Processing method of tempered glass sheet and making method of g2 touch screen

A processing method and manufacturing method technology, applied in glass production, data processing input/output process, instruments, etc., can solve the problems of increased touch screen defective rate, reduced production efficiency, long time consumption, etc., to shorten time, increase Productivity, easy-to-remove effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention will be described in more detail with reference to the drawings.

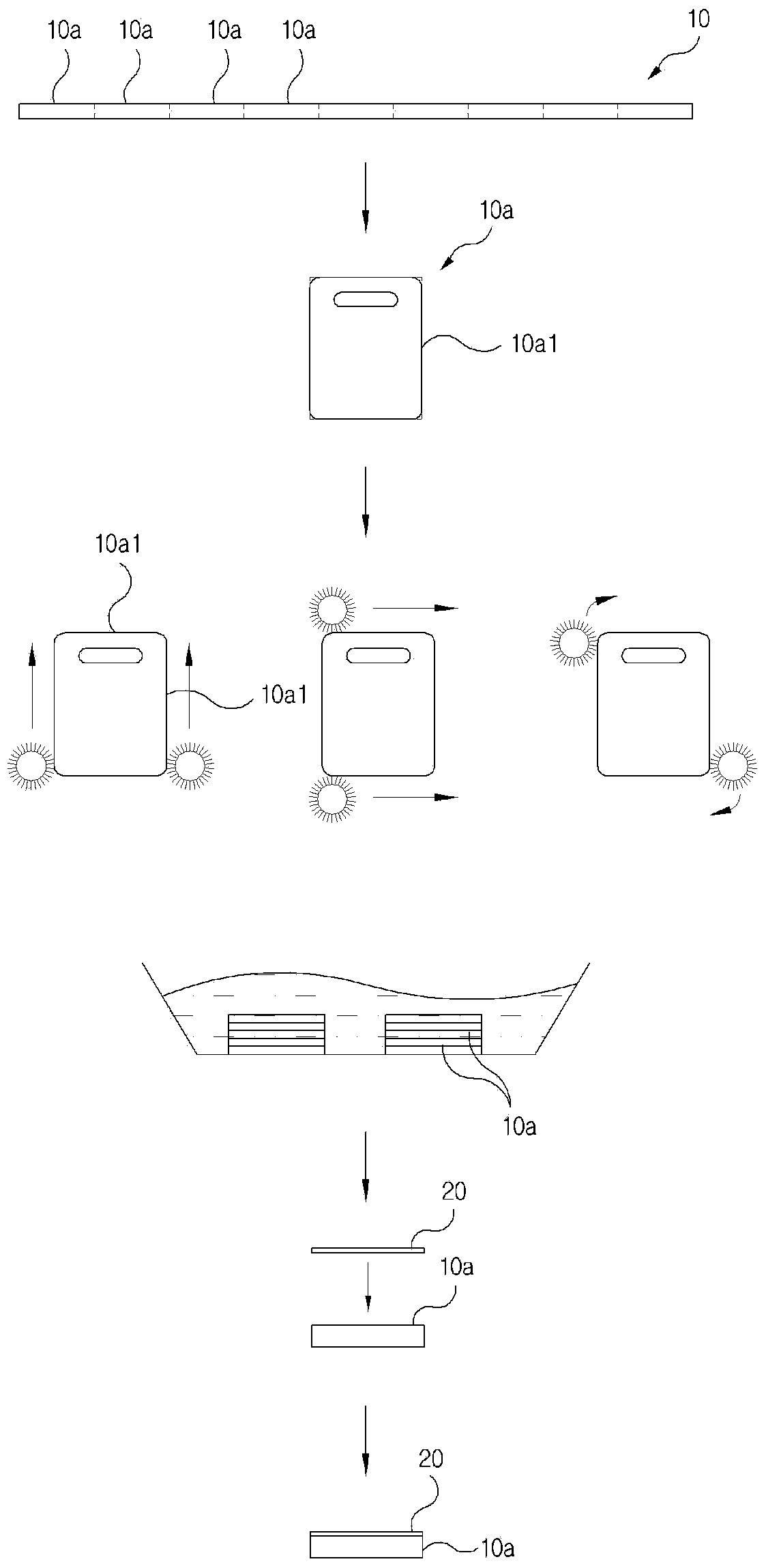

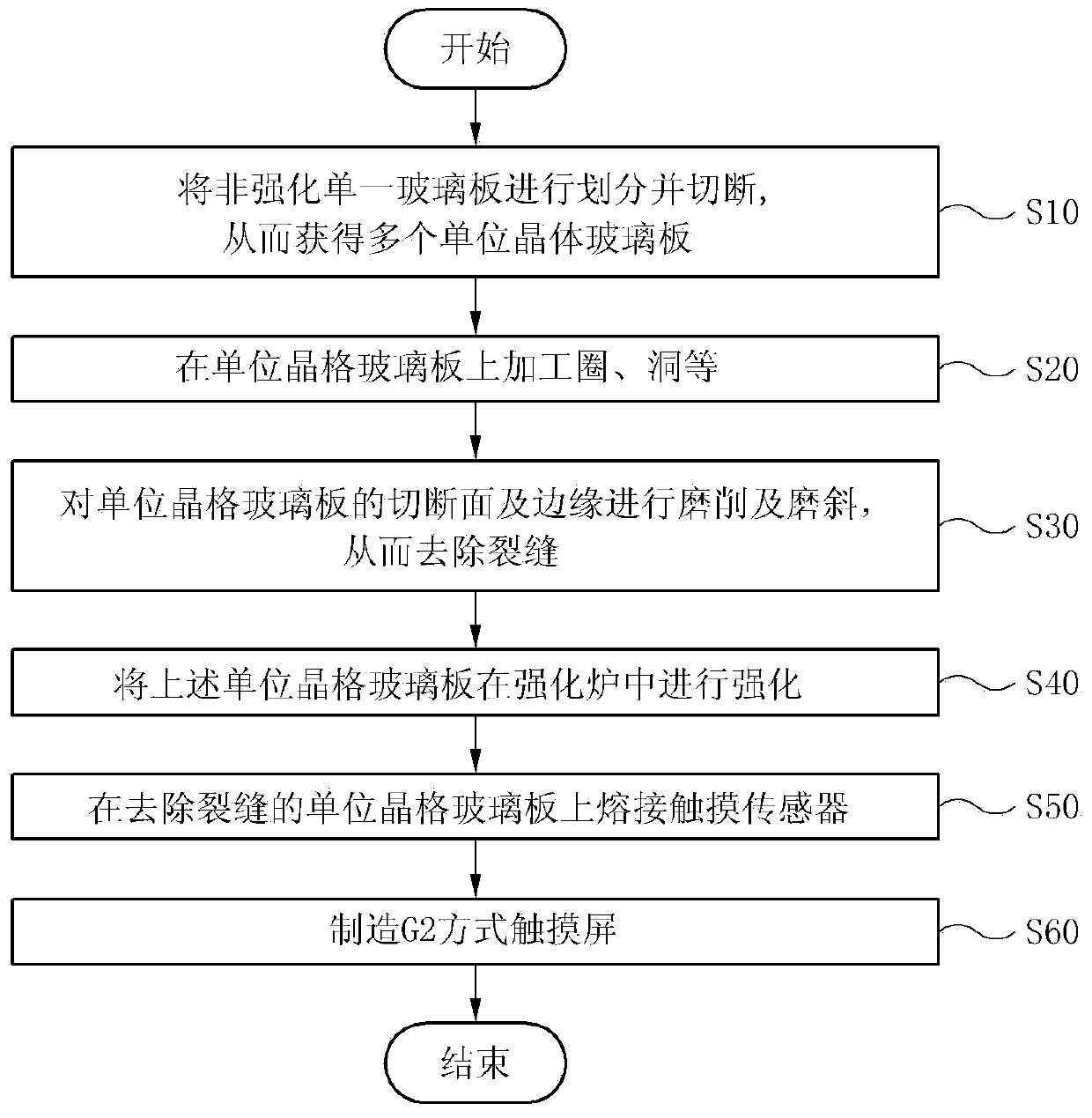

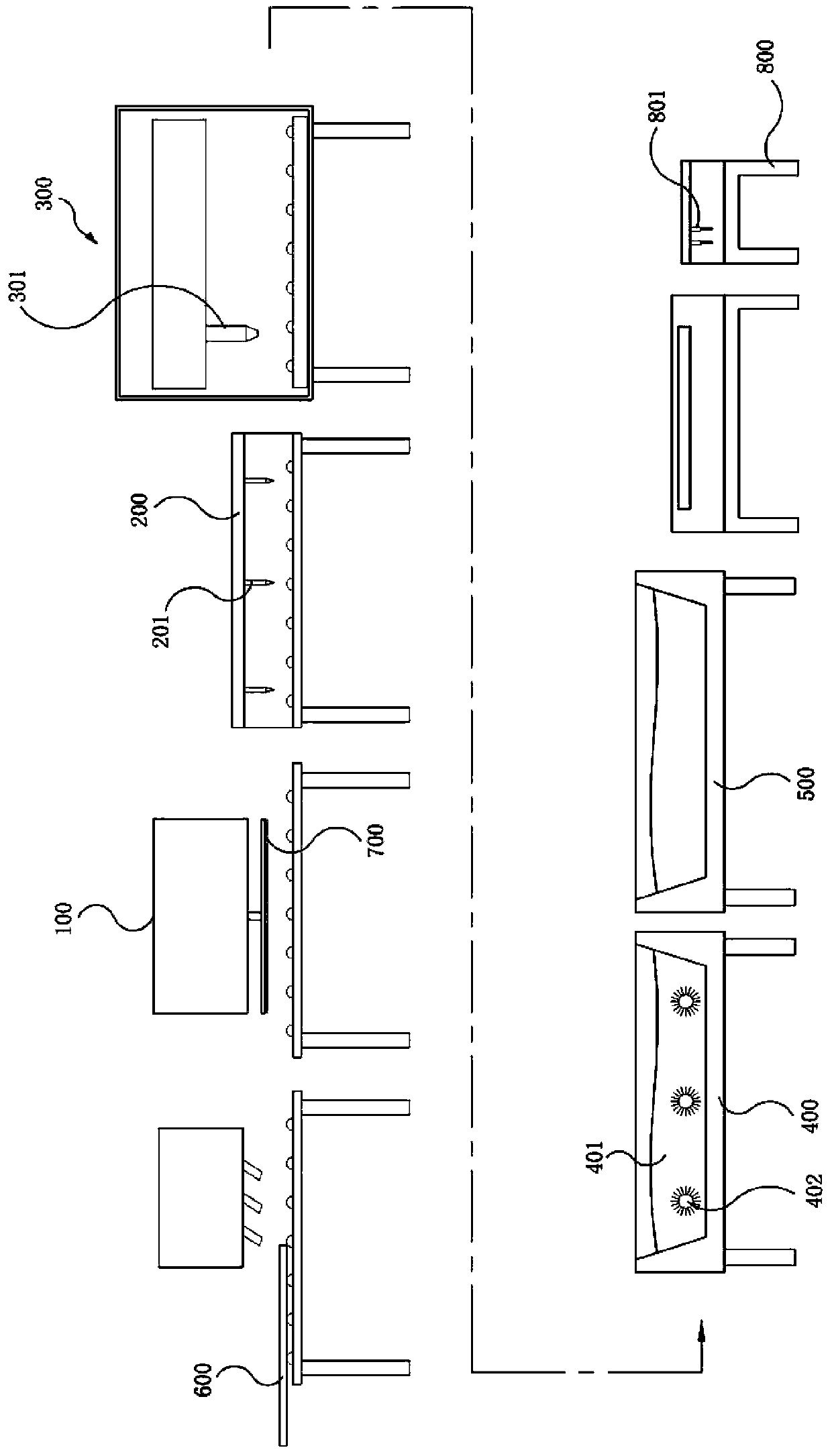

[0041] image 3 It is an example showing a manufacturing apparatus for manufacturing a G2-type touch panel by processing a plurality of tempered glass plates formed by a plurality of G2-type touch sensors according to the present invention. It has the following configuration: a laminator for forming a protective film layer; Cutting machine for cutting the protective film layer, sand blasting equipment for cutting the strengthened glass plate, etching water tank containing chemicals for etching the unit cell glass plate, and soaking water for removing the protective film sink.

[0042] The laminator 100 attaches the protective film 701 on the upper and lower surfaces of the strengthened glass plate 600 formed by the plurality of G2 touch sensors 601 to form the protective film layer 700 on the upper and lower surfaces of the strengthened glass plate 600 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com