Holding clamp for etching

A fixture and etching technology, which is applied in the field of holding fixtures, can solve the problem of unsmooth flow field of etching liquid, etc., and achieve the effect of reducing etching time and making it easier to go up and down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

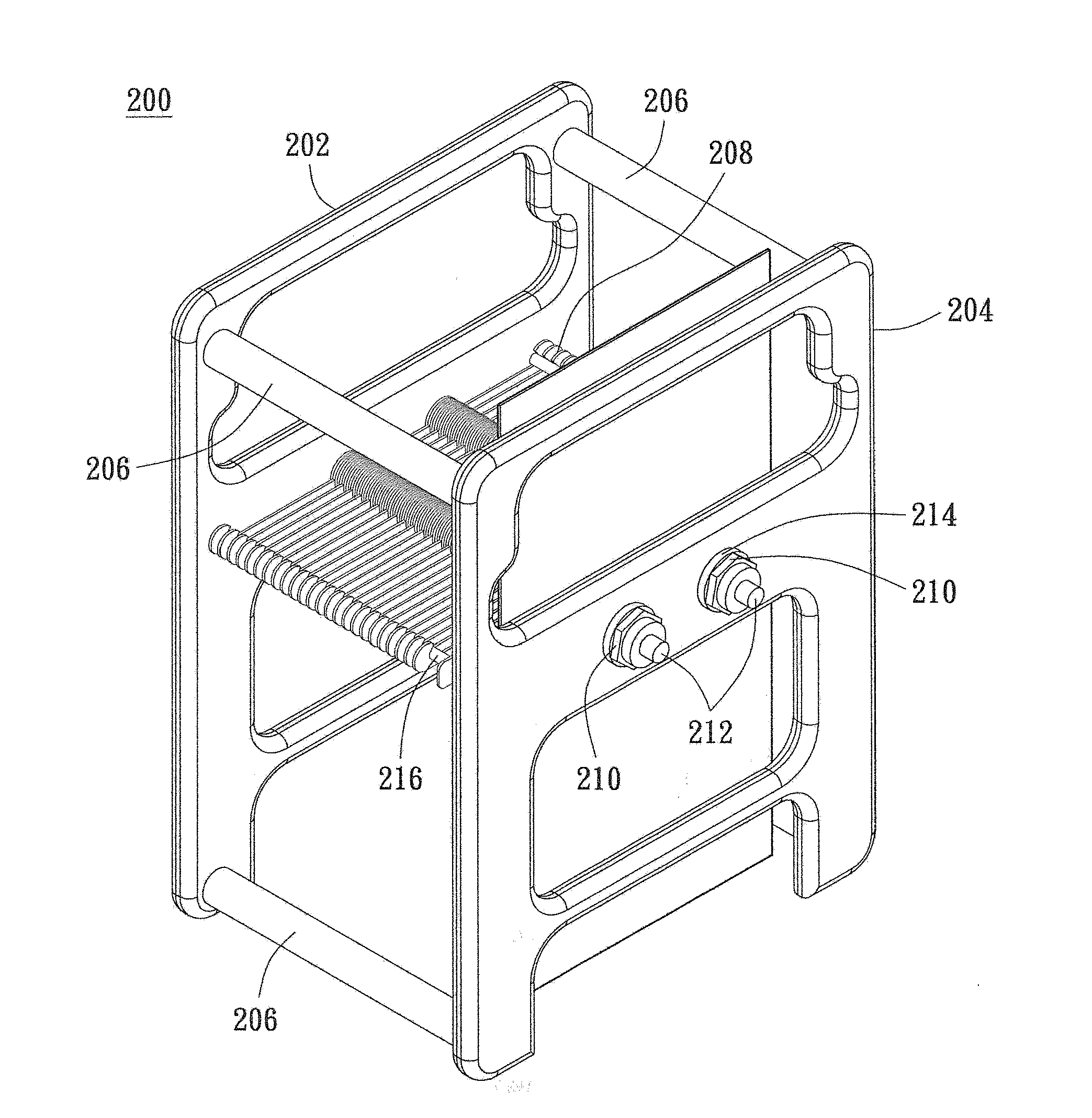

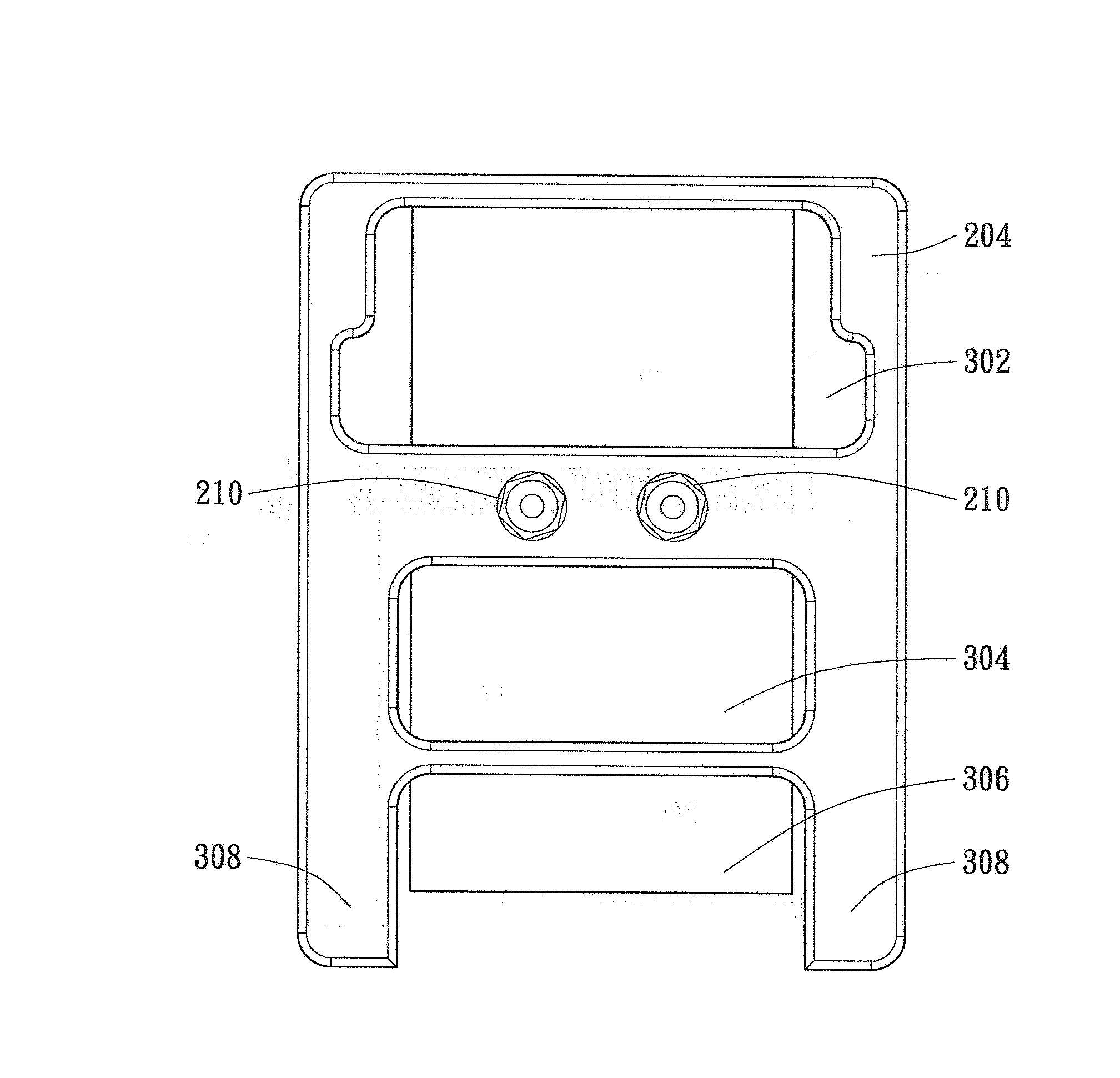

[0044] see Figure 2 to Figure 7 , the present invention provides an etching holding fixture 200 for a glass sheet or a wafer, which includes two side plates 202, 204, four support rods 206, a plurality of splints 208, two splint slide bars 216 and two A splint bar 214.

[0045] The side plates 202, 204 are preferably but not limited to square plate bodies. The two side plates 202, 204 are separated from the left and right sides, and the four support rods 206 are connected to the left and right side plates 202, 204. A support rod 206 is connected to the four corners of the two side plates 202,204. Two ends of the supporting rod 206 are connected to the left and right side plates 202 , 204 to form an open body of the etching holding fixture 200 . The two ends of the support rod 206 can be connected to the two side plates 202, 204 by means of welding, screwing or embedding, and the two ends of the support rod 206 can also be connected to the two side plates 202, 204 by integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com