Patents

Literature

66results about How to "No fragmentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

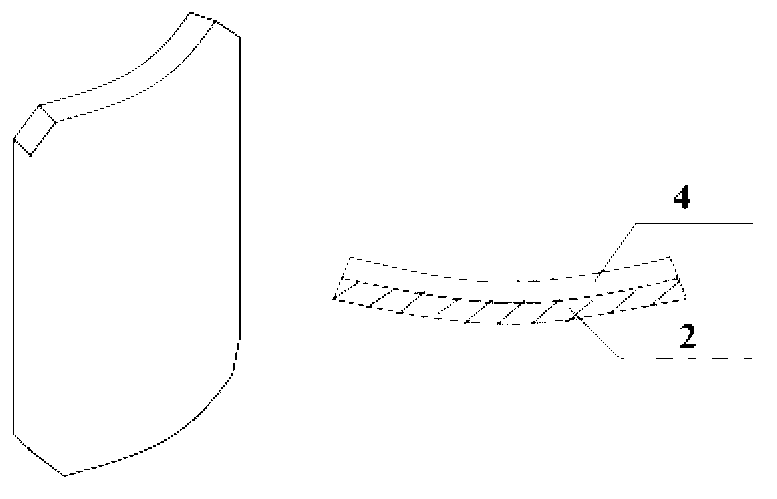

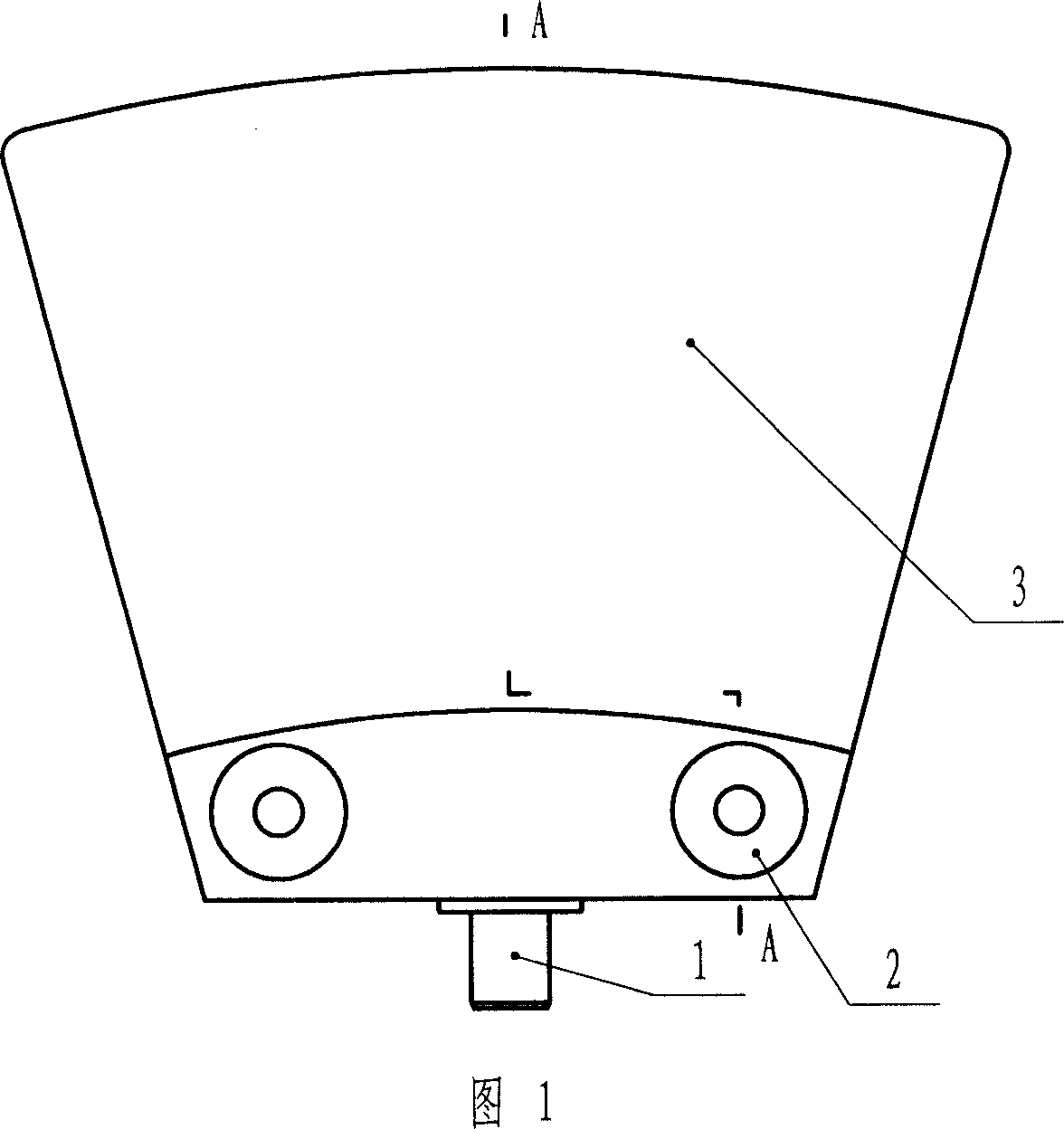

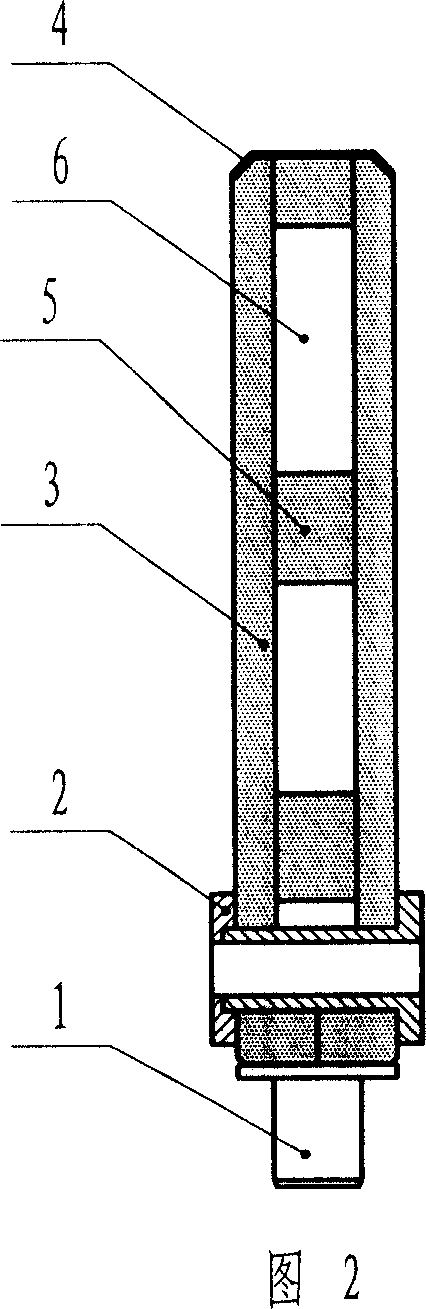

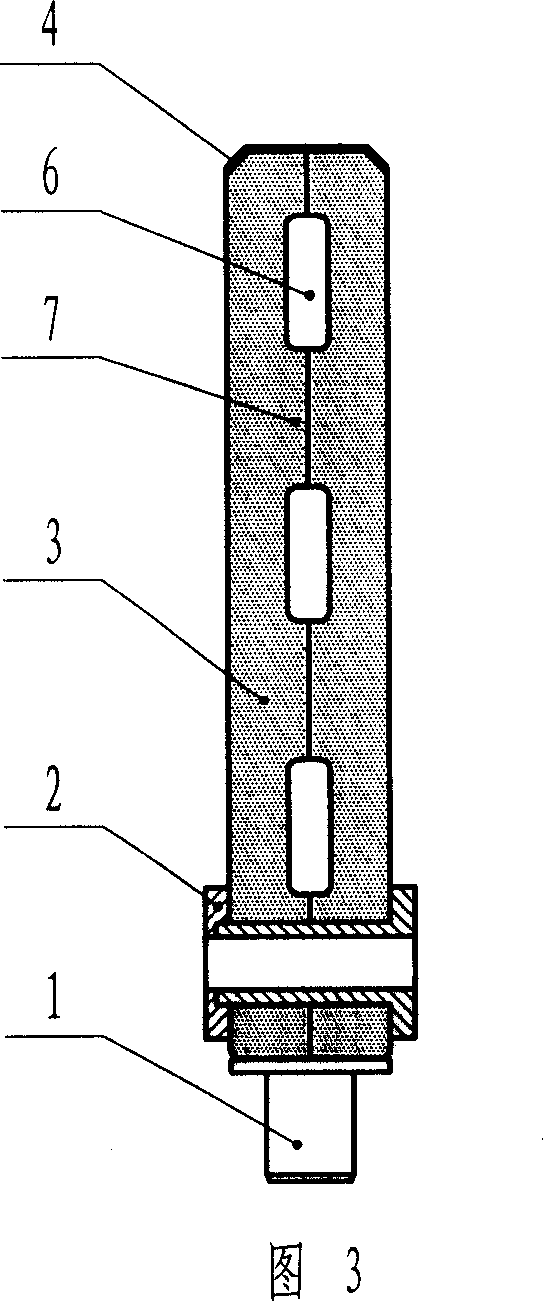

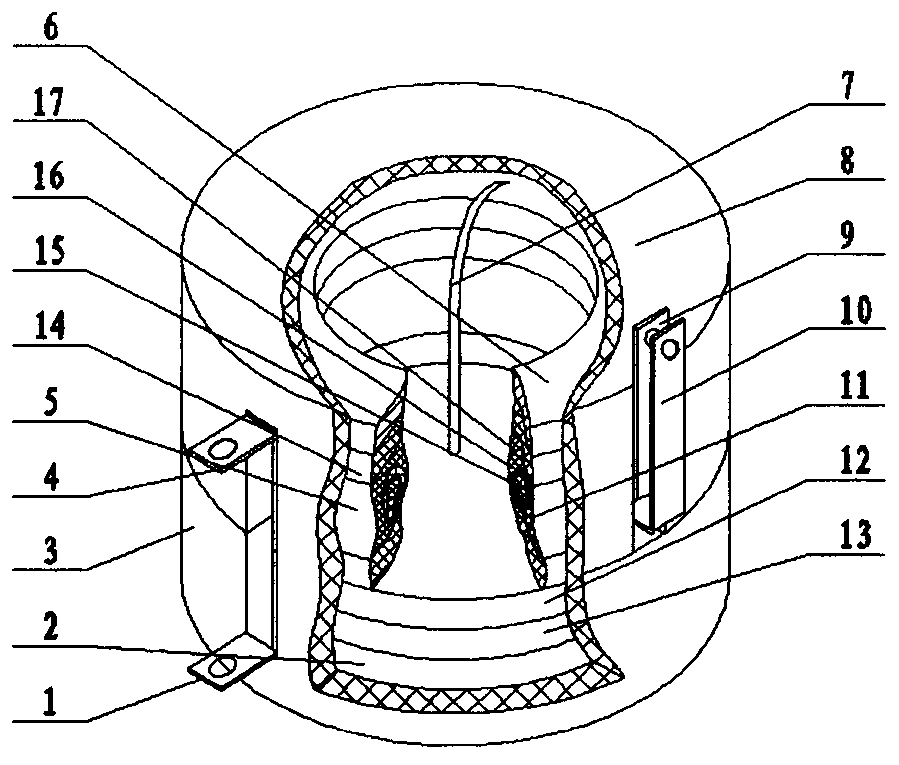

Composite bulletproof flashboard and preparation method and application thereof

ActiveCN103017609ANo fragmentationImprove bulletproof survivabilitySynthetic resin layered productsPersonal protection gearNanotechnologyCoating

The invention discloses a bulletproof flashboard and a preparation method and an application thereof. The preparation method of the bulletproof flashboard comprises the following steps of: bonding a protective layer, a ceramic layer, a middle layer, a supporting layer and a buffer layer which are coated with bonding agents in sequence; coating an outermost layer with a coating layer which is coated with a bonding agent; and molding under the negative pressure and curing. Due to the adoption of a novel structural design for the bulletproof flashboard, the entire bulletproof flashboard can effective resist the impact of bullets continuously shot by a light weapon without being broken. Moreover, the bulletproof flashboard has the characteristics of light weight, high bullet resistance, easiness in processing and the like.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

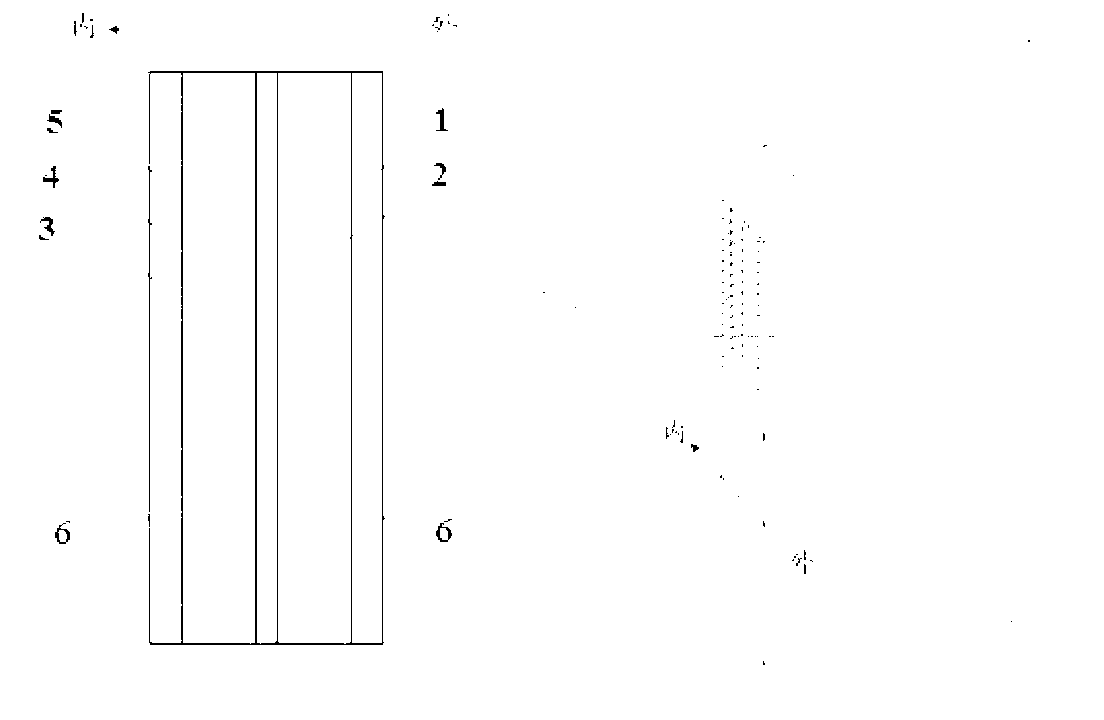

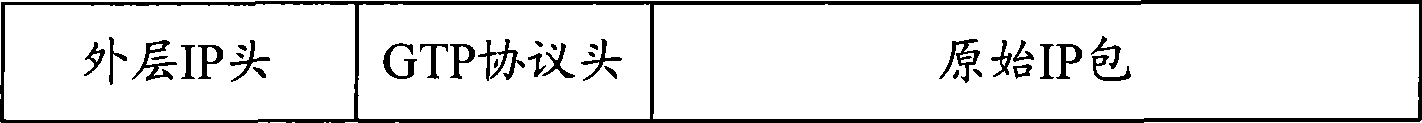

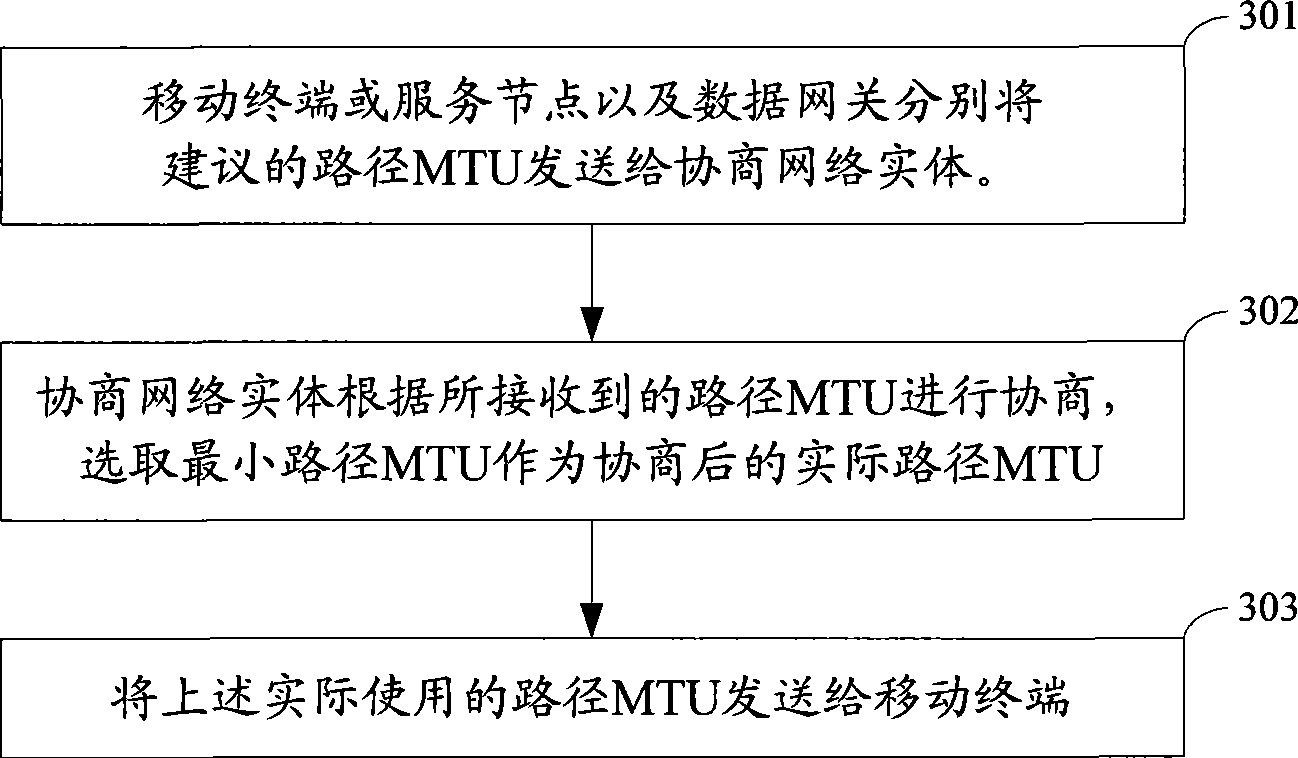

Method, device and system for negotiating maximum transmission unit value of path

InactiveCN101400085AImprove transmission performanceNo fragmentationNetwork traffic/resource managementWireless network protocolsMobile communication networkMaximum transmission unit

An embodiment of the invention discloses a method of consulting path MTU, comprising: consulting according to the received path MTU, selecting the minimal path MTU as the practical path MTU after consulting, transmitting the practical path MTU into a movable terminal. The embodiment of the invention also discloses a device of consulting the path MTU and a system, the device comprising: a receiving module, a consulting module and a transmitting module; the system comprising: a movable terminal, a service node and a data gateway. According to the method, the method and the system, the service node and the data gateway obtain the practical path MTU through consulting and respectively inform the movable terminal and opposite terminal, which use correct path MTU to control the largest length of the transmitted original IP message, causing the original IP message after entering the communication network not to generate bursts, thereby increasing transmission ability of the network.

Owner:HUAWEI TECH CO LTD

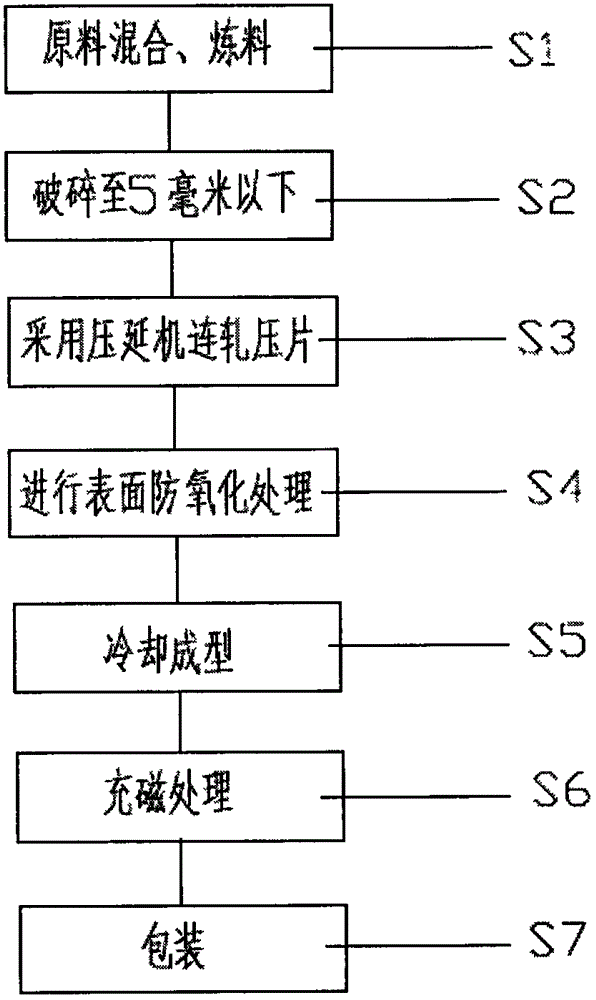

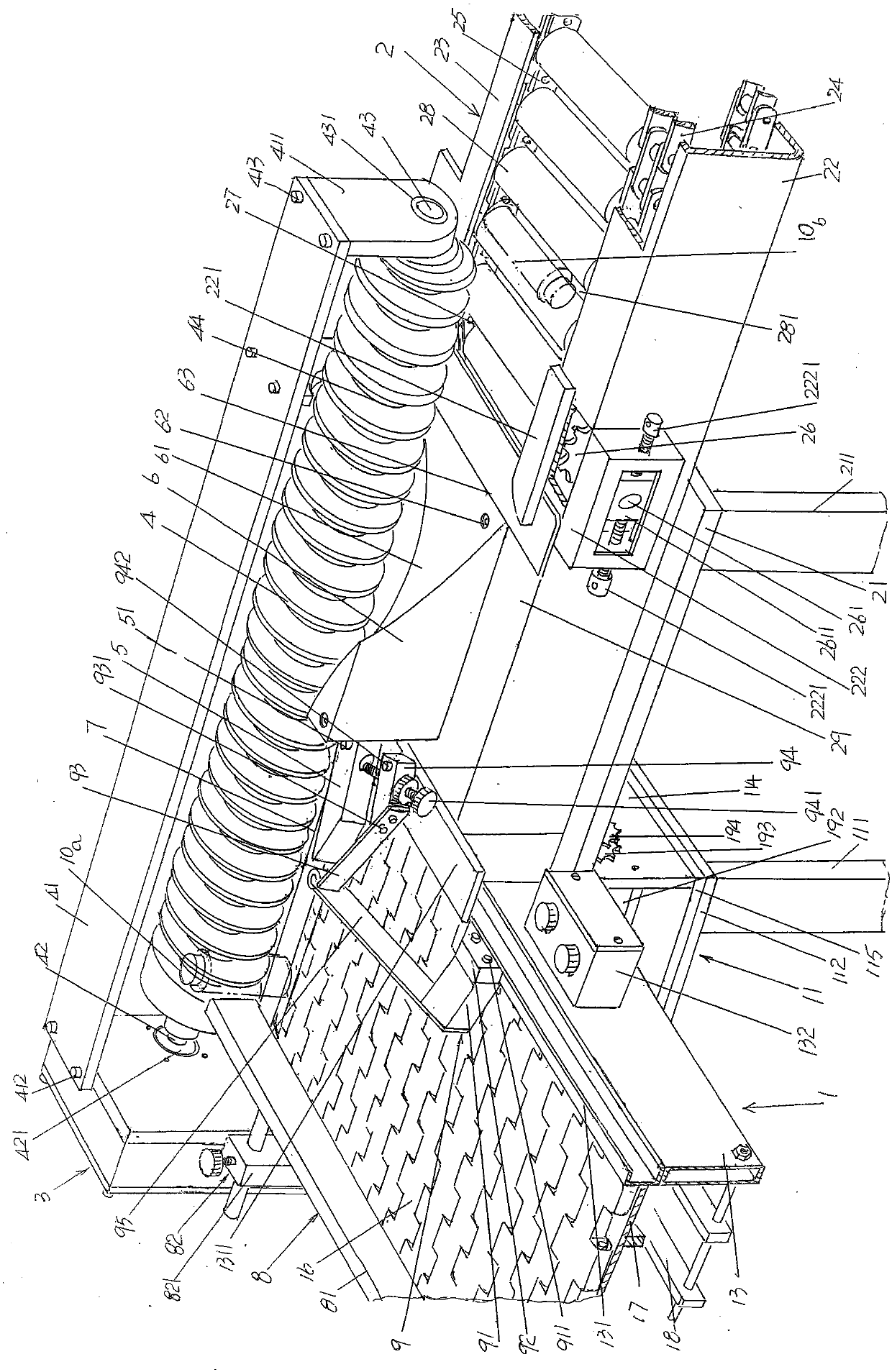

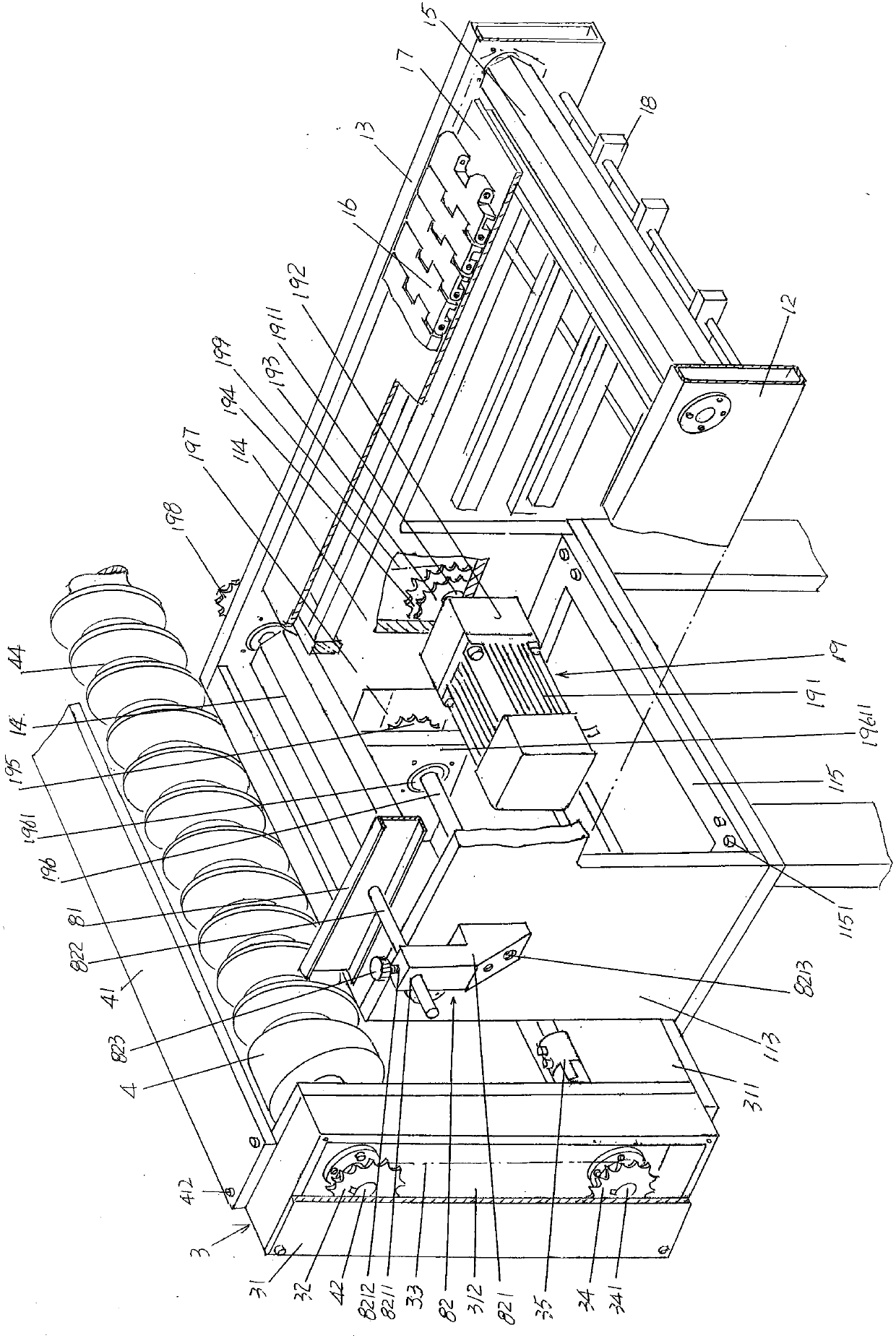

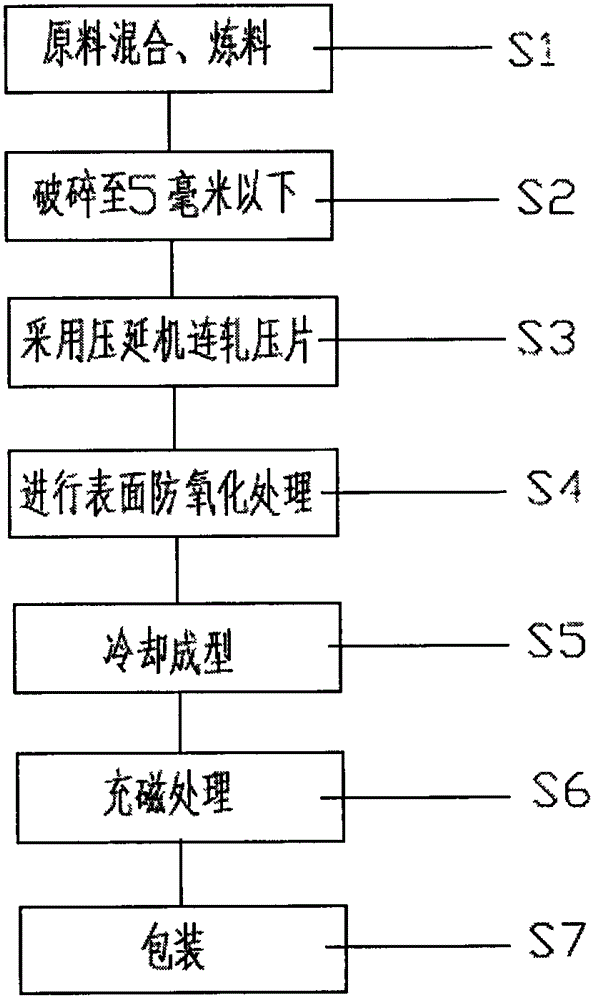

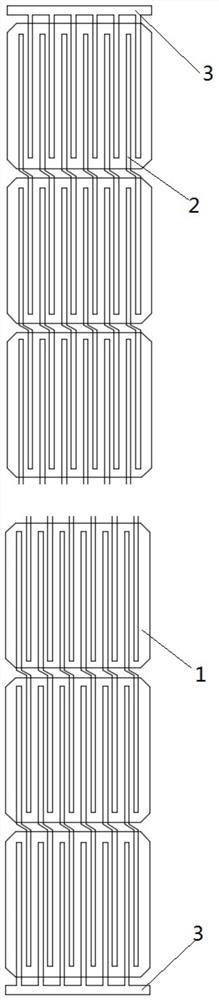

Bonded NdFeB (neodymium, ferrum and boron) strong magnet and preparation method thereof

ActiveCN102723165ALow densityUniform and stable magnetismPermanent magnetsInorganic material magnetismBoronFerric

The invention provides a bonded NdFeB (neodymium, ferrum and boron) magnet. The magnet comprises the following raw materials in percentage by weight: 80-95 percent of NdFeB powder, 0-20 percent of ferrite rubber magnetic powder, 0-20 percent of rubber, 0-20 percent of functional plastic, and the balance of assistant. The invention further provides a preparation method of the bonded NdFeB strong magnet. With the adoption of the bonded NdFeB strong magnet and the preparation method thereof, the produced product is soft, small in brittleness, high and stable in magnetic property, easy to be assembled, and various specifications and dimensions can be easily formed, and meanwhile, the preparation cost is low, the efficiency is high, the energy is saved the consumption is reduced; and moreover, the magnet and the method are environment-friendly and halogen-free, and are pollution-free for the environment.

Owner:金华市磁莱福磁铁科技有限公司

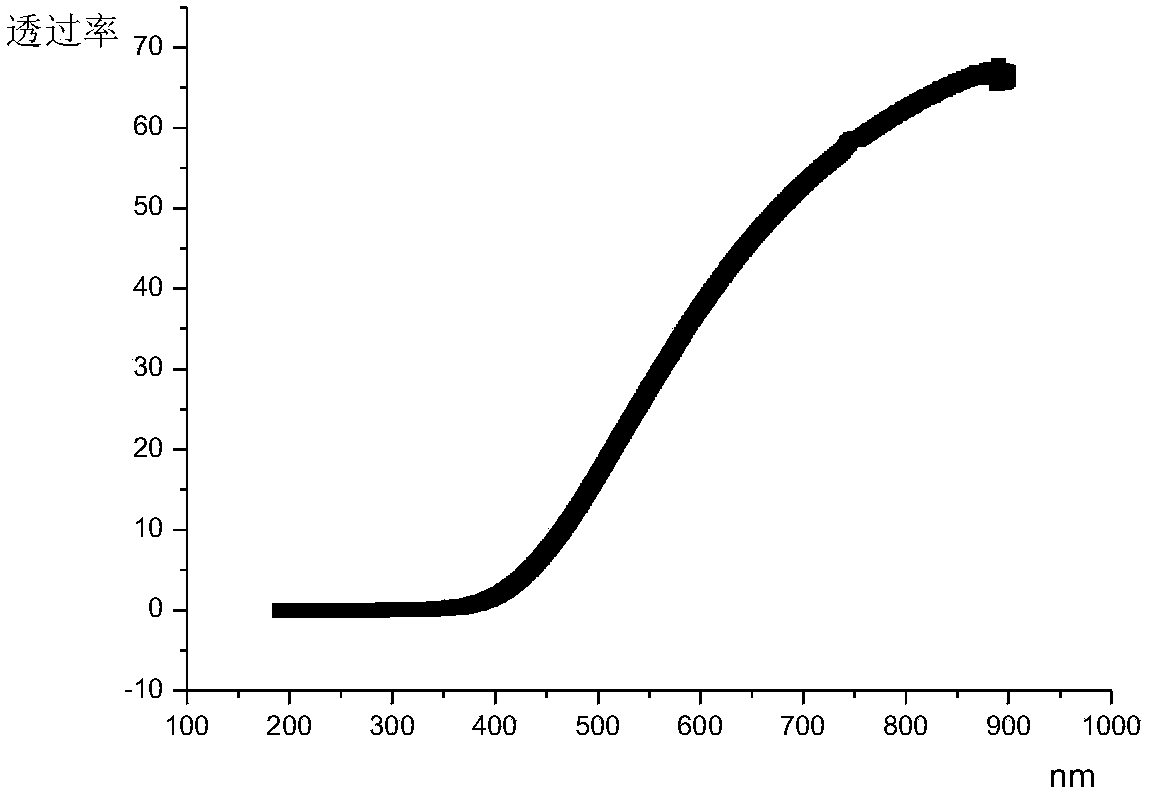

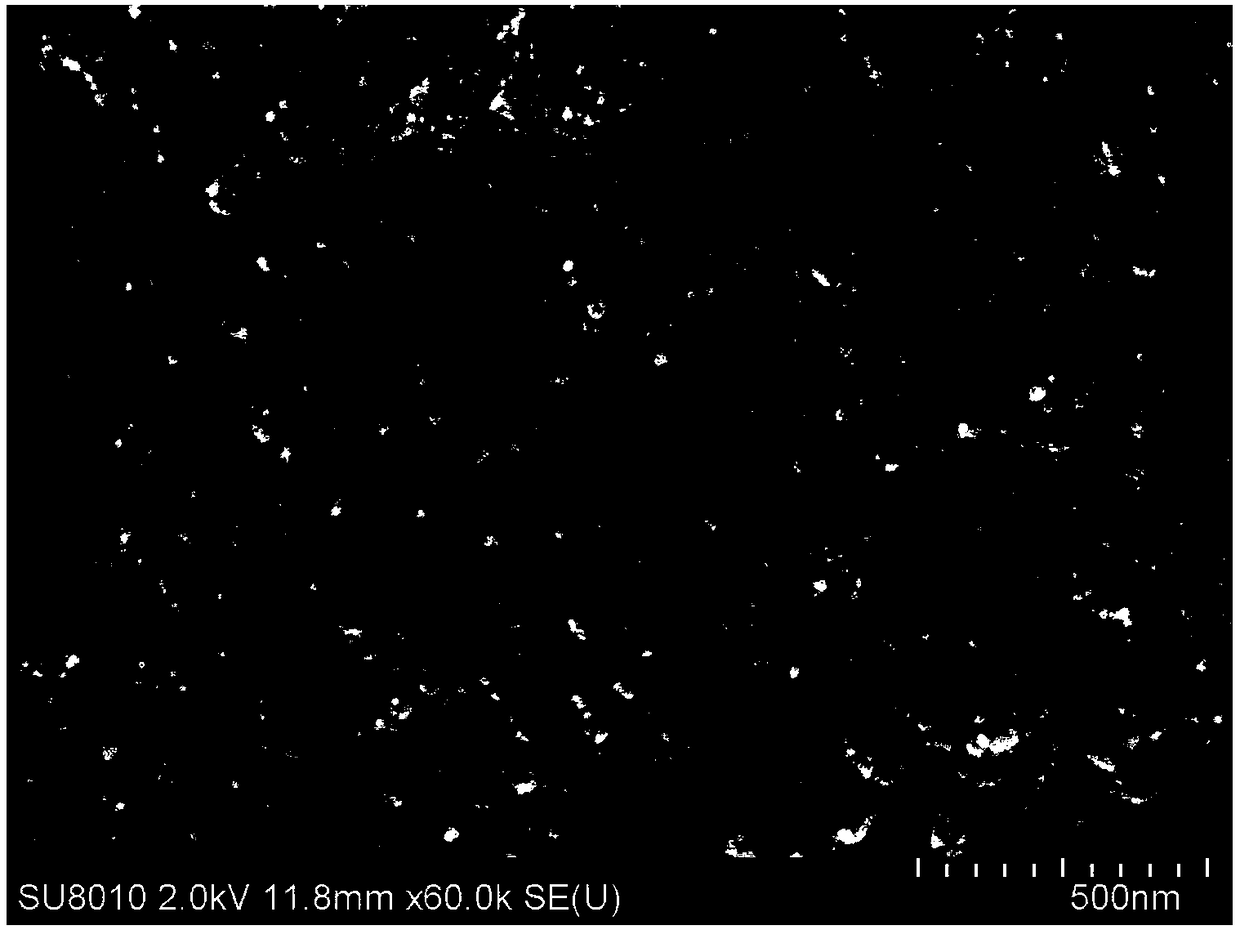

Polysilsesquioxane aerogel and preparation method thereof

The invention relates to a preparation method of a polysilsesquioxane material. The preparation method comprises the following steps that (1) in water and an organic solvent, acid is used for catalyzing a polysilsesquioxane precursor for hydrolysis to form sol; (2) organic alkali is added into a sol system for catalytic polycondensation to form gel; (3) the gel is aged and dried to obtain aerogel.The polysilsesquioxane aerogel has high tolerance degree on water, salt, acid, alkali and the like; high transmittance is realized in the visible light range; high shielding capability is realized onultraviolet light.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Application and method for temporarily reinforcing cultural relics in excavation site by one type of reinforcing material

InactiveCN104631105AMeet non-toxicFulfil requirementsWood working apparatusOld paper after-treatmentMentholFiber

The invention discloses application and a method for temporarily reinforcing cultural relics in an excavation site by one type of reinforcing material. The reinforcing material is selected one or more of 4-tert-butylcyclohexanol, coumarin and ethyl maltol. The reinforcing method comprises the following steps: heating and melting or dissolving one or the mixture of more than two of 4-tert-butylcyclohexanol, coumarin and ethyl maltol into an organic solvent to obtain a reinforcing solution; covering the cultural relics to be reinforced with fiber textiles, and pouring or brushing the prepared reinforcing solution on the fiber textiles or directly brushing the reinforcing solution on the excavated cultural relics; and naturally volatilizing the organic solvent in the reinforcing solution, and cooling and condensing to temporarily reinforce the cultural relics. The reinforcing material is safe and toxin-free and has low price, and can be in direct contact with a human body; and compared with newly-developed menthol and a derivative reinforcing material thereof, the harsh environments including high heat and the like can be met, and the problems that the melting point of menthol is low, the volatilization is too fast and the like are solved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

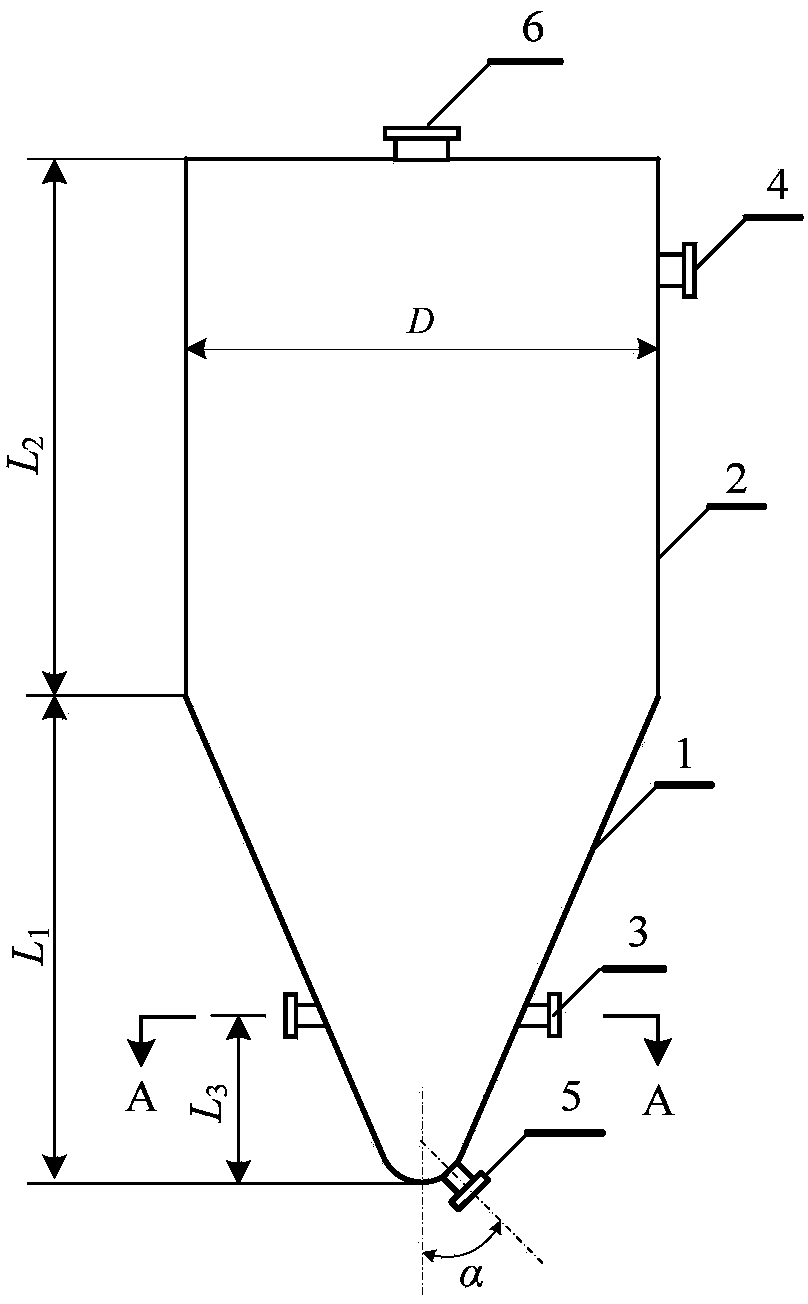

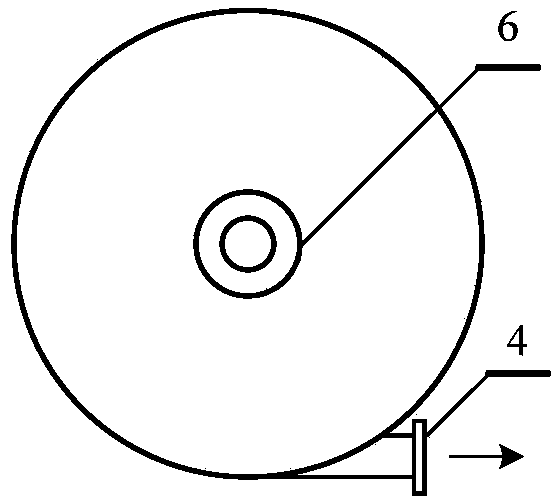

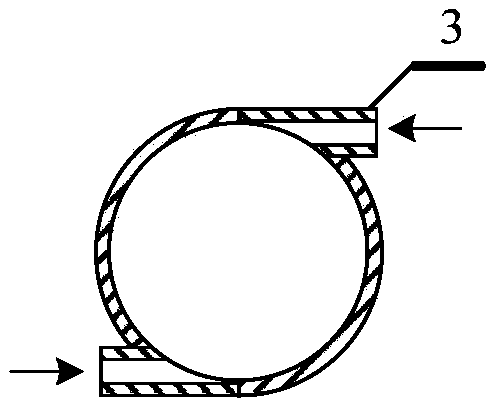

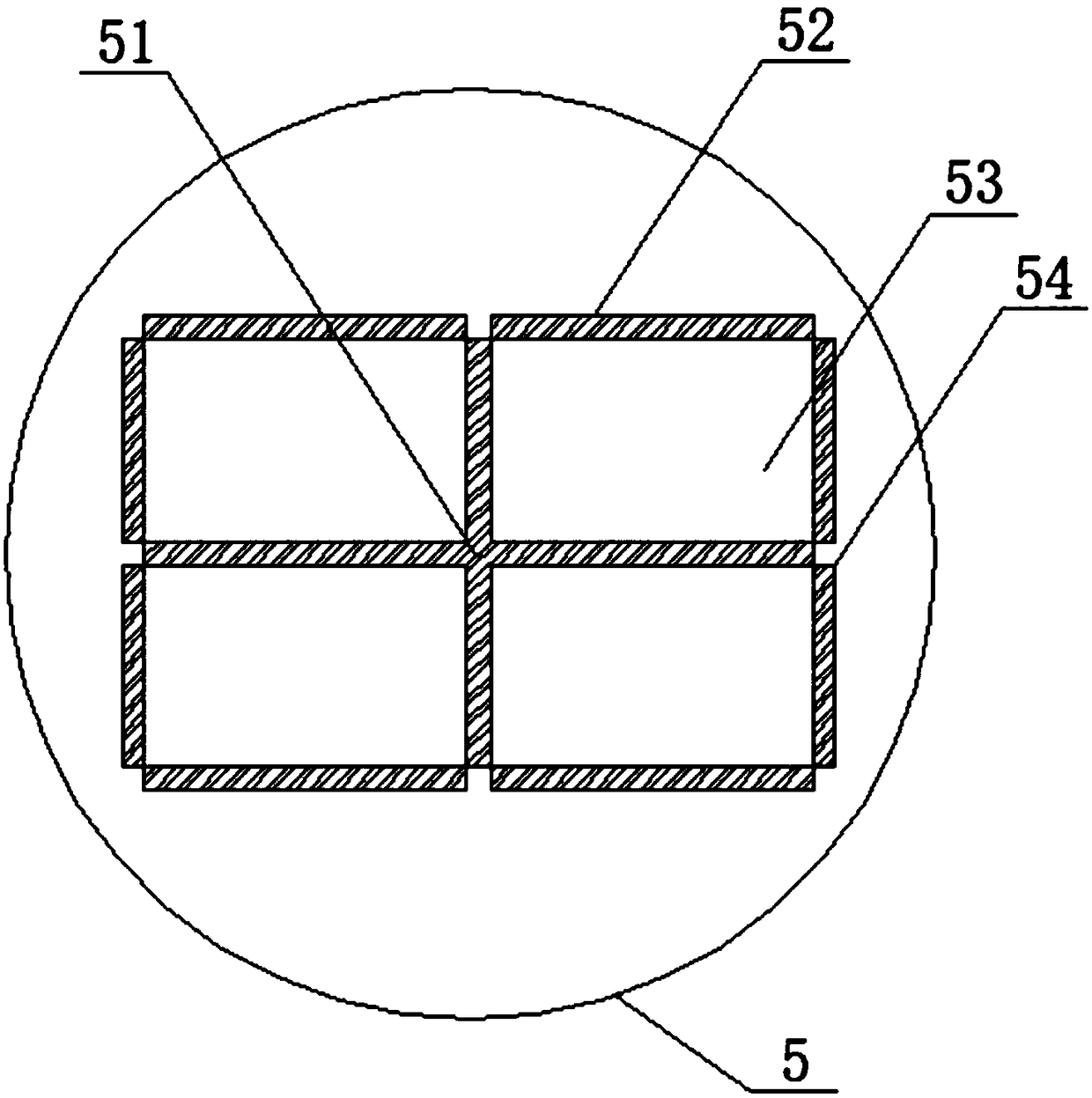

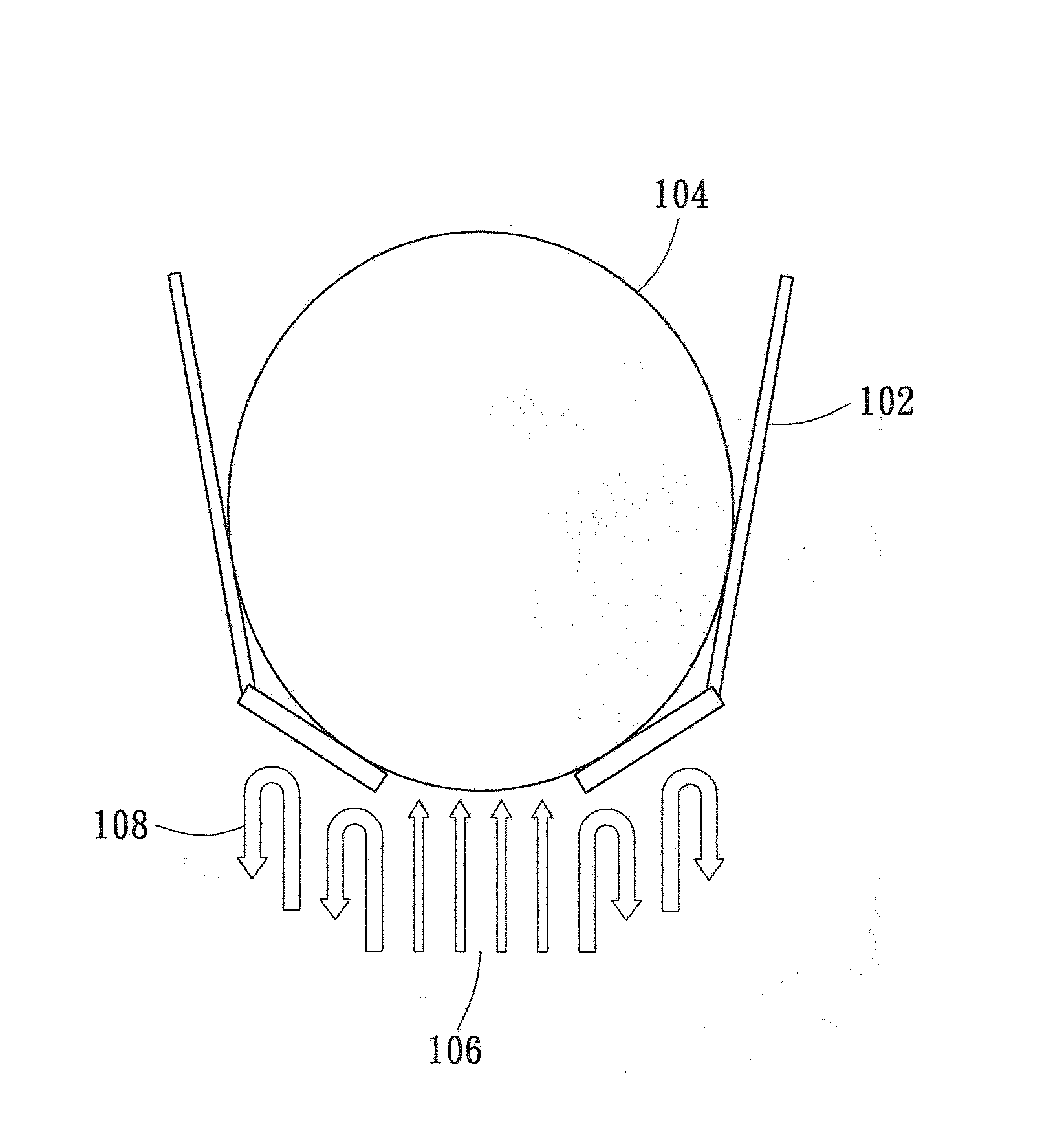

Rotational flow type fluidized bed crystallizer

InactiveCN104162288AEvenly dispersedNo fragmentationSolution crystallizationFluidized bedEngineering

The invention discloses a rotational flow type fluidized bed crystallizer. The rotational flow type fluidized bed crystallizer comprises a bed body, wherein the bed body is formed by combining a cylinder and a cone cylinder; the inner diameter of the large end of the cone cylinder is equal to that of the cylinder; the cone top of the cone cylinder is of a circular arc shape; the cone cylinder is positioned below the cylinder; the large end of the cone cylinder is connected with the lower end of the cylinder; the upper end of the cylinder is closed; a seed crystal adding opening is formed in the end surface of the upper end of the cylinder; at least two feeding pipes for adding material liquid are arranged on the side wall of the lower section of the cone cylinder and are uniformly distributed around the cone cylinder at the same height; each feeding pipe is positioned in the horizontal tangential direction of the cone cylinder; a crystal outlet is formed in the cone top of the lower end of the cone cylinder; a discharging pipe for outputting mother liquid is arranged on the side wall of the upper part of the cylinder and is positioned in the horizontal tangential direction of the cylinder, and an outlet of the discharging pipe is in accordance with the rotational direction of rotational flow formed by the material liquid. In order to meet requirements of a clearance crystallization process, a cooling jacket can be arranged on the basis of the structure.

Owner:SICHUAN UNIV

Preparation method of aluminum conductive paste of high-performance environment protection solar cell

InactiveCN101752459AImprove photoelectric conversion rateReduce stressFinal product manufactureNon-conductive material with dispersed conductive materialSilicon chipLinear expansion coefficient

The invention discloses a preparation method of aluminum conductive paste of a high-performance environment protection solar cell. The aluminum conductive paste produced by the method is free of lead and solves the problem of environment pollution. The linear expansion coefficient of lead-free glass powder obtained in the preparation process is close to that of a silicon chip, and the success rate after burning is improved. The preparation method of the paste comprises the following steps: (1) preparing glass powder; (2) preparing inorganic adhesive glass metal powder; (3) manufacturing organic carriers; (4) adopting carbon powder of 2-5 mu m for later use; and (5) preparing the aluminum conductive paste: taking the following components by mass percent: 75-85% of aluminum powder coated by aluminum nitride, 9-20% of organic carrier, 3-4% of inorganic adhesive glass metal powder and 1-3% of C powder, wherein the total amount is 100%, and after mixing, grinding with a three-roller mill to particle size of 15-30 mu m to obtain the product with the viscosity of 25000-35000 mpa.s.

Owner:广东鑫皇冠新材料有限公司

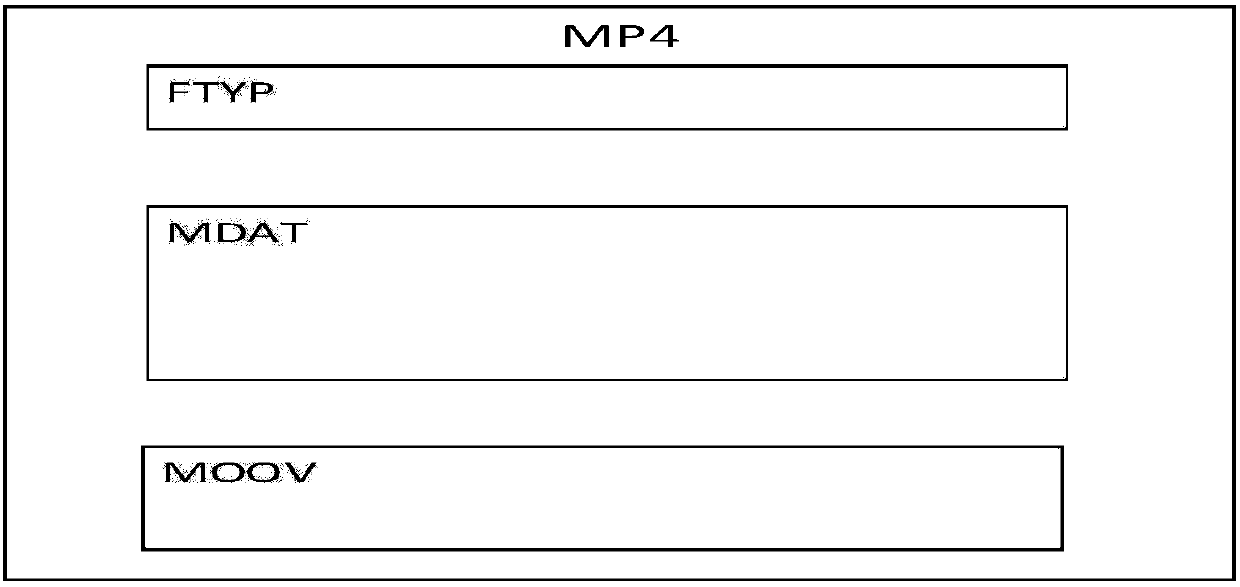

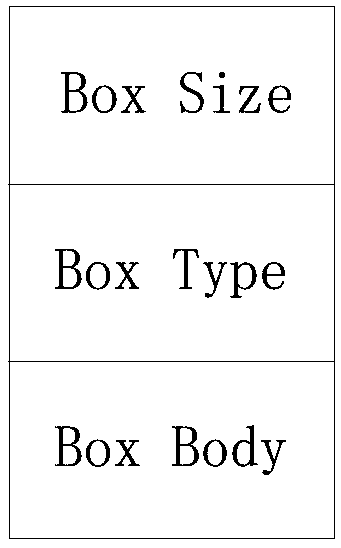

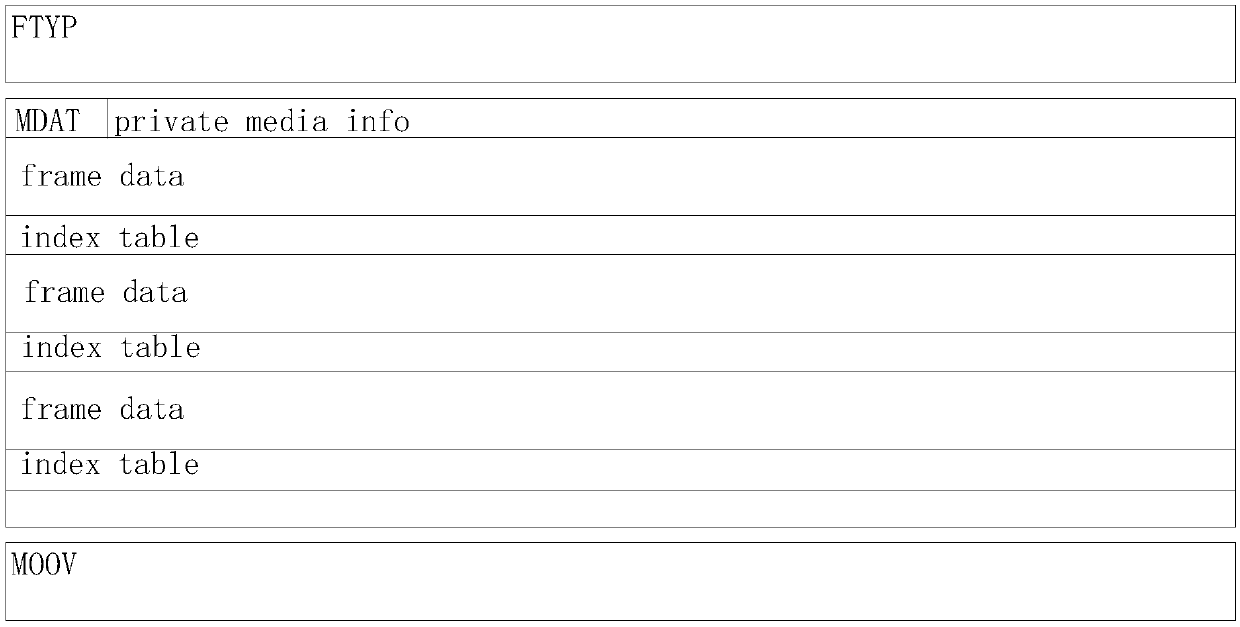

An MP4 file processing method and related equipment thereof

ActiveCN109936715ANo fragmentationDoes not affect flash lifeTelevision system detailsColor television detailsTime domainComputer science

The embodiment of the invention discloses an MP4 file processing method and related equipment thereof, which are used for solving the problem that a file cannot be played due to incomplete tail of thefile and ensuring that the recorded MP4 file is normally available before abnormal termination. The method comprises the steps that when an MP4 file is input, private media information is stored in the head of an MP4 file MDAT, and the private media information comprises media information parameters of frame data in the MP4 file; And storing the index information of the frame data in the MDAT insections, wherein the index information comprises the time domain information and the spatial domain information of the frame data.

Owner:HUAWEI TECH CO LTD

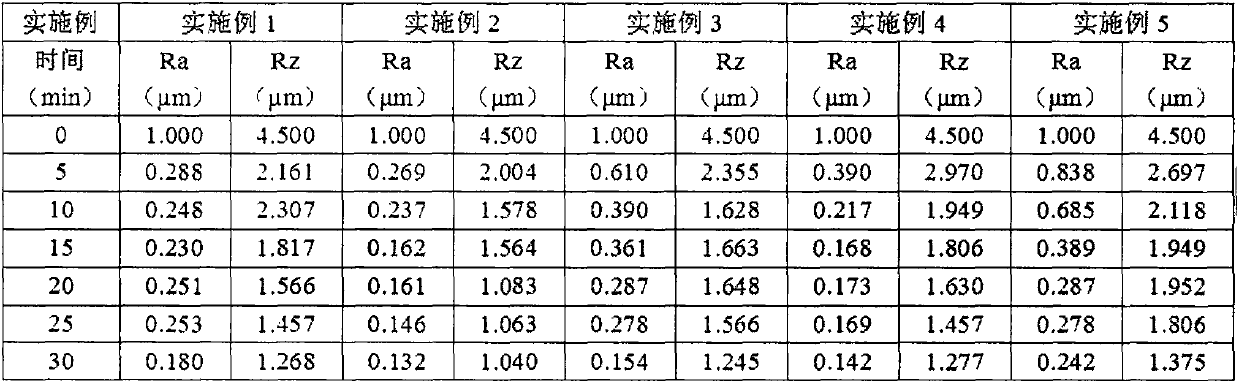

Thermoplastic abrasive for polishing hard alloy and manufacture method thereof

The invention discloses a thermoplastic abrasive for polishing a hard alloy and a manufacture method thereof. The abrasive is prepared from the following components in parts by weight: 60-80 parts ofabrasive, 19-35 parts of thermoplastic polymer, 0.1-1.5 parts of dispersing agent, 0.1-1 part of lubricant, 0.1-1.5 parts of antioxidant, 0.6-2.4 parts of coupling agent, and 60-240 parts of industrial alcohol. The abrasive is prepared through the process of internal mixing-pelletizing. The abrasive has high cutting performance, good wear resistance and high toughness, prevents workpieces from pitdamage and scratch, fails to break the hard alloy, and is easy to clean. The thermoplastic abrasive is easy to prepare, can be produced efficiently in a short production cycle, is environmentally friendly, and can be recycled for many times.

Owner:KUNSHAN NANO NEW MATERIAL TECH

Hollow extracting micro-hole filtering element

InactiveCN101032672AImprove toughnessStrong impact resistanceMoving filtering element filtersMicrocellular plasticMicroparticle

The present invention is improved filter plate for solid-liquid separating drier. The improved filter plate is hydrophilic microporous plastic plate with average pore size of 0.2-1.5 microns, and forms the sucking filter element walls. It is superior to available ceramic plate, and has pore opening rate of about 60 %, 20-30 % higher production capacity, high toughness, high impact resistance, and acid and base resistance.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

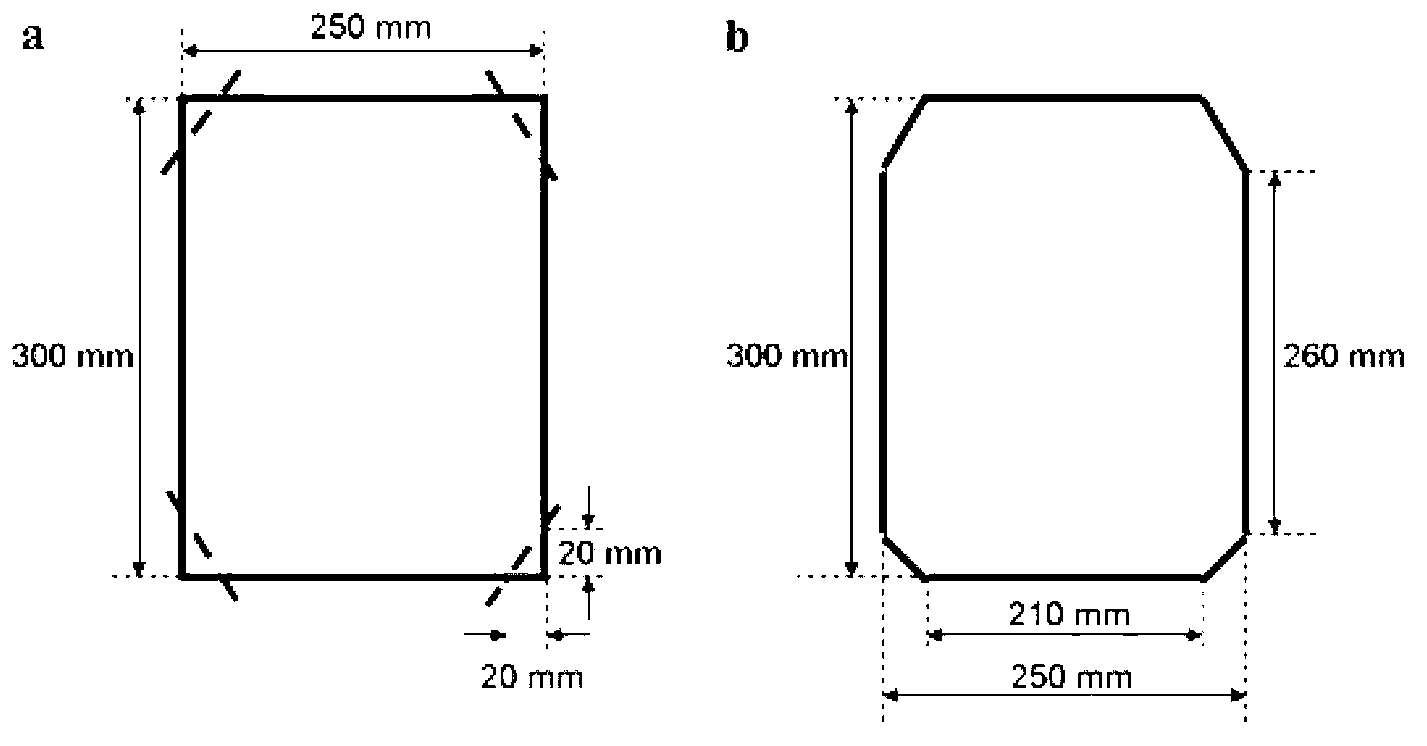

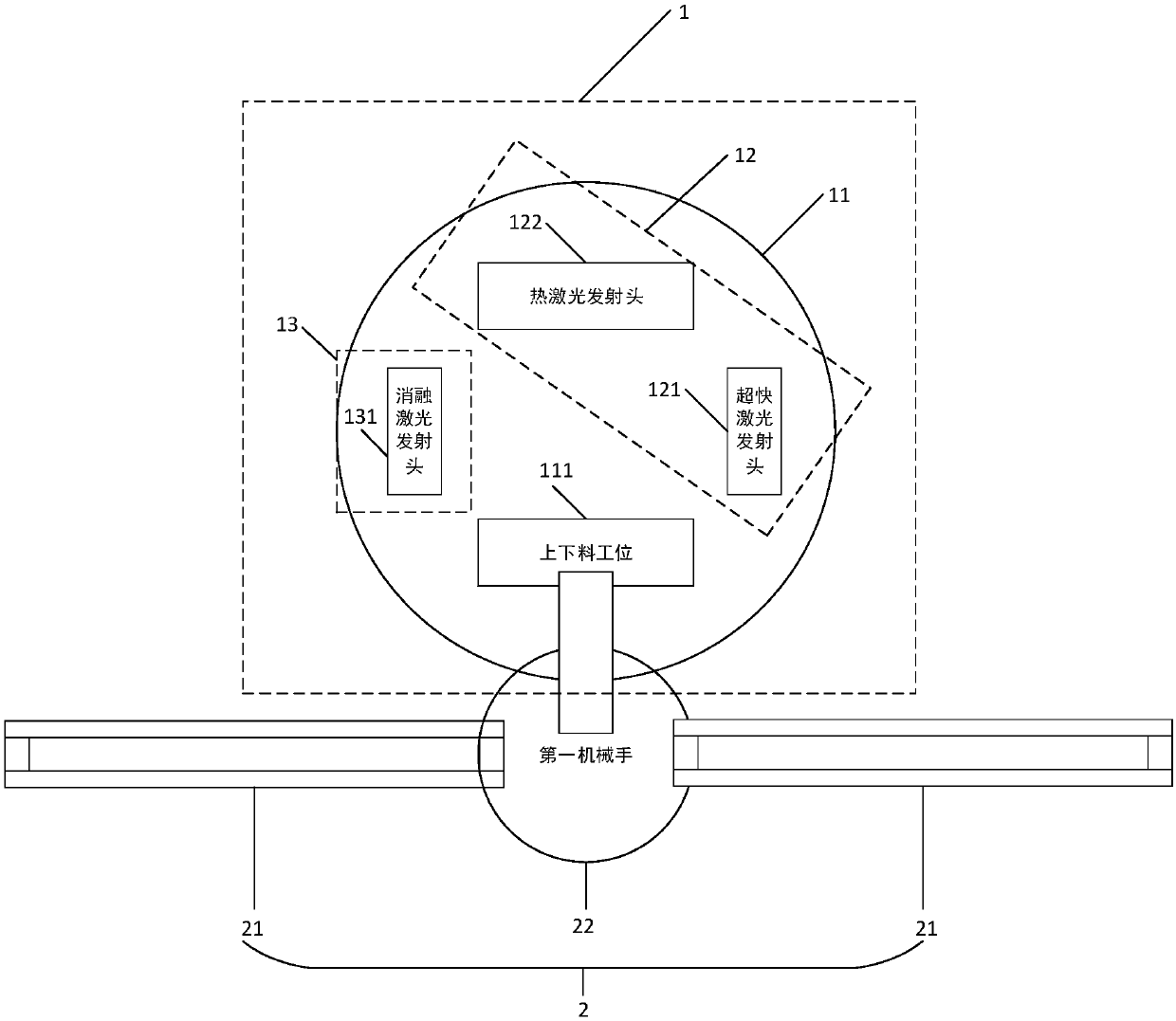

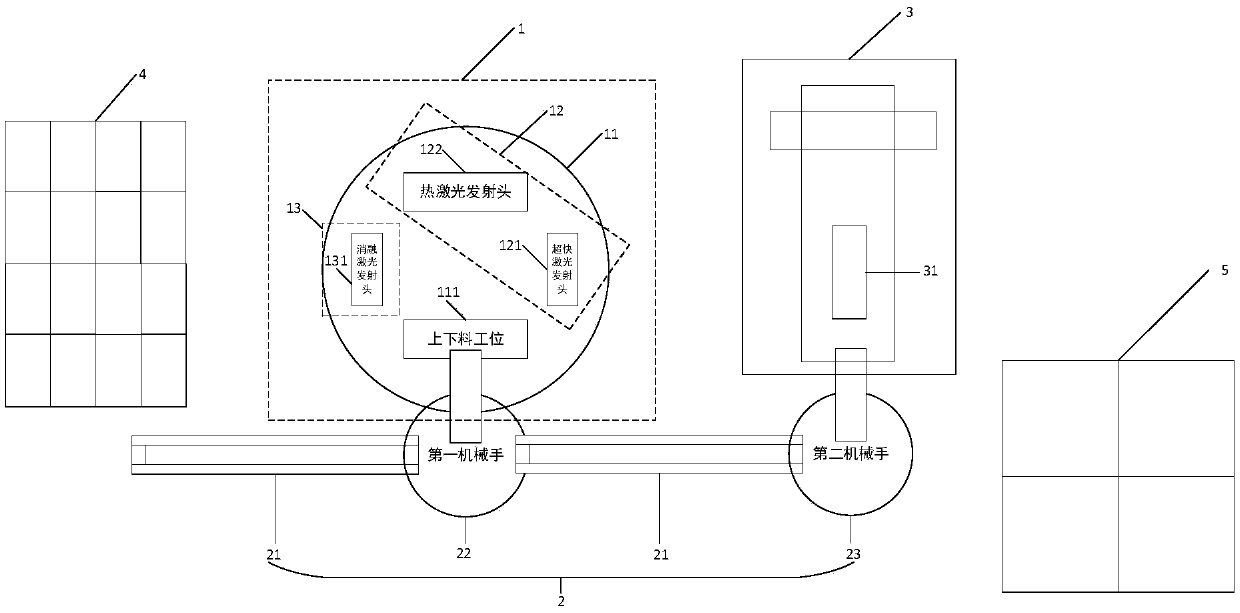

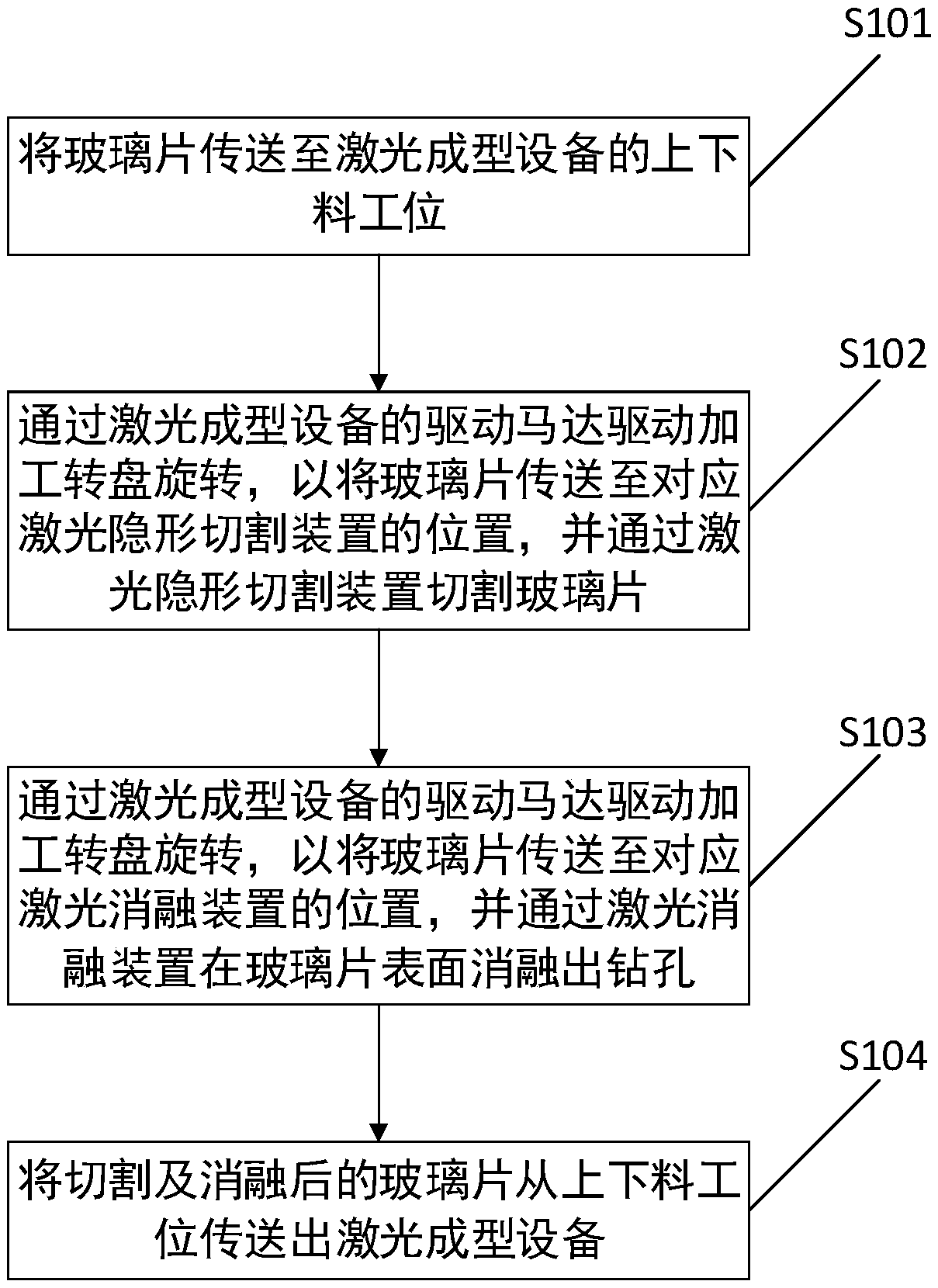

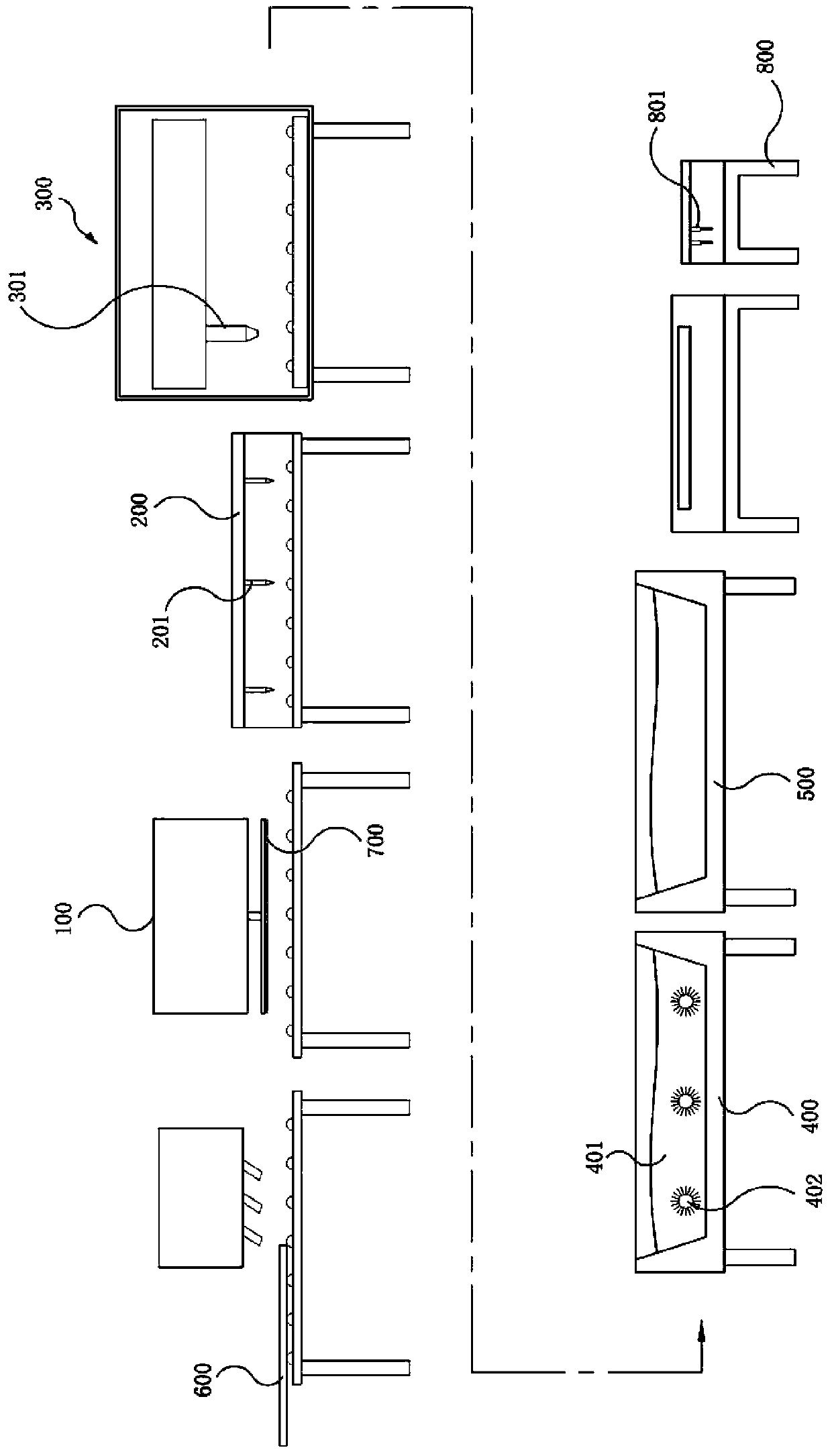

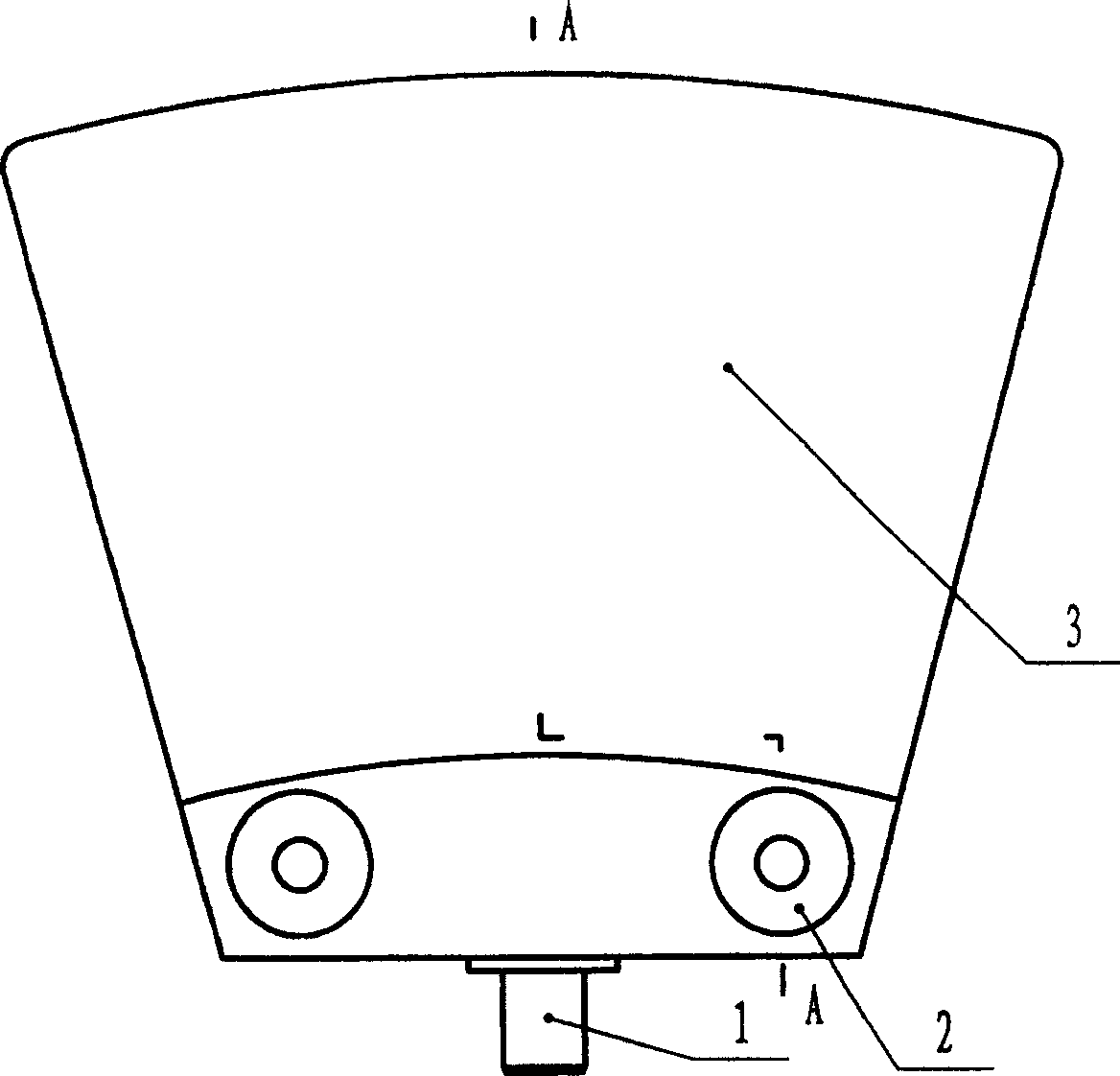

Processing system and processing method for glass cover plate

InactiveCN109514103AImprove yield rateNo fragmentationLaser beam welding apparatusGlass coverDrive motor

The invention discloses a processing system for a glass cover plate. A laser forming device comprises a processing rotary plate and a feeding and blanking station on the surface of the processing rotary plate; the processing rotary plate corresponds to a laser stealth dicing device and a laser ablation device; when a glass sheet is processed, a drive motor connected with the processing rotary plate can drive the processing rotary plate to rotate; laser stealth dicing and laser drilling belong to non-contact processing, so that the yield of the glass cover plate can be effectively improved; meanwhile, the drive motor drives the processing rotary plate to rotate, so that only coarse positioning is required when the glass sheet is placed on the feeding and blanking station; and when accuratepositioning is required during the specific cutting and drilling process, accurate positioning can be carried out by depending on the rotation repeated positioning accuracy of the drive motor and theprocessing accuracy of various devices, so that the time required for positioning is greatly saved. The invention further provides a processing method for the glass cover plate, and the above beneficial effects are achieved as well.

Owner:LANS INTELLIGENT ROBOT CHANGSHA CO LTD

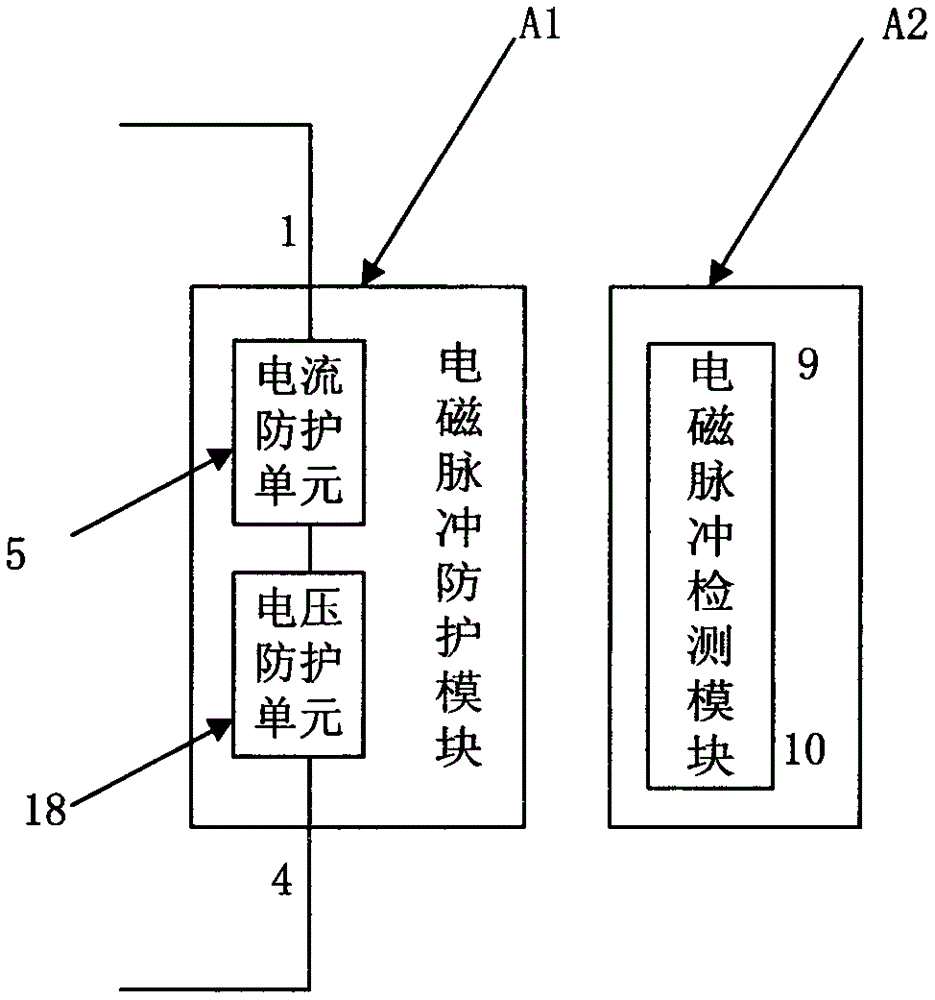

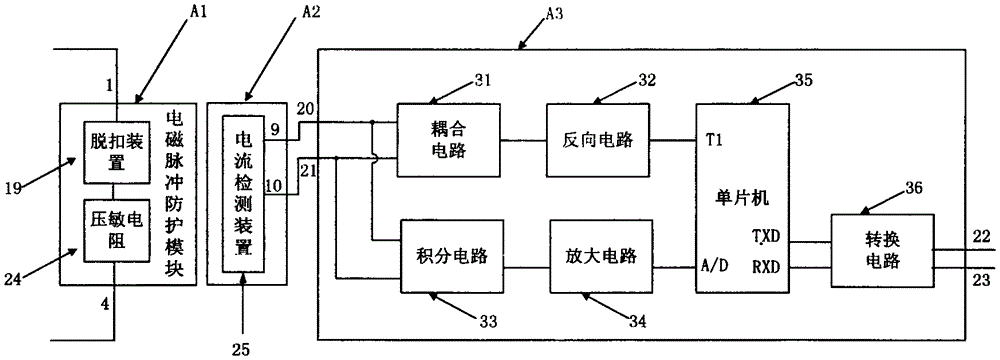

Electromagnetic pulse protecting device

ActiveCN104143822AEffective protectionEnsure safetyCurrent/voltage measurementArrangements responsive to excess currentComputer modulePass rate

The invention provides an electromagnetic pulse protecting device. The electromagnetic pulse protecting device comprises an electromagnetic pulse protecting module and an electromagnetic pulse detecting module which are integrally designed. The electromagnetic pulse protecting module comprises a voltage protecting unit and a current protecting unit, wherein the voltage protecting unit clamps voltage to be smaller than or equal to a preset voltage value when the voltage applied to the electromagnetic pulse protecting module exceeds the preset voltage value, and the current protecting unit cuts off a circuit of the current protecting unit to carry out over-current protection on a protected circuit when a current flowing through the electromagnetic pulse protecting module exceeds a preset current value. The electromagnetic pulse detecting module is used for detecting electromagnetic pulses acted on the electromagnetic pulse protecting module and generating a signal of a detected result. As the current protecting unit for limiting the passing rated current and a low-temperature welding spot with designed melting temperature are effectively combined, the electromagnetic pulse protecting module has the function of overheating and over-current open circuit protection for the internal integrated voltage protecting unit and can protect the internal voltage protecting unit in time, and the safety of rear-end electric equipment can be protected.

Owner:SICHUAN SUNUP SCI & TECH

Bottle state transition device for full-automatic bottled oral liquid packing machine

PendingCN107934000ASave labor resourcesSave valuable labor resourcesConveyorsPackaging bottlesEngineeringBottle

The invention provides a bottle state transition device for a full-automatic bottled oral liquid packing machine. The full-automatic bottled oral liquid packing machine comprises a vertical bottle feeding mechanism and a horizontal bottle discharging mechanism, the bottle state transition device comprises a bottle vertical-to-horizontal roller driving mechanism, a bottle vertical-to-horizontal roller, a vertical bottle channel guiding block and a horizontal bottle guiding-out block, the bottle vertical-to-horizontal roller driving mechanism is arranged on the left side of the rear end of the vertical bottle feeding mechanism and is connected with the vertical bottle feeding mechanism, the left end of the bottle vertical-to-horizontal roller is connected with the bottle vertical-to-horizontal roller driving mechanism, the right end of the bottle vertical-to-horizontal roller extends to the left end of the horizontal bottle discharging mechanism and supports on the horizontal bottle discharging mechanism, the vertical bottle channel guiding block is connected to the right side of the rear end of the vertical bottle feeding mechanism, and the horizontal bottle guiding-out block is fixed on the horizontal bottle discharging mechanism and further corresponds to the front of the middle part of the bottle vertical-to-horizontal roller simultaneously. Labor resources are saved, and sanitation is ensured; and pollution and resource waste are avoided.

Owner:苏州华葆药业股份有限公司

A bonded NdFeB strong magnet and its preparation method

ActiveCN102723165BLow densityUniform and stable magnetismPermanent magnetsInorganic material magnetismEnvironmental resistanceMetallurgy

The invention provides a bonded NdFeB (neodymium, ferrum and boron) magnet. The magnet comprises the following raw materials in percentage by weight: 80-95 percent of NdFeB powder, 0-20 percent of ferrite rubber magnetic powder, 0-20 percent of rubber, 0-20 percent of functional plastic, and the balance of assistant. The invention further provides a preparation method of the bonded NdFeB strong magnet. With the adoption of the bonded NdFeB strong magnet and the preparation method thereof, the produced product is soft, small in brittleness, high and stable in magnetic property, easy to be assembled, and various specifications and dimensions can be easily formed, and meanwhile, the preparation cost is low, the efficiency is high, the energy is saved the consumption is reduced; and moreover, the magnet and the method are environment-friendly and halogen-free, and are pollution-free for the environment.

Owner:金华市磁莱福磁铁科技有限公司

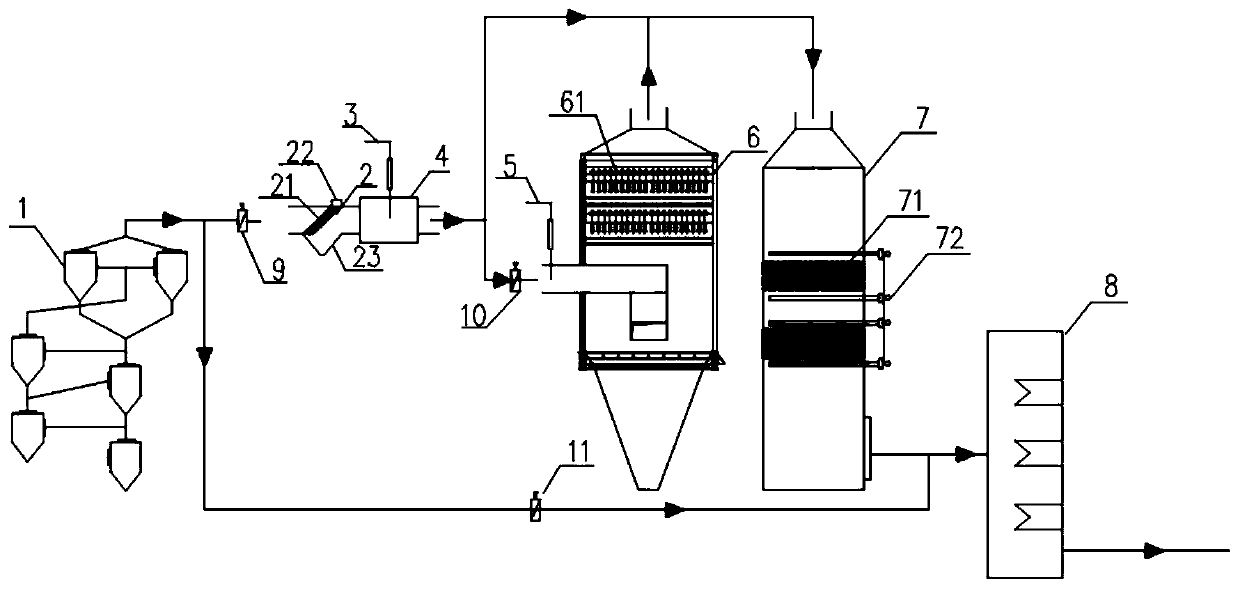

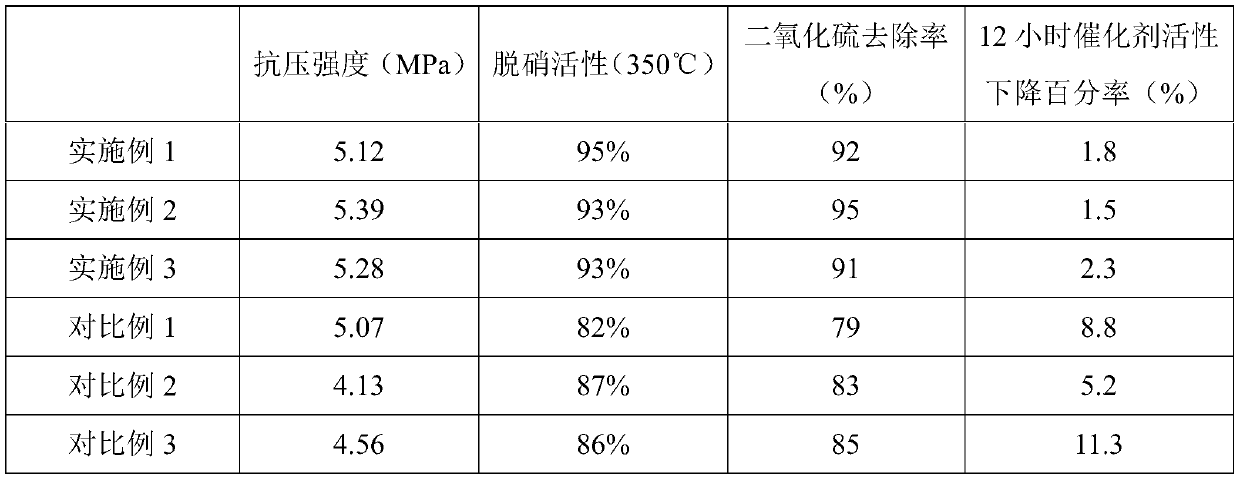

Catalyst for cement kiln flue gas SCR denitration and denitration system

ActiveCN110124708AGood activity at low temperatureImprove sulfur resistanceGas treatmentHeterogenous catalyst chemical elementsAdhesiveCement kiln

The invention discloses a catalyst for SCR denitration of cement kiln flue gas, a preparation method of the catalyst and a denitration system. The catalyst comprises 20-50 parts of silicon carbide, 5-15 parts of metal oxide, 3-8 parts of a vanadium-titanium composite oxide, 1-2.5 parts of an adhesive and 0.5-2 parts of a lubricant. The metal oxide is lanthanum oxide or cobalt oxide. The vanadium-titanium composite oxide is a titanium dioxide / vanadium pentoxide composite oxide. The denitration system comprises a preheater system, an intercepting net system, a ceramic filter pipe integrated system, an SCR denitration system and a waste heat power generation system, which are arranged in the flowing direction of flue gas. According to the invention, the catalyst carrier is prepared from silicon carbide and metal oxide, and the self-made composite oxide is used as the catalyst, so that the catalyst with good low-temperature activity, high sulfur resistance and good activity retention is prepared. The denitration system can greatly reduce one-time investment and operation cost of downstream desulfurization and dust removal equipment.

Owner:JIANGSU CTIEC ENVIRONMENTAL PROTECTION RES INST

Preparation method of glass ionomer cement for orthodontic bonding

InactiveCN106389133AHigh strengthSimple preparation stepsImpression capsDentistry preparationsGlass ionomersWear resistant

The invention discloses a preparation method of glass ionomer cement for orthodontic bonding, and belongs to the technical field of glass ionomer cement preparation. According to the method, fresh beef bones are used as raw materials and are washed, steamed and boiled; surface beef and fascia are removed; then, the beef bones are subjected to drying, crushing, roasting and ball milling to be prepared into natural hydroxyapatite powder; then, a glass flake is taken; the surface of the glass flake is subjected to roughening treatment by hydrofluoric acid; next, the surface is subjected to chemical modification by zirconium oxide and silane coupling agents KH-570; the wear-resistant performance and the mechanical intensity are improved; finally, the treated glass flake is subjected to mixing and ball milling with the natural hydroxyapatite powder and the like to prepare the glass ionomer cement. The preparation method has the beneficial effects that the preparation steps are simple; the obtained glass ionomer cement has high intensity; the intensity is improved by 23 to 26 percent through being compared with that of other cementing mediums; the wear-resistant performance is good; after the use, the bonding force with enamel is high; no breaking or cracking phenomena occur.

Owner:张静

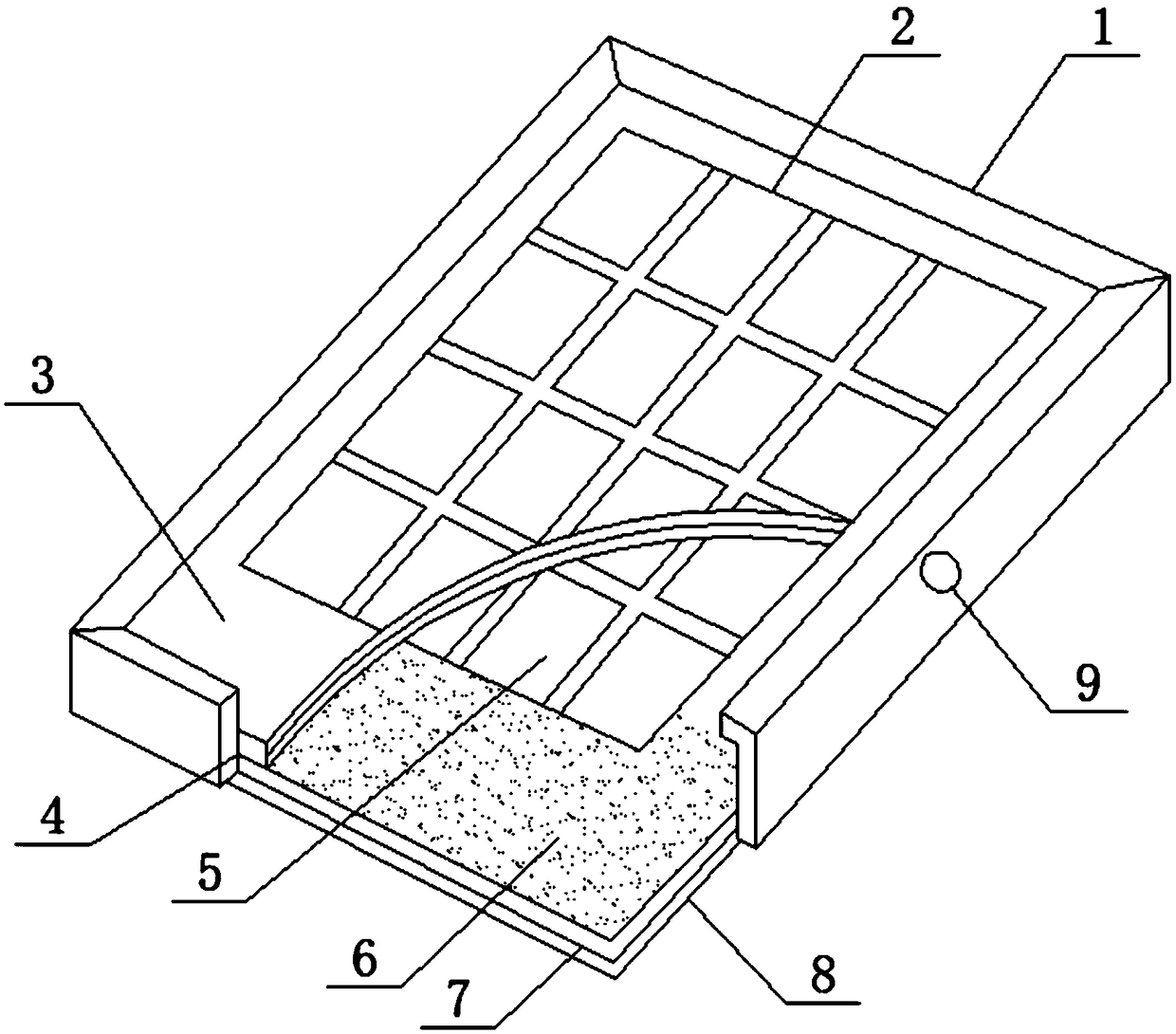

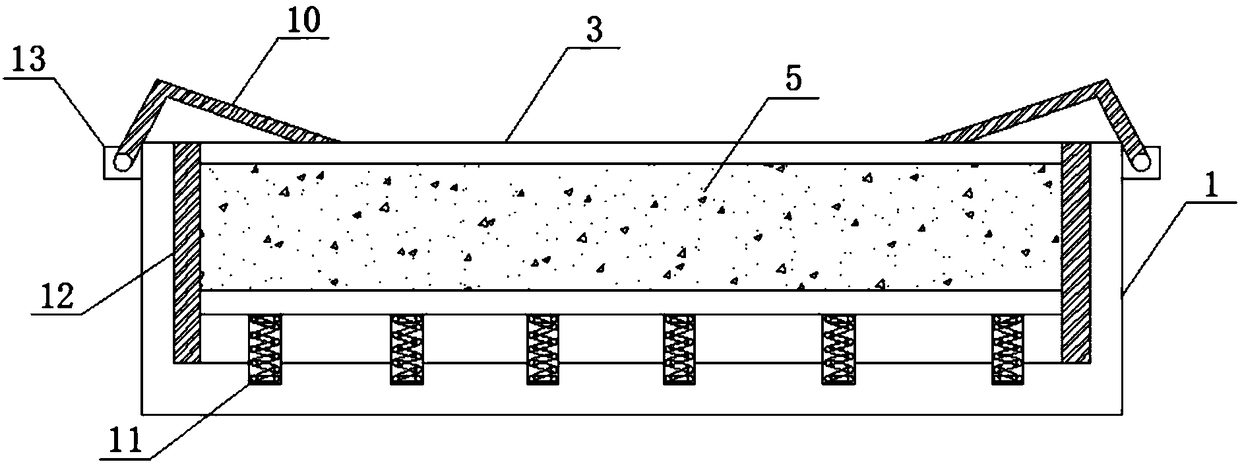

Solar panel module

PendingCN109301014AAvoid damageNo fragmentationPhotovoltaicsPhotovoltaic energy generationGlass coverSolar module

The present invention discloses a solar panel module. The solar panel module comprises a solar energy frame and an upper glass cover plate, the solar energy frame is internally provided with the upperglass cover plate which sleeves and is connected with the internal portion of the solar energy frame, the solar energy frame sleeves and is connected with the upper glass cover plate, and the internal portion of the upper glass cover plate is provided with an installation groove in an embedding mode. Compared to a current solar energy module rain-proof method, the solar panel module is very convenient for later maintenance and replacement and enough to cover the solar energy module, rainwater is exhausted from a rain-proof groove to prevent the solar cell panel from being damaged, when the solar energy module is suffered from the load of the external force, the force is transmitted to a spring ring at the lower end when the solar panel is suffered from the load so as to prevent the solarpanel from being damaged caused by the action of the rigid force and improve the service life of the solar energy module.

Owner:无锡英鹏新能源有限公司

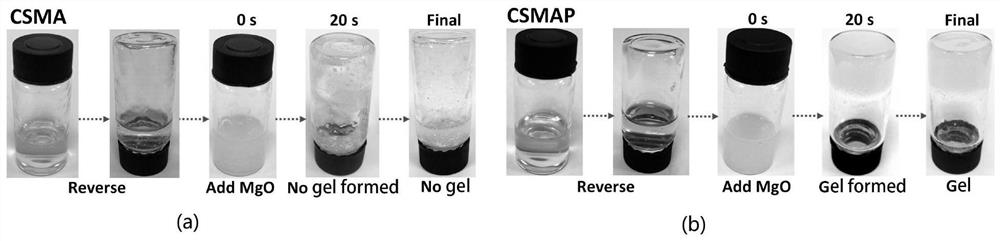

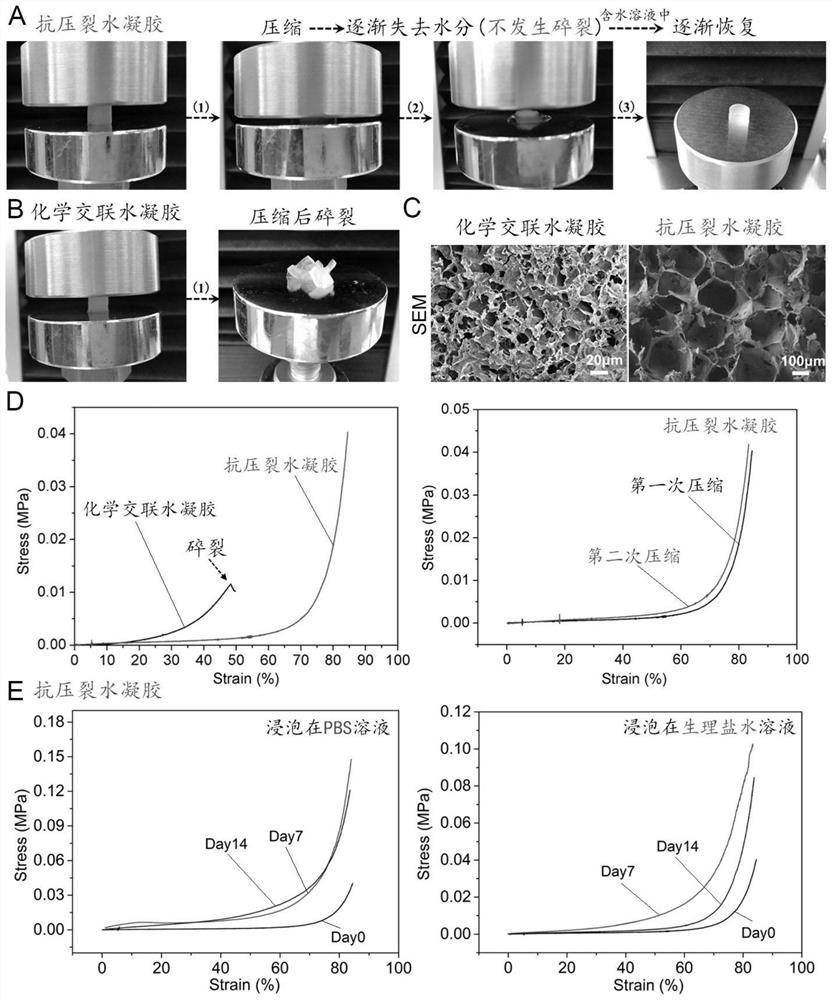

Preparation method of injectable anti-fracturing degradable supramolecular hydrogel

ActiveCN111909395AInjectableWith anti-fracture performancePharmaceutical delivery mechanismProsthesisPolymer scienceO-Phosphoric Acid

The invention belongs to the technical field of polymer hydrogel, and particularly relates to a preparation method of injectable anti-fracturing degradable supramolecular hydrogel, which comprises thefollowing steps: carrying out methacrylic anhydride and phosphoric acid or phosphonic acid modification on natural polysaccharides, and compounding metal-containing particles to form supramolecular binding, thereby preparing the injectable anti-fracturing degradable hydrogel. The hydrogel obtained by the preparation method disclosed by the invention has anti-fracturing performance, is not brokenwhen being compressed to a certain degree (the compression strain is greater than 85%), and can be recovered to be close to the initial height after being soaked in an aqueous solution for a period oftime.

Owner:PEKING UNIV SHENZHEN HOSPITAL

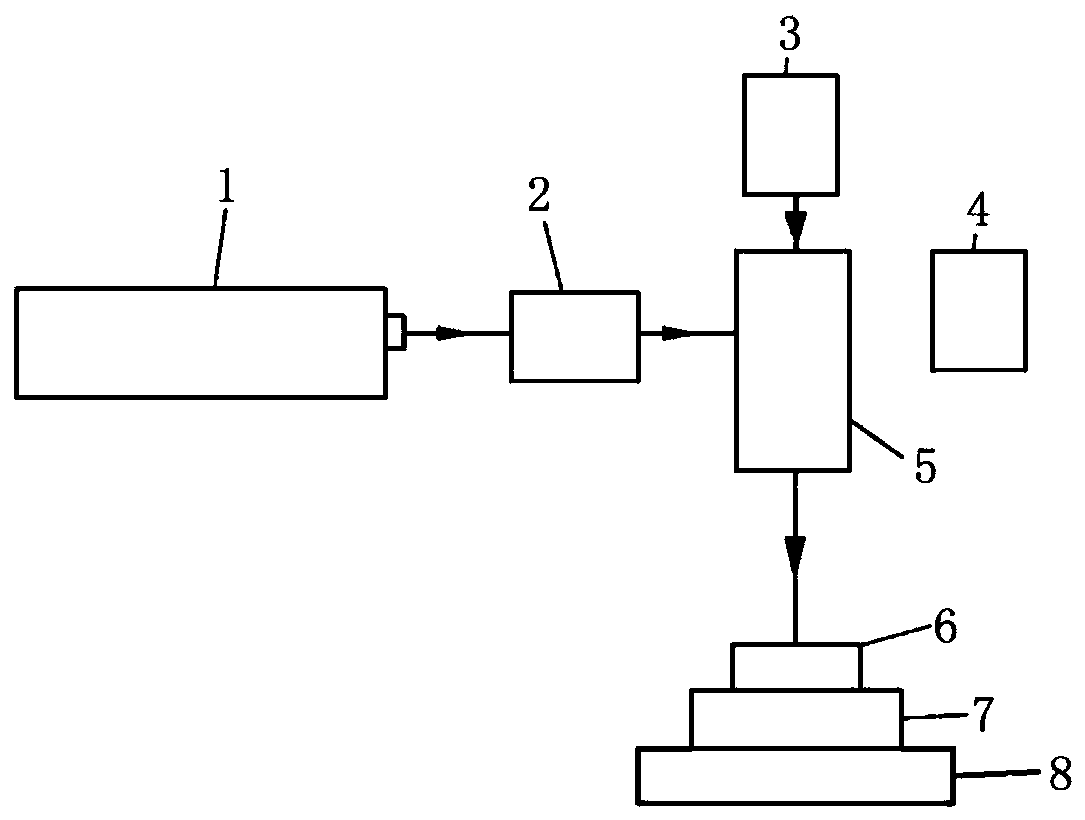

System precision processing method of fragile transparent special-shaped 3D structure

ActiveCN110788486AEasy to observeLight transmittance has little effectAfter-treatment detailsWelding/soldering/cutting articlesTemperature curveEngineering

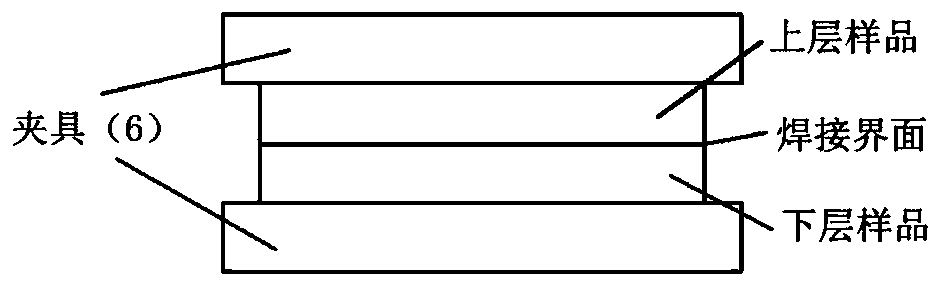

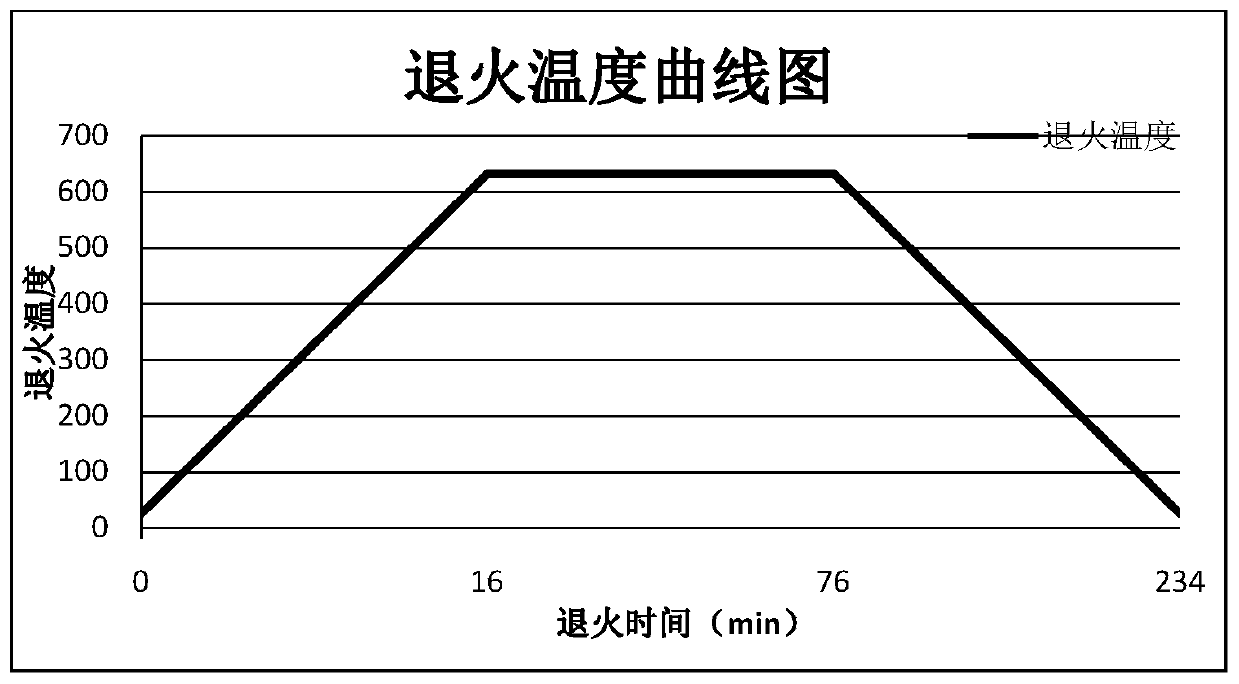

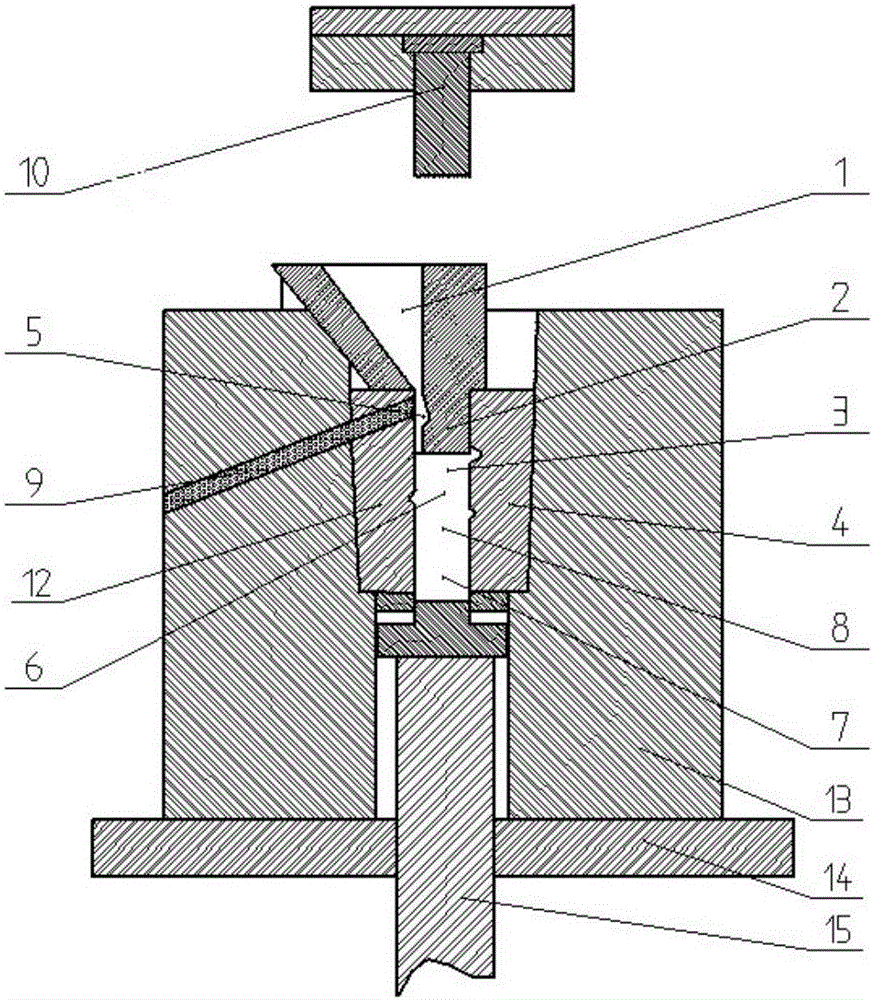

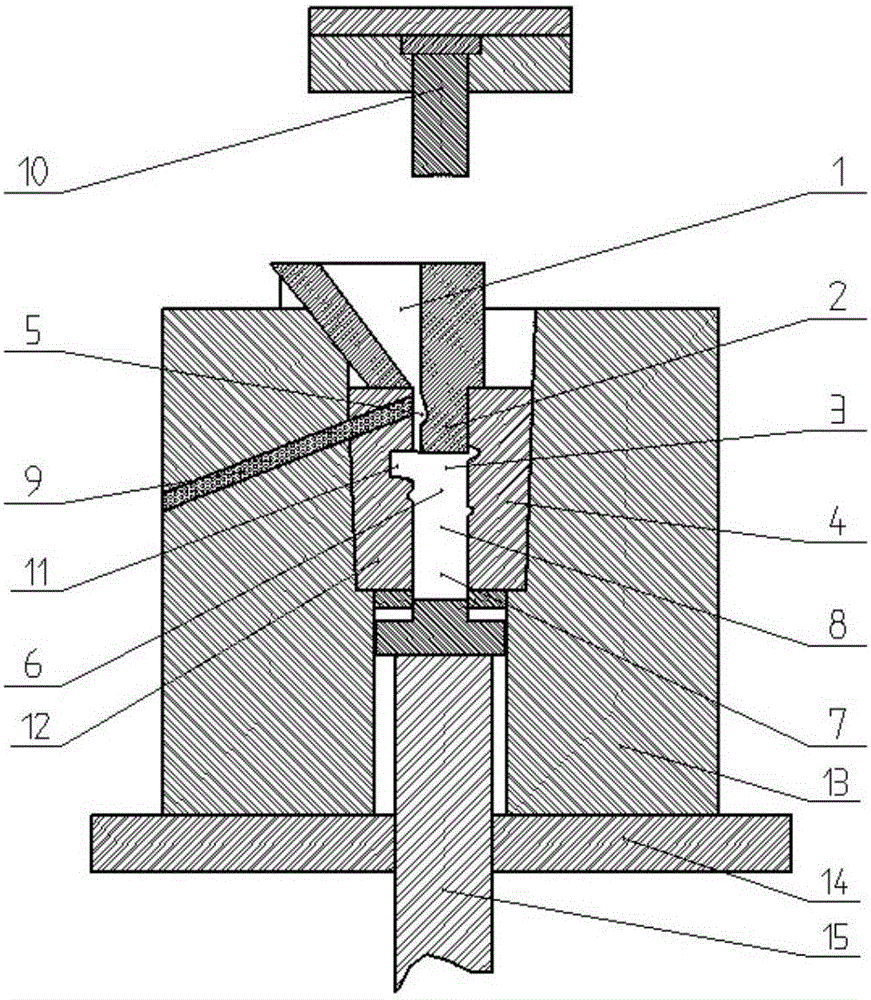

The invention discloses a system precision processing method of a fragile transparent special-shaped 3D structure. The system precision processing method comprises the following steps of building a laser welding platform of the special-shaped 3D structure, wherein the platform comprises a laser, a laser path, a coaxial vision system, a paraxial vision system, a welding head, a clamp, a horizontalwelding bracket and a movement platform; clamping a sample by the clamp; mounting the clamp after clamping the sample to the movement platform, and adjusting the clamp by the coaxial vision system and the horizontal adjusting bracket; and grabbing a welding profile by the paraxial vision system to perform profile positioning and processing path planning; generating laser by the laser, and focusing the laser on a welding interface to be welded through the laser path and the welding head, and moving the movement platform according to the positioned profile and the planned processing path untilfinishing the welding; placing a welded sample in an annealing furnace, and annealing according to a temperature curve of heating, constant annealing temperature and cooling; and placing the annealedwelded sample in a reinforcing furnace to be reinforced.

Owner:WUHAN HGLASER ENG CO LTD

Graphene wave absorbing composite material with high thermal conductivity and preparation method thereof

InactiveCN110157266AStrong stretchStrong hardnessUnspecified rubber coatingsPolyurea/polyurethane coatingsHardnessCvd graphene

The invention belongs to the technical field of composite materials, in particular to a graphene wave absorbing composite material with high thermal conductivity and a preparation method thereof. Thecomposite material is based on a wave absorbing material, and a plurality of graphene film layers are coated on the substrate. The raw materials of the graphene film layer include graphene, an organicpolymer solution and a resin, and the mass components of the graphene film layer are as follows: (0.1-10): (1-20): (0.5-1); the high thermal conductivity graphene wave absorbing composite material ofthe invention adopts the graphene film and the wave absorbing material to prepare the graphene wave absorbing material, and the performance of the wave absorbing material is not affected, and the heat dissipation performance of the whole wave absorbing material is greatly improved because of the excellent thermal conductivity of the graphene; the high thermal conductivity graphene wave absorbingcomposite material of the invention adopts a multi-layer coating mode, which is different from the traditional graphene as an additive, and the surface of the prepared graphene wave absorbing materialhas stronger toughness and hardness, and can be applied to various kinds of machining without fragmentation or deformation.

Owner:常州威斯双联科技有限公司

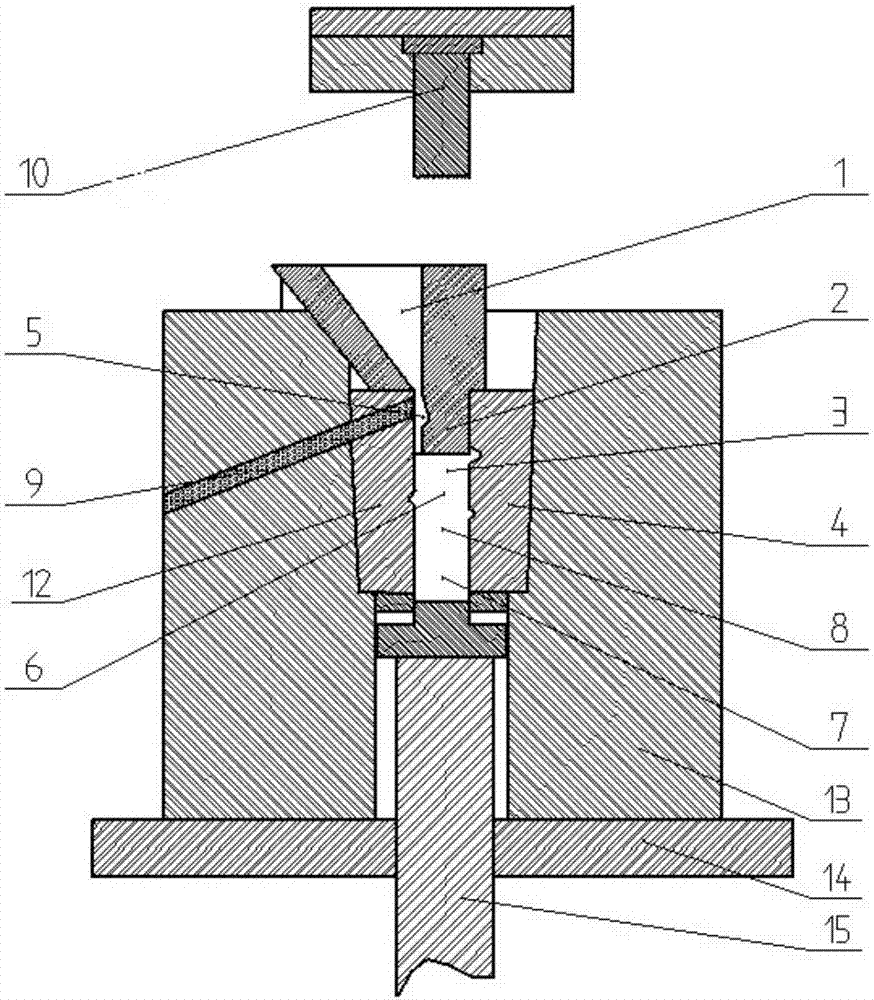

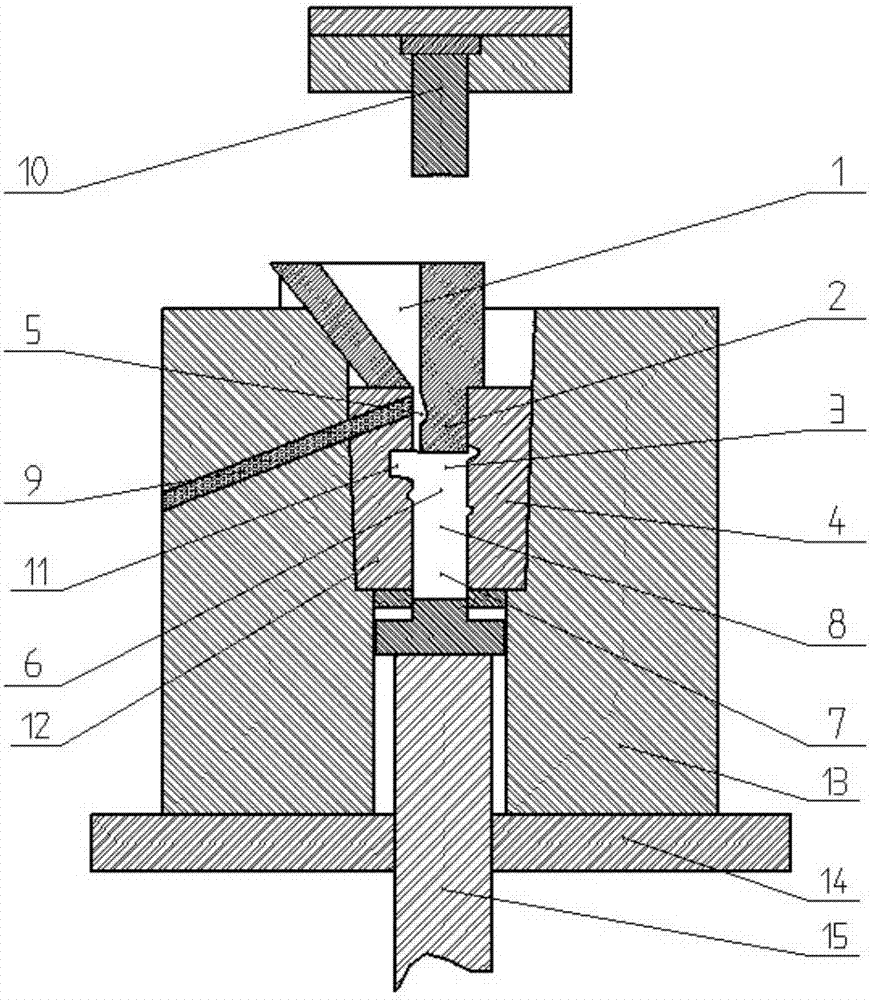

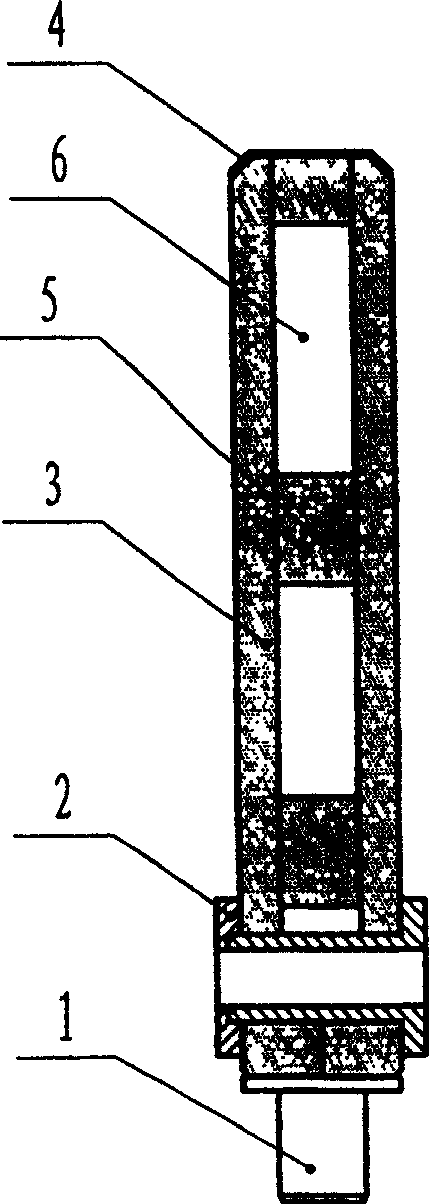

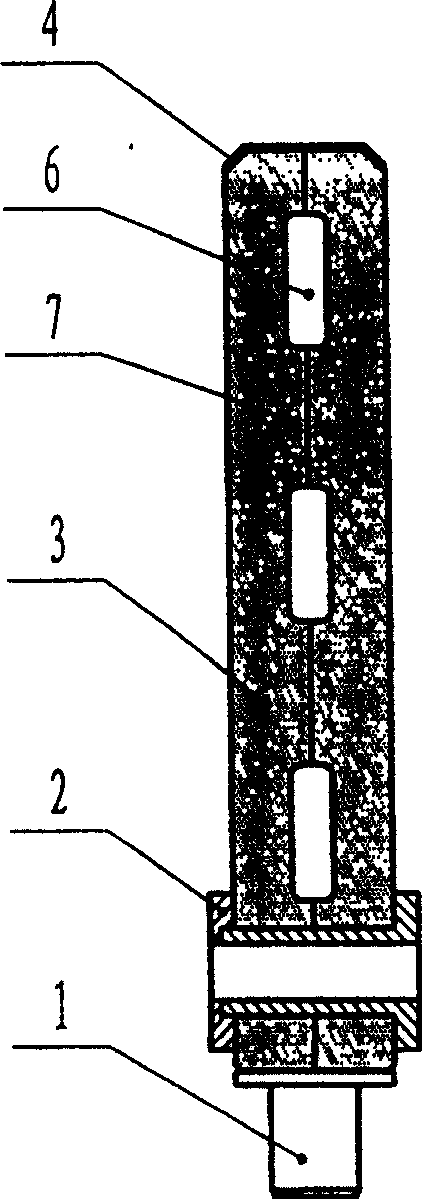

Preparation device and method for composite plate hammer

The invention relates to a preparation device and method for a composite plate hammer. The preparation device comprises a sprue cup, a plate hammer mold cavity, a left half mold, a right half mold, a sprue cavity, a ceramic particle cavity, a pressing head, a mold locking seat, a mold bottom plate and a lower jacking block. The preparation method comprises the following steps that S1, the plate hammer mold cavity and the ceramic particle cavity are preheated to 150-250 DEG C, and ceramic particles are preheated to 800-1200 DEG C; S2, the preheated ceramic particles are added into the ceramic particle cavity to the set quantity; S3, the sprue cup is placed; S4, mixing is conducted along with flowing; S5, liquid forging compounding is conducted, specifically, within the time of 5-15 seconds after pouring of plate hammer molten metal is stopped, a ceramic particle-metal mixture is pressurized directly by the pressing head until all the mixture is solidified; and S6, part out-taking and heat treatment are conducted, specifically, the left half mold and the right half mold are opened, the composite plate hammer is taken out and put into a slow cooling furnace to be cooled to 400 DEG C or below, reheating, quenching and tempering heat treatment are conducted, and the composite plate hammer is obtained.

Owner:BEIJING JIAOTONG UNIV

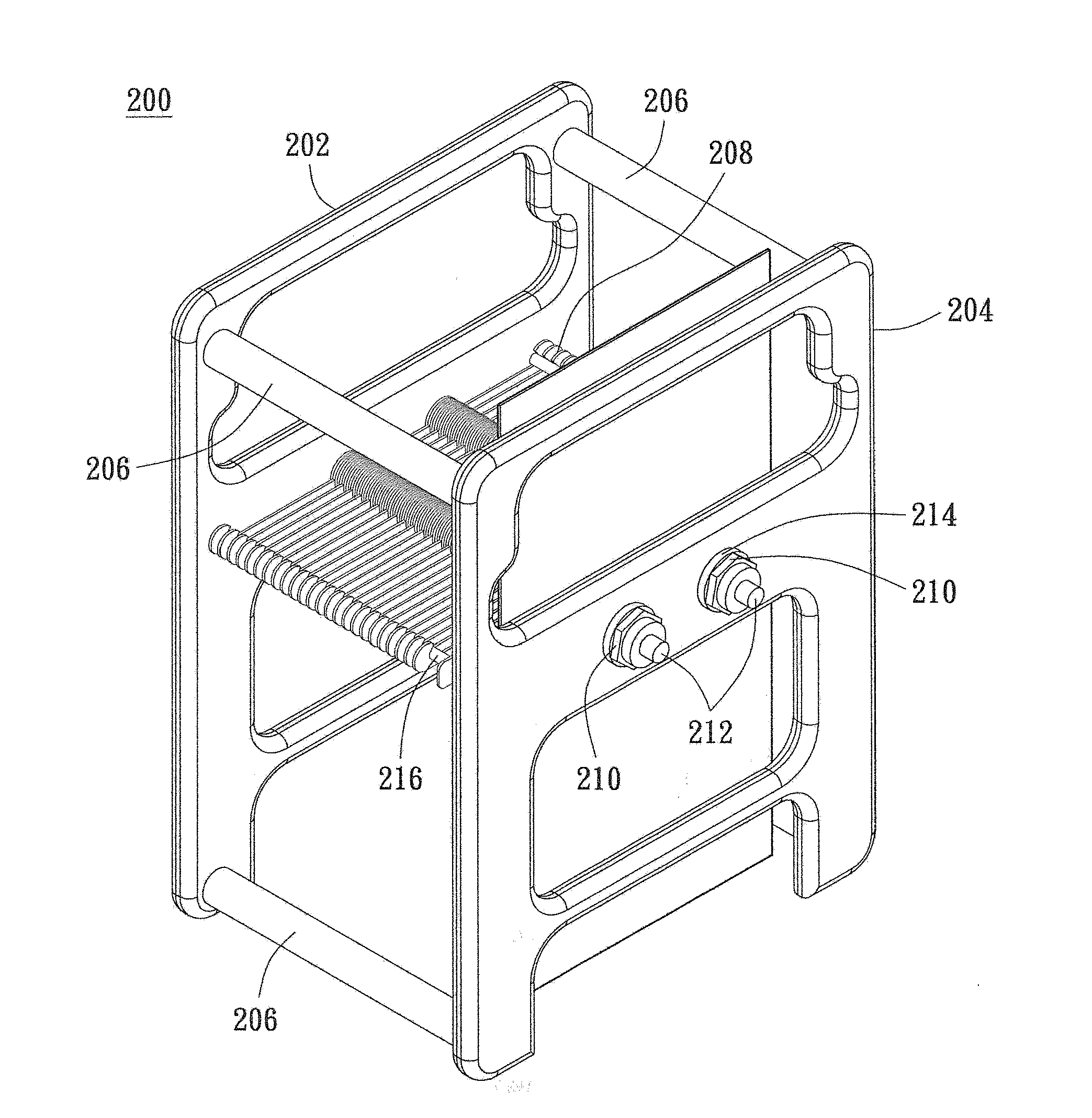

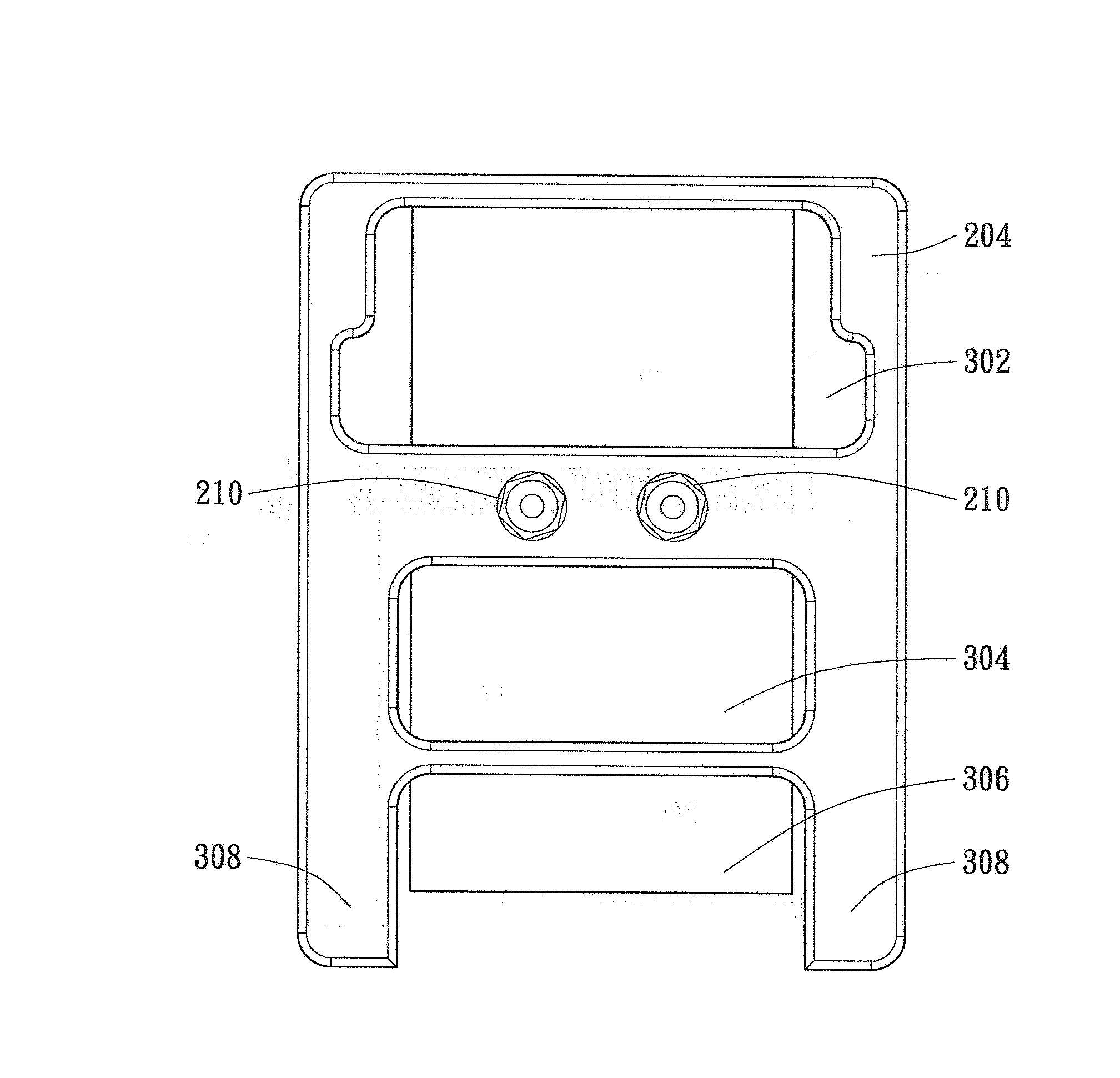

Holding clamp for etching

ActiveCN103420616AImprove the flow fieldConvenient and easy to get on and offGlass sheetMechanical engineering

A holding clamp for etching comprises two side plates, a plurality of support rods, a plurality of clamp plates, at least two clamp plate sliding rods and at least one clamp plate press rod, wherein the two side plates are disposed at a left side and a right side respectively; the plurality of support rods are connected to the two side plates; the plurality of clamp plates are disposed between the two side plates; the at least two clamp plates are disposed between the two side plates and pass through the plurality of clamp plates; and the at least one clamp plate press rod is disposed on one side plate. With the above structure, the holding clamp can hold workpieces such as glass sheets or wafers etching and make etching liquid flow smoothly. Edges of the workpieces such as the glass sheets or the wafers are not contacted with the clamp, so that the edges can be etched clean.

Owner:GRAND PLASTIC TECH

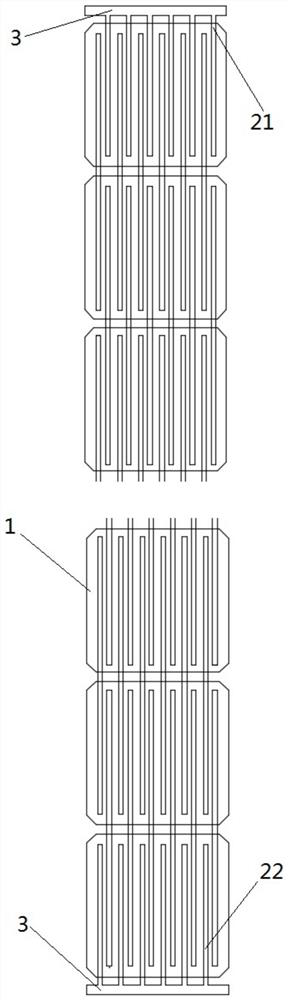

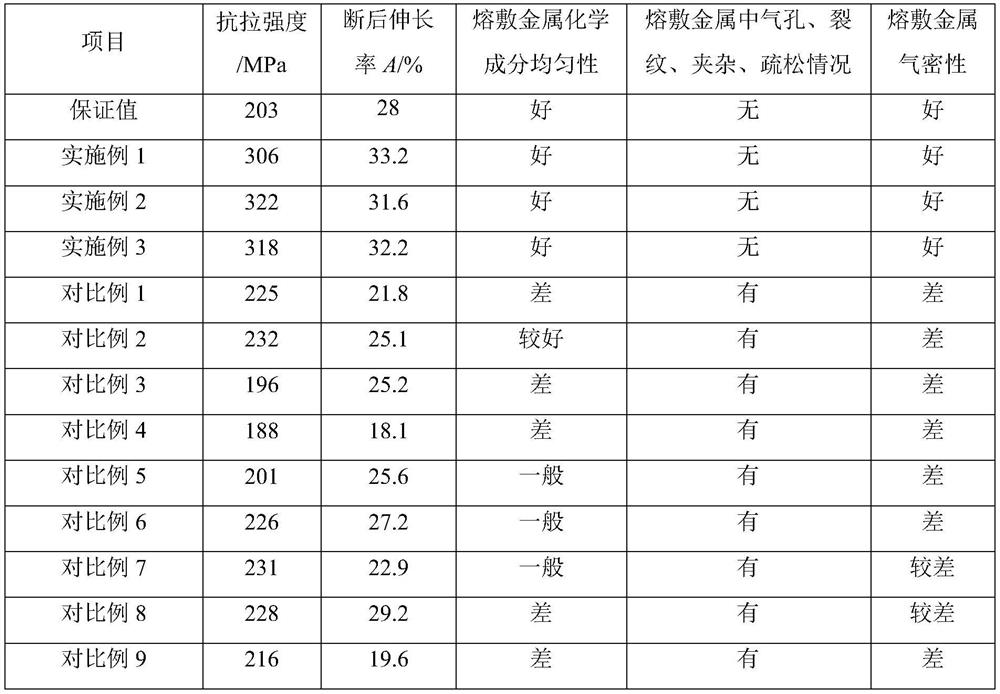

Back contact solar cell interconnection structure

PendingCN111668331AFlexible connectionFlexible settingsPhotovoltaic energy generationSemiconductor devicesElectrical batteryEngineering

The invention provides a back contact solar cell interconnection structure, relates to the field of solar cells, and can solve the problem that fragments are generated in the lamination process of anassembly. The interconnection structure comprises a plurality of back contact solar cells and an electric connection layer, wherein the electric connection layer comprises a plurality of conductive metal wires, a bus bar and a packaging material, the conductive metal wires and the bus bar are embedded in the packaging material, and the packaging material is a thermoplastic packaging material. According to the invention, conductive metal wires and a bus bar are embedded into a thermoplastic packaging material in a pre-laminating manner, and then the conductive metal wires are connected with theback electrode of a solar cell to realize flexible interconnection, so that the phenomenon of fragment generation in the module laminating process is avoided; and the parallel and staggered conductive metal wires are connected with the back electrode of the cell, so that the back contact solar cell interconnection structure can be flexibly arranged, cut and interconnected according to the area ofthe cell and the pattern of the back electrode of the cell.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

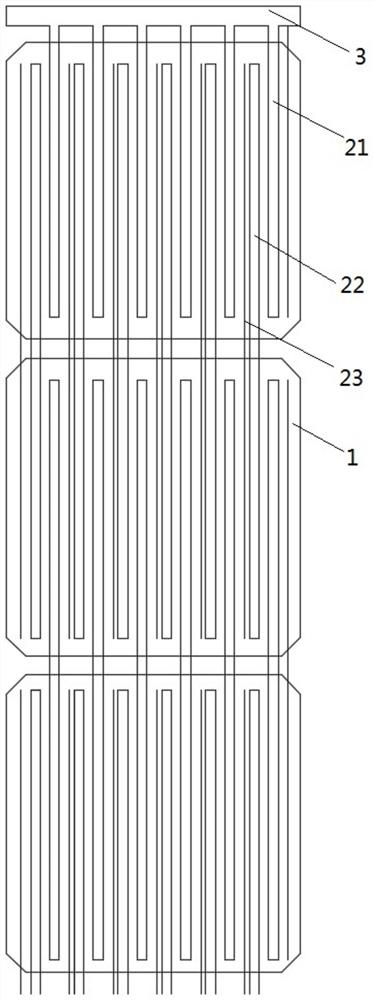

Matched flux-cored wire for medical gas and vacuum seamless copper pipe fusion welding

ActiveCN112077476AUniform chemical compositionHigh droplet temperatureWelding/cutting media/materialsSoldering mediaPipeFusion welding

The invention belongs to the field of welding materials, and particularly relates to a matched flux-cored wire for medical gas and vacuum seamless copper pipe fusion welding. The matched flux-cored wire comprises a TU1 semi-hard copper alloy sheath and a flux core; the flux core comprises 2.1%-3.2% of CuSi16 powder, 2.2%-3.0% of CuMn30 powder, 1.5%-2.2% of CuP12 powder, 3.0%-3.8% of AlSr40 powder,2.8%-3.6% of nanometer F3Ti powder, 3.2%-4.5% of nanometer NdF3 powder, and the balance FTD1 electrolytic copper powder; and the filling rate of the flux core is 32%-38%. Chemical components of deposited metal are uniform, inclusion, cracks and air hole defects are avoided, the air tightness is good, the minimum value of the tensile strength of the deposited metal is 306 MPa, the minimum value ofthe percentage elongation after fracture is 31.6%, and a component formed by fusion welding the seamless copper pipe completely meets the medical gas and vacuum requirements.

Owner:ZHENGZHOU UNIV

A kind of preparation device and method of composite blow bar

The invention relates to a preparation device and method for a composite plate hammer. The preparation device comprises a sprue cup, a plate hammer mold cavity, a left half mold, a right half mold, a sprue cavity, a ceramic particle cavity, a pressing head, a mold locking seat, a mold bottom plate and a lower jacking block. The preparation method comprises the following steps that S1, the plate hammer mold cavity and the ceramic particle cavity are preheated to 150-250 DEG C, and ceramic particles are preheated to 800-1200 DEG C; S2, the preheated ceramic particles are added into the ceramic particle cavity to the set quantity; S3, the sprue cup is placed; S4, mixing is conducted along with flowing; S5, liquid forging compounding is conducted, specifically, within the time of 5-15 seconds after pouring of plate hammer molten metal is stopped, a ceramic particle-metal mixture is pressurized directly by the pressing head until all the mixture is solidified; and S6, part out-taking and heat treatment are conducted, specifically, the left half mold and the right half mold are opened, the composite plate hammer is taken out and put into a slow cooling furnace to be cooled to 400 DEG C or below, reheating, quenching and tempering heat treatment are conducted, and the composite plate hammer is obtained.

Owner:BEIJING JIAOTONG UNIV

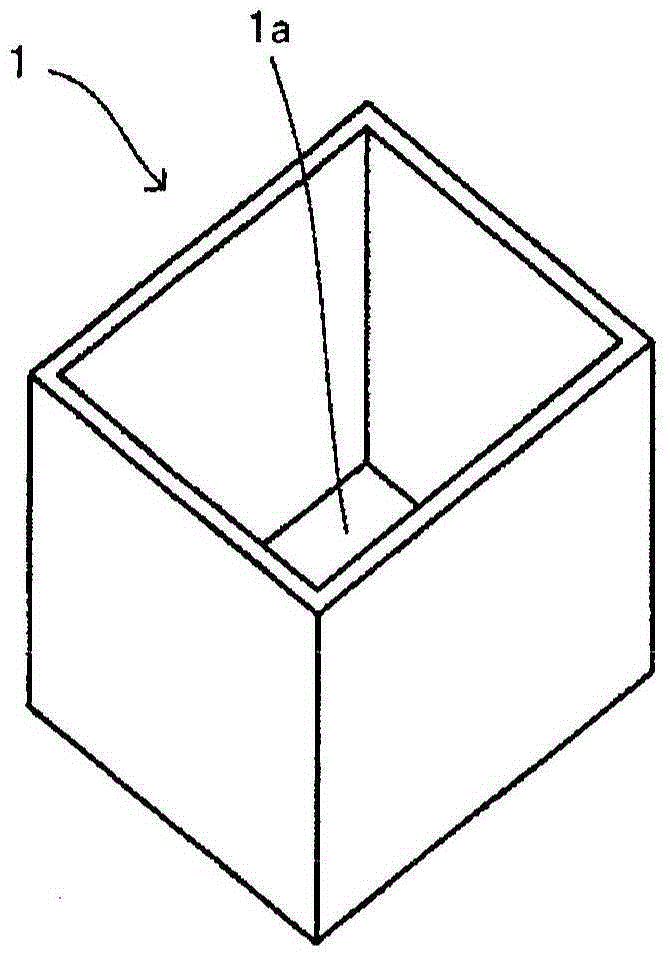

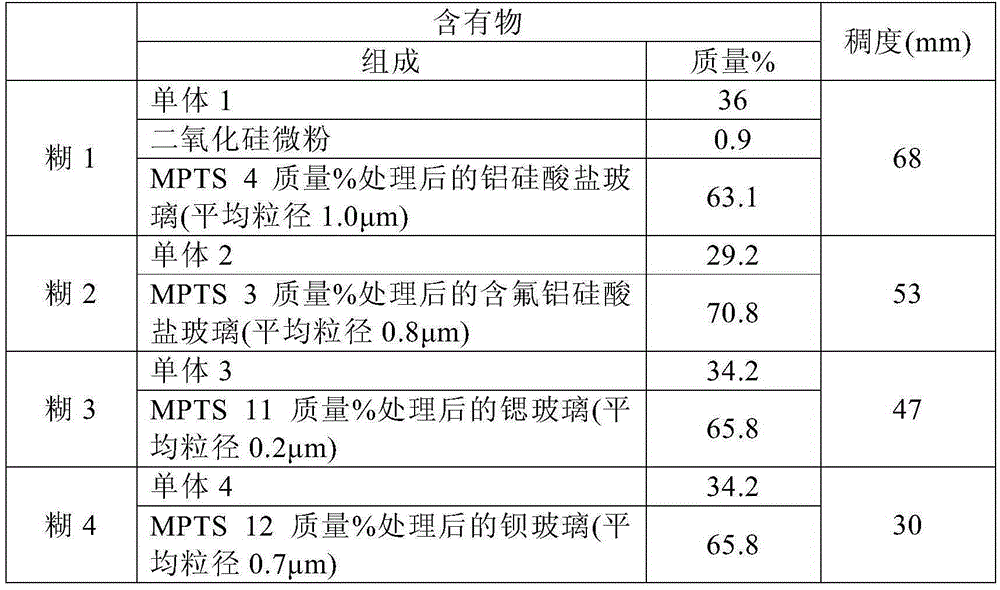

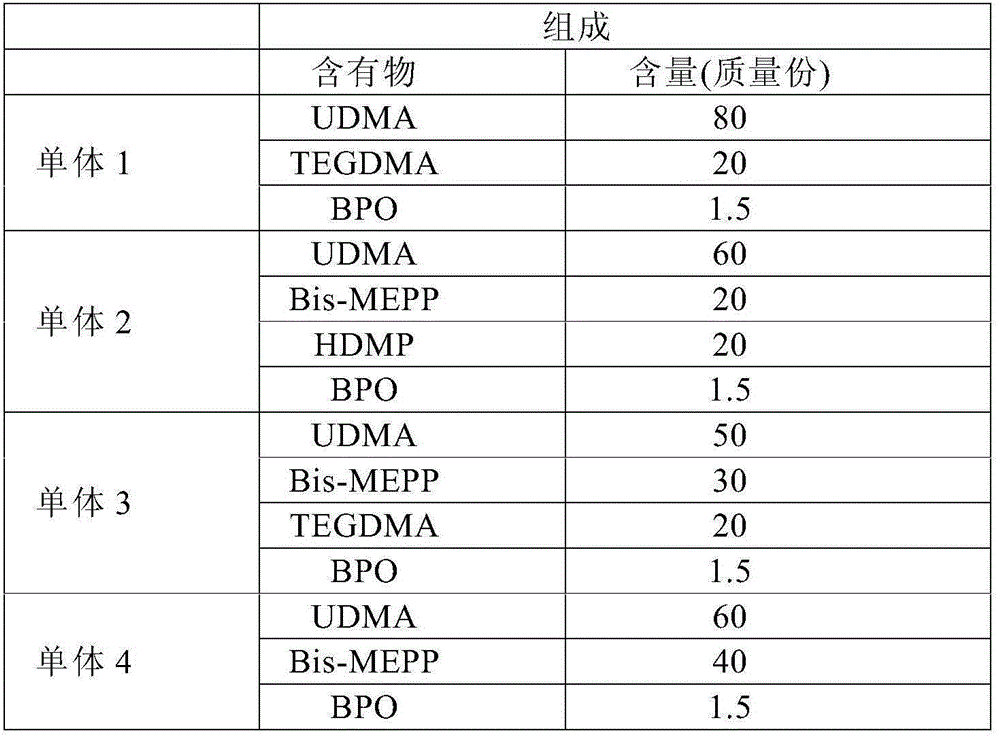

Method for manufacturing dental resin block

Provided is a method for manufacturing a dental resin block that has little cracks and bubbles. The method comprises: a step for pouring a material before curing, said material being for manufacturing a dental resin block, into a mold formed of a non-metal material; a step for pressurizing at 1.0 MPa or higher the mold and the material before curing that has been poured thereinto; and a step for heating at 60 DEG C or higher the mold and the material that has been poured thereinto.

Owner:GC CORP

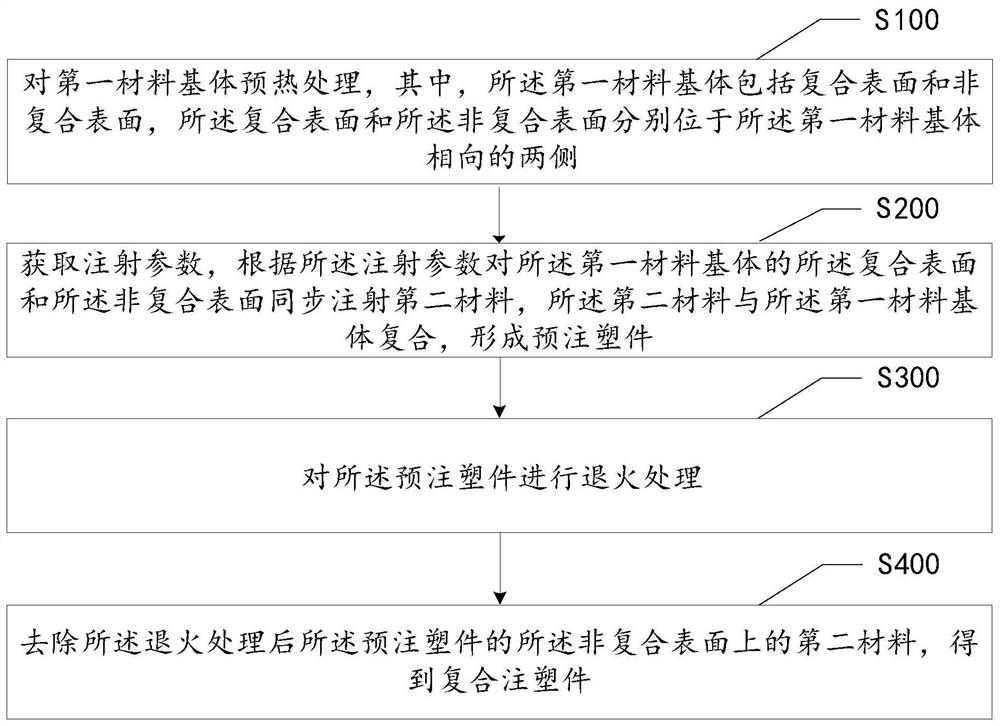

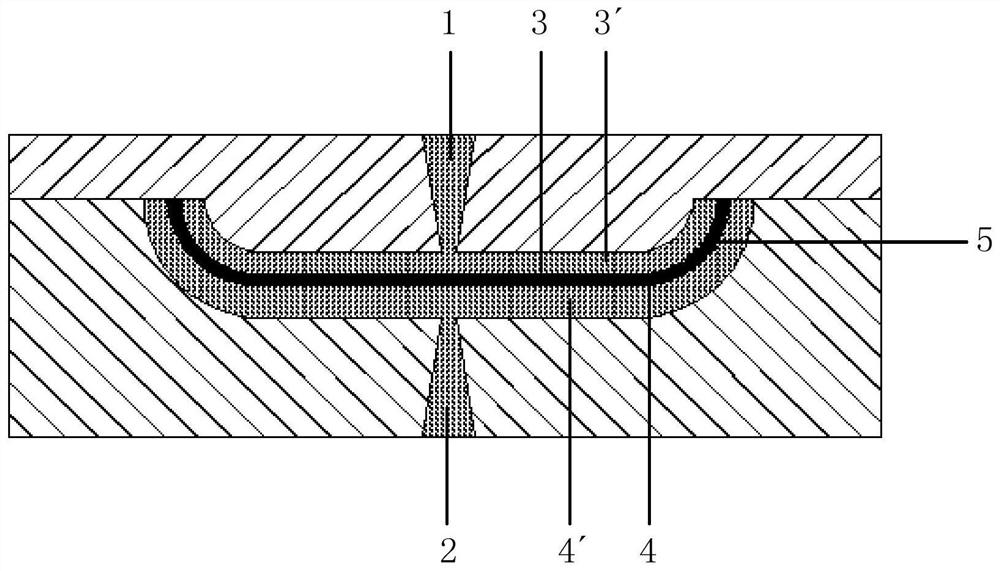

Composite material injection molding method

PendingCN113942172ANo fragmentationUniform pressureCoatingsInjection molding processInjection moulding

The invention discloses a composite material injection molding method. The composite material injection molding method comprises the following steps: preheating a first material matrix; obtaining injection parameters, and injecting a second material to a composite surface and a non-composite surface of the first material matrix synchronously according to the injection parameters, so that the second material is compounded with the first material matrix to form a pre-injection molded part; carrying out annealing treatment on the pre-injection molded part; and removing the second material on the non-composite surface of the pre-injection molded part subjected to annealing treatment, so that the composite injection-molded part is obtained. Compared with the prior art, the composite material injection molding method provided by the invention has the advantages that: the injection parameters are set, and the second material is simultaneously injected on the composite surface and the non-composite surface on the inner side and the outer side of the first material matrix according to the injection parameters, so that the pressure borne by the two sides of the first material matrix from the second material is always kept balanced; and therefore, the first material matrix is prevented from being broken in the injection molding process.

Owner:GOERTEK INC

Adhesive for magnetic materials

InactiveCN106752990AHigh bonding strengthGood resistance to mediaNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemistryWorking range

The invention belongs to the field of magnetic material adhesives and particularly relates to an adhesive for magnetic materials. The adhesive is prepared by modified polyolefin resin, epoxy resin, coupling agent, nano sericite, butyl acrylate, polydimethyl siloxane, lanolin, polyacrylamide and citronellol. The adhesive has the advantages that the adhesive can allow the magnetic materials to adapt to a wide frequency working range, the working environment use temperature of the magnetic materials can reach above 160 DEG C, and the adhesive has extremely high magnetic material adhering strength, has good medium resistance and can meet magnetic material's requirements on high resistivity.

Owner:马鞍山起劲磁塑科技有限公司

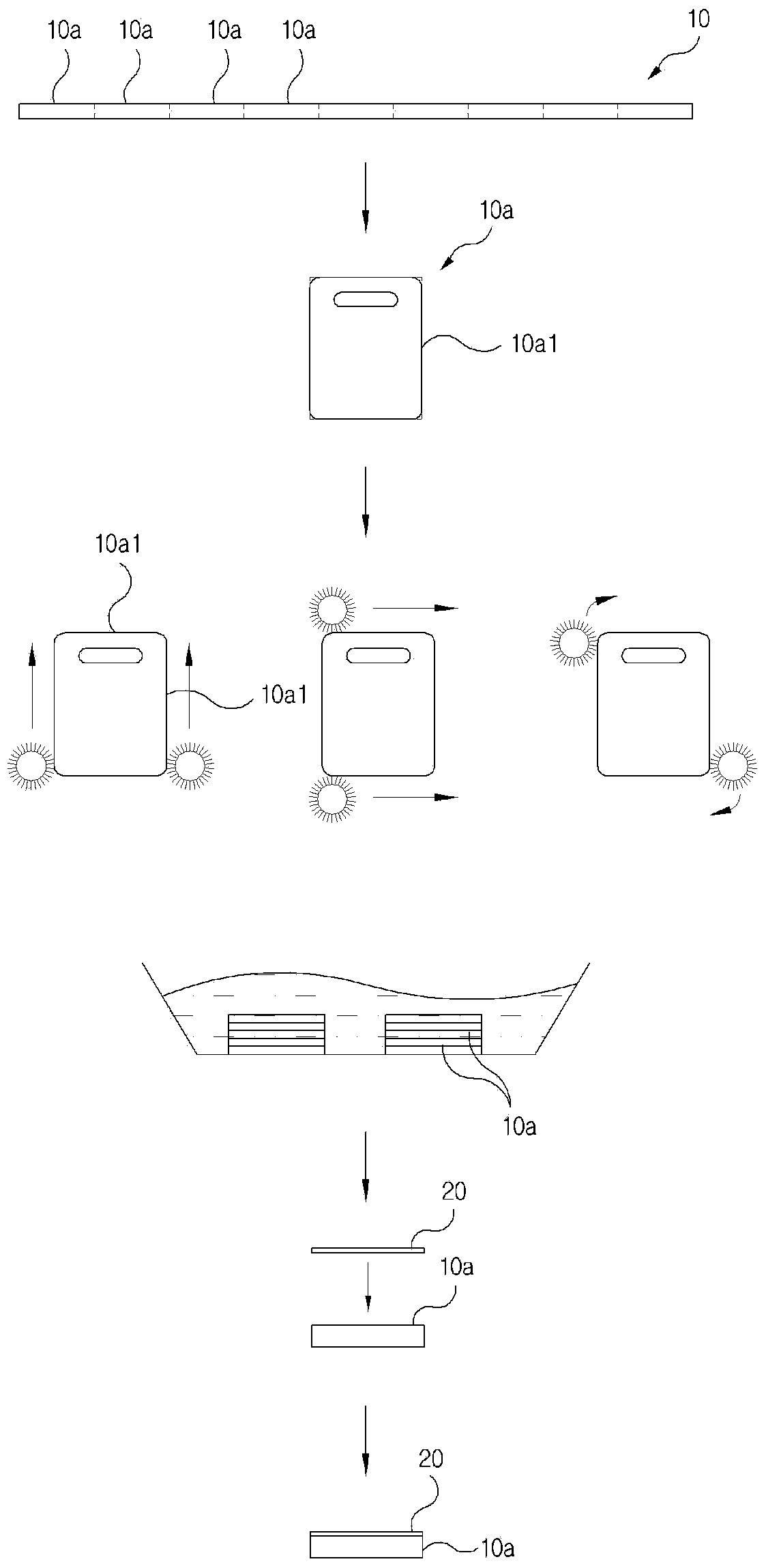

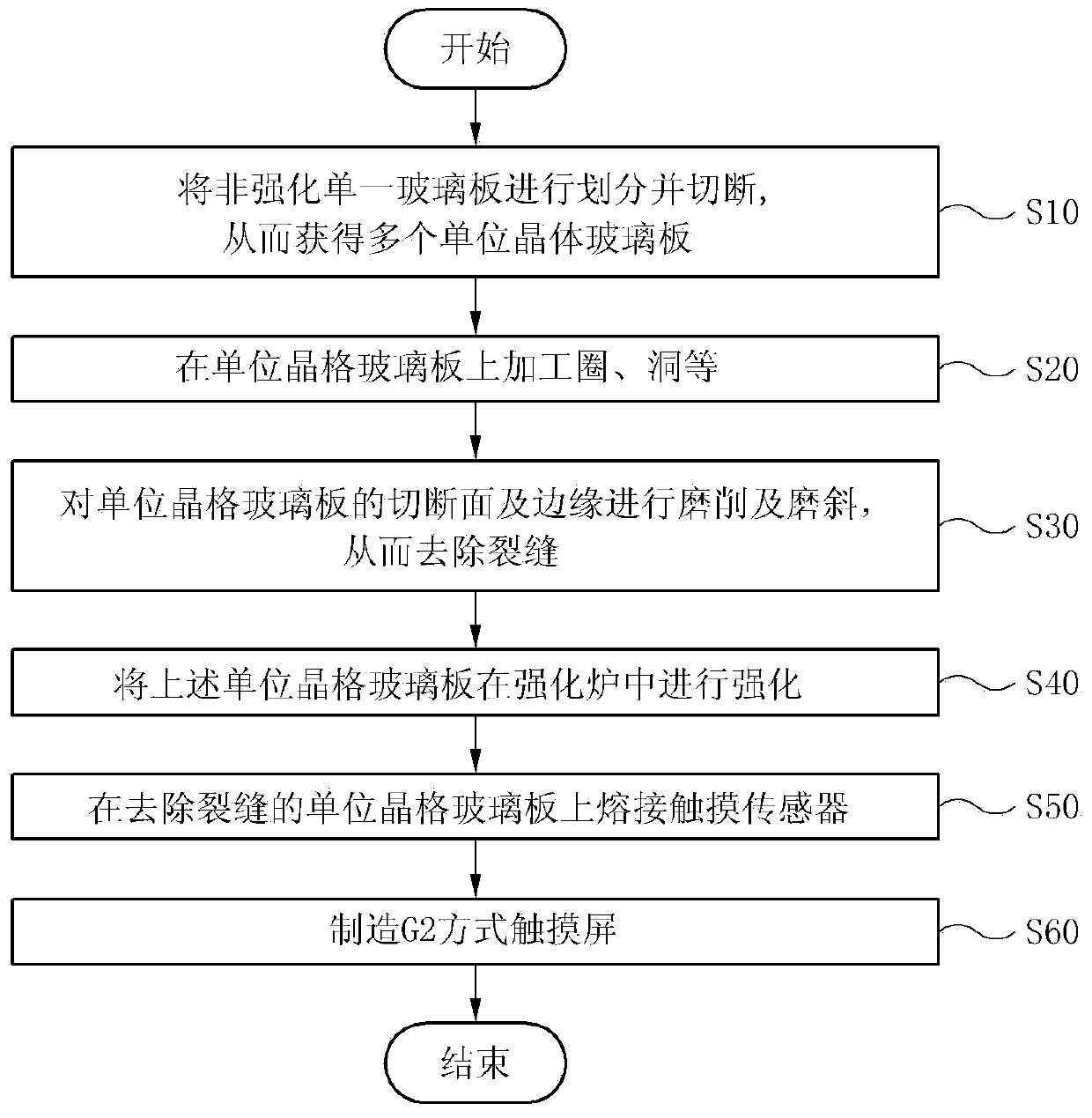

Processing method of tempered glass sheet and making method of g2 touch screen

InactiveCN103853375AShorten the timeIncrease productivityInput/output processes for data processingGlass productionComputer scienceGlass sheet

The invention relates to a processing method of one tempered glass sheet shaped of a unit cell G2 touch sensor and a making method of a G2 touch screen. The upper surface and the lower surface of the tempered glass sheet shaped of the unit cell G2 touch sensor are adhered to protecting films to form protecting film layers. Then, the protecting film layers belonging to warning lines of all unit cells are cut and removed. The tempered glass sheet is cut off along the warning lines removed by the protecting film layers so that multiple unit-cell glass substrates formed by the G2 touch sensor is obtained. The cutting portion at the side surface of each unit-cell glass substrate is etched at the specified thickness of depth. A crack formed in the cutting portion is removed. Each unit-cell glass substrate is soaked to the water to remove the protecting film layers through soaking operation so that the G2 touch screen formed by the G2 touch sensor is made. The processing method of one tempered glass sheet shaped of the unit cell G2 touch sensor and the making method of the G2 touch screen have following advantages: the multiple unit-cell glass substrates are rapidly obtained so that production efficiency is boosted; and therefore time spent on making the touch screen is shortened and mass production is carried out.

Owner:TAE SUNG ENG

Hollow extracting micro-hole filtering element

InactiveCN100471544CImprove toughnessStrong impact resistanceMoving filtering element filtersMicrocellular plasticMicroparticle

The present invention is improved filter plate for solid-liquid separating drier. The improved filter plate is hydrophilic microporous plastic plate with average pore size of 0.2-1.5 microns, and forms the sucking filter element walls. It is superior to available ceramic plate, and has pore opening rate of about 60 %, 20-30 % higher production capacity, high toughness, high impact resistance, and acid and base resistance.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com