Variable wing leading edge combining subsonic aerodynamic performance and supersonic aerodynamic performance

A technology for leading edge and aerodynamic performance of wings, applied in supersonic aircraft, wings, motor vehicles, etc., can solve the problems of decreased aerodynamic efficiency, low lift-to-drag ratio, increased fuel consumption, etc., to reduce the use cost, High lift-drag ratio, the effect of improving lift-drag ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

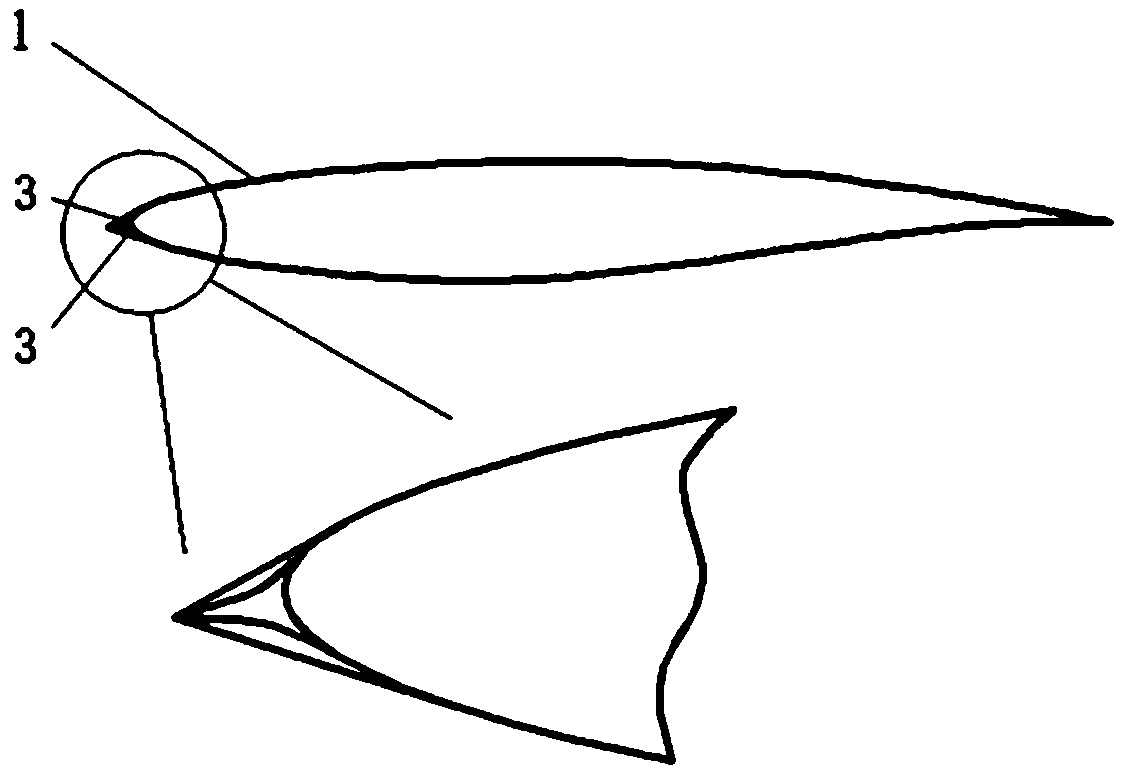

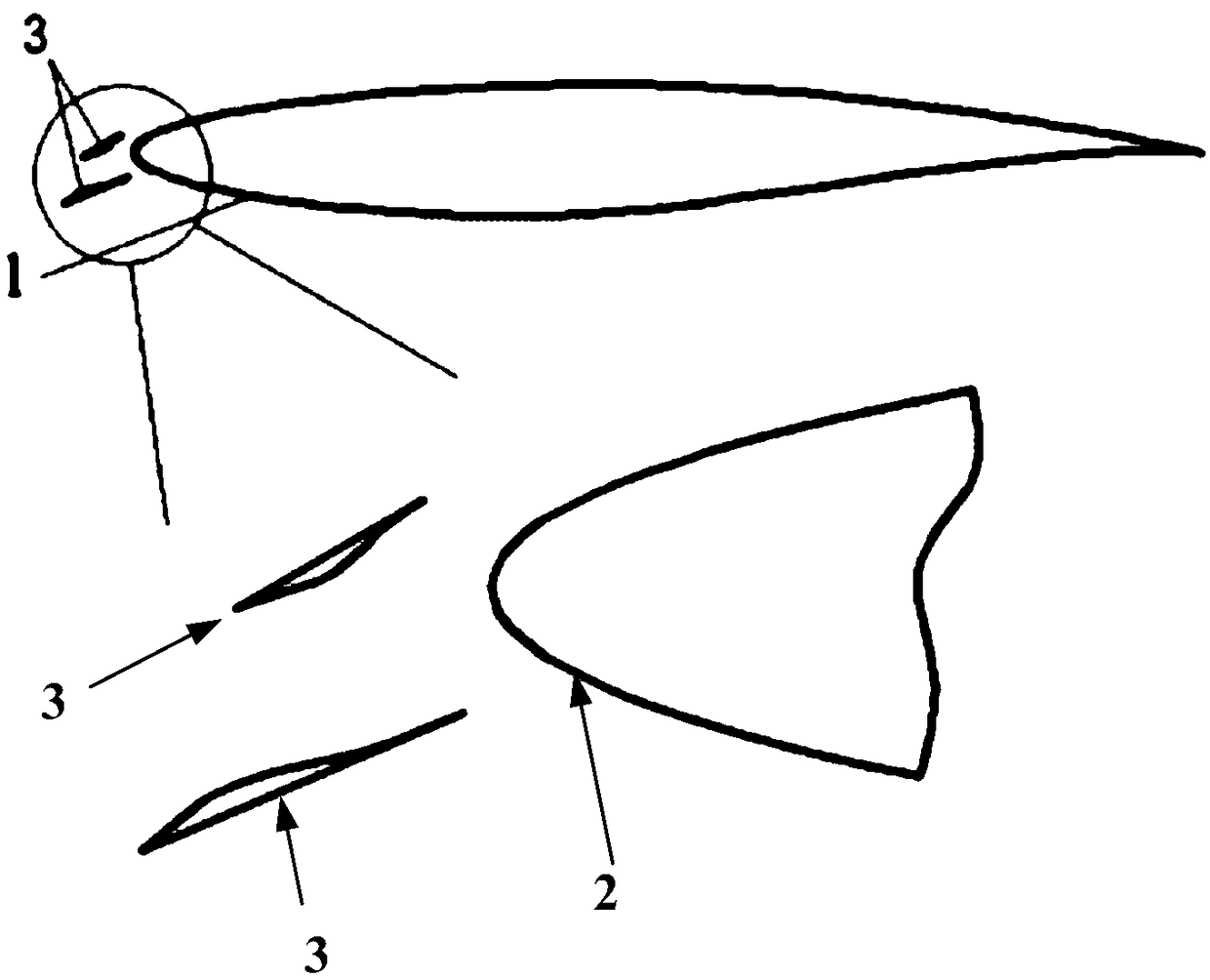

[0027] Example 1: When the flow Mach number is 0.3, the flow Reynolds number is 6.5×10 6 , when the incoming flow angle of attack is 6°, the calculation and verification of the leading edge of the wing of the aircraft is carried out. It can be known from the technical knowledge that the airfoil is the section of the wing in each plane parallel to the aircraft symmetry plane in the span direction, and the flow analysis of the airfoil is equivalent to the analysis of the flow of the wing in a certain section. Figure 5 It is a schematic diagram of the airflow streamline of the traditional sharp wing leading edge in subsonic flight state. The sharp wing leading edge 5 surface produces leading edge separation bubbles 6, and the lift-to-drag ratio is low when the aircraft is flying at subsonic speed. Using the traditional sharp wing The lift coefficient of wing leading edge 5 under the condition that present embodiment provides is 0.77124, and drag coefficient is 0.022767, and lift...

Embodiment 2

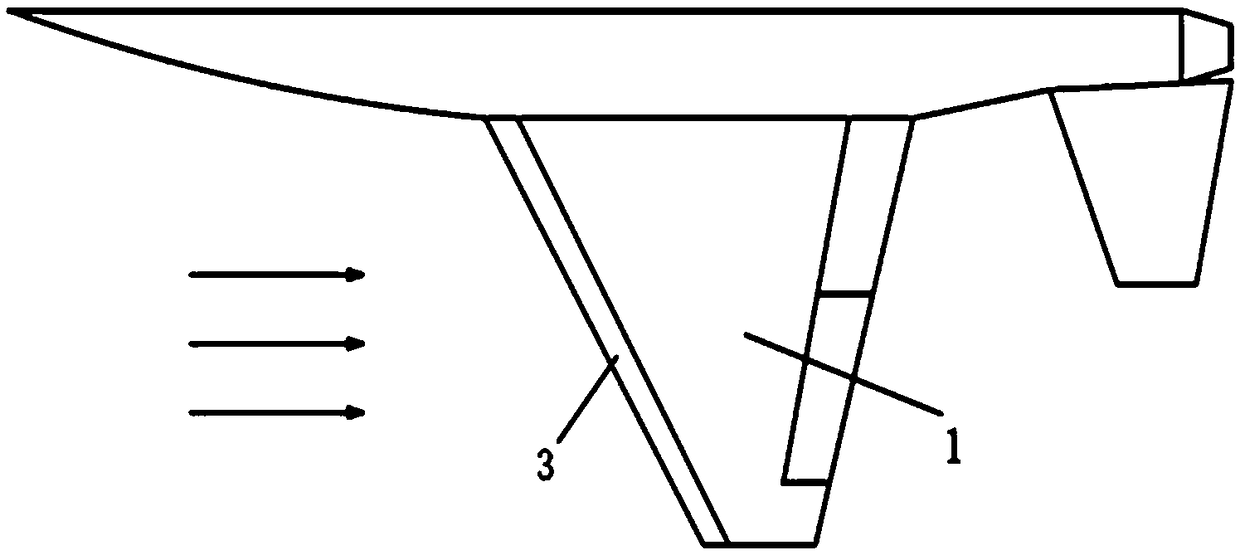

[0028] Example 2: When the flow Mach number is 2.2, the flow Reynolds number is 3.2×10 7 , when the incoming flow angle of attack is 2°, the calculation and verification of the leading edge of the wing of the aircraft is carried out. Such as Figure 7 Shown is a schematic diagram of the pressure distribution of the conventional blunt wing leading edge under supersonic flight. The obvious pressure dividing line in front of the wing leading edge is the shock wave. The shock wave presents a bow shape, which brings a large In this state, the lift coefficient of the wing with blunt wing leading edge when the aircraft flies at supersonic speed is 0.13917, the drag coefficient is 0.17941, and the lift-to-drag ratio is 0.78; Figure 8 In order to adopt the variable wing leading edge of the present invention to carry out the pressure distribution diagram of supersonic flight, the movable leading edge baffle 3 of the wing adopting the variable wing leading edge design is retracted so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com