Aircraft head-on resistance and heat reduction method

A technology of aircraft and thermal method, applied in aircraft parts, fuselage, transportation and packaging to achieve the effect of reducing shock wave resistance and reducing heat flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

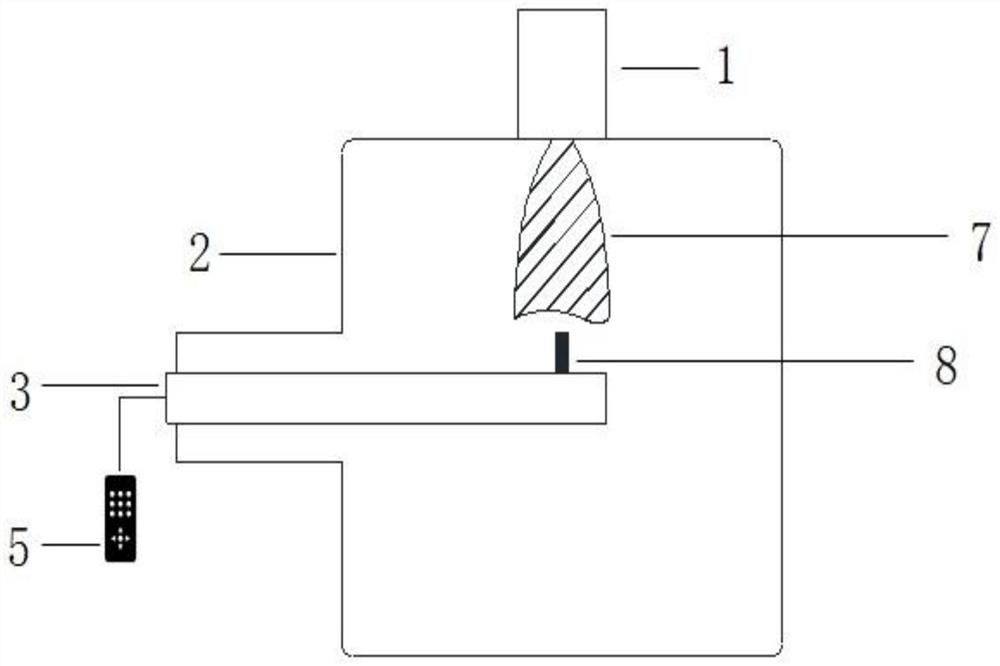

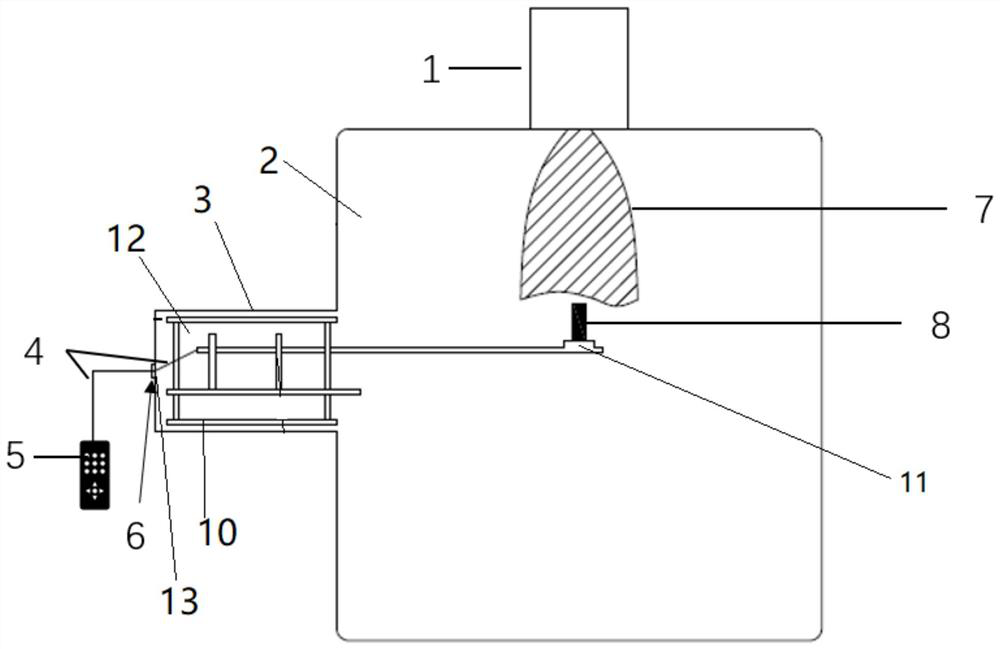

[0026] like figure 2 , image 3 and Figure 4 As shown, a aircraft is slightly reduced by the heating method, and the configuration entity is provided in the head of the aircraft, which can be ablated into a sharp structure in the aircraft flight, to maintain the hustle The transition is a tapered hike to reduce the hustle resistance to the aircraft.

[0027] The present invention mainly passes through the head to a sharp-shaped nasal cone structure, and the configuration entity can be kept in the shape throughout the process, and the arcuate hindle can be converted to the on-one manner. Conical hike, thereby effectively reducing hustle resistance; on the other hand, it can also reduce the surface heat flow of the aircraft body.

Embodiment 2

[0029] like figure 2 , image 3 and Figure 4 As shown, a aircraft is slightly reduced by the aircraft, and a configuration entity is provided in the aircraft head, and the configuration entity extends along the front end of the aircraft, and the structural entity uses a material having thermal lifting characteristics. A tip structure or cylindrical structure is prepared, the tip structure maintains the configuration in the ablation process, which is burn into a sharp configuration in the ablation process and maintained.

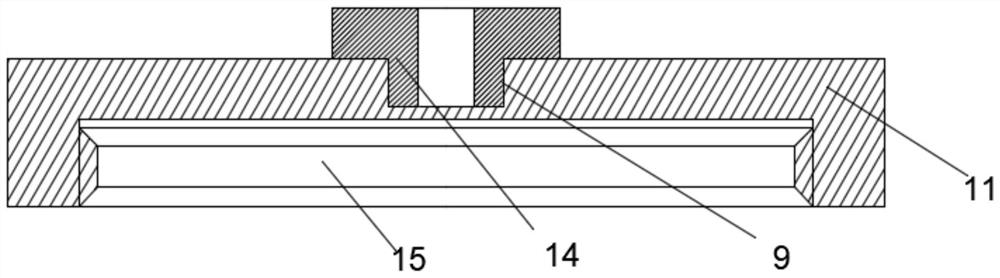

[0030] Further, such as figure 2 , image 3 and Figure 4 As shown, a aircraft is averaged, and the graphite cylinder is provided in the front end of the aircraft. The graphite cylinder has thermal lifting characteristics and can protect the characteristics of ablation, the length direction of the graphite cylinder along the aircraft The head is extended outwardly, and one end portion of the graphite cylinder is positively received on the head of the aircraft, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com