

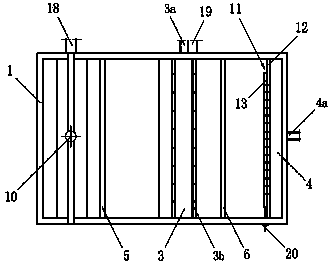

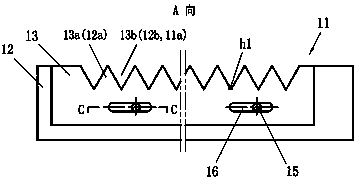

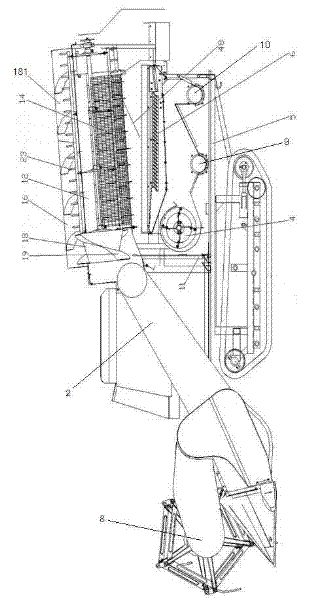

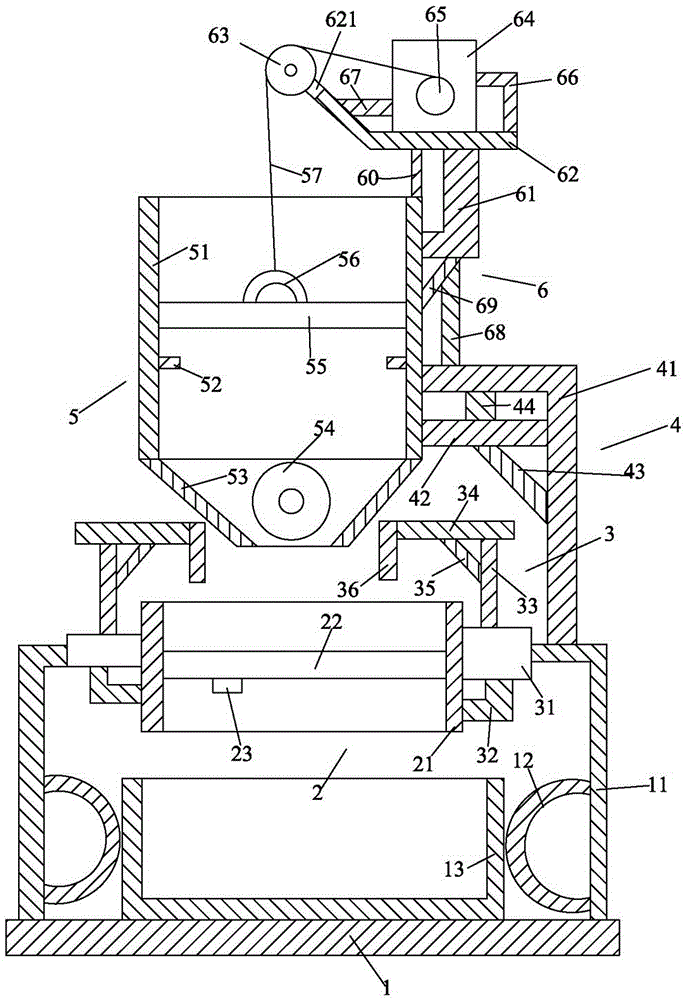

Threshing device of harvester

The invention relates to a harvester, in particular to a threshing device of a harvester. According to the technical scheme, the threshing device of the harvester comprises an underframe, a threshing frame, a main threshing mechanism, a rethreshing mechanism, a separation, cleaning and vibration screen and an impurity lifting screw, wherein the threshing frame is fixed on the underframe, both the main threshing mechanism and the rethreshing mechanism are connected to the threshing frame and disposed along the travelling direction of the harvester, the separation, cleaning and vibration screen is fixedly connected to the threshing frame and positioned between the underframe and the main threshing and rethreshing mechanisms, and the impurity lifting screw is disposed between the position below the rear end of the separation, cleaning and vibration screen and the rethreshing mechanism. The main threshing mechanism comprises a main threshing roller, a large concave screen and a main roller cover, wherein the main threshing roller is hinged to the threshing frame, the large concave screen is fixed to the threshing frame and encloses the main threshing roller, and the main roller cover covers an opening of the large concave screen. The main threshing roller is slantingly disposed along the advancing direction of the harvester. A corner between the main threshing roller and a conveying chute of the threshing device compared with the prior art is reduced, so that conveying of crops is smooth, and the shortages of the prior art are made up.

Owner:ZHONGJI SOUTHERN MACHINERY

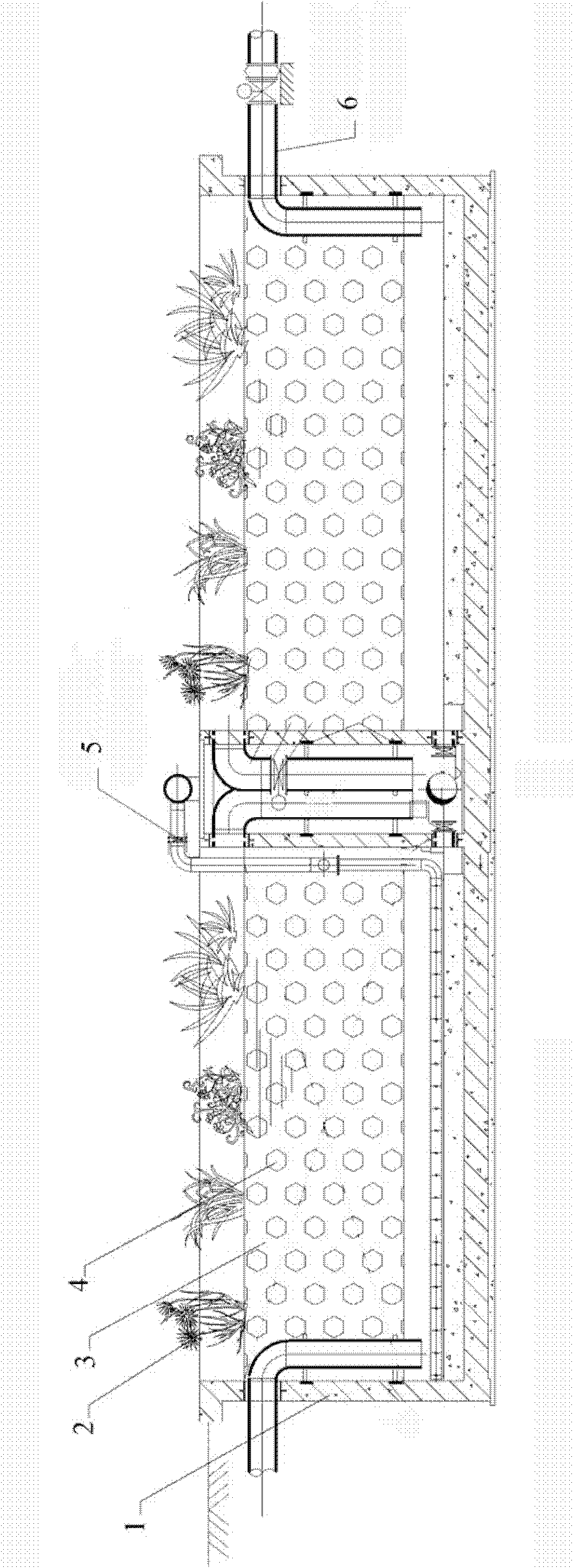

Artificial wetland and construction method thereof

ActiveCN102167446AGood absorption environmentImprove treatment efficiency and purification effectTreatment with aerobic and anaerobic processesSustainable biological treatmentEnvironment of AlbaniaBiology

The invention discloses an artificial wetland and a construction method thereof. The artificial wetland comprises an artificial wetland pool, a layer of oyster shells serving as a filler are arranged in the artificial wetland pool, and aquatic plants are grown on the oyster shells. Therefore, compared with the artificial wetland taking sand as a filler in the prior art, the artificial wetland has the advantages that: (1) the oyster shells serve as the filler, wastes are utilized, the filler is wide in sources, low in cost and high treatment efficiency, high porosity ensures smooth flowing of water and avoids blockage, and the service life is long; and the artificial wetland is generally dredged once after 2 to 3 years, and about 1 / 3 of oyster shells are replaced, so the operation and management are convenient, the plants are easy to grow and kept, and the plants can be partially harvested according to growth vigor; (2) the artificial wetland has good purification effect without odor, and a few of flies and mosquitoes appear; and (3) the artificial wetland purifies and beautifies environment.

Owner:中咨城建设计有限公司 +1

Automatic bale plucker

InactiveCN103422198AComb evenlySimple structureFibre breaking by beater armsEconomic benefitsEngineering

The invention discloses an automatic bale plucker which comprises an air suction hood and a driving device, wherein the driving device comprises a bale plucking arm, a power source and a center post, wherein the center post is fixedly arranged on a base; the power source is arranged inside the center post and drives the bale plucking arm to operate; a lifting device is arranged between the power source and the bale plucking arm; the air suction hood is fixedly arranged on the bale plucking arm; a bale plucking beater is arranged at the bottom of the air suction hood; blades are arranged at the periphery of the bale plucking beater; a cotton storage bin is arranged at the bottom of the air suction hood and is fixedly arranged on the base; a mobile cotton storage bin is also arranged on the base. The automatic bale plucker disclosed by the invention has the advantages of simple structure, simpleness and convenience in operation, reduced production cost, high bale plucking efficiency and low possibility of blocking; cotton raw materials are scutched to be more uniform, the working efficiency is increased and economic benefits are increased.

Owner:张志洲

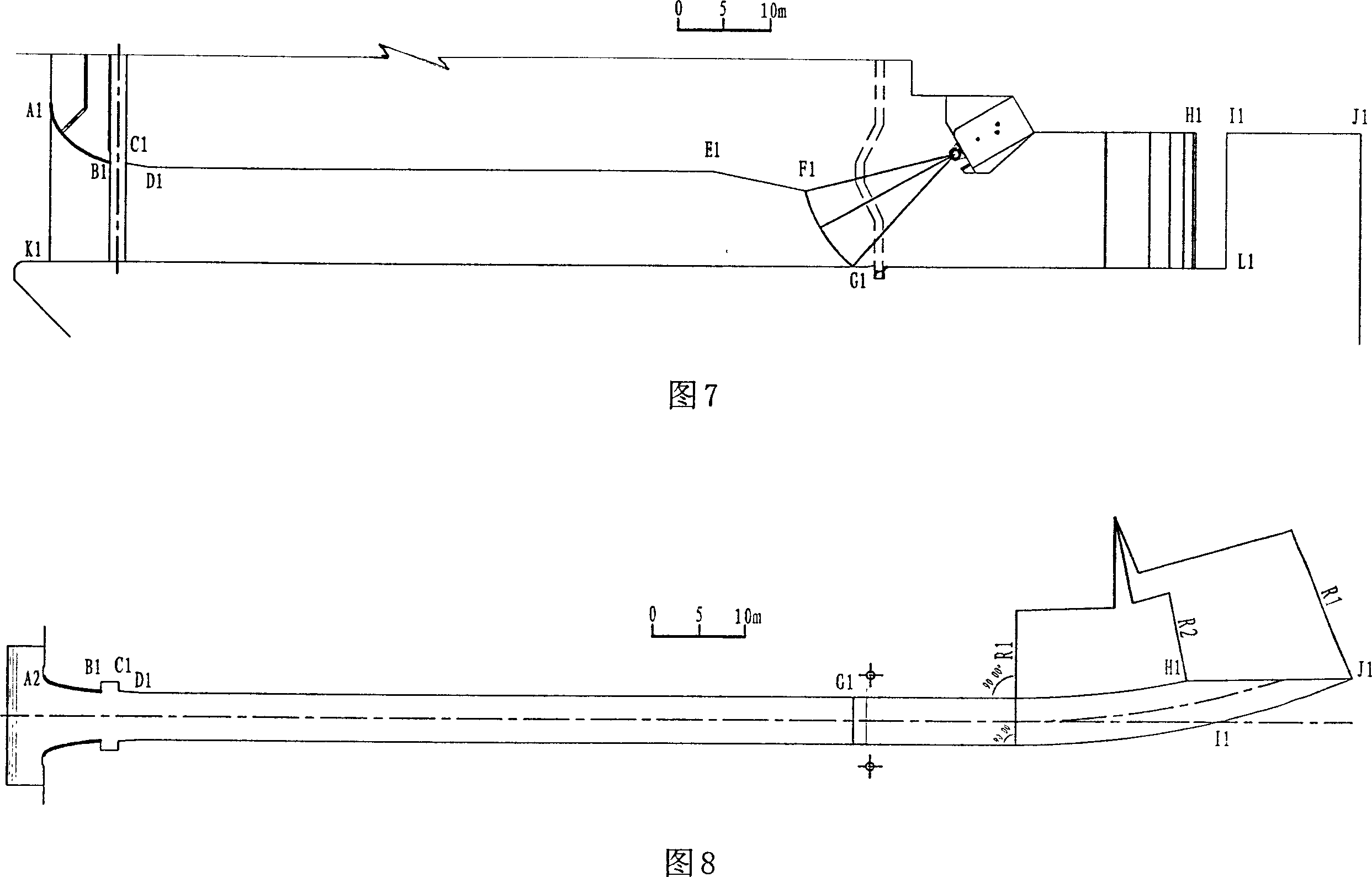

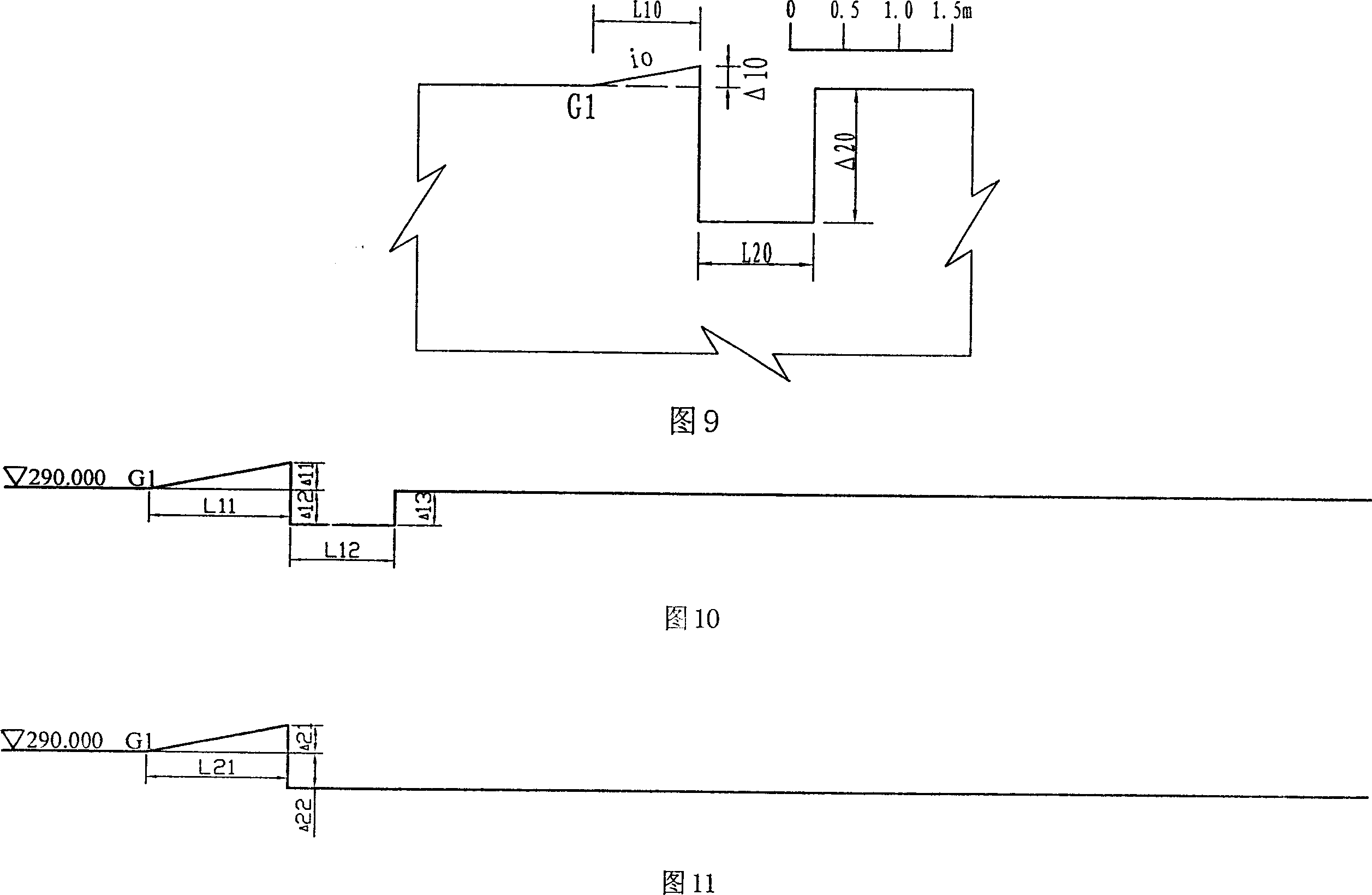

Aerator for flat-bottomed water release structure

This invention relates to an aeration device of a flat-bottomed building to aerate with a combined way of raised ridge, aeration tank and a drop ridge and sets a paste ridge at the back of the tank, in which the profile line of the top of the paste ridge extends to the bottom from the top gradually along the counter flow direction in a cavity sphere, the profile line on top of the paste ridge along the current direction extends to the bottom from the top gradually at the bump section of the current and the paste ridge at the back of the cavity. Advantage: obliquity of the jet with the paste ridge is small across a ventilation tank, it's not easy to generate back flow to block the cavity, a stable cavity is formed at the flow surface of the building to reduce back flow and increase aeration efficiency, extra part is removed to improve distribution of pressure in the cavity to increase contact area of water and gas.

Owner:HOHAI UNIV

Quantitative feeding device for powdery food packaging

InactiveCN108163237ANot prone to cloggingAchieve the effect of gap blankingLarge containersSolid materialEngineeringFood packaging

The invention discloses a quantitative feeding device for powdery food packaging. The quantitative feeding device comprises a support frame; the support frame is fixedly provided with a stocking tank;the bottom end of the stocking tank is fixedly provided with a feeding pipe; a first installation cover is fixedly arranged at the bottom end of the stocking tank and located at one side of the feeding pipe; the first installation cover is internally fixedly provided with a first rotating motor; the inner wall of the bottom end of the stocking tank is fixedly provided with a first rotating rod; the first rotating rod is fixedly connected with an output shaft of the first rotating motor; the top end of the first rotating rod is fixedly provided with a first bevel gear; the stocking tank is roatably provided with a second rotating rod arranged horizontally; the outer side of the second rotating rod is fixedly provided with a second bevel gear; the fist bevel gear and the second bevel gear are meshed; one side of the feeding pipe is fixedly provided with a second installation cover; and the inner wall of one side of the second installation cover is fixedly provided with a second rotatingmotor. The quantitative feeding device for the powdery food packaging is simple in structure, convenient to operate, and low in production cost, and blockage is prone to happening during feeding.

Owner:绍兴市北斗星电气有限公司

Ore vibrating screen for ore mining

The invention discloses an ore vibrating screen for ore mining. The ore vibrating screen comprises a bottom plate, a first filtering device, a knocking device, a bracket device, a second filtering device and a motor device, wherein a first bracket, a first bending rod and a recycling box are arranged on the bottom plate; the first filtering device comprises a first frame body, a first filter mesh and a vibrator; the knocking device comprises an electric cylinder, a second bracket, a first pushing rod, a first cross rod, a first inclined rod and a knocking rod; the bracket device comprises a third bracket, a second cross rod, a second inclined rod and a first vertical rod; the second filtering device comprises a second frame body, a first fixing block, a discharge hopper, a roller, a second filter mesh, a first fixing ring and a pull line; the motor device comprises a fourth bracket, a fifth bracket, a fixed pulley, a motor, an output shaft, a sixth bracket, a first fixing rod, a third inclined rod and a second fixing rod located under the third inclined rod. The ore vibrating screen provided by the invention can effectively screen ores, and has high screening efficiency and speed.

Owner:张丽凤

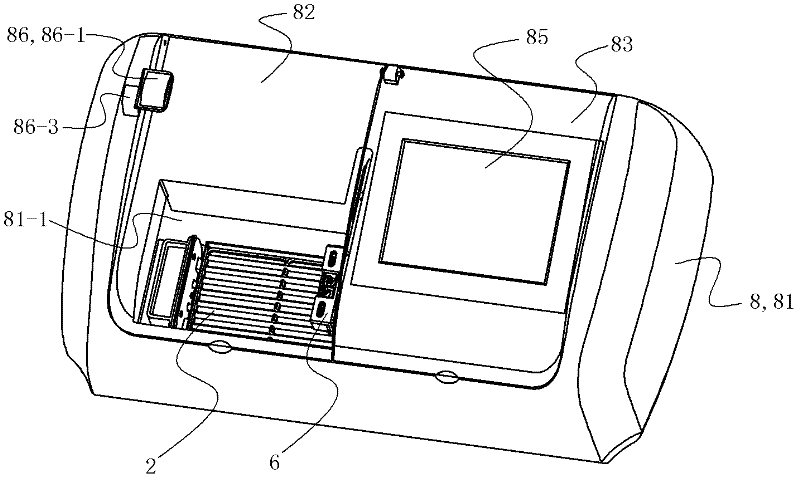

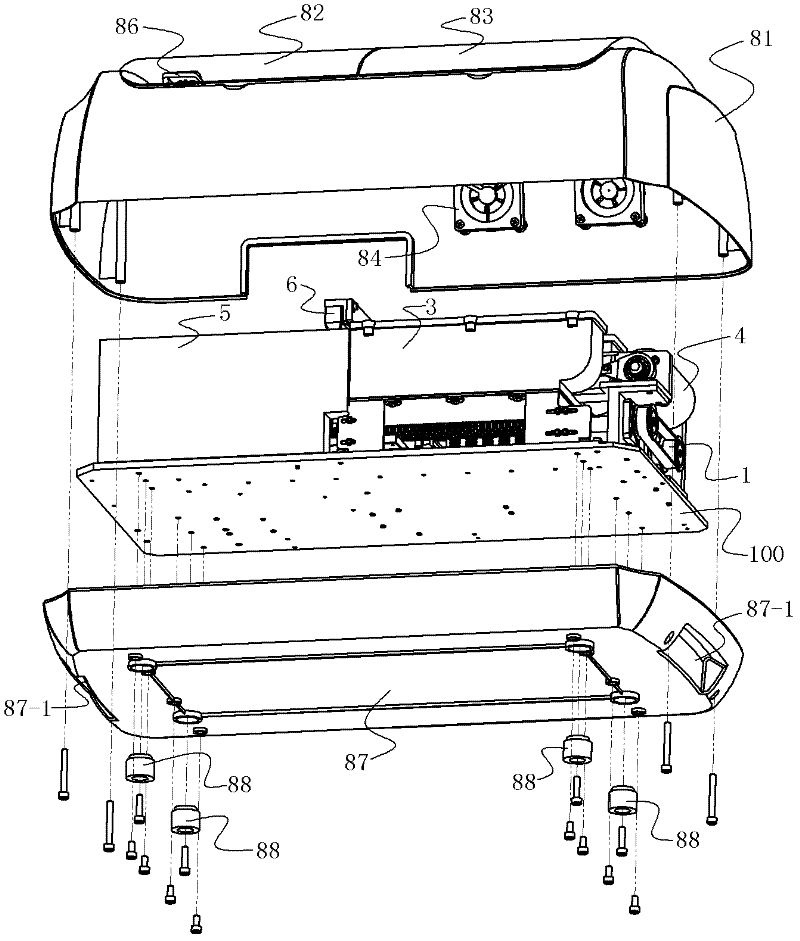

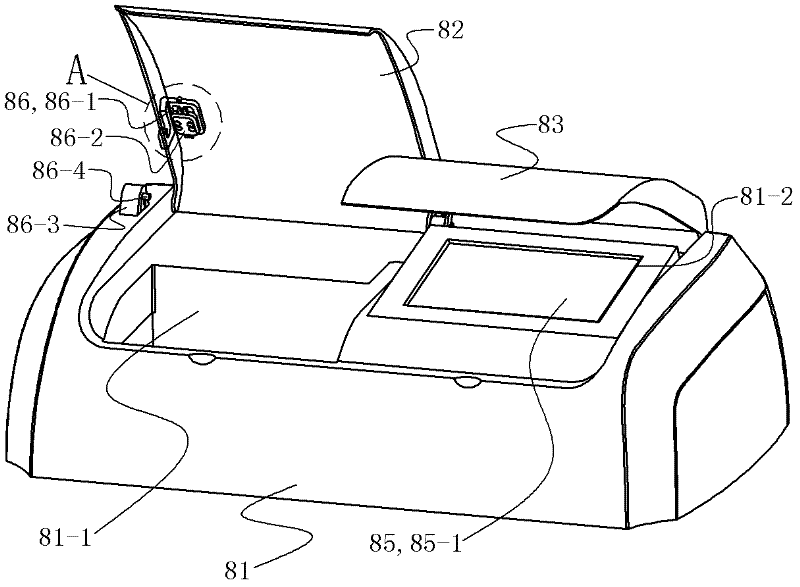

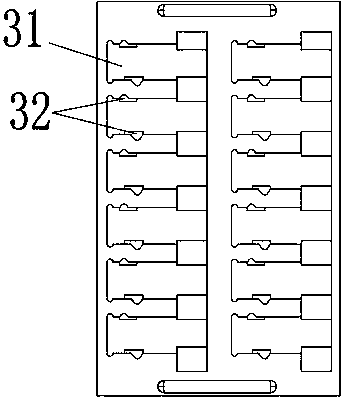

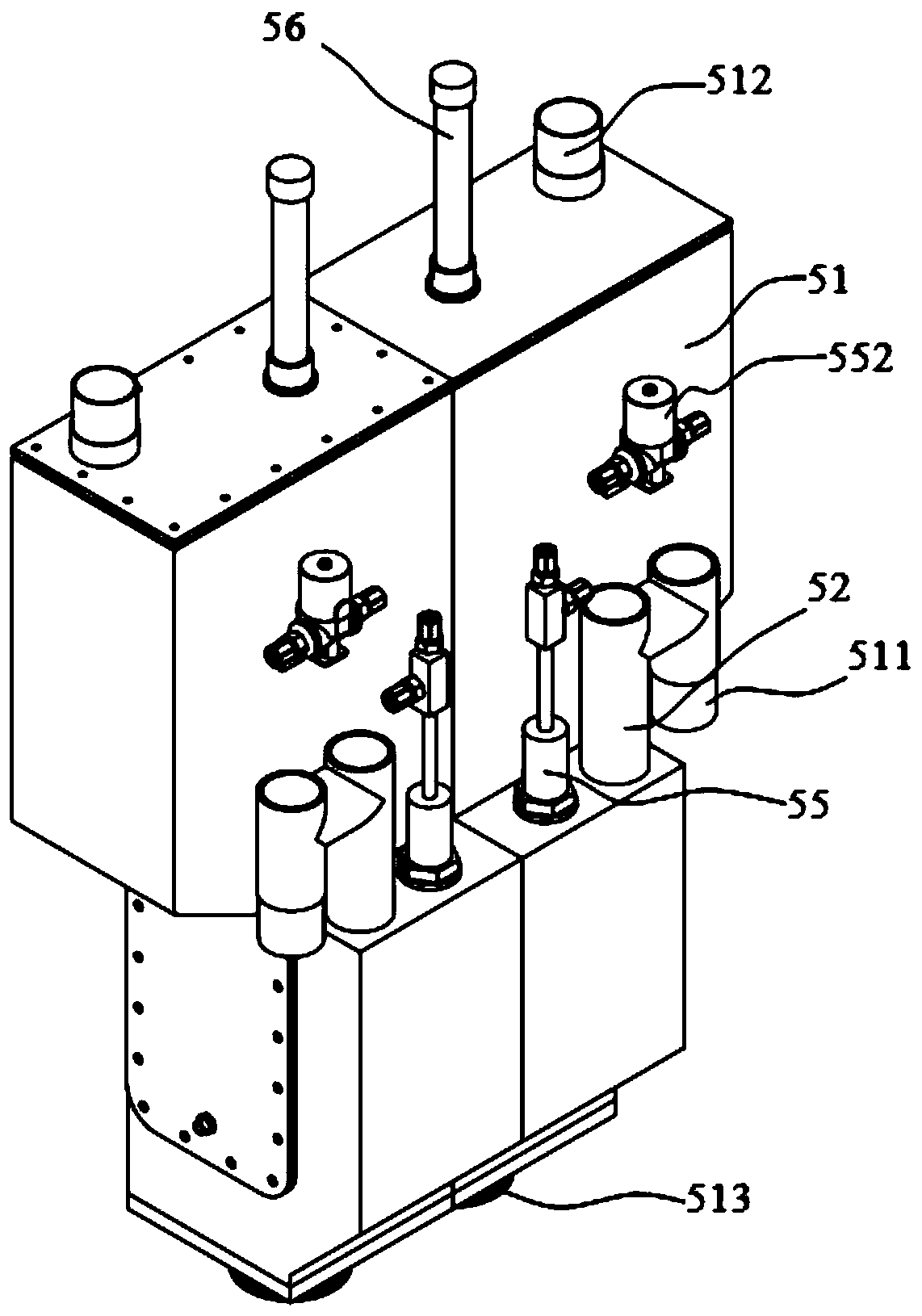

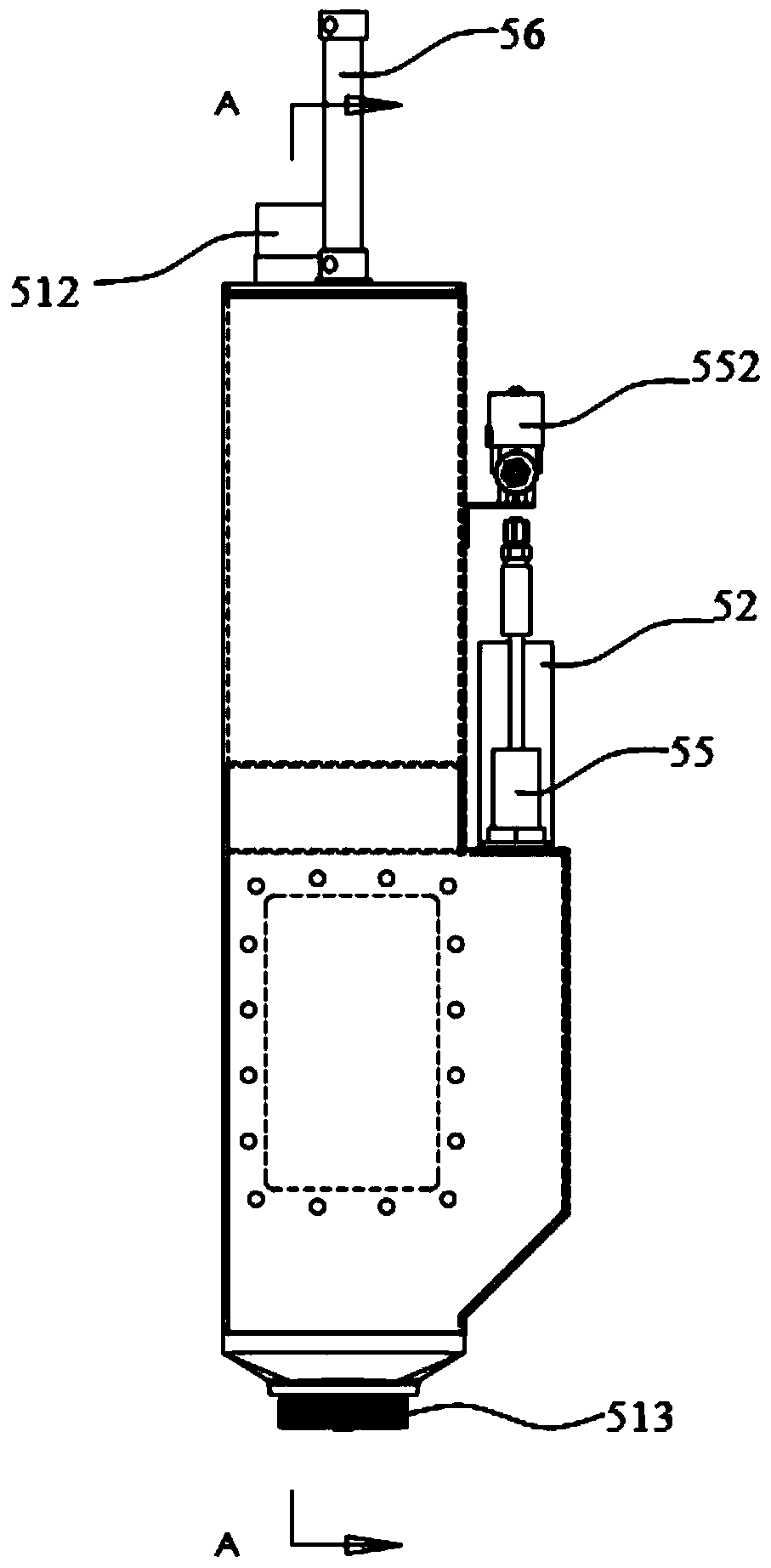

Full-automatic reactor

ActiveCN102507964AImprove accuracyGood repeatabilityMaterial analysisEngineeringMechanical engineering

The invention relates to a full-automatic reactor, which comprises a translation mechanism, a holding platform, an incubator component, an oscillating mechanism, a cleaning mechanism, an electrical unit, a shell component and a bottom plate. The holding platform comprises a holding table and a holding table support component; the holding table is bilaterally, elastically and slidably connected onto the holding table support component; the holding table support component of the holding platform is bilaterally and slidably connected onto the bottom plate through the translation mechanism; the incubator component comprises an incubator with a leftward opening, and an incubator base which is fixed onto the bottom plate from the upper side and positioned above the translation mechanism and on the right of the holding platform; the oscillating mechanism is arranged on the right of the incubator; an oscillating part of the oscillating mechanism extends into the incubator; the cleaning mechanism comprises a cleaning head, a lifting device and a pump unit; and the cleaning head is vertically and slidably connected onto the bottom plate through the lifting device. The reactor is used for cleaning, oscillating and reacting protein membrane chips or microtiter plates.

Owner:上海裕隆生物科技有限公司

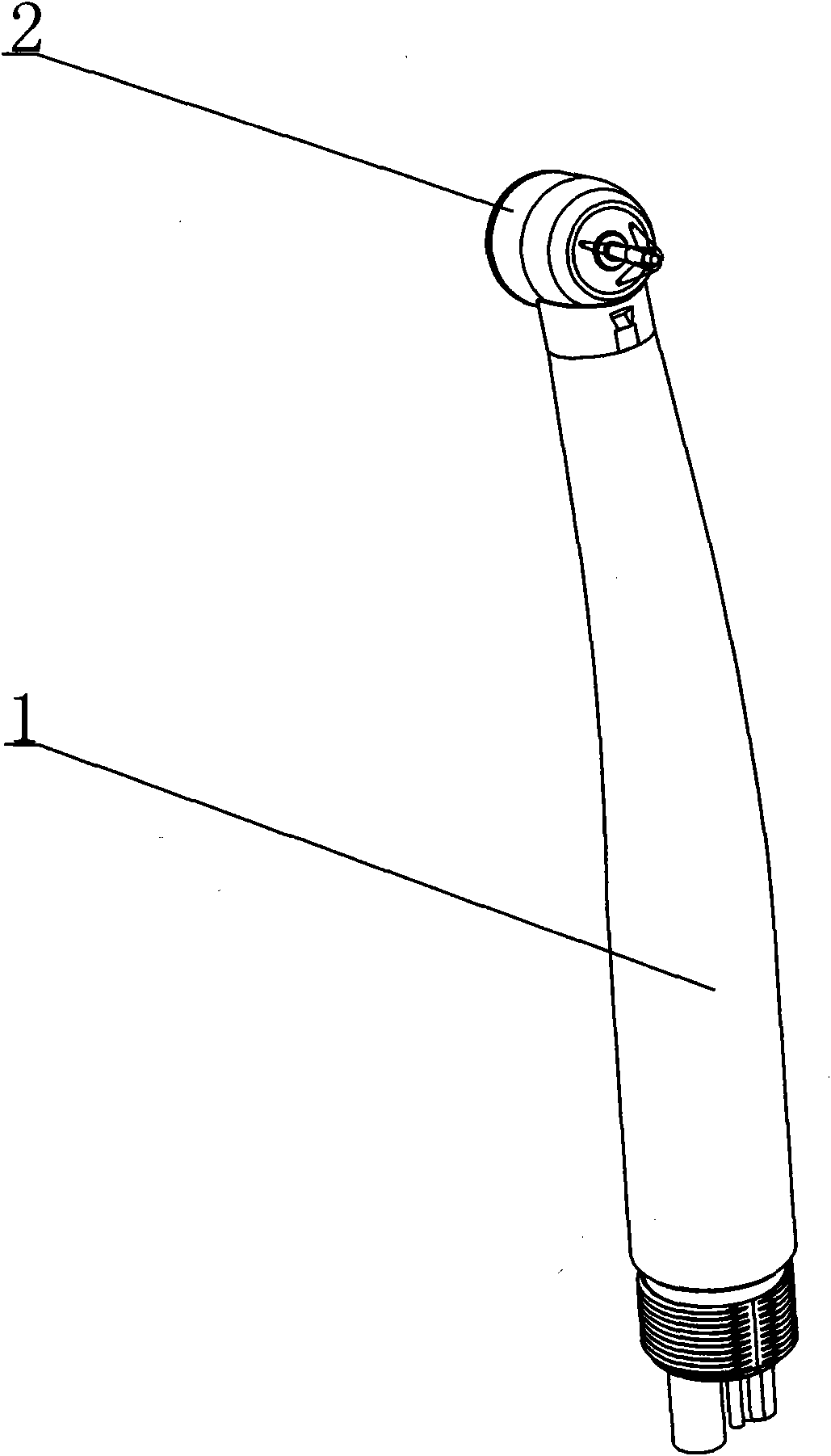

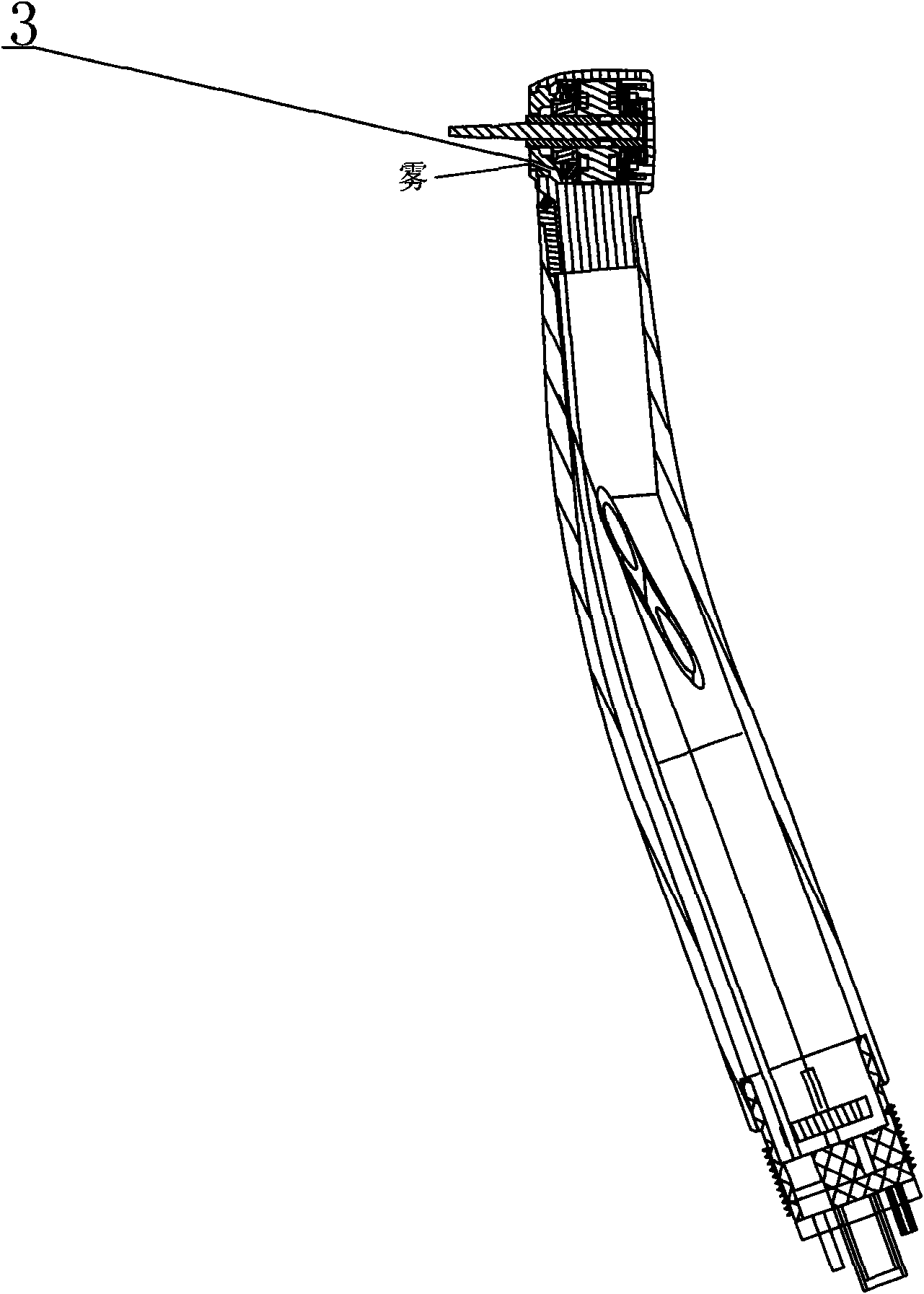

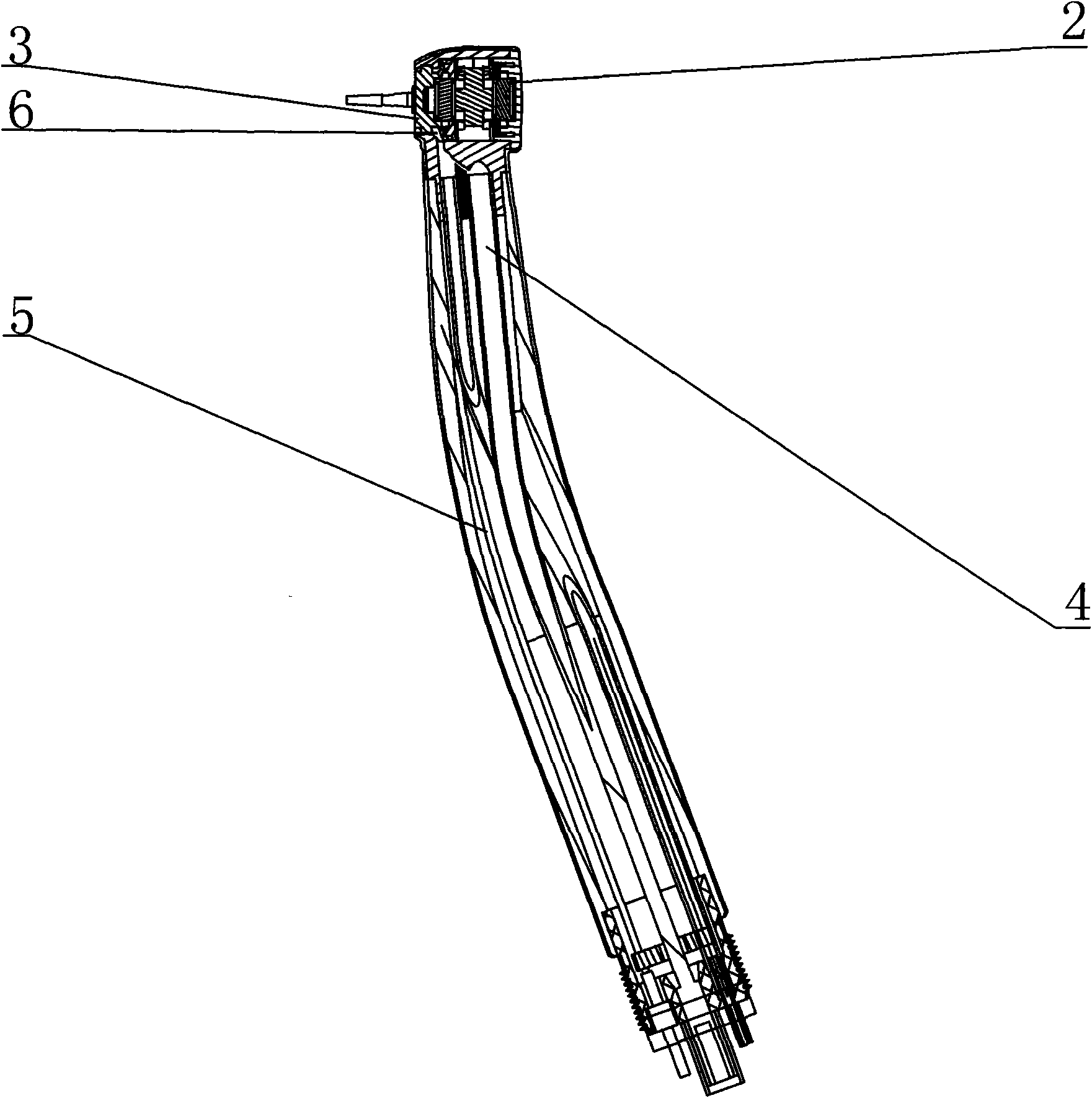

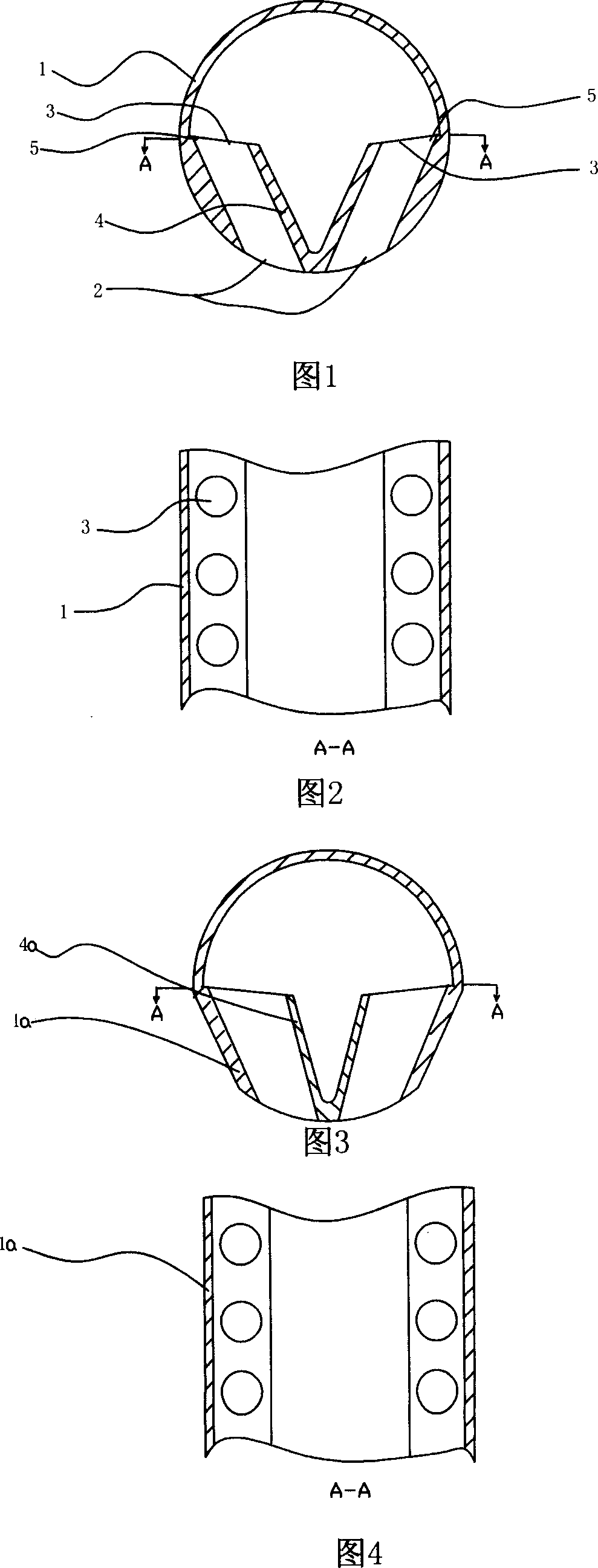

Disposable spraying high-speed turbine dental handpiece

The invention discloses a disposable spraying high-speed turbine dental handpiece, which comprises a handle and a handpiece connected with the handle. The turbine dental handpiece is characterized in that: a water-air mixing chamber is formed in the handpiece, an air inlet tube connected with the water-air mixing chamber and positioned in the handle is arranged in the handpiece, a water inlet tube connected with the water-air mixing chamber and positioned in the handle is arranged in the handpiece, the air of the air inlet tube and the water of the water inlet tube are mixed together due to pressure after entering the water-air mixing chamber to form fog, the fog is sprayed out through fog spraying holes, the number of the fog spraying holes is three, the three fog spraying holes are uniformly distributed at the front end of the handpiece, and the front end of the handpiece is provided with the three fog spraying holes which are communicated with the water-air mixing chamber to realize the fog spraying effect and are regularly and annularly distributed. The invention provides the disposable spraying high-speed turbine dental handpiece with high use efficiency, convenience and simple structure.

Owner:佛山市碧盈医疗器材有限公司

Irrigation and drainage pipes

InactiveCN101091448ANot prone to cloggingWatering devicesCultivating equipmentsWater channelEngineering

The present invention discloses a drainage and irrigation pipe. It includes external pipe and several external wall drainage and irrigation holes which are cut on the external pipe wall; in the pipe interior of said external pipe also a main water channel is set; on the wall of said main water channel, in the position higher than external wall drainage and irrigation holes several internal wall drainage and irrigation holes are set. Compared with existent technique, in the process of use of said drainage and irrigation pipe lots of sand-mud granules can not be fed into the drainage and irrigation interior.

Owner:土谷神生活科技有限公司

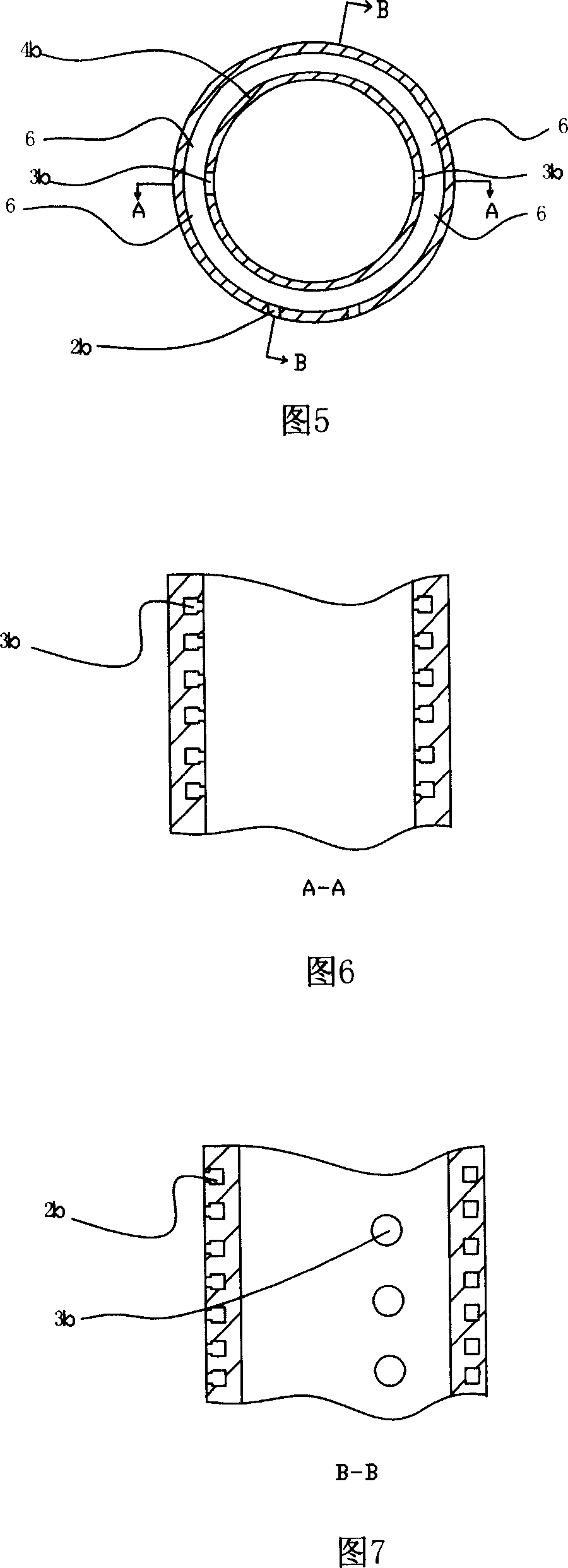

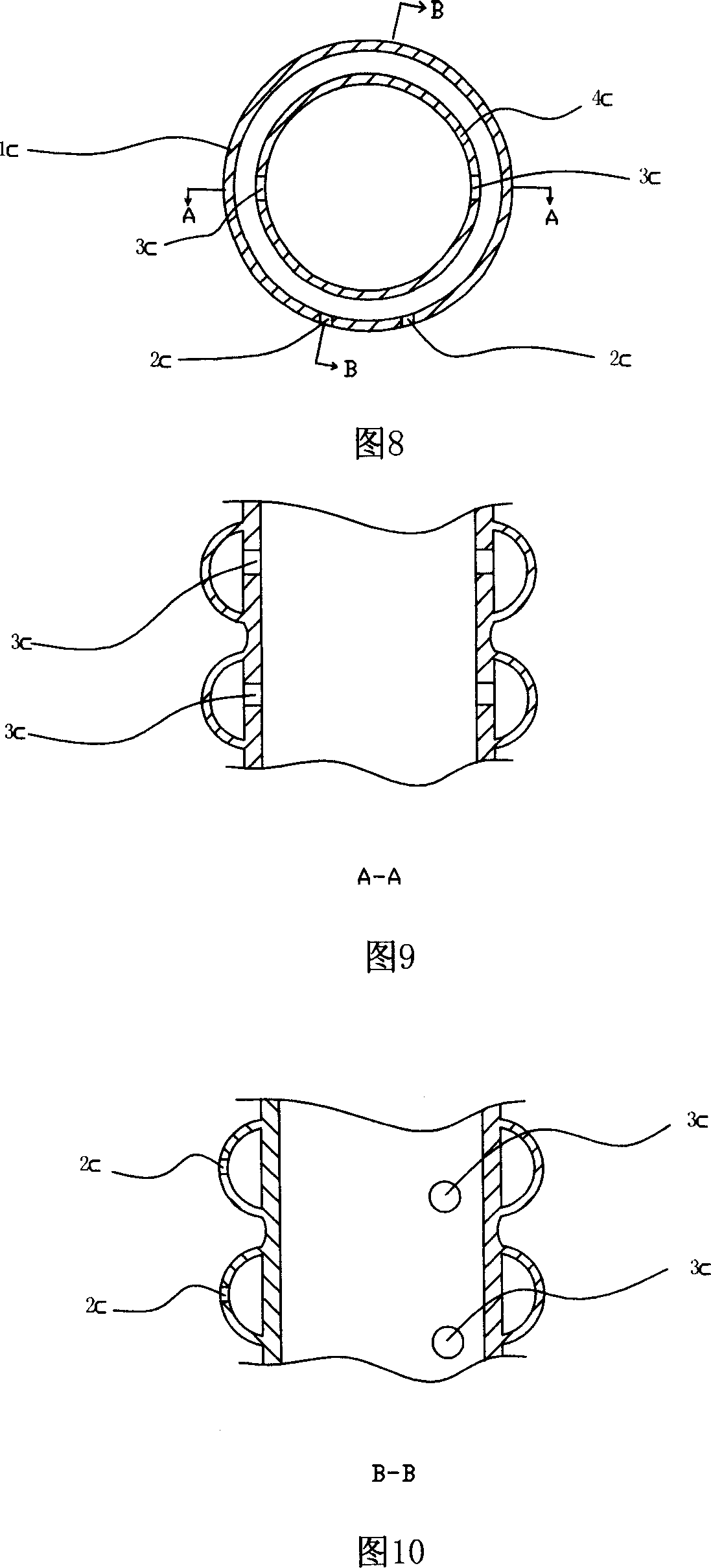

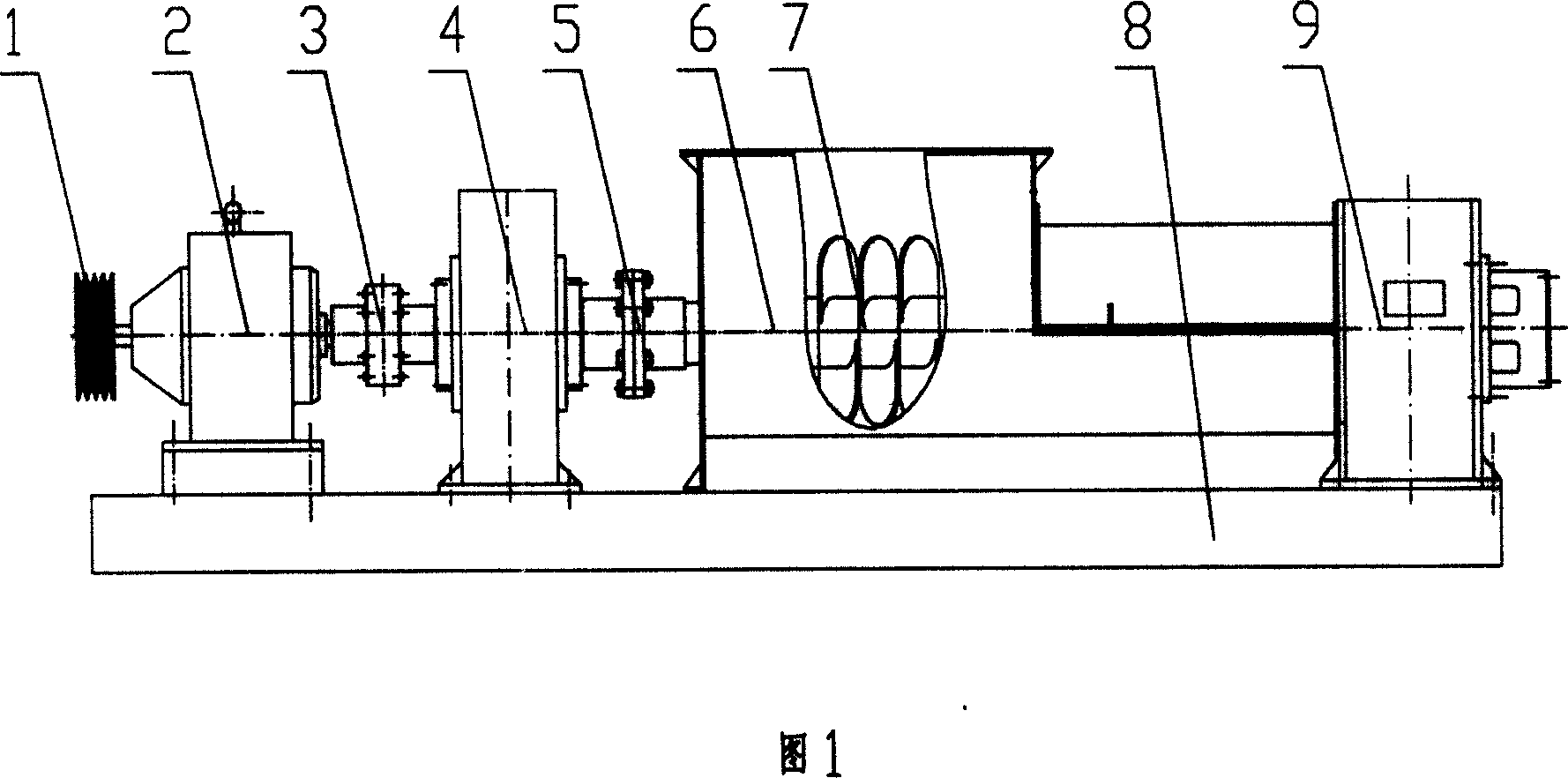

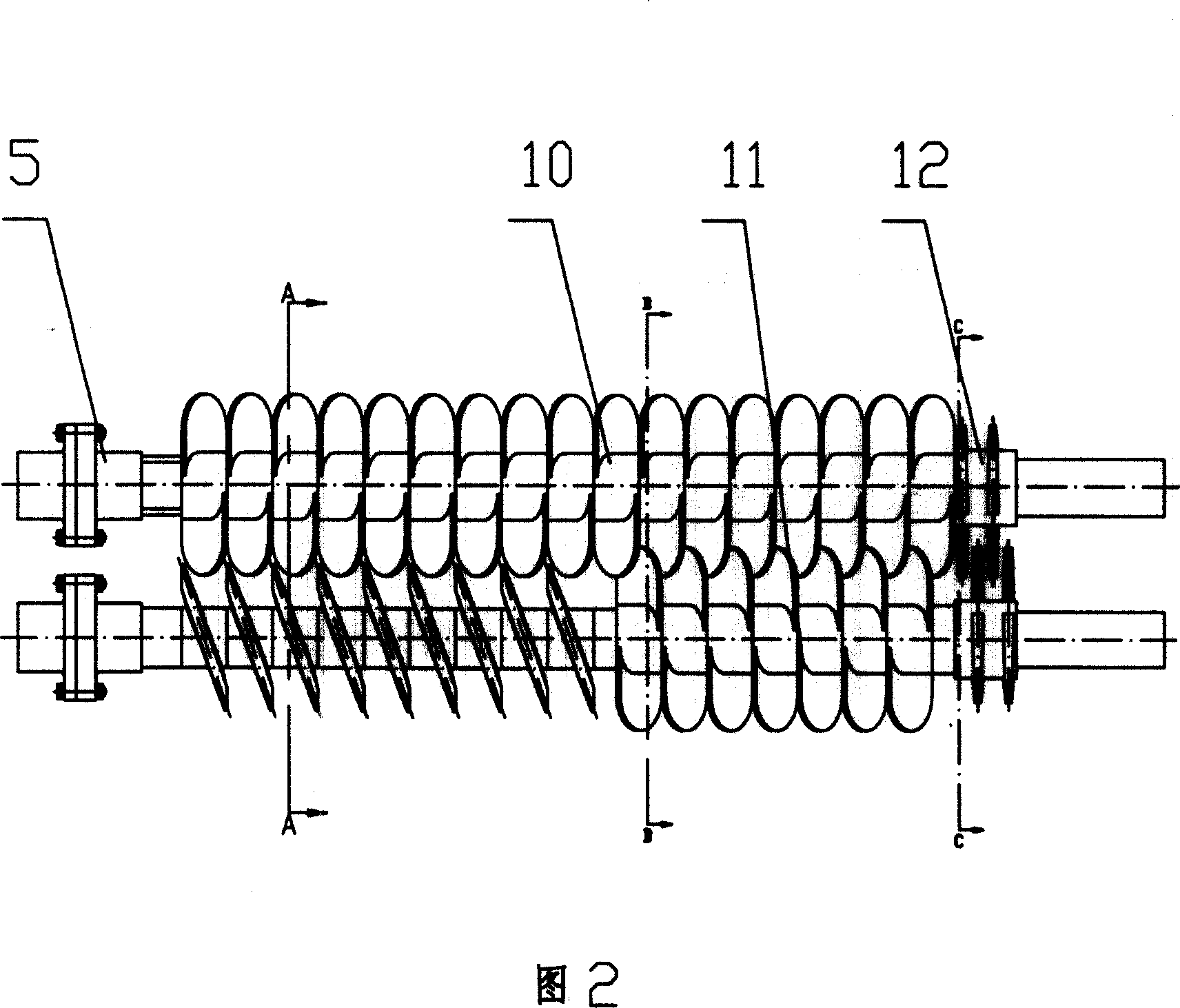

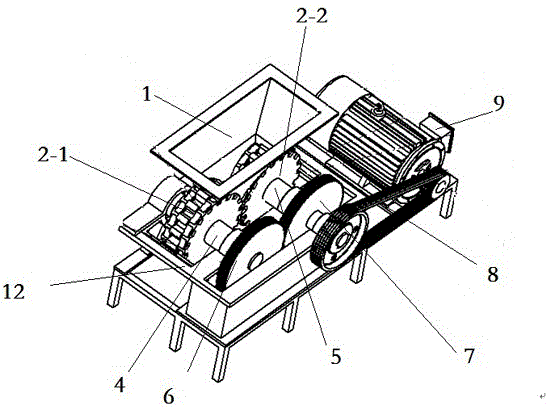

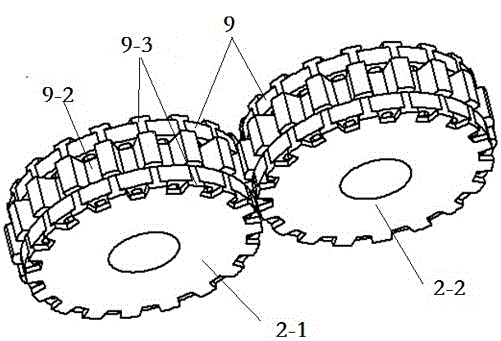

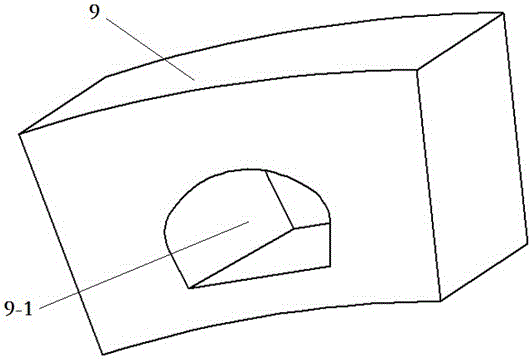

Coal slime rubbing-kneading equipment

ActiveCN101125307AImprove crushing effectNot prone to adhesionGrain treatmentsPulp and paper industryReducer

The present invention relates to a coal slurry twine and the device, wherein, the power source, the reducer, the gear box, the feed bin and the material outlet hopper are arranged on the bottom frame, and the transmission shaft is a pair of shafts rotating in an opposite direction. The two rotating shafts are respectively provided with spiral cutting blades with different rotating direction, and synchronously the two rotating shafts are respectively provided with the non spiral cutting blades. The cutting blade on the crossed part of the phase positions of the left rotating cutting blade and the right cutting blade has the cutting up effect for the coal slurry. The cutting blade on the equal part of the phase positions of the left rotating cutting blade and the right cutting blade has the tearing up effect for the coal slurry. The invention makes cutting and tearing to the coal slurry after dehydration by cutting and tearing methods, and synchronously makes the coal slurry transported along the axial direction. When cutting and tearing the material with certain glutinosity, the phenomenon of glued connecting, agglomeration and blocking is unlikely to be produced, and the invention particularly has good effect for the coal slurry smashing after dehydration.

Owner:光大清洁技术股份有限公司

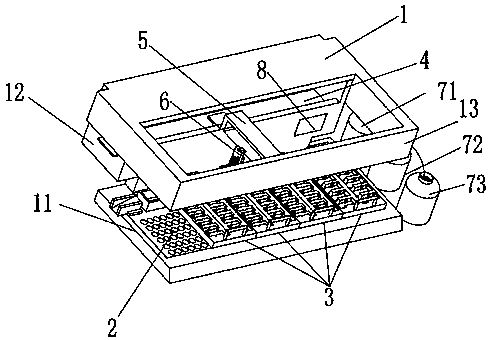

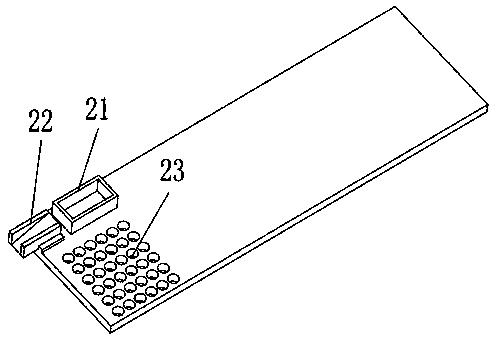

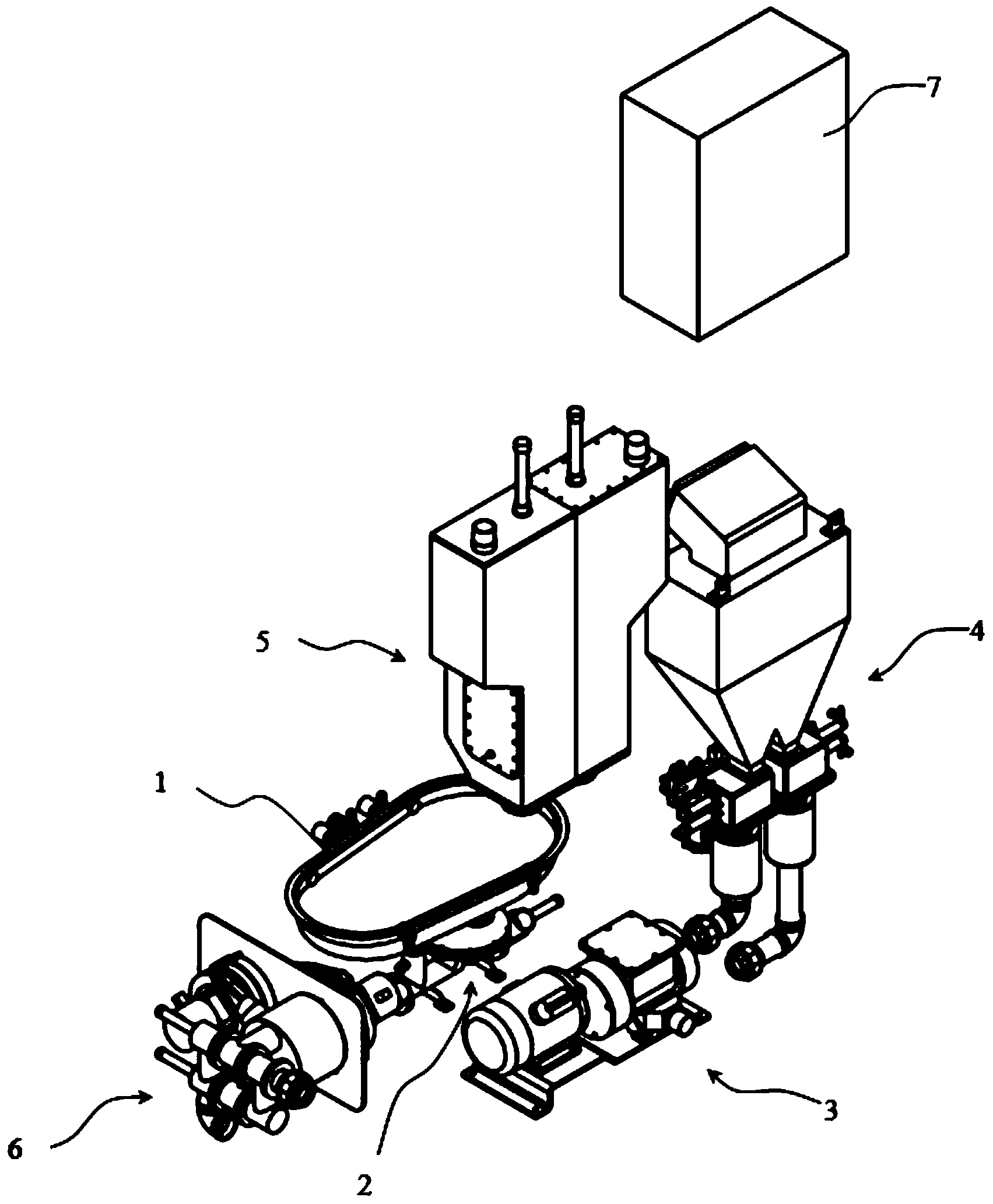

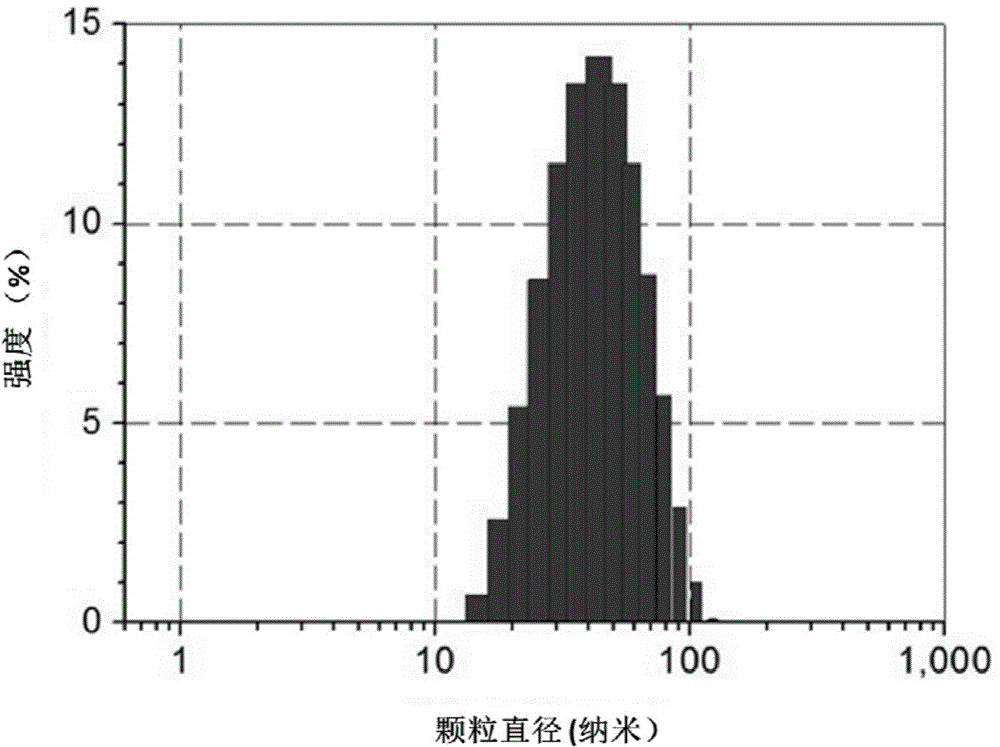

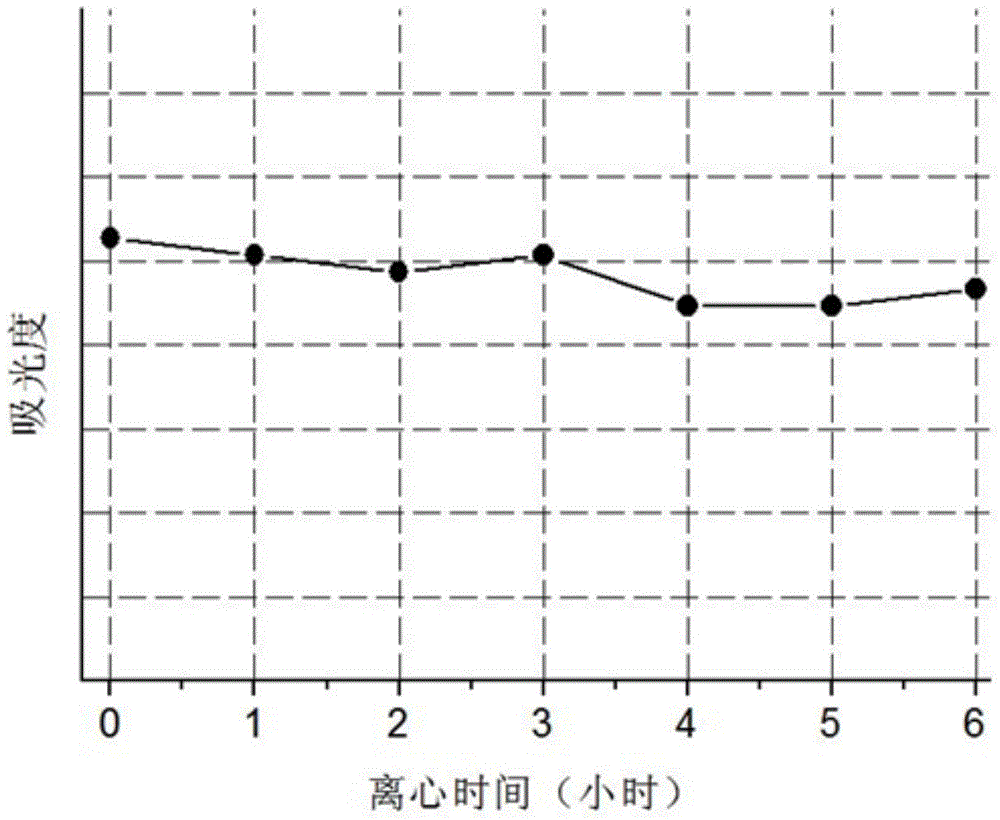

Liquid-based cell sheet producing system and liquid-based cell sheet producing method

ActiveCN103398890ASave resourcesSave on consumables and reagentsPreparing sample for investigationEngineeringCantilever

The invention discloses a liquid-based cell sheet producing system which comprises a rack, a sheet producing platform fixed on the rack, a plurality of sheet producing plates fixed on the sheet producing platform, a moving device perpendicularly connected with a bearing frame of the rack, a mechanical arm perpendicularly and slidingly connected with the moving device, a cantilever perpendicularly and slidingly connected with the mechanical arm, a reagent bottle connected with the cantilever by a catheter, and a microcomputer system controlling the moving device, the mechanical arm and the cantilever, wherein a control window is arranged on the rack, and controls the microcomputer system; and the reagent bottle comprises a waste liquid barrel, a flushing fluid reagent bottle part and a buffer fluid reagent bottle part. A liquid-based cell sheet producing method adopts the liquid-based cell sheet producing system. With the adoption of the technical scheme, the defects that a system operation mode is single, a procedure is solidified, a pipeline cannot be flushed automatically, a requirement on the quantity of specimens is strict, flux is low, energy consumption and reagent consumption material loss are great, a failure rate is high, maintenance is difficult, and equipment is costly are overcome.

Owner:MOTIC XIAMEN MEDICAL DIAGNOSTICS SYST

Double-roller briquetting machine

The invention discloses a double-roller briquetting machine which comprises a base and a feeding opening. A first pressing roller and a second pressing roller which are engaged with each other are mounted in the base. The feeding opening is located above the engagement position of the first pressing roller and the second pressing roller. The two side faces of every two adjacent teeth on the first pressing roller and the second pressing roller are provided with single modules. A mold hole is formed in each single module. A compression cavity is jointly formed by every two adjacent teeth on the first pressing roller and the second pressing roller and the corresponding single modules. According to the double-roller briquetting machine, the types of different current popular biomass extrusion molding machines are provided, the device is of an open structure, and the single modules are convenient to replace; material blocking is not prone to happening, and the extrusion molding efficiency is high; and meanwhile the double-roller briquetting machine is simple in structure, low in manufacturing cost and convenient to use and facilitates batch production.

Owner:JIANGSU UNIV

Harmless resource dry type sanitary tool and method for treating feces or urine

InactiveCN103462549AEasy to collectPrevent splashBathroom accessoriesAgainst vector-borne diseasesPositive pressureAnimal feces

The invention relates to a harmless resource dry type sanitary tool and a method for realizing better feces or urine treatment effect. The sanitary tool comprises a fan assembly, a feces and urine separating device, a powder feeding device and a feces and urine treatment device, wherein the feces and urine separating device is arranged under a feces hopper, the powder feeding device is used for respectively feeding powder into the separated feces and urine, the feces and urine treatment device comprises two tank bodies which are used for respectively treating feces or urine, each tank body is provided with a feeding port, an air passage port and a solid discharge port, the feeding port is communicated with the powder feeding device, the air passage port is communicated with the fan assembly, an inner cavity of each tank body is provided with a feces collecting pipe, a retaining plate and a solid and liquid separator, the feces collecting pipe is communicated with the feeding port, the retaining plate is positioned at one side of the air passage port to form a bypass passage, and the fan assembly provides positive pressure for discharging solid matters at the bottom of the tank body. The method comprises the step of mixing the feces or urine with the powder, namely under the action of pneumatic force and self weight, the feces or urine and the powder do reciprocating circulation movement along the bypass passage which is formed by the retaining plate between the feces collecting pipe and the air passage port in each tank body.

Owner:上海伊洁环保设备工程有限公司

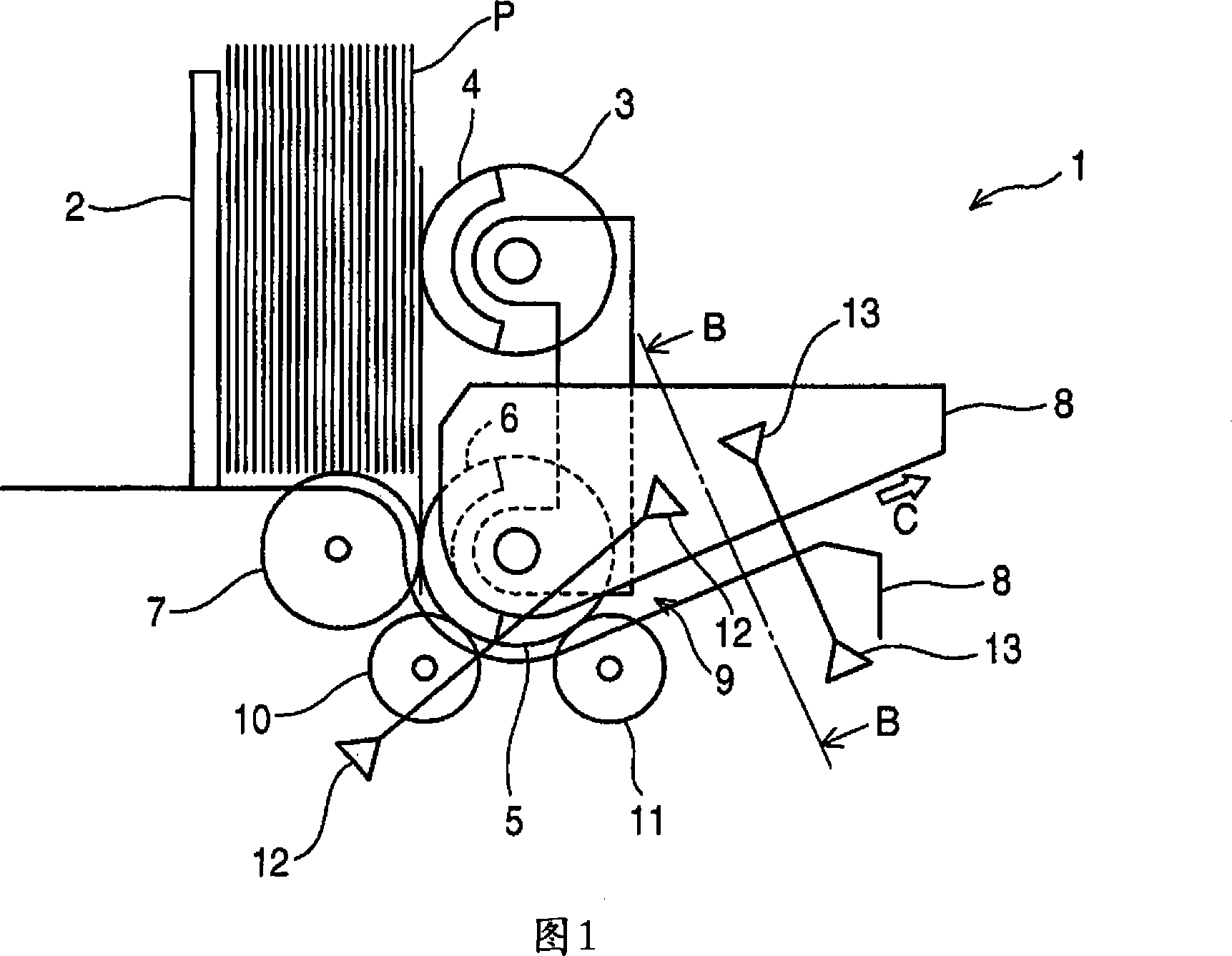

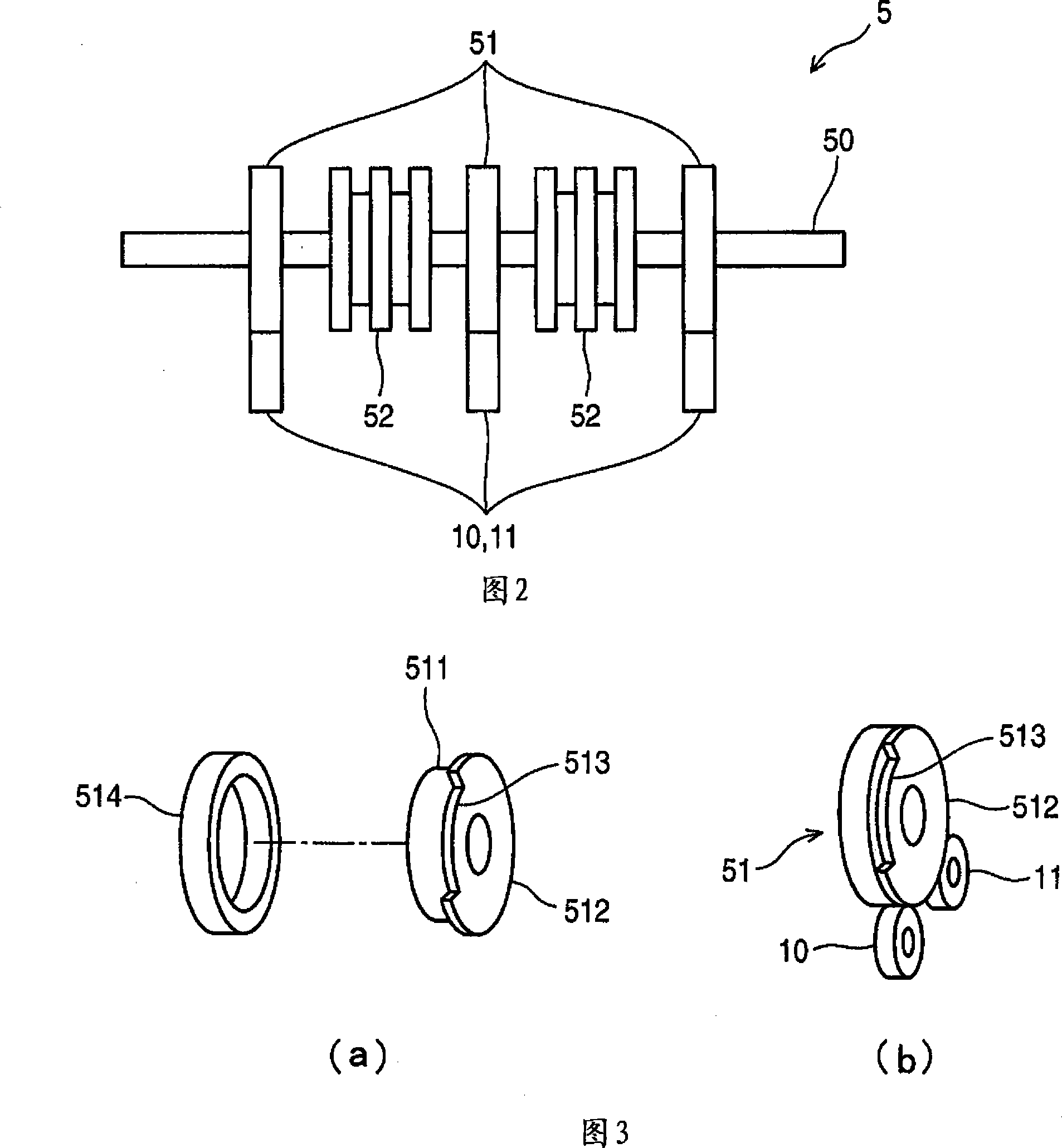

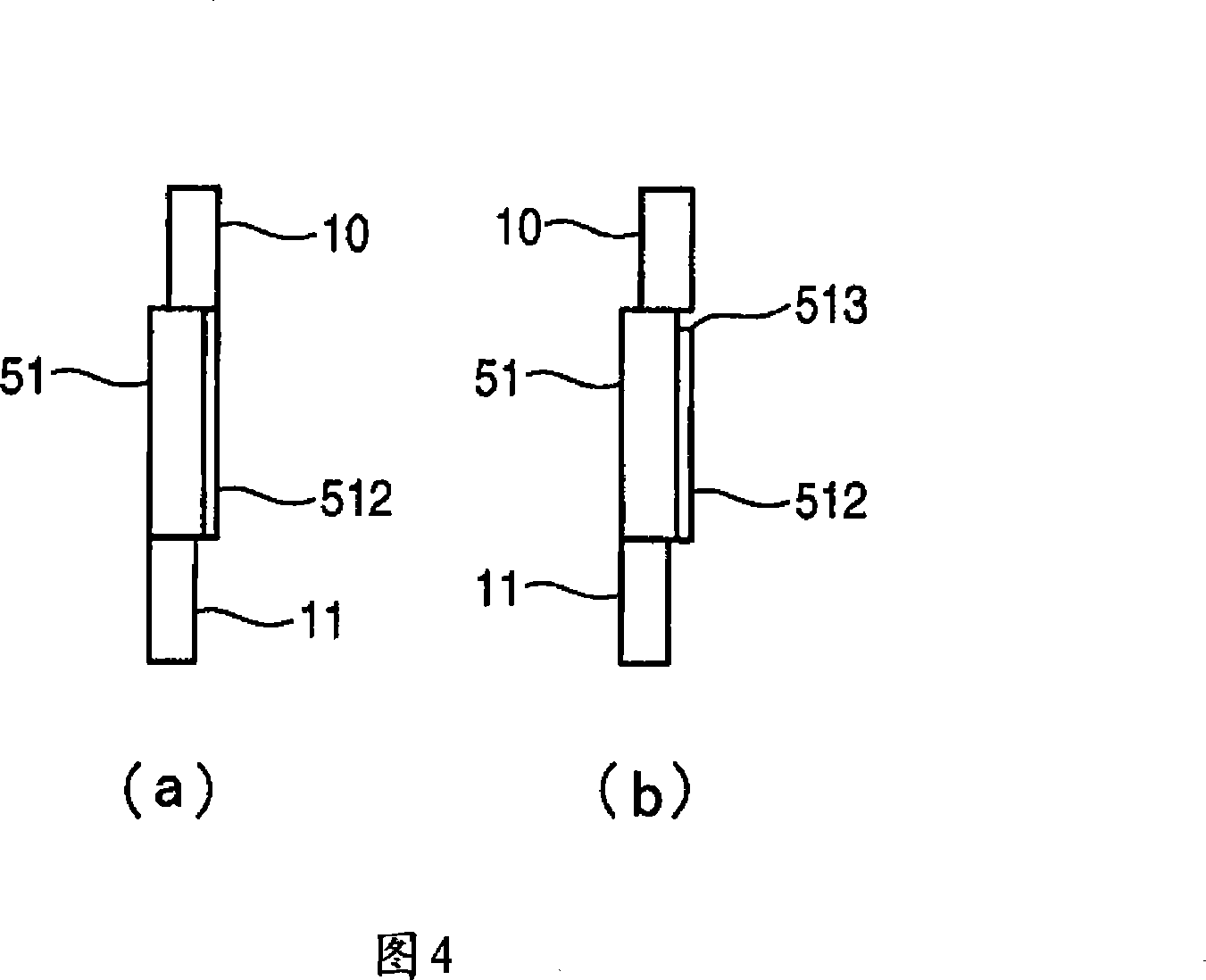

Separating mechanism for paper

InactiveCN101209784ANot prone to cloggingImprove operating rateArticle feedersArticle separationElastic componentPulp and paper industry

The present invention provides a paper disengaging mechanism, capable of detecting distorted paper before being collected into a machine. Papers exported one by one from gate roll wheel hub (52) are holded by an elastic component of a conveying roller wheel hub (51) and a first conveying roller (10), and are transmitted to a second conveying roller (11), when the front of the paper is transmitted to the second conveying roller (11), to make the first conveying roller (10) contact to a horniness component of the conveying roller wheel hub to reduce the force for conveying paper and make the distorted paper pass through with inclined state.

Owner:OKI ELECTRIC IND CO LTD

Long distance conveying and drag reducing method for sludge

The present invention belongs to the field of water conservancy engineering technology, and is long distance conveying and drag reducing method for sludge. Before sludge is conveyed for long distance, it is high frequency micro amplitude vibrated with the high frequency micro amplitude vibration source set in the pipeline inlet section to become fluidized slurry with high flowability. During the conveyance of slurry, it is high frequency micro amplitude vibrated with the high frequency micro amplitude vibration sources to ensure the homogeneity and flowability of the slurry and small conveying drag. The present invention is simple and has less water head loss of the conveyed sludge, less blocking of pipeline, low power consumption and high efficiency. The present invention may be used widely.

Owner:SHANGHAI JIAO TONG UNIV

Fully-automatic screening plant for aggregate

InactiveCN107626578ARealize blankingNot prone to cloggingSievingScreeningArchitectural engineeringElectric machinery

The invention discloses a fully-automatic screening plant for an aggregate, and relates to the technical field of building appliances. A connecting spring is installed at the bottom part of a box body; the lower end of the connecting spring is installed at the upper end of a support foot; a vibration motor is installed on a cross rod of the support foot; a feed hopper is installed at the right upper end of the box body; a screening filter screen is arranged slantly in the box body, is arranged in a way that the left part is low and the right part is high, and is fixed on the inner side wall ofthe box body through a right angle frame; a large particle discharge pipe is installed at the left end of the screening filter screen; a driver is arranged on the upper side of the large particle discharge pipe; a flashboard is installed on a driving rod of the driver and is connected in a hole groove of the large particle discharge pipe in a penetrating manner; a material guide plate is arrangedon the lower side of the screening filter screen and is arranged in a way that the left part is high and the right part is low; a small particle discharge pipe is installed at the right end of the material guide plate. The fully-automatic screening plant automatically screens and discharges the material, does not cause the phenomenon of blockage easily in use, is high in efficiency, and can workcontinuously.

Owner:JINLING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com