System precision processing method of fragile transparent special-shaped 3D structure

A transparent material and precision processing technology, applied in metal processing equipment, chemical instruments and methods, manufacturing tools, etc., can solve problems such as fragmentation, glass welding interface appearance effect, etc., to achieve small impact, eliminate material internal stress, repeat The effect of high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

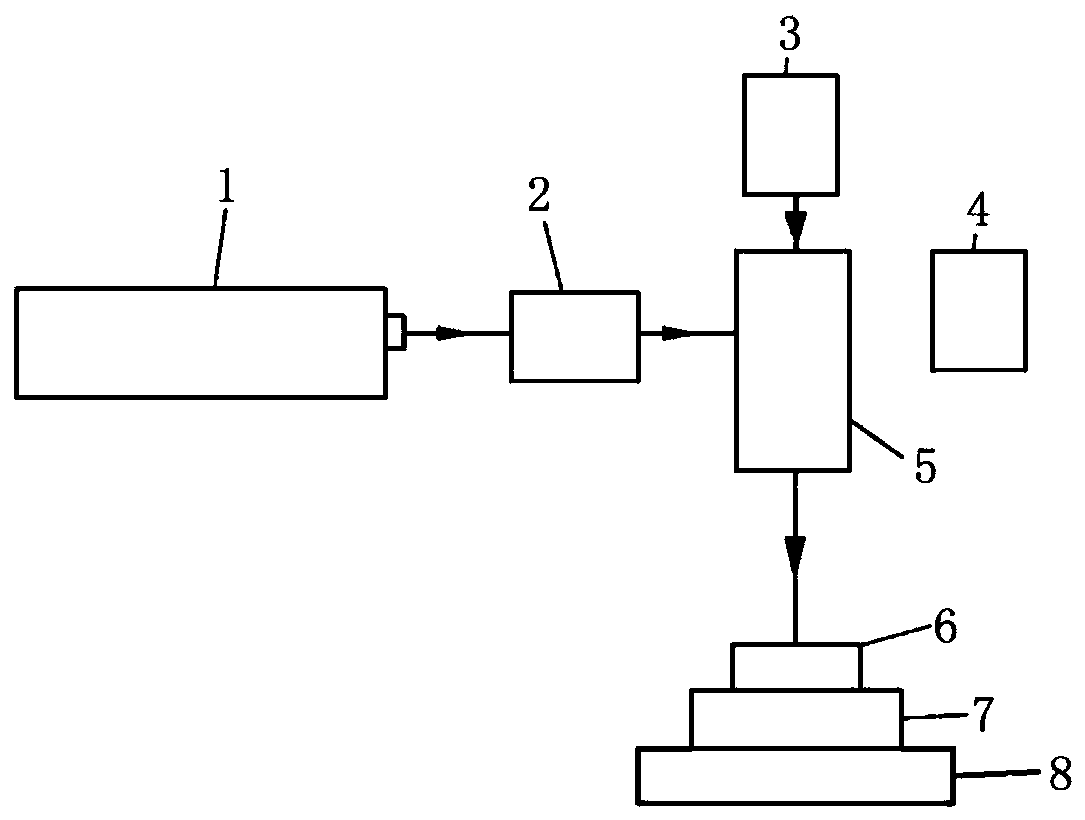

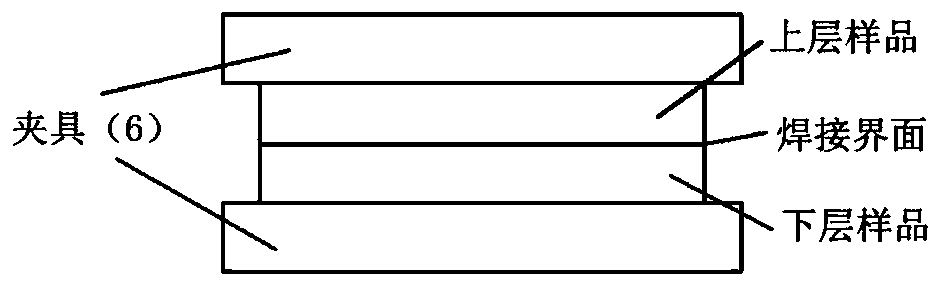

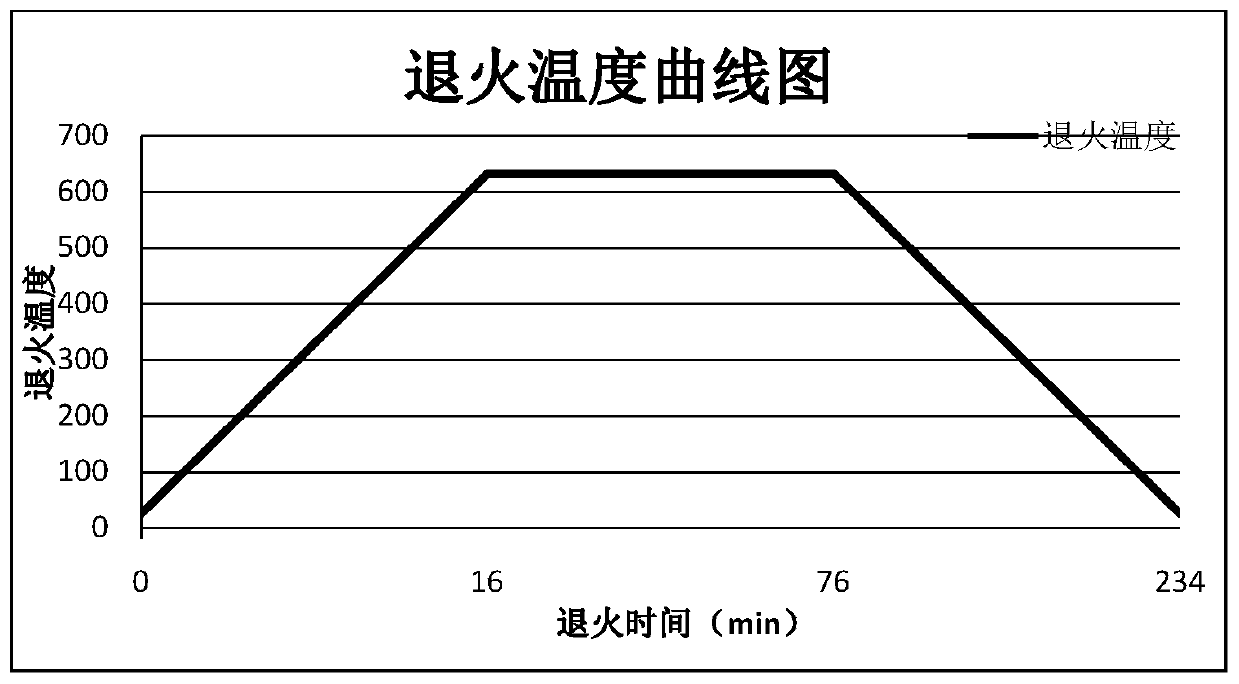

[0053] This embodiment provides a systematic precision machining method for special-shaped 3D structures of brittle transparent materials. , coaxial vision system 3, paraxial vision system 4, welding head 5, fixture 6, horizontal adjustment bracket 7, motion platform 8; the second step, the surface cleaning of samples and fixtures; the third step, sample clamping; the fourth step , the fixture is installed on the motion platform; the fifth step is contour positioning and processing trajectory formulation; the sixth step is glass welding; the seventh step is annealing; the eighth step is strengthening.

[0054] In the specific implementation, the method is used to weld the processed sample glass frame and the glass plate, wherein the thickness of the glass frame is 2.7mm, the width of the frame is 2.0mm, the thickness of the glass plate is 0.5mm, and the boundary between the glass frame and the glass plate does not contain chamfers / rounds horn. Clean and clamp the glass frame,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com