Rotational flow type fluidized bed crystallizer

A technology of fluidized bed and crystallizer, which is applied in the field of crystallization of chemical engineering, can solve the problems of unsatisfactory crystal shape and particle size distribution of crystallized products, and achieve the effect of being conducive to popularization and use, narrow particle size distribution and neat appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

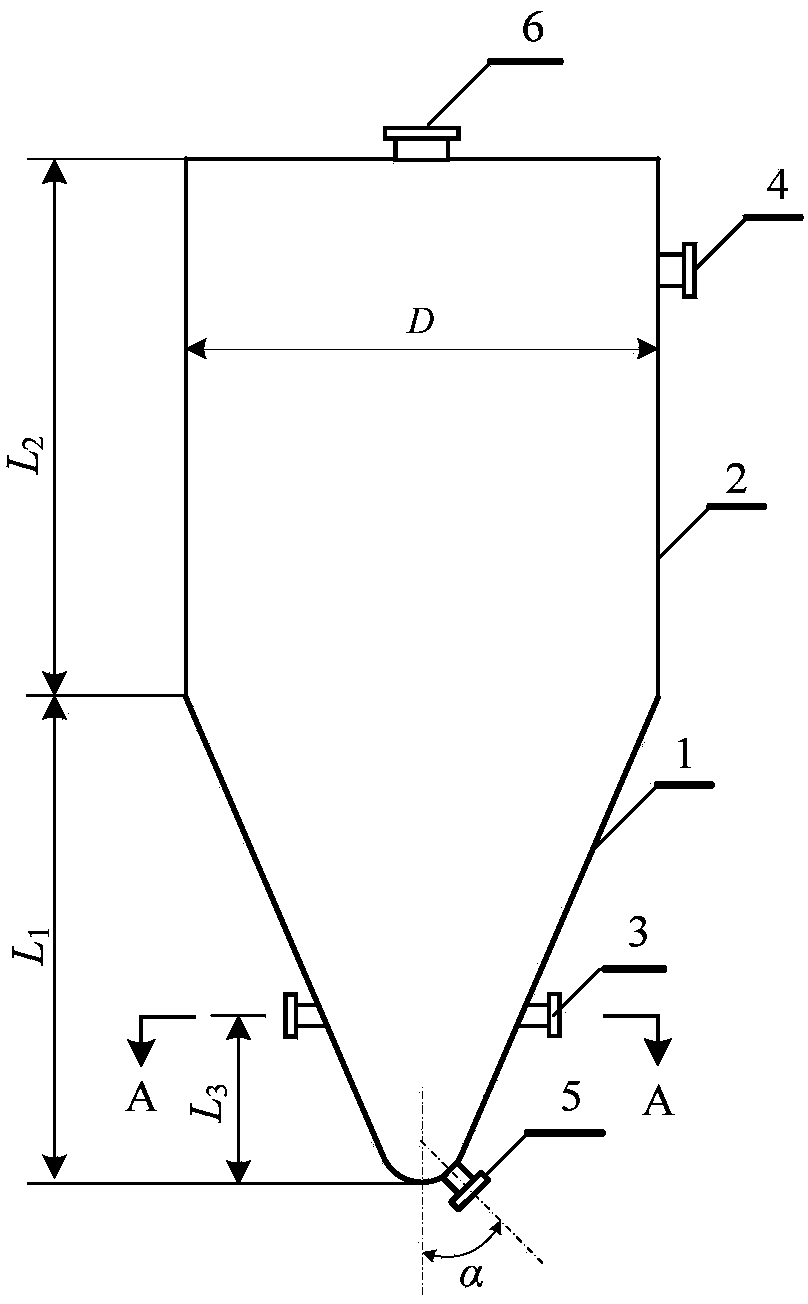

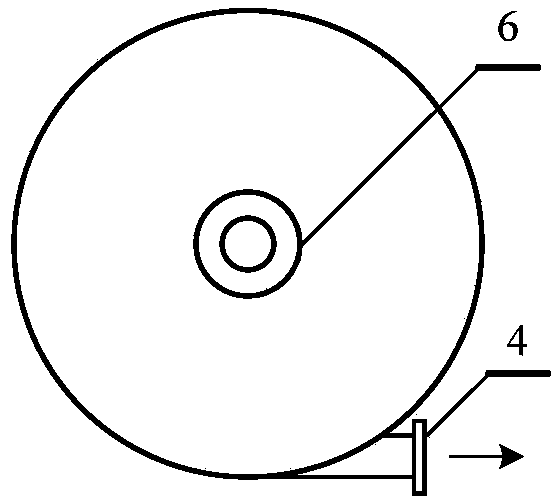

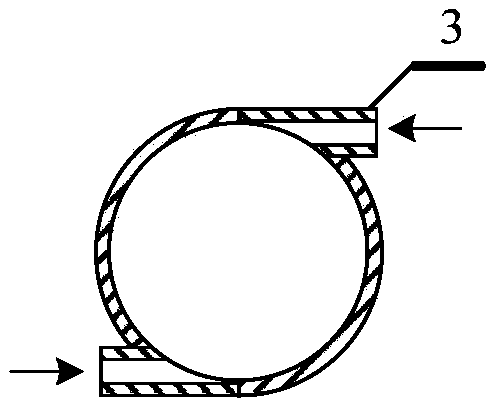

[0030] In this embodiment, the structure of the swirling fluidized bed crystallizer is as follows figure 1 As shown, it is composed of a bed body, the bed body is a combination of a stainless steel cylinder 2 and a stainless steel conical cylinder 1, the inner diameter of the large end of the conical cylinder is the same as that of the cylinder, and the cone top of the conical cylinder is a circular Arc-shaped, the conical cylinder 1 is located below the cylinder 2, and its large end and the lower end of the cylinder are welded to form an integrated structure. When welding, the axes of the cylinder 2 and the cone 1 should be coincident; the cylinder The upper end of the body 2 is closed, and the closed end surface is provided with a seed crystal inlet 6, and the side wall of the lower section of the conical cylinder 1 is provided with a feed pipe 3 for adding the feed liquid. There are two feed pipes surrounding the conical cylinder The same height is distributed 180° apart, ...

Embodiment 2

[0035] In this embodiment, the structure of the swirling fluidized bed crystallizer is as follows Figure 4 As shown, it consists of a bed body and a cooling jacket 9 . The bed body is a combination of a stainless steel cylinder 2 and a stainless steel conical cylinder 1, the inner diameter of the large end of the conical cylinder is the same as that of the cylinder, the top of the conical cylinder is arc-shaped, and the conical cylinder 1 is located at Below the cylindrical body 2, its large end and the lower end of the cylindrical body form an integrated structure by welding. When welding, the axes of the cylindrical body 2 and the conical cylindrical body 1 should be coincident; the upper end of the cylindrical body 2 is closed, and the closed The end face is provided with a seed crystal feeding port 6, and the side wall of the lower section of the conical cylinder body 1 is provided with a feed pipe 3 for adding feed liquid. The feeding pipes are all located in the horizo...

Embodiment 3

[0040] In this embodiment, the swirling fluidized bed crystallizer in Example 2 is combined with other equipment into a batch crystallization system, and its structure is shown in Figure 6 ,From Figure 6 It can be seen that the batch crystallization system includes a swirling fluidized bed crystallizer 10 , a circulation pump 11 , a batching tank 12 , a liquid-solid separator 13 and a mother liquor storage tank 14 . The liquid inlet pipe of the circulation pump 11 is connected with the discharge pipe that constitutes the bed body of the swirl type fluidized bed crystallizer 10 through a pipe fitting, and the liquid outlet pipe of the circulation pump 11 is connected with the composition of the swirl type fluidized bed crystallizer 10 through a pipe fitting. The feed pipe provided on the bed body is connected, the batching tank 12 is placed at a high position, and its discharge port is connected to the pipe fitting connected to the liquid outlet pipe of the circulating pump 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com