Mixed-flow device of ship diversion propelling system

A propulsion system and mixed-flow technology, which is applied to ship propulsion, propulsion components, rotary propellers, etc., can solve problems such as not being recycled or utilized, propulsion load reduction, and propulsion efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

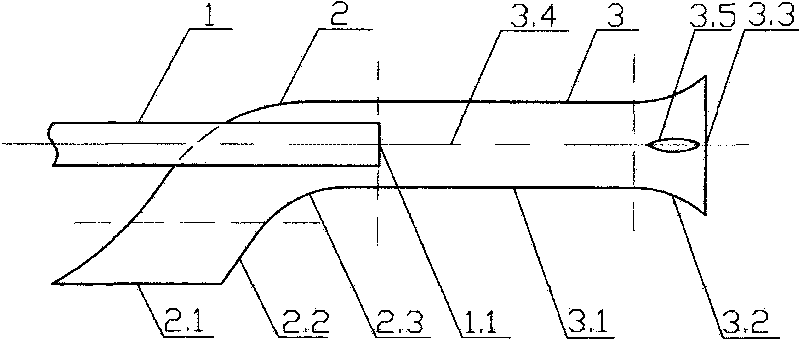

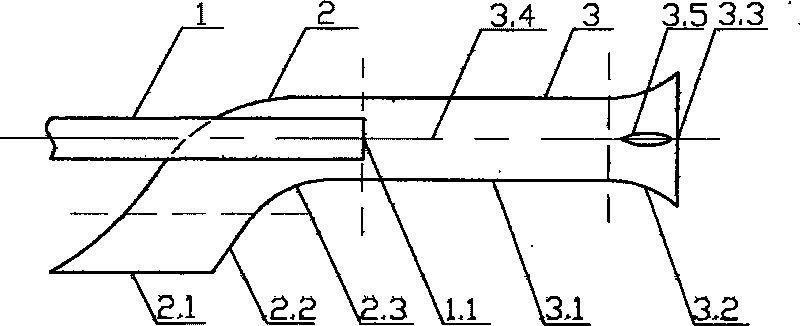

[0030] Such as figure 1As shown, the mixed flow device at the rear of the water jet propulsion system is mainly composed of three parts: the jet pipe 1, the follower pipe 2 and the mixed flow pipe 3. This is equivalent to upgrading the water jet pipe of the water jet propulsion system to a mixed flow device. Wherein, the jet pipe 1 of this mixing device is just equivalent to the original spray pipe; the follower pipe 2 includes the bell mouth 2.2 of the follower pipe and the elbow 2.3 of the follower pipe; the mixed flow pipe 3 includes the mixed flow part 3.1 and The bell mouth 3.2 of the mixed flow tube has a split fluid 3.5 and its support in the bell mouth 3.2 of the mixed flow tube.

[0031] At the moment when the propulsion pump of the water jet propulsion system starts forward, the positive pressure difference is transmitted from the propulsion pump to the mixed flow chamber 3.4 through the jet pipe 1, and the water in the mixed flow chamber 3.4 flows to the outlet 3.3...

Embodiment 2

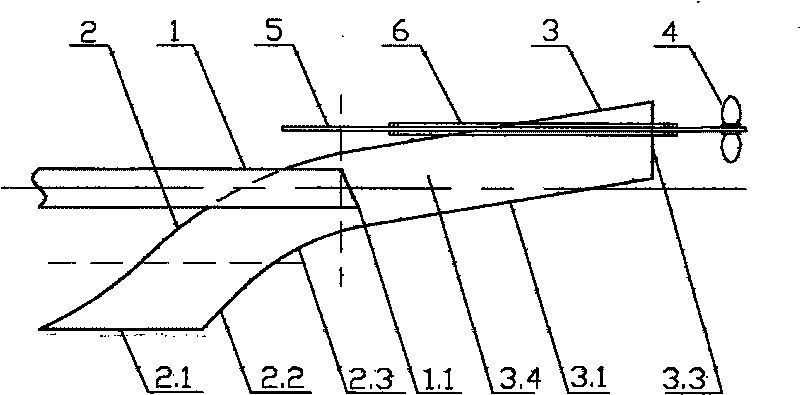

[0034] Such as figure 2 As shown, the mixing device in front of the propeller or the pump wheel is mainly composed of three parts: the jet tube 1, the follower tube 2 and the mixing tube 3. Among them, the jet pipe 1 is equivalent to the original water spray pipe; the follower pipe 2 includes the bell mouth 2.2 of the follower pipe and the bend pipe 2.3 of the follower pipe; the mixed flow pipe 3 is mainly the mixed flow part 3.1 of the mixed flow pipe. The mixed flow tube 3 deflects in the direction opposite to the inlet 2.1 of the follower tube relative to the centerline of the jet tube 1, and its deflection angle is smaller than the angle of the flow direction of the follower entering the mixed flow tube 3 relative to the centerline of the jet tube 1. The end face of the nozzle 1.1 of the jet tube is deflected in the deflection direction of the mixing tube 3 .

[0035] There is a propeller or a pump wheel 4 behind the outlet 3.3 of the mixing tube. The transmission shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com