Patents

Literature

47results about How to "Light transmittance has little effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance heat-insulation coating and preparation method thereof

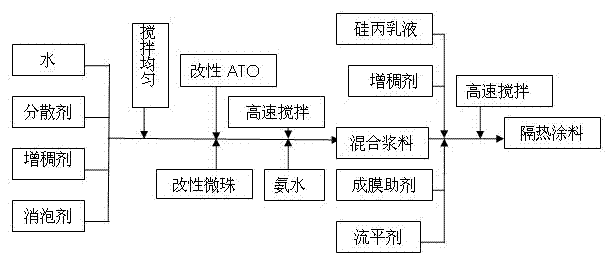

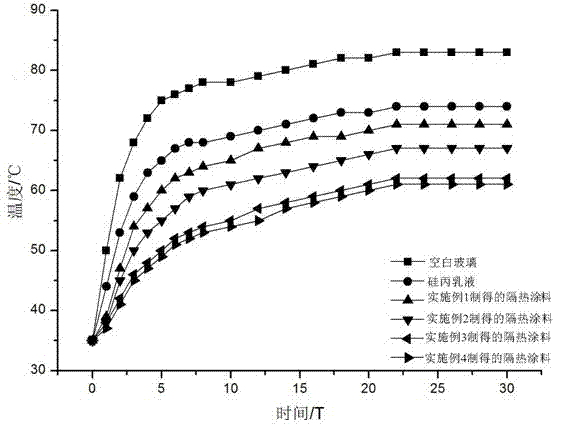

The invention provides a high-performance heat-insulation coating and a preparation method thereof. The preparation method of the high-performance heat-insulation coating specifically comprises: firstly modifying nano antimony tin oxide powder (nano ATO powder) and hollow glass microbeads with a silane coupling agent, and then dispersing with water, an organosilicone dispersant, an organosilicone defoamer, an associative thickener and the like under the effect of high-speed stirring to obtain mixed slurry; and then adding an associative thickener, a film forming agent, an organosilicone leveling agent, an film-forming additive and the like to the mixed slurry and carrying out high-speed stirring to obtain the heat-insulation coating. The coating prepared by the preparation method has the advantages of good stability, strong heat-insulation capacity and the like, and simultaneously has anti-static, anti-radiation and other effects because of the self-characteristics of nano ATO powder.

Owner:SOUTH CHINA UNIV OF TECH

Light diffusing agent, PMMA (polymethyl methacrylate) light diffusing plate and manufacturing method thereof

ActiveCN103193915AImprove performanceImprove mechanical propertiesDiffusing elementsOligomerRefractive index

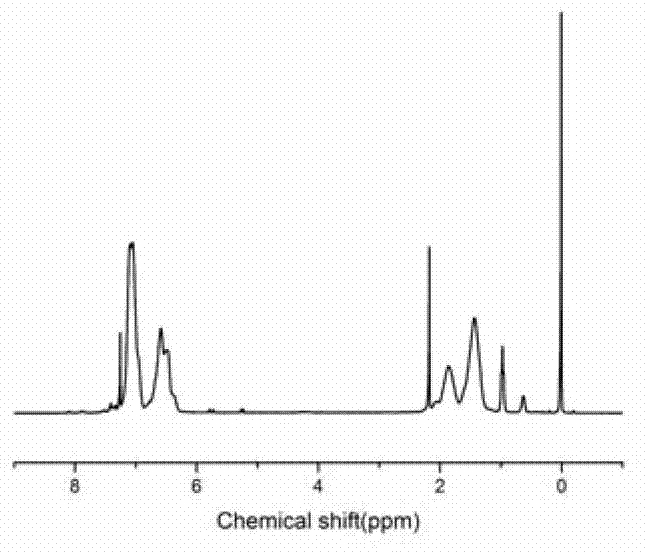

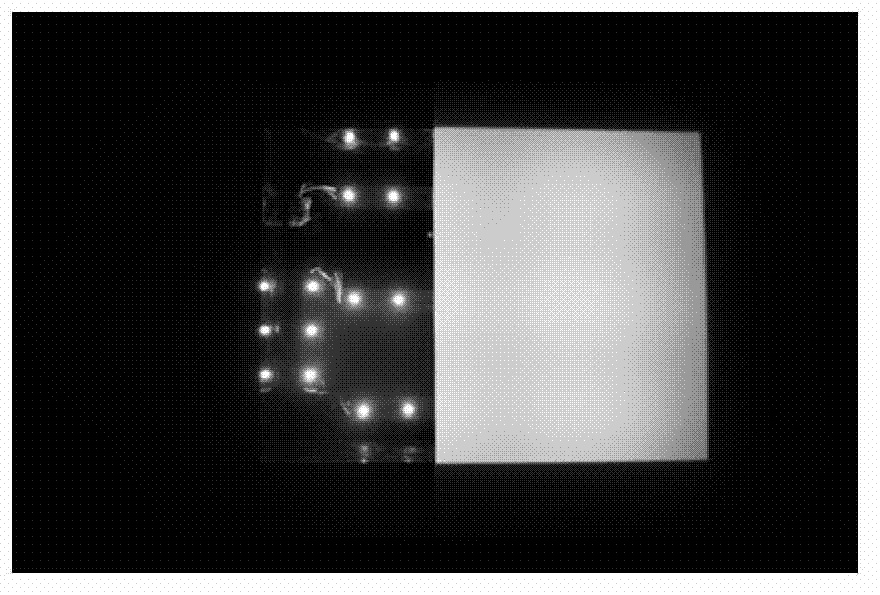

The invention relates to a light diffusing agent, a PMMA (polymethyl methacrylate) light diffusing plate and a manufacturing method thereof. The light diffusing agent is a random copolymer of styrene (St) and methacryloxypropylisobutyl polyhedral oligomer silsesquioxane (MAiBuPOSS). The PMMA light diffusing plate comprises the following components in percentage by weight: 97.0-99.5% of polymethyl methacrylate and 0.5-3.0% of light diffusing agent. The refractive indexes of the styrene component and the MAiBuPOSS component in the light diffusing agent differ from the refractive index of PMMA; when passing through a material, a light ray is refracted for many times and becomes bright and soft after passing through a substrate. Meanwhile, the MAiBuPOSS component ensures that the dispersibility of PS (Poly Styrene) in PMMA is remarkably improved, excellent light transmission and light scattering are obtained, and the optical efficacy is high. The PMMA light diffusing plate manufactured by the invention can be used for LED (Light Emitting Diode) illumination lamps, such as a plate lamp, an advertising lamp box, a professional film viewer, a down lamp and the like.

Owner:石狮市天生化工有限公司 +1

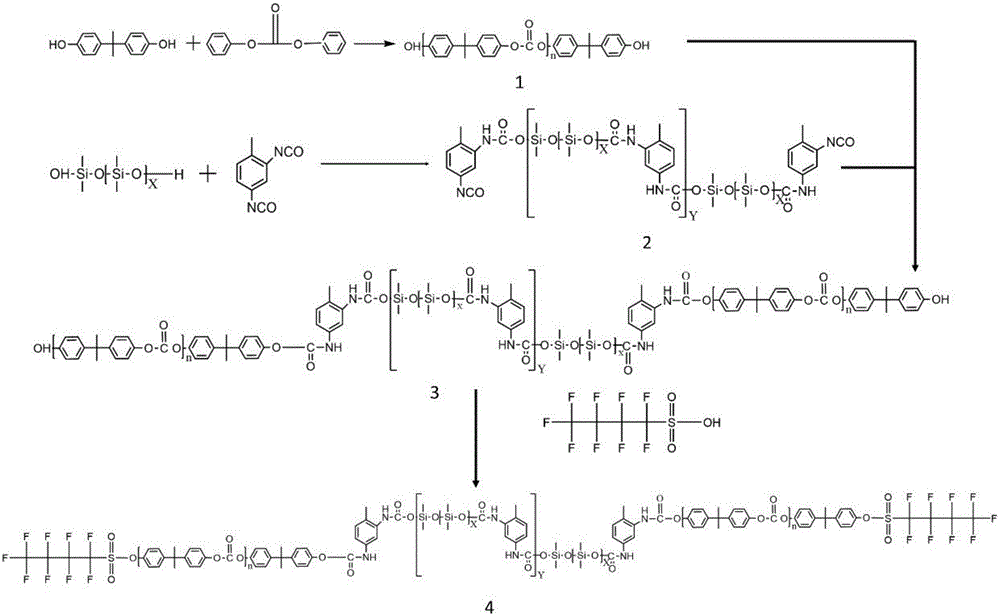

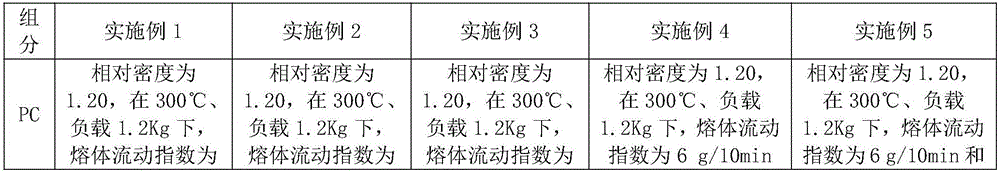

Weather-resistant and flame-resistant light-diffusion PC applicable to outdoor lampshades and preparation method of weather-resistant and flame-resistant light-diffusion PC

ActiveCN106810842AGuaranteed light transmittanceHigh flame retardant efficiencyWeather resistanceFire retardant

The invention discloses weather-resistant and flame-resistant light-diffusion PC applicable to outdoor lampshades and a preparation method of the weather-resistant and flame-resistant light-diffusion PC. The weather-resistant and flame-resistant light-diffusion PC is prepared by, by weight percentage, 81.25-90.17% of PC, 5-15% of toughening agent, 0.8% of light diffusion agent, 1.5-2.5% of flame retardant, 0.4-0.6% of synergic-effect flame retardant, 0.1-0.5% of hydrolysis-resistant agent, 0.1-0.5% of anti-UV agent, 0.03-0.05% of pigment, 0.3% of antioxidant and 0.3% of dispersing agent. The light-diffusion PC has the advantages that the light-diffusion PC is good in flame-retardant effect and weather resistance, indoor and outdoor use requirements can be satisfied, the light-diffusion PC is high in light permeability, good in toughness and ideal in appearance color, and consumers' requirements on lamps can be satisfied.

Owner:厦门天宇新材料科技有限公司

LED fluorescent glue and packaging method for improving luminescence uniformity, and LED

InactiveCN105845812AGood dispersionLarge specific surface areaSolid-state devicesSemiconductor devicesFluorescenceWavelength

The invention discloses an LED fluorescent glue that improves the uniformity of light emission. In parts by weight, the fluorescent glue consists of 1 part of packaging glue, 0.01-1 part of fluorescent powder, 0.01-0.1 part of silica-based inorganic nanoparticles, 0.01 part of ‑1 part silicone granules. Inorganic nanomaterials and silicone particles are mixed in the encapsulation glue, which reduces the sedimentation rate of the phosphor in the encapsulation glue, improves the uniformity of the phosphor distribution in the colloid, makes the white light spot more uniform, and improves the light diffusivity and transmittance. The light rate is maximized, and by changing the propagation path of the light, the light of various wavelengths is more fully mixed, and the spatial color uniformity of the light is further improved. It also provides an LED packaging method and LED that improve the uniformity of light emission, which improves the consistency of products, reduces the probability of uneven color distribution in space due to uneven distribution of phosphor powder, and improves product yield and product production. efficiency.

Owner:SHENZHEN JUFEI OPTOELECTRONICS CO LTD

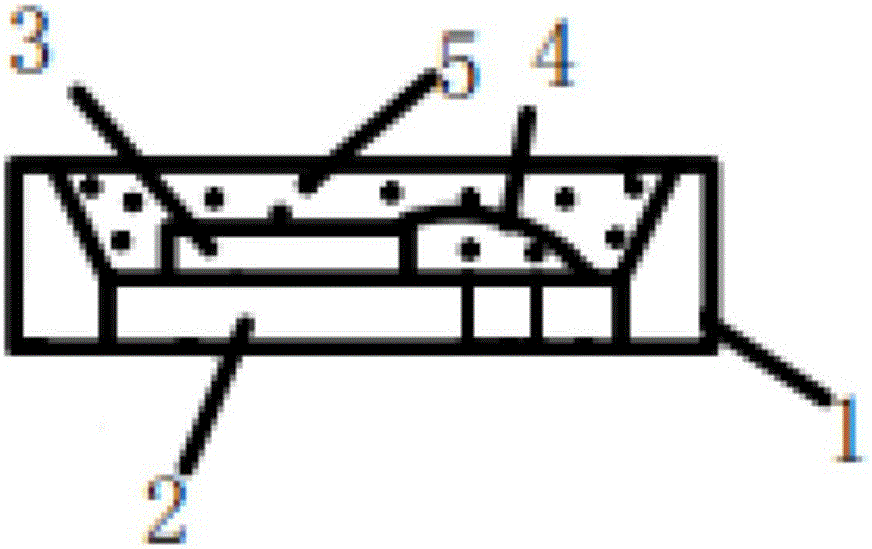

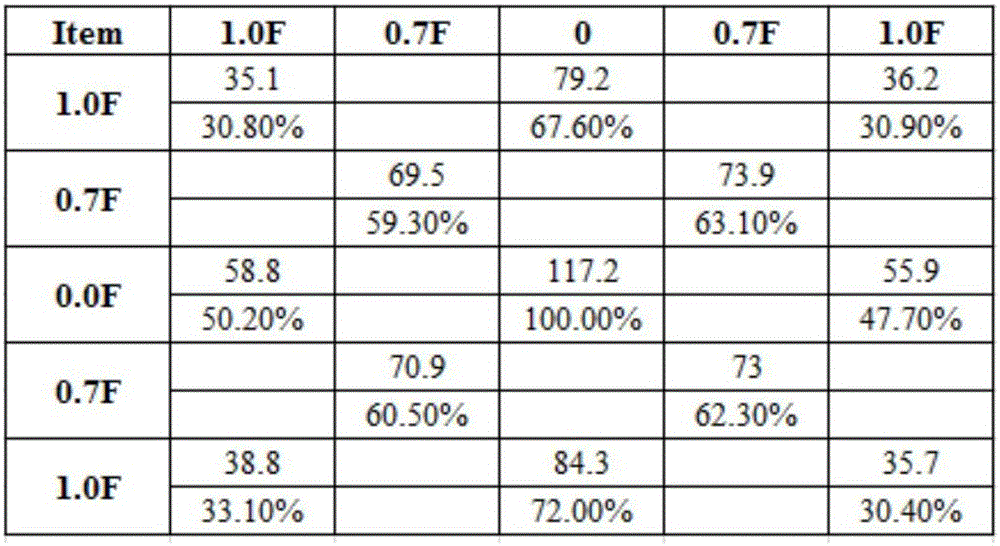

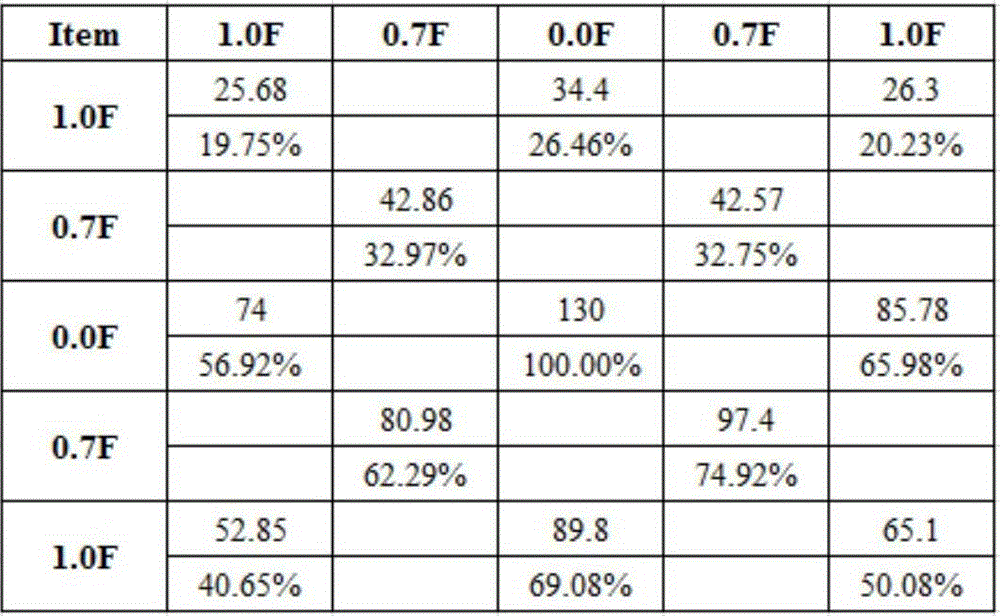

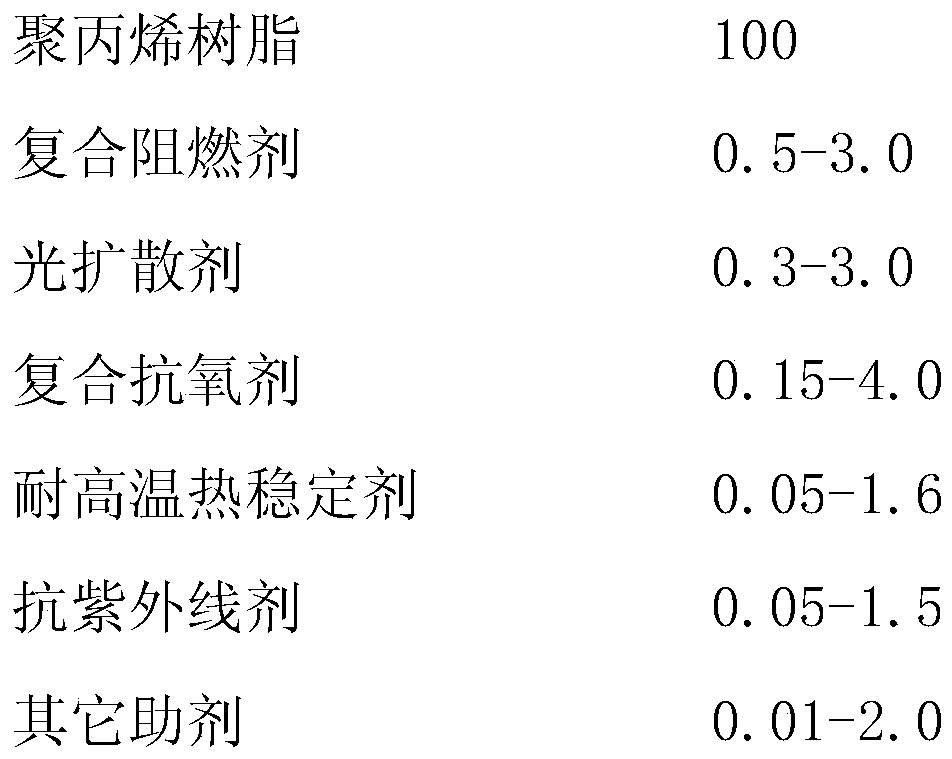

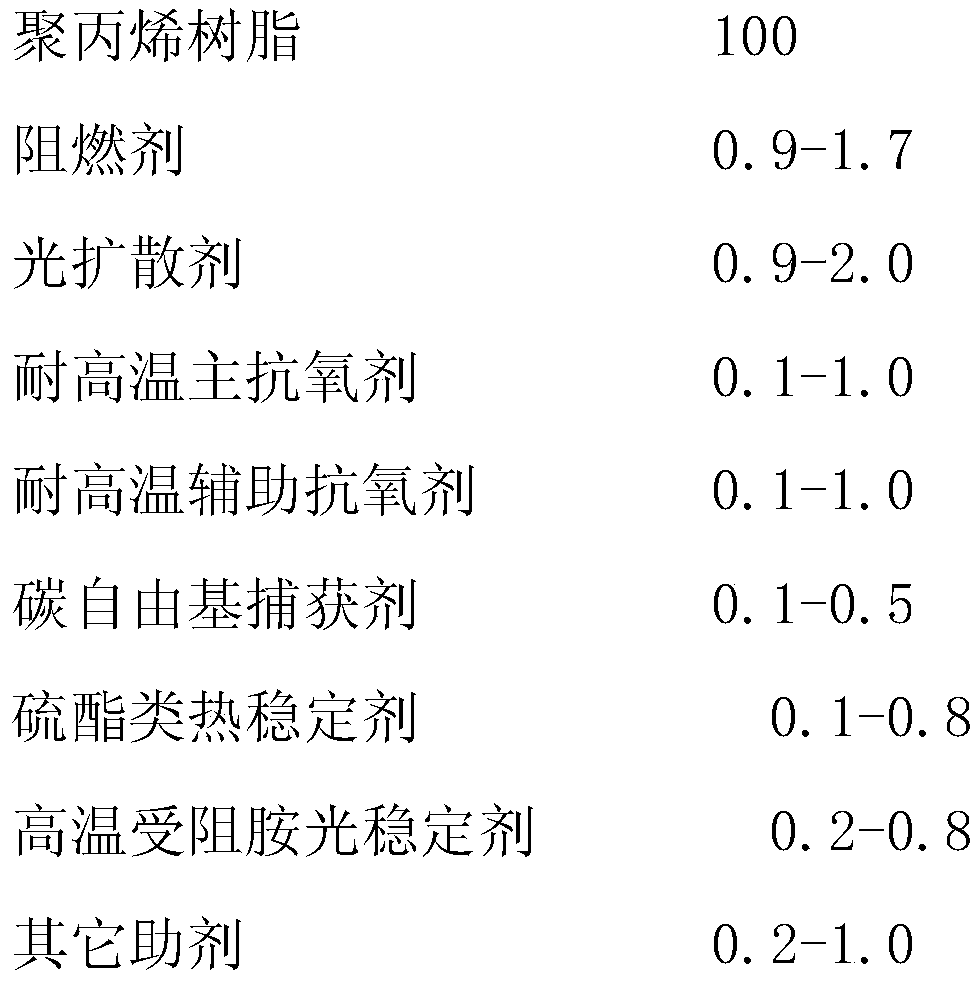

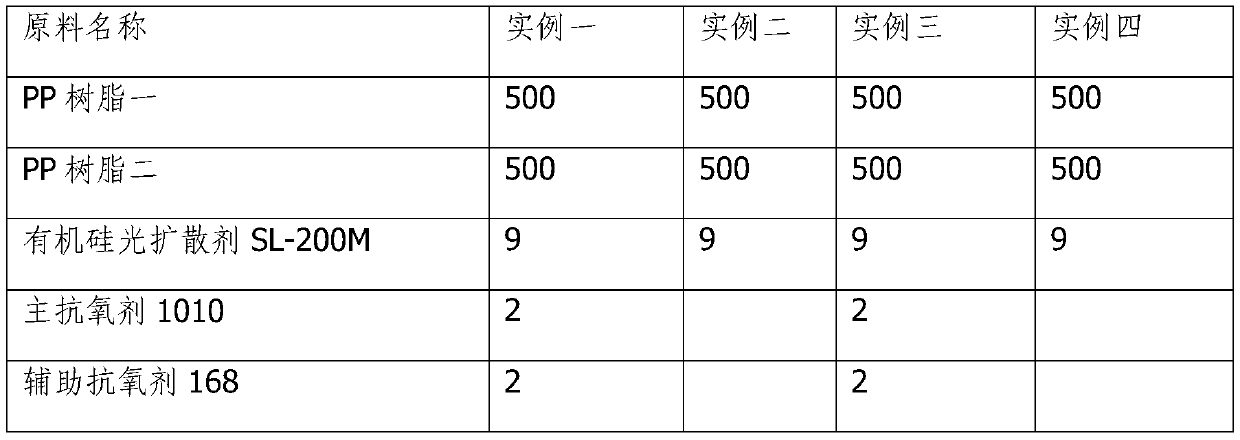

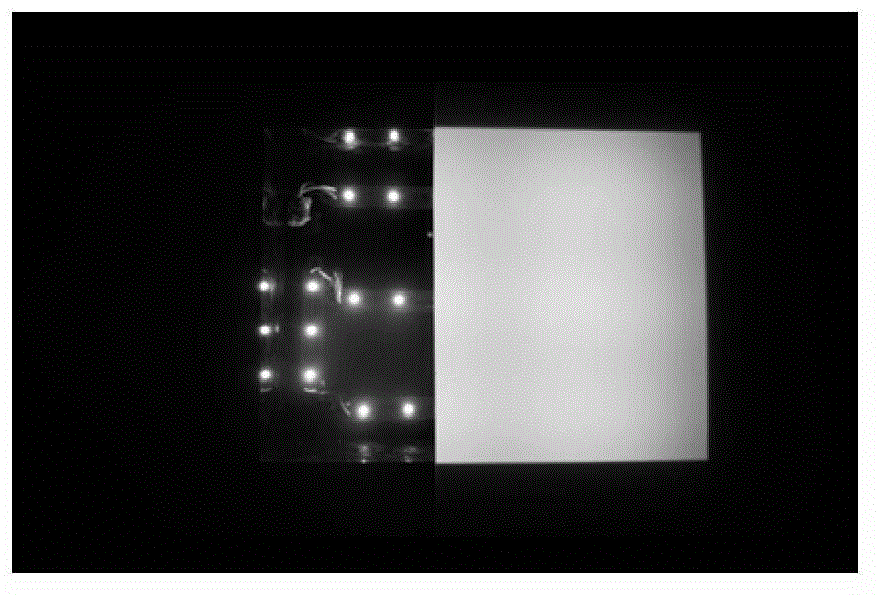

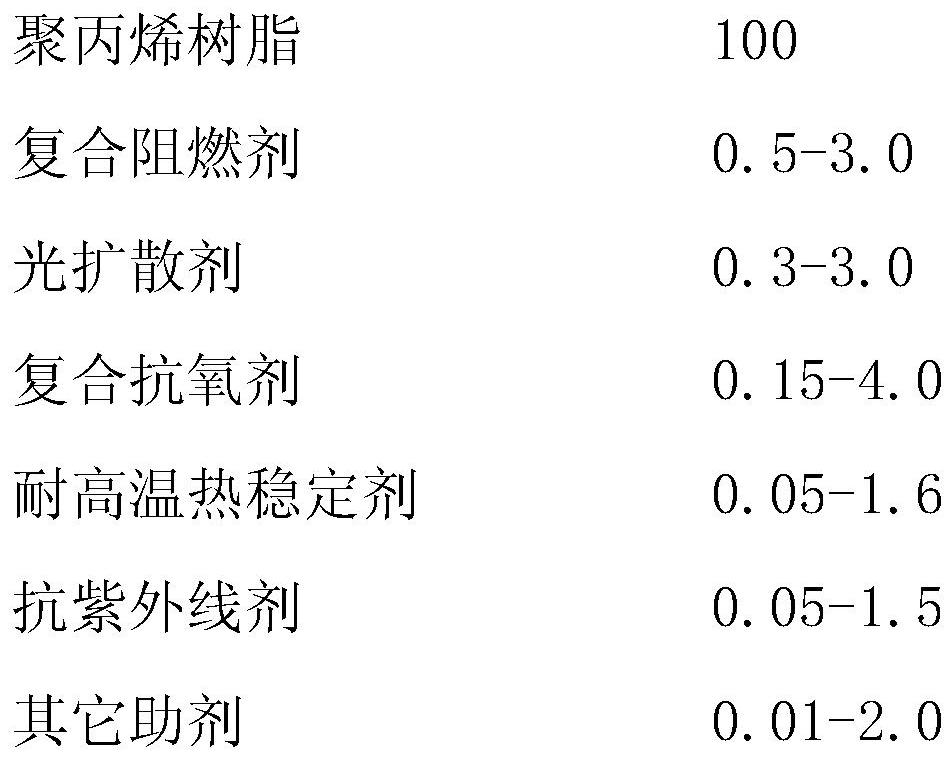

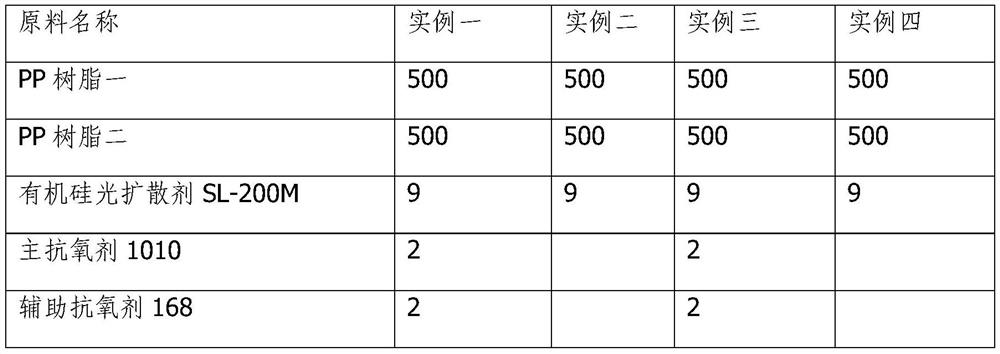

Flame-retardant light-diffusing PP material with thermal-oxidative aging resistant function and preparation method thereof

The invention discloses a flame-retardant light-diffusing PP material with the thermal-oxidative aging resistant function and a preparation method thereof. The PP material comprises a polypropylene resin, a composite flame retardant, a light diffusing agent, a composite antioxidant, a high temperature resistant heat stabilizer, an anti-ultraviolet agent, and other auxiliary agents. The prepared flame-retardant light-diffusing PP material has the characteristics of high luminous flux, good flame retardancy, no precipitation of the flame retardant during the use, long service life, and the like.

Owner:NANTONG DONGFANG PLASTIC CO LTD +1

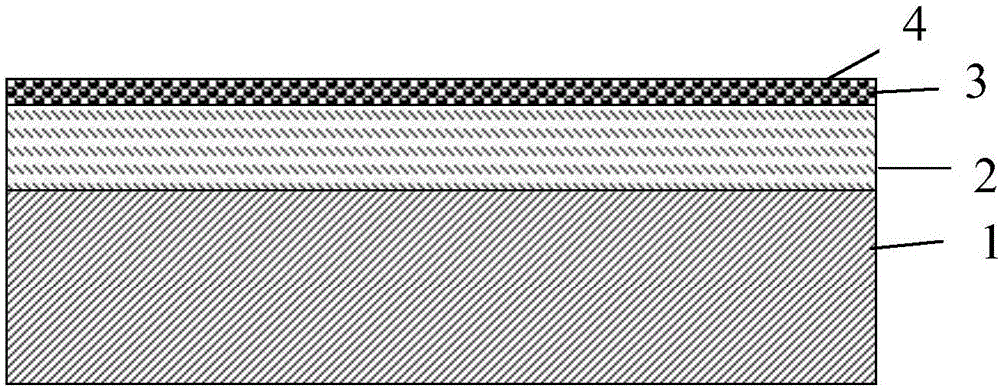

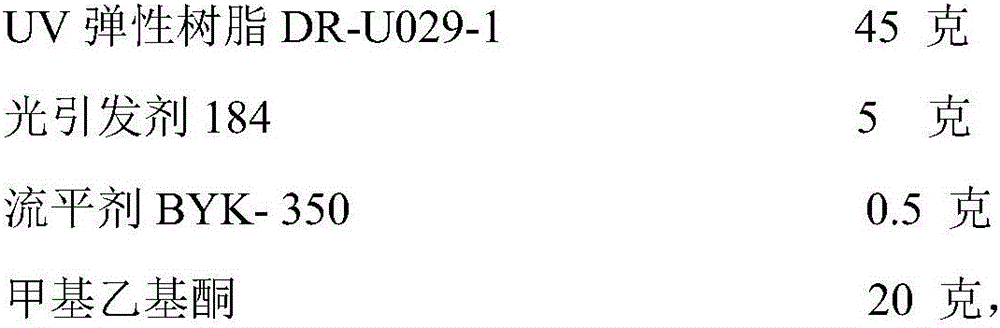

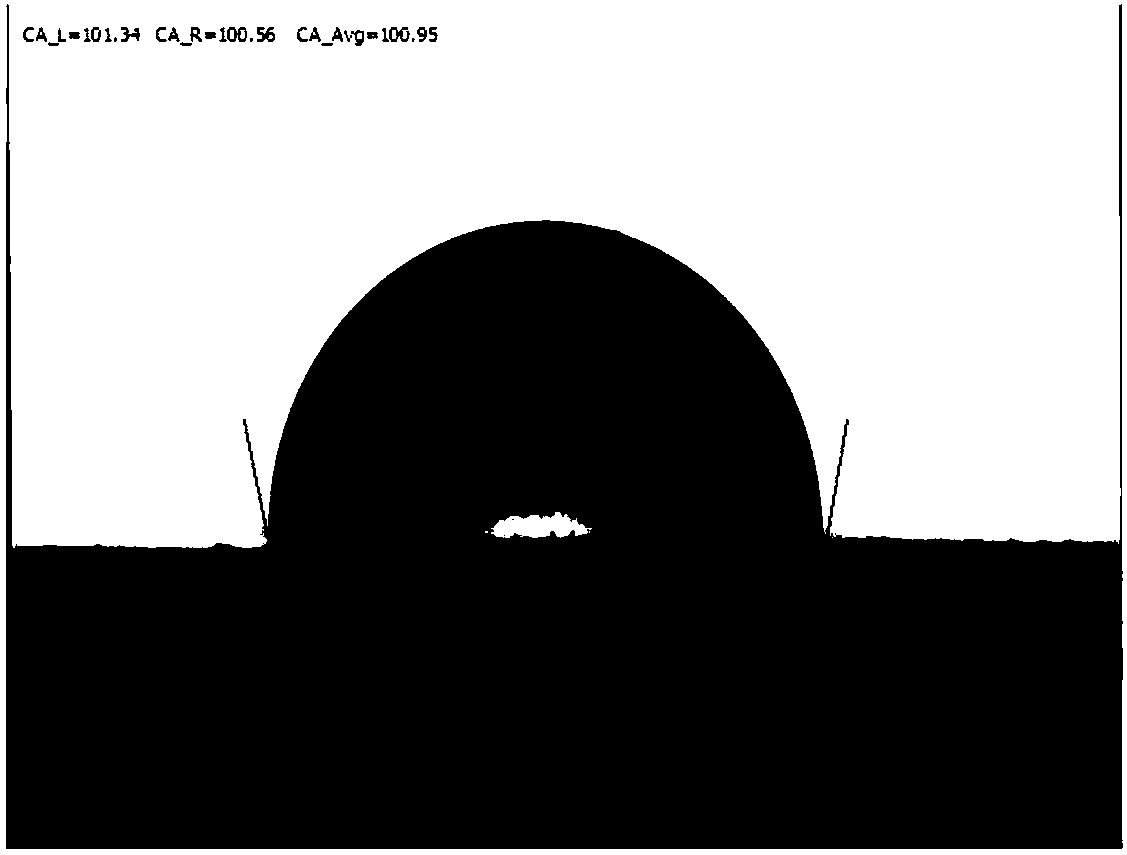

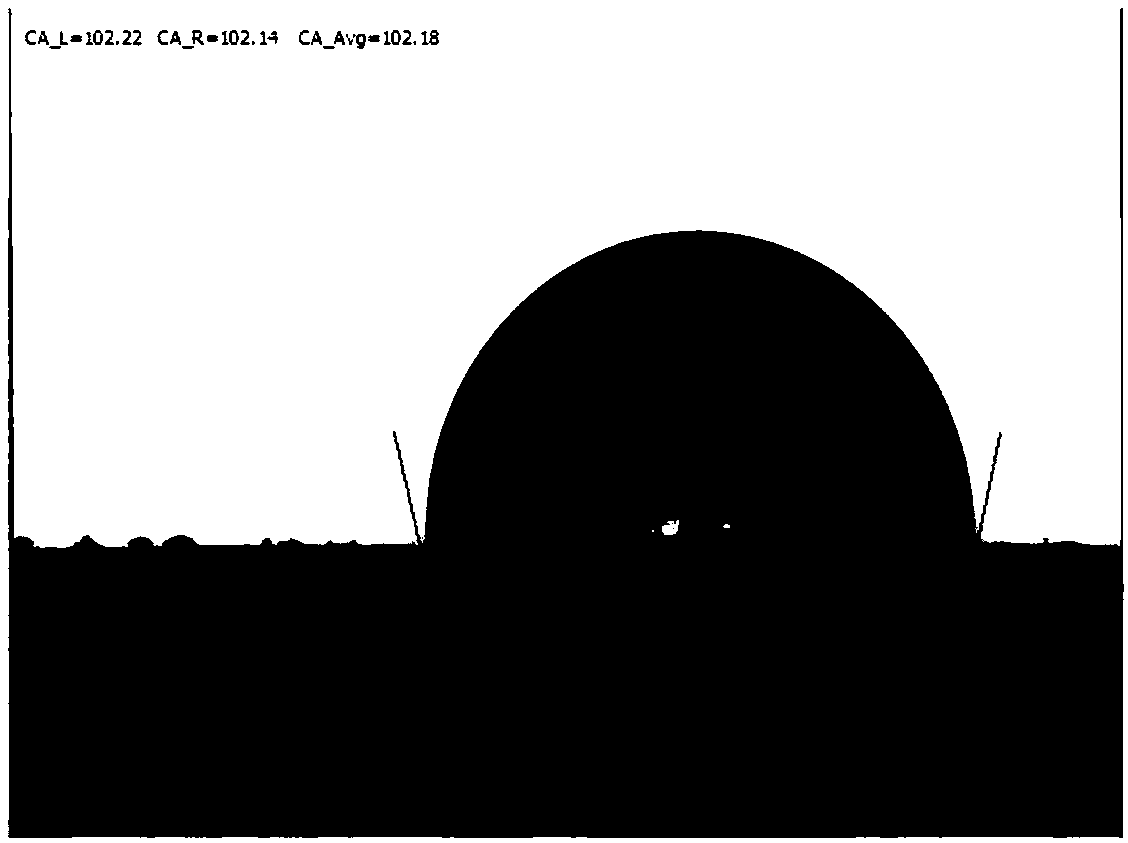

Soft-touch hardening film

ActiveCN106633149AIncrease elasticityLight transmittance has little effectPolyurea/polyurethane coatingsOrganic solventOptical surface

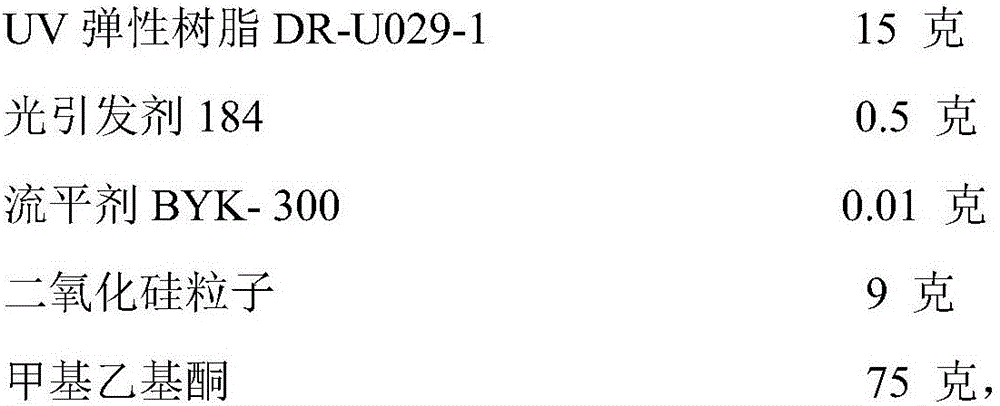

The invention relates to a soft-touch hardening film. The soft-touch hardening film comprises a transparent supporter, wherein a hand feeling layer of which the thickness is 10 to 30 mum and a frosting layer of which the thickness of 0.5 to 3 mum are sequentially arranged on one optical surface of the transparent supporter; the hand feeling layer and the frosting layer are prepared from coating liquid through ultraviolet curing; the coating liquid is prepared from the following components in parts by weight: 15 to 45 parts of UV (Ultraviolet) elastic resin, 0.5 to 5 parts of light initiator, 0.01 to 0.5 part of flatting agent and 20 to 70 parts of organic solvent. Through a double-layer structure, the soft-touch hardening film integrating smoothness and elasticity can be obtained, and the soft-touch hardening film can be widely applied to the field of screen protection and the field of in-mold decoration.

Owner:HEFEI LUCKY SCI & TECH IND

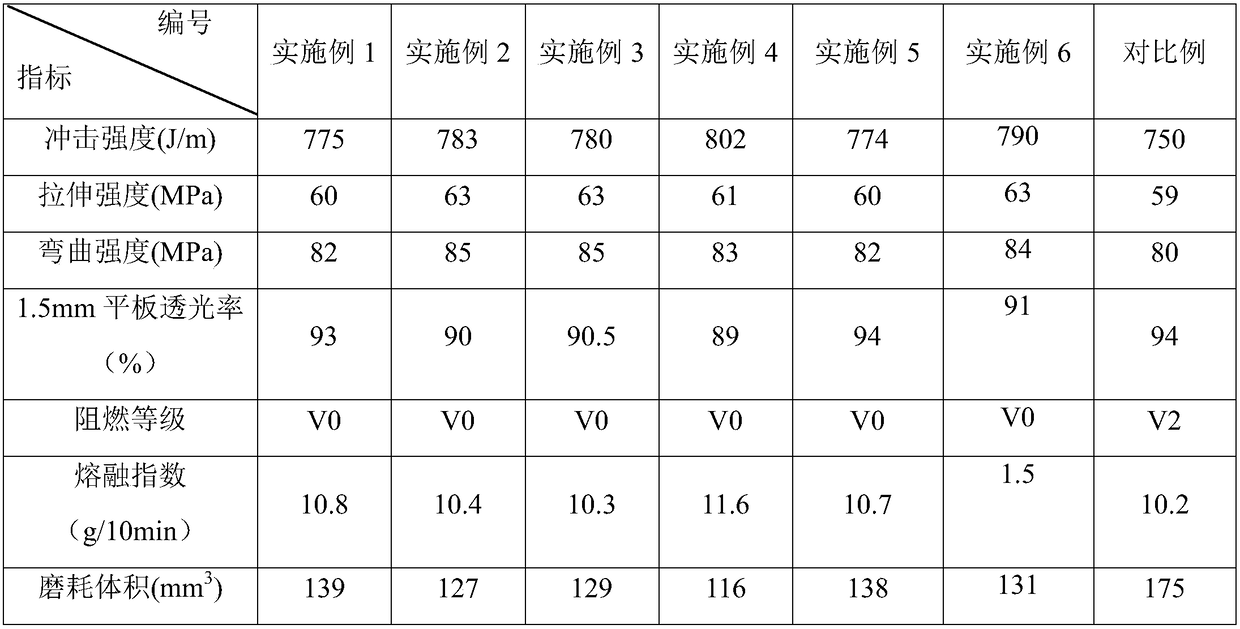

Wear-resistant transparent flame-retardant polycarbonate material and preparation method thereof

ActiveCN109082093AImprove flame retardant performanceHigh light transmittancePolycarbonateWear resistance

The invention relates to a wear-resistant transparent flame-retardant polycarbonate material and a preparation method thereof. The wear-resistant transparent flame-retardant polycarbonate material comprises the following raw materials in parts by weight: 90-95 parts of polycarbonate, 5-10 parts of transparent flame-retardant masterbatches, 0.5-1 part of ZnO / SiO2 nano composite and 0.1-1 part of anantioxidant. The prepared polycarbonate material has high flame retardancy, high light transmitting rate and good wear resistance, and the other original mechanical properties of the material can beimproved. The flame-retardant masterbatches serve as the raw material components, the consistency is good, and the quality of the product is uniform and stable; and a double-screw extruder serves as processing equipment, and the technological process is simple and continuous.

Owner:PUYANG SHENGTONGJUYUAN ADVANCED MATERIALS CO LTD

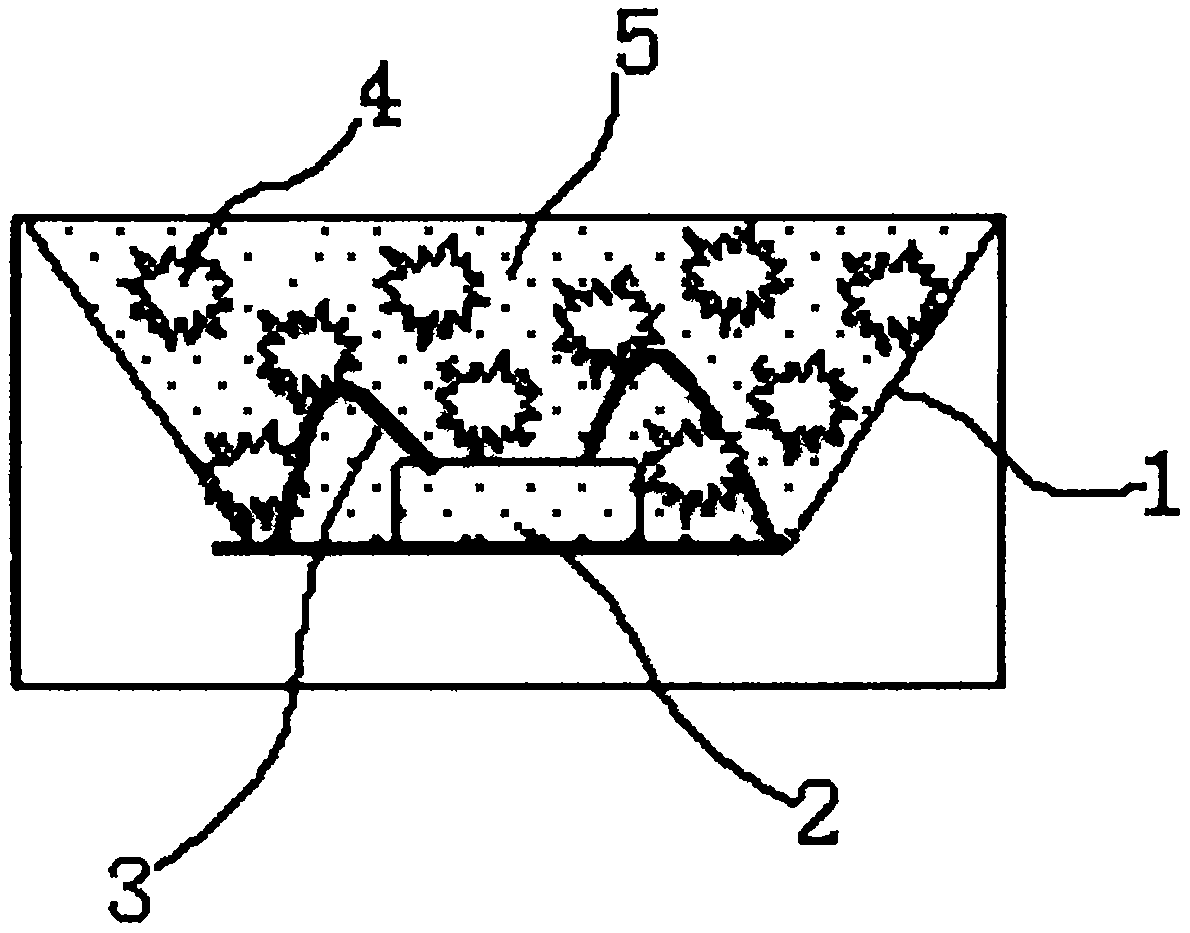

Hydrophobic dust-proof coating for greenhouse film, a preparing method thereof and applications of the coating

InactiveCN108034311ASimple preparation processEasy to useAntifouling/underwater paintsPaints with biocidesGreenhouseFluorocarbon

Hydrophobic dust-proof coating for greenhouse film, a preparing method thereof and applications of the coating are disclosed. The coating includes, by mass, 40-71% of modified fluorocarbon resin, 0-1%of a leveling agent, 16-56% of a diluting agent and 4-12% of a curing agent. The preparing method of the coating is also disclosed. The fluorocarbon-resin-containing coating prepared by the method has excellent film forming performance, adhesion and flexibility, good ultraviolet resistance, weather fastness and resistance to dirt, and the like, and is convenient to scrub and simple in process. Aproduction process is substantially free of pollution. The coating is prone to industrial production and large-scale popularization and application.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

High-heat-resistance packaging adhesive, LED packaged device employing same and packaging method

InactiveCN109735258AThe process steps are simpleMild conditionsNon-macromolecular adhesive additivesSemiconductor devicesHeat resistanceTransmittance

The invention belongs to the technical field of semiconductor packaging and discloses high-heat-resistance packaging adhesive, an LED packaged device employing the same and a packaging method. The high-heat-resistance packaging adhesive is made from, by weight, 100 parts of an adhesive material and 5-500 parts of a fluoride material. Compared with traditional packaging adhesive materials, the high-heat-resistance packaging adhesive has a higher doping ratio of the inorganic fluoride material, which helps effectively improve heat resistance and heat-dissipating property of the packaging adhesive; more importantly, the high-ratio mixing of the fluoride powder material herein brings very low influence on the light transmittance of the adhesive material; after the high-heat-resistance packaging adhesive is applied to an LED packaged device and solidifies, very high light transmittance can be maintained for the device herein, and therefore, light emergence efficiency of the pacakaged deviceis never affected.

Owner:深圳市艾迪恩科技有限公司

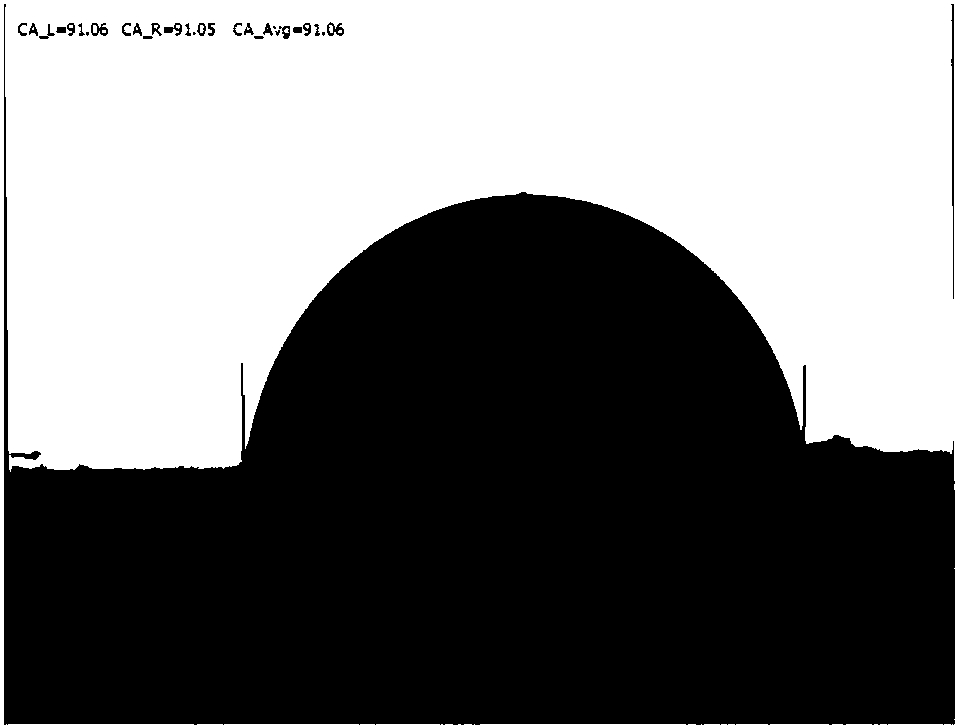

Greenhouse thin film water-based hydrophobic coating as well as preparation method and application thereof

The invention discloses a water-based hydrophobic coating as well as a preparation method and application thereof. The coating comprises the following components in mass fraction: 57-80% of modified fluorocarbon resin, 2.4-4.8% of coalescing agent, 0.5-0.8% of base material wetting agent, 0.3-0.8% of leveling agent, 0-0.2% of antifoaming agent, 0-1% of thickener, 1-2% of hydrophobic agent, 3.8-7.7% of curing agent, and the balance liquid paraffin. The prepared fluorocarbon resin water-based hydrophobic coating has excellent film forming property and hydrophobicity, has high coating adhesion, is safe and environment-friendly, has simple process, and is easy for industrial production and large-scale popularization and application.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

PC material with high light transmittance and high haze and application of PC material

The invention relates to the technical field of PC materials, in particular to a PC material with high light transmittance and high haze and application of the PC material. The PC material includes the following raw materials: in parts by weight, 100 parts of PC, 2-6 parts of a special light diffusant, 0.5-1 part of an antioxidant, 0.4-0.6 part of a light stabilizer and 0.4-0.6 part of an ultraviolet absorbent. The refractive index of polyacrylonitrile which is obtained through co-polymerization of acrylonitrile and methyl acrylate is about 1.4, and therefore polymethyl methacrylate also has acertain light diffusion effect through second refraction; since nano silica as a core is adopted as the inorganic light diffusant, a high refraction effect is achieved, and therefore the haze of thePC material is improved significantly; and moreover, through the three-layer structure of nano-silica, polymethyl methacrylate and polyacrylonitrile, the use amount of nano silica is reduced, and thusthe effect on the light transmittance of the PC material is small.

Owner:DONGGUAN JISHUO IND CO LTD

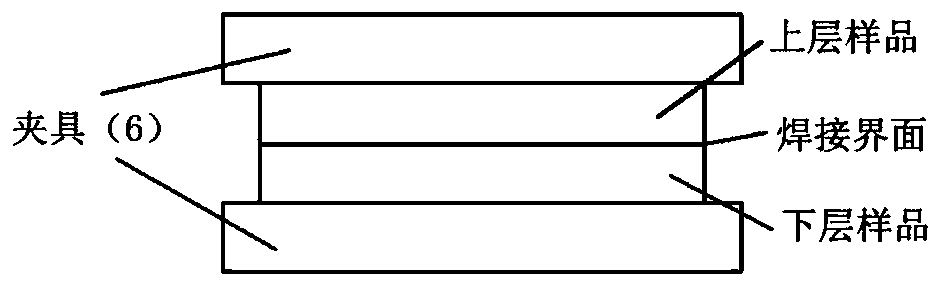

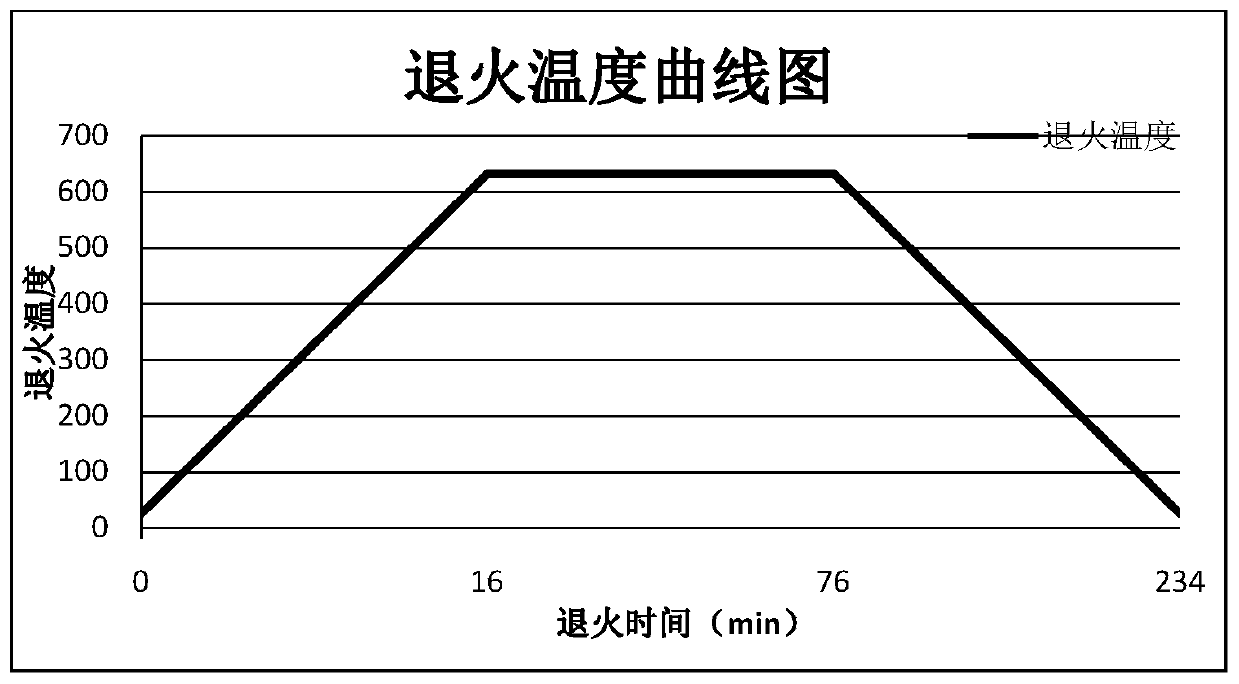

System precision processing method of fragile transparent special-shaped 3D structure

ActiveCN110788486AEasy to observeLight transmittance has little effectAfter-treatment detailsWelding/soldering/cutting articlesTemperature curveEngineering

The invention discloses a system precision processing method of a fragile transparent special-shaped 3D structure. The system precision processing method comprises the following steps of building a laser welding platform of the special-shaped 3D structure, wherein the platform comprises a laser, a laser path, a coaxial vision system, a paraxial vision system, a welding head, a clamp, a horizontalwelding bracket and a movement platform; clamping a sample by the clamp; mounting the clamp after clamping the sample to the movement platform, and adjusting the clamp by the coaxial vision system and the horizontal adjusting bracket; and grabbing a welding profile by the paraxial vision system to perform profile positioning and processing path planning; generating laser by the laser, and focusing the laser on a welding interface to be welded through the laser path and the welding head, and moving the movement platform according to the positioned profile and the planned processing path untilfinishing the welding; placing a welded sample in an annealing furnace, and annealing according to a temperature curve of heating, constant annealing temperature and cooling; and placing the annealedwelded sample in a reinforcing furnace to be reinforced.

Owner:WUHAN HGLASER ENG CO LTD

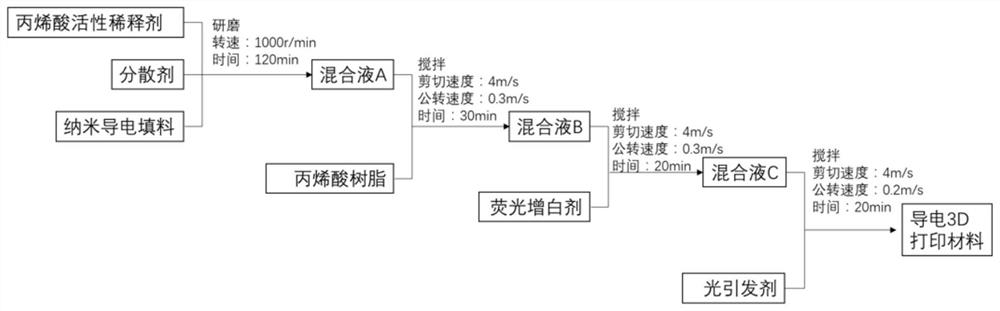

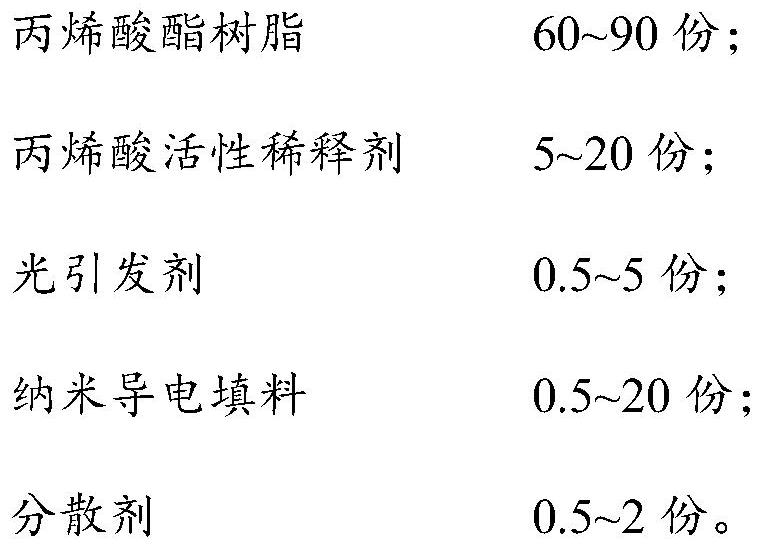

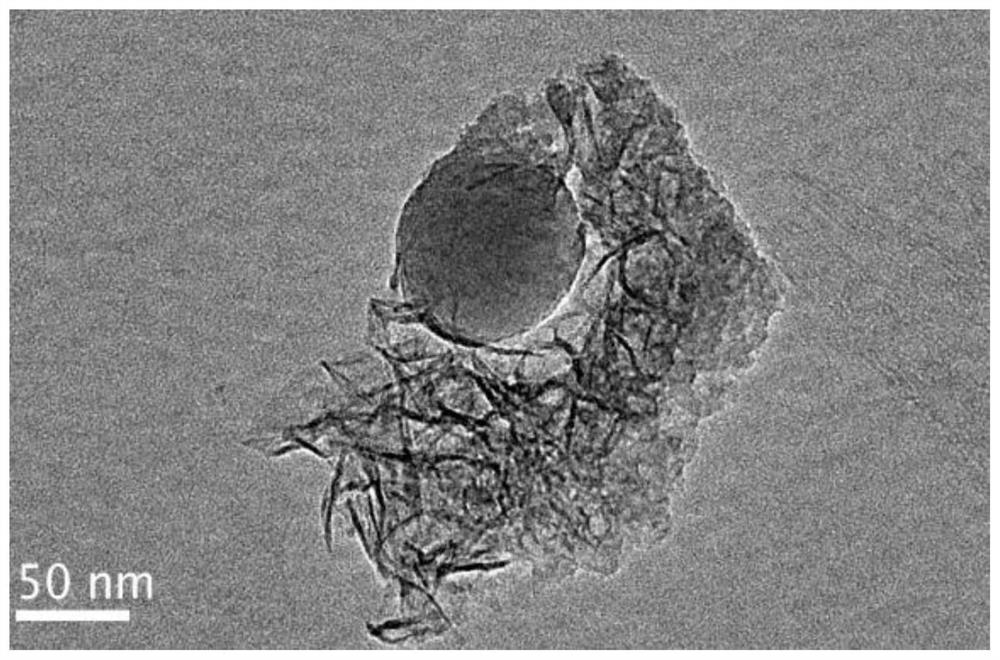

Conductive 3D printing material, and preparation method and application thereof

ActiveCN113105737AReduce settlementLight transmittance has little effectAdditive manufacturing apparatusIncreasing energy efficiencyWhitening AgentsPhotopigment

The invention provides a conductive 3D printing material, and a preparation method and application thereof. The conductive 3D printing material is prepared from the following components in parts by mass: 60 to 90 parts of acrylate resin, 5 to 20 parts of an acrylic reactive diluent, 0.5 to 5 parts of a photoinitiator, 0.5 to 20 parts of a nanometer conductive filler and 0.5 to 2 parts of a dispersing agent. As needed, the conductive 3D printing material may also comprises 0-0.2 part of a fluorescent whitening agent and 0-2 parts of a pigment and other second fillers. The conductive filler adopted by the conductive 3D printing material is nano-sized, so the problem of sedimentation of the conductive filler in the storage and application processes of the conductive 3D printing material is relieved, and the problem of low light transmittance of a 3D part printed by the conductive 3D printing material is also relieved. The conductive filler is in a rod shape, a point shape, a sheet shape and the like, so a net-shaped conductive system with high conductivity can be formed, cost is finally reduced, conductivity is improved, and the sedimentation problem of the conductive filler is relieved.

Owner:湖南创瑾技术研究院有限公司

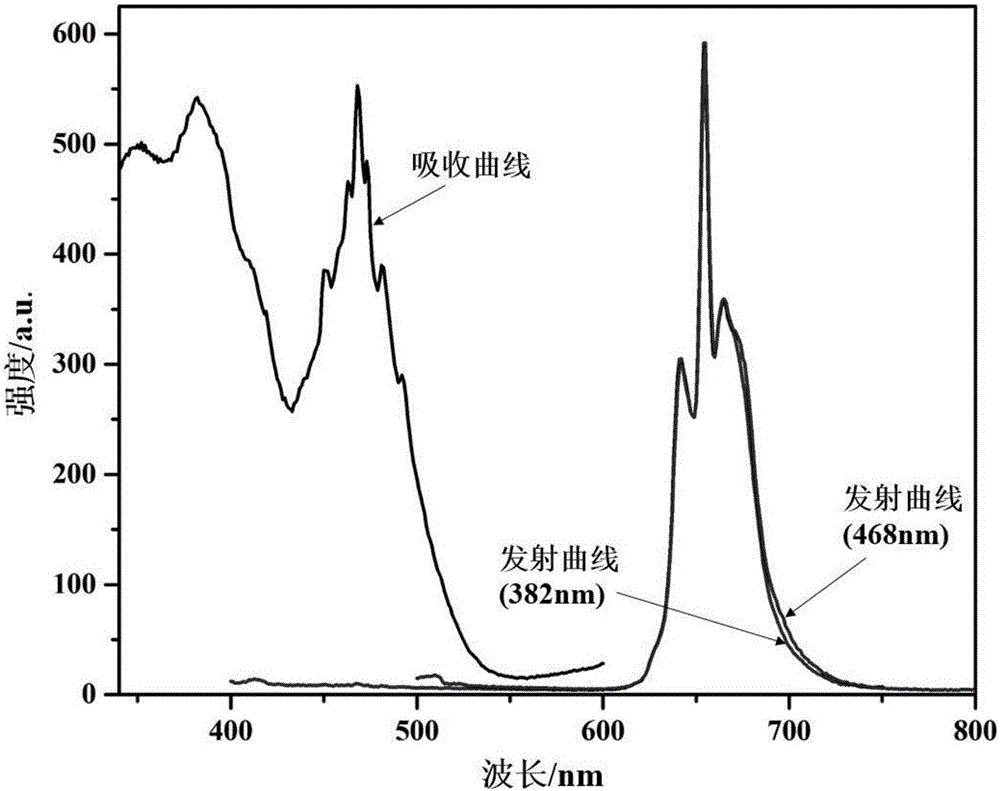

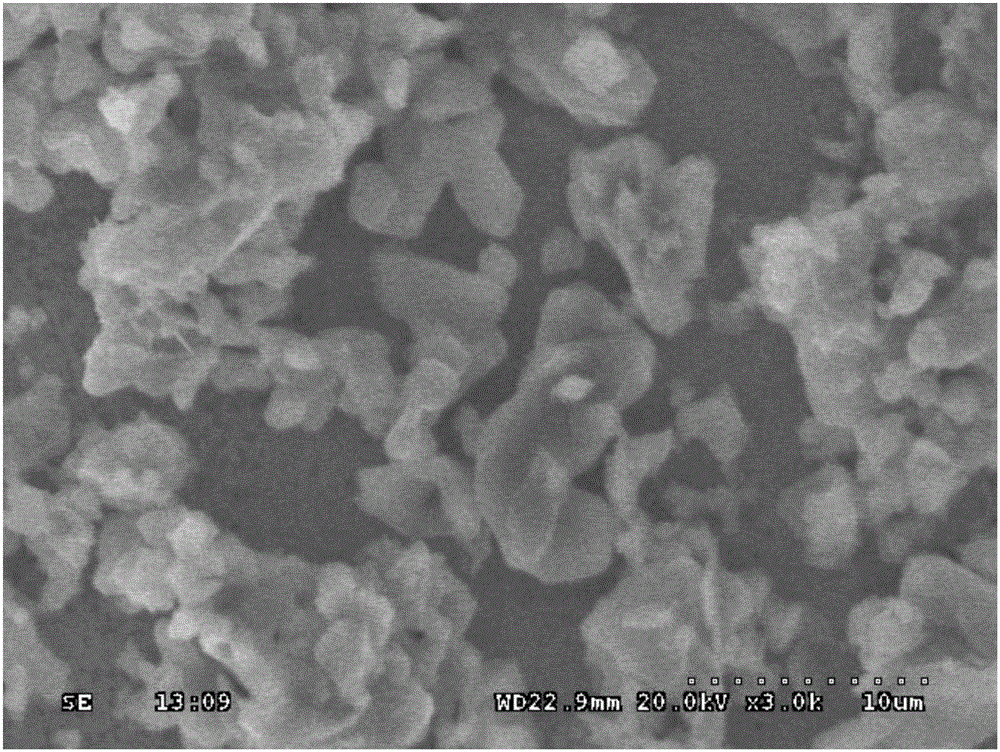

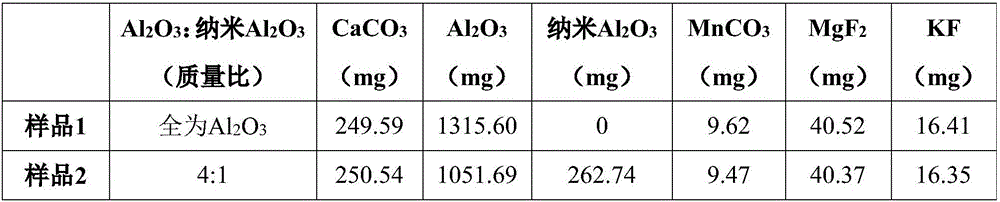

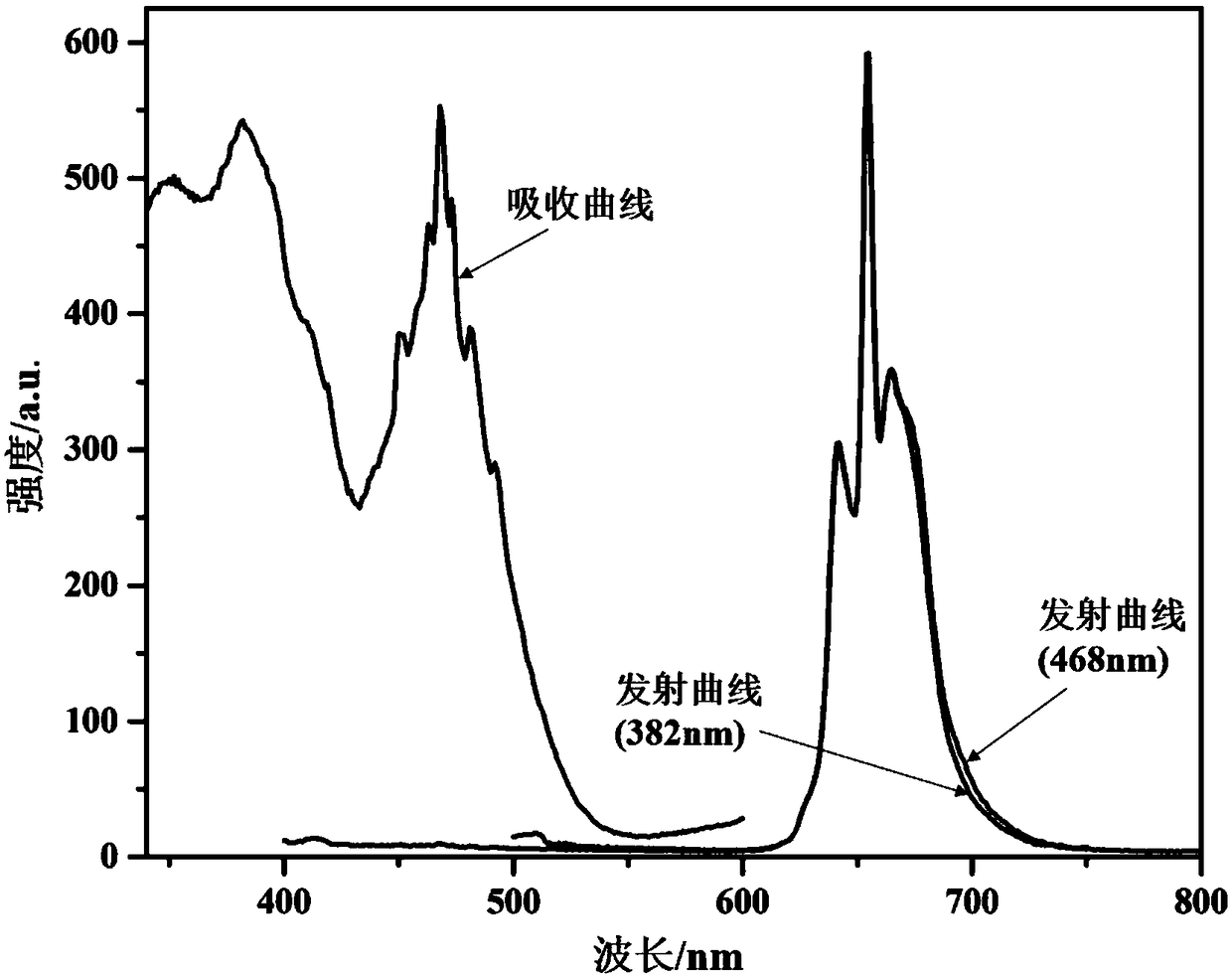

Aluminate light conversion agent and preparation method thereof as well as light conversion film containing aluminate light conversion agent

ActiveCN106750520AHigh luminous intensityGood compatibilityLuminescent compositionsCrucibleOptical transmittance

The invention discloses an aluminate light conversion agent and a preparation method thereof as well as a light conversion film containing the aluminate light conversion agent. The general formula of the aluminate light conversion agent is A1-xZnxAl12O19: Mn<4+>, wherein A is at least one of Ca<2+>, Sr<2+> and Ba<2+> and x is more than or equal to 0 and less than 1. The preparation method comprises the following steps: sufficiently grinding metal oxide, nano metal oxide, alkaline-earth salt, an activating agent and a fluxing agent, and uniformly mixing; adding a mixture into a crucible; putting the crucible into a high-temperature furnace; and carrying out program temperature rising and cooling to obtain the aluminate light conversion agent. The light conversion film containing the aluminate light conversion agent is prepared from the following raw materials in parts by mass: 100 parts of a thin film matrix, 8-45 parts of a master batch matrix, 0.5-10 parts of the aluminate light conversion agent, 0.15-0.3 part of a lubricating agent, 0.5-1.5 parts of a light stabilizer and 0.3-1.5 parts of an antioxygen. The aluminate light conversion agent disclosed by the invention has the advantages of high light emitting strength, high light conversion efficiency, good stability, long service life and simple preparation method; the adding amount in an agricultural thin film is small, and the aluminate light conversion agent has good compatibility with the thin film matrix and has less influences on light transmittance of the thin film.

Owner:SOUTH CHINA AGRI UNIV

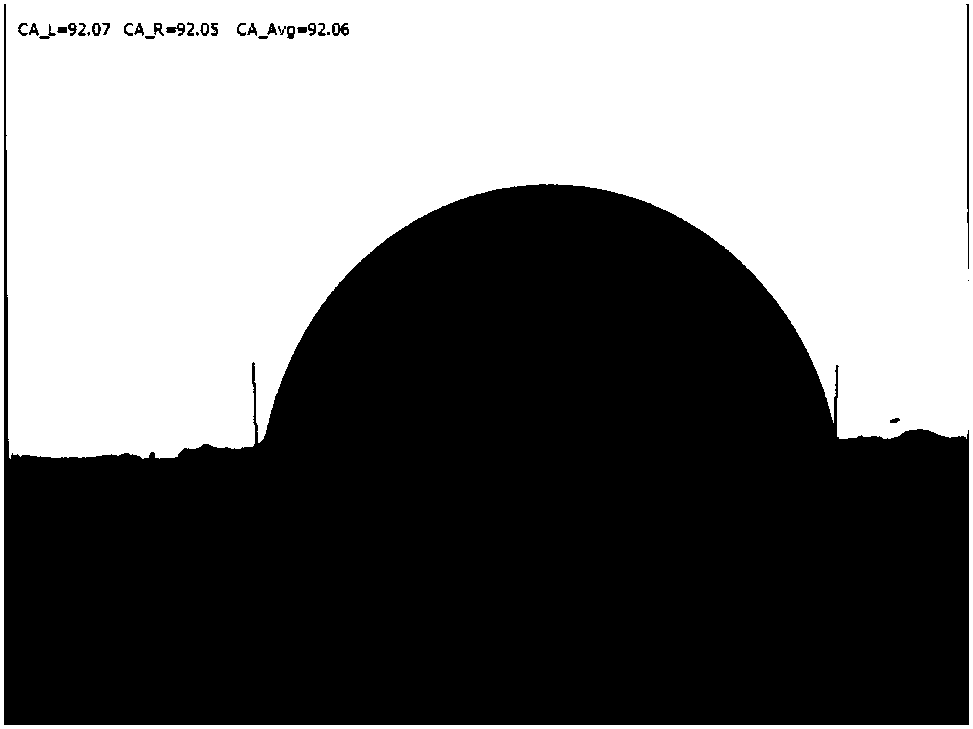

Method for preparing anti-fogging and anti-adhesion plastic film by nano-silica-polyhedral oligomeric silsesquioxane

The invention discloses a method for preparing an anti-fogging and anti-adhesion plastic film by nano-silica-polyhedral oligomeric silsesquioxane. The method includes the steps: pre-crystallizing anti-adhesion master batches and PA6 slices, performing vacuum drying, adding products, triethanolamine laurate and antioxidants into a reactive blending extruder for rolling film formation, cleaning a film with ethyl alcohol and then performing vacuum drying; adding deionized water into obtained copolymer solution, performing water-bath heating, stirring and uniform dissolution, uniformly coating thefilm with the solution by a scraper bar, and naturally drying the film at room temperature to prepare the anti-fogging and anti-adhesion plastic film. Nano-silica is pretreated by silane coupling agents and compounded with allyl hepta-isobutyl polyhedral oligomeric silsesquioxane to modify PA6, melt blending is performed to prepare the anti-adhesion master batches, the thermal stability of the PA6 is obviously improved, and the processability of the master batches is improved. The friction coefficient of the film is obviously decreased, the adhesion resistance of the film is obviously improved, the water contact angle of the film is increased, the infiltration process is slowed down, and the water barrier property and the mechanical property of the film can be improved.

Owner:BENGBU WEIGUANG PLASTIC PRODS

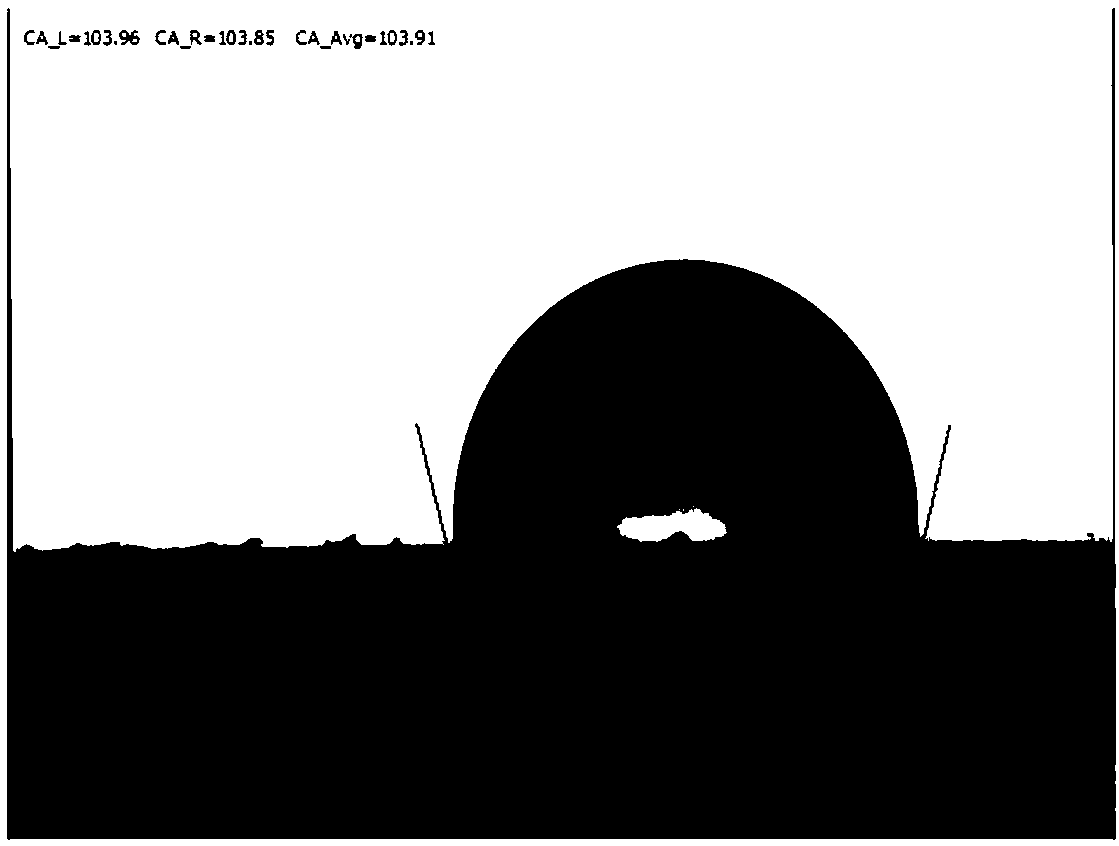

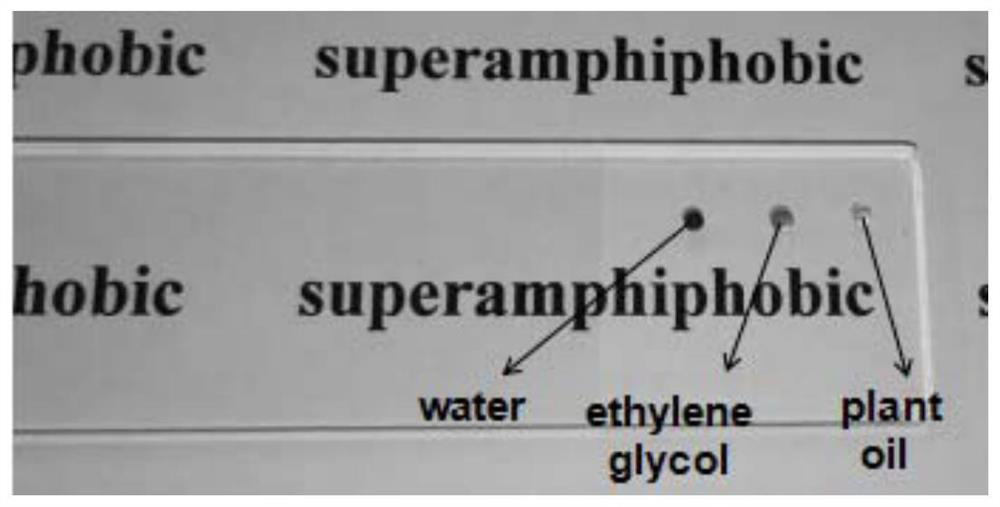

A kind of preparation method of high light transmittance double thinning anti-reflection film

The invention belongs to the technical field of anti-reflection films, and in particular relates to a method for preparing a double-thin anti-reflection film with high light transmittance: preparing a grass-like alumina sol and a solid silicon dioxide sol by a sol-gel method, and then dipping- The mixed sol was plated on the glass substrate by the pulling method, and the grass-like alumina plus silica solid pellets were treated with 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane by chemical vapor deposition. modified. The coating prepared by the invention has high light transmittance, and has excellent properties such as superhydrophobic, oleophobic, and self-cleaning. The sol-gel method is simple, scalable, low-cost and has high light transmittance. It is used in solar energy and architectural glass. , optical devices and other applications have great prospects.

Owner:CHANGZHOU UNIV

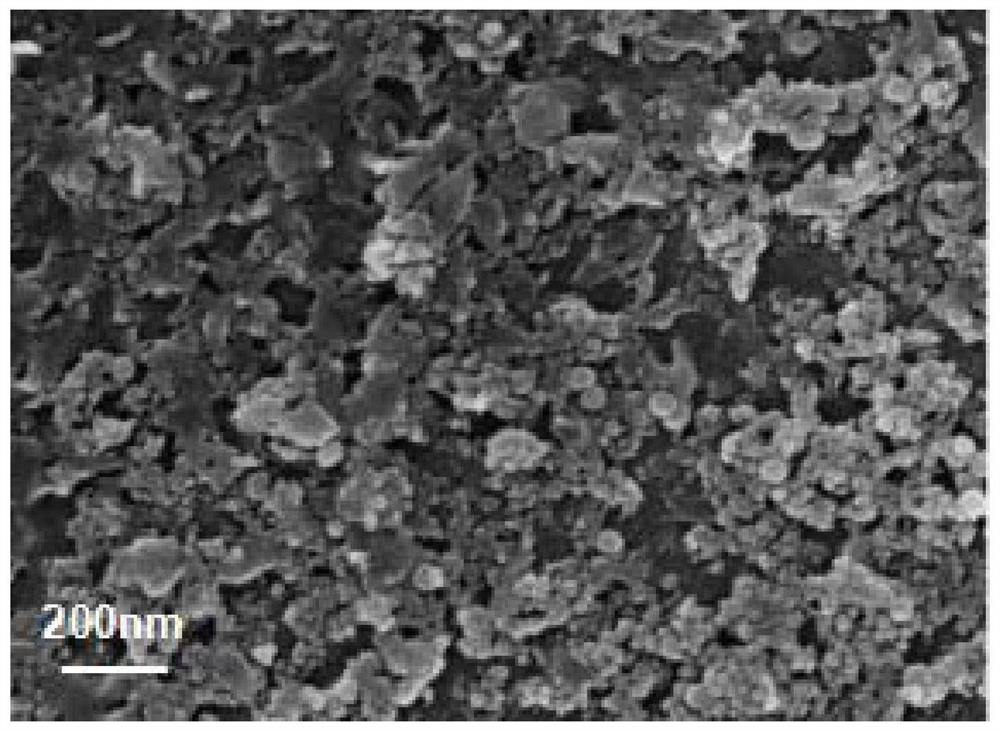

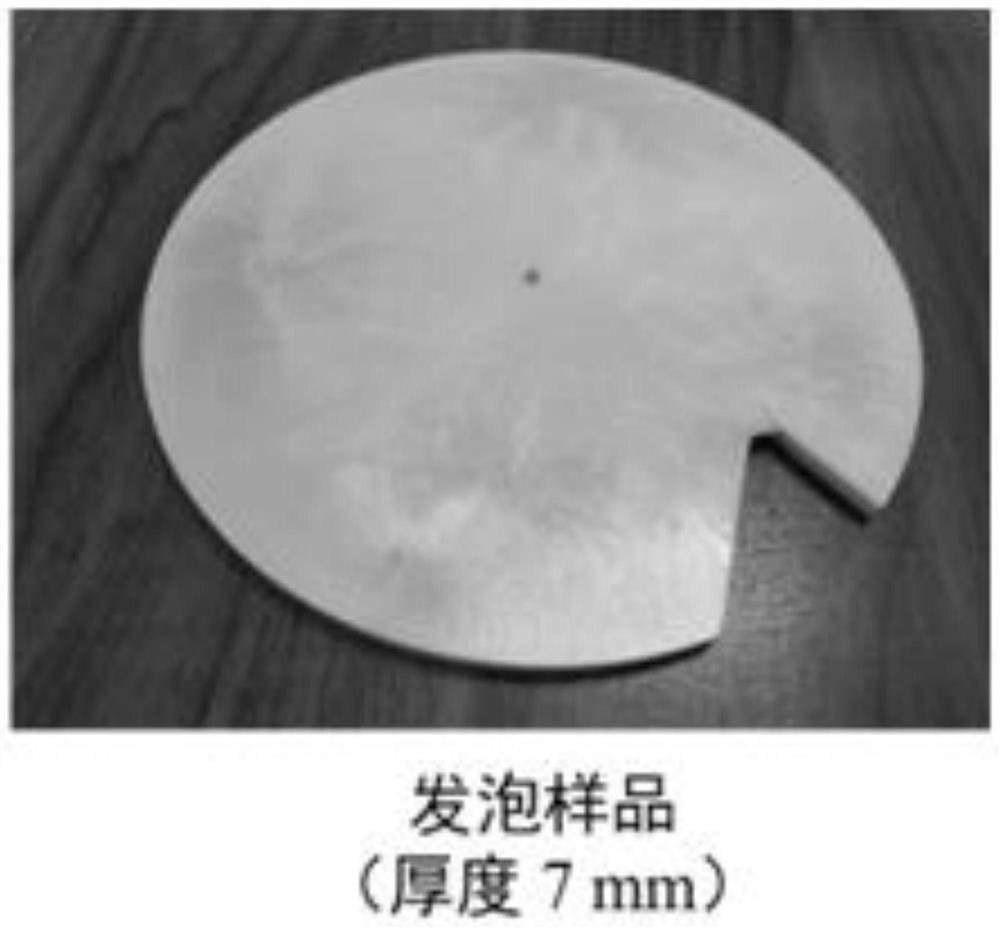

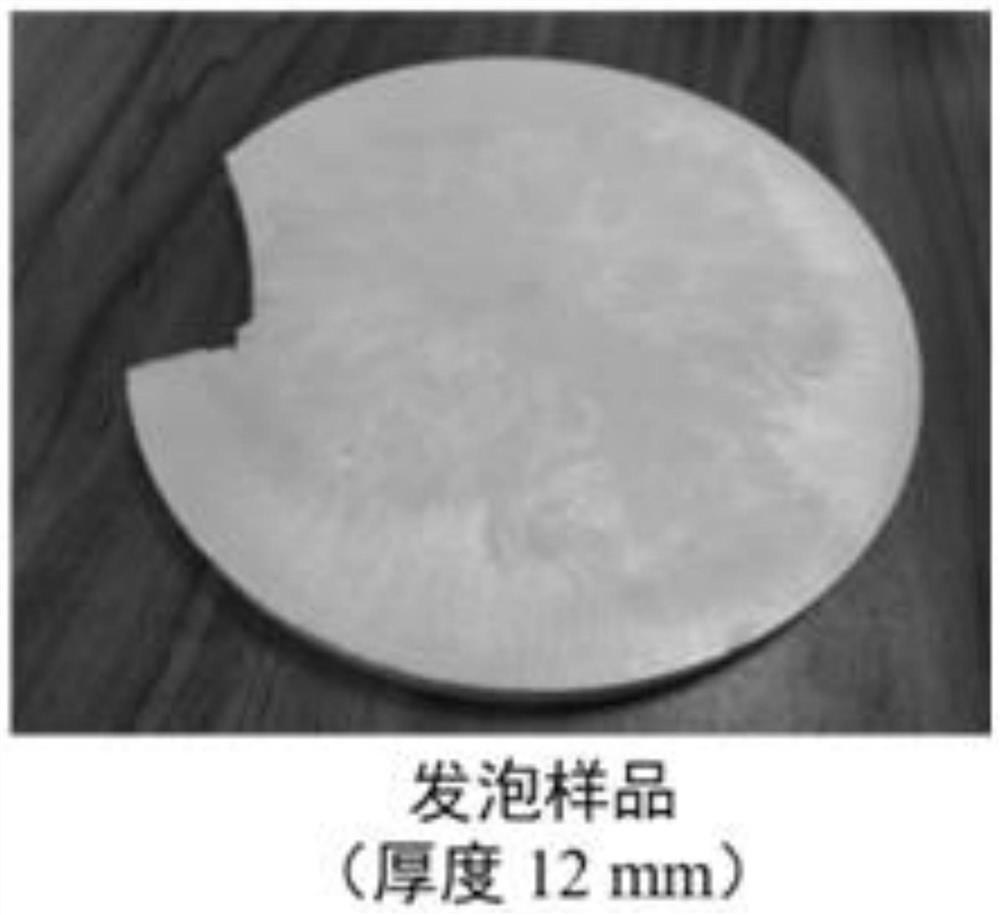

Foamed light diffusion material and preparation method thereof

ActiveCN113352536AReduce residual contentReduce the possibility of precipitation sticking moldBulk chemical productionPolymer scienceInjection molding process

The invention relates to the field of light diffusion materials, and particularly discloses a foamed light diffusion material and a preparation method thereof. The foamed light diffusion material is prepared from the components in parts by weight: 93-105 parts of PC, 0.1-0.5 part of antioxidant and 0.3-0.8 part of a release agent. The preparation method comprises the following steps that granules are prepared, and 93-105 parts by weight of PC, 0.1-0.5 part by weight of antioxidant and 0.3-0.8 part by weight of the release agent are uniformly mixed and extruded to obtain the granules; and injection molding foaming and monomer removal are carried out, supercritical carbon dioxide is injected in the injection molding process to carry out foaming and steam stripping monomer removal to obtain the foamed light diffusion material. The temperatures of different areas of a screw rod are 280 to 300 DEG C, 280 to 300 DEG C, 280 to 300 DEG C, 280 to 300 DEG C, 280 to 300 DEG C, 230 to 380 DEG C and 60 to 80 DEG C in sequence; and the pressure maintaining pressure is 60 to 100 MPa. The foamed light diffusion material can be used for processing an LED lamp housing, and has the advantages of high haze and low residual monomer content; and in addition, the preparation method has the advantage of reducing the possibility of mold sticking of a product in the processing process.

Owner:NINGBO ZHETIE DAPHOON CHEM

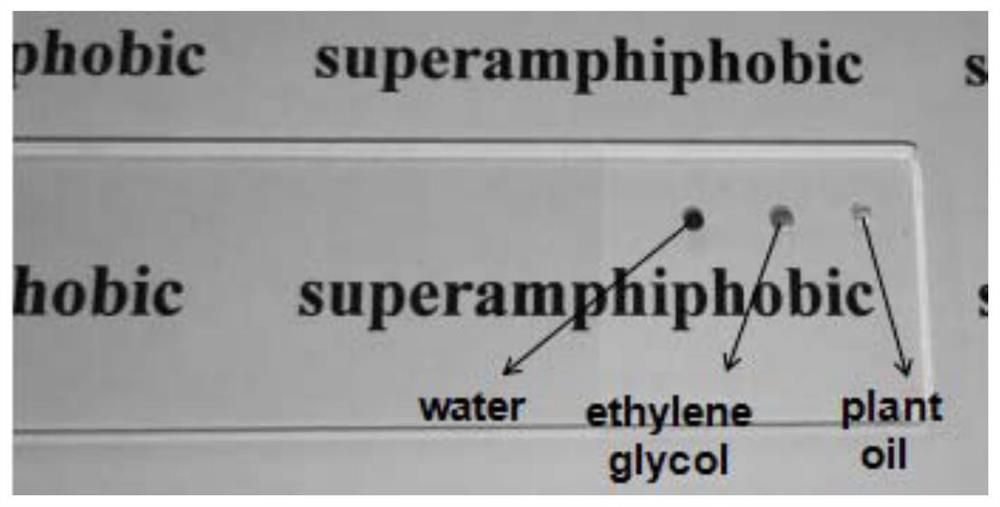

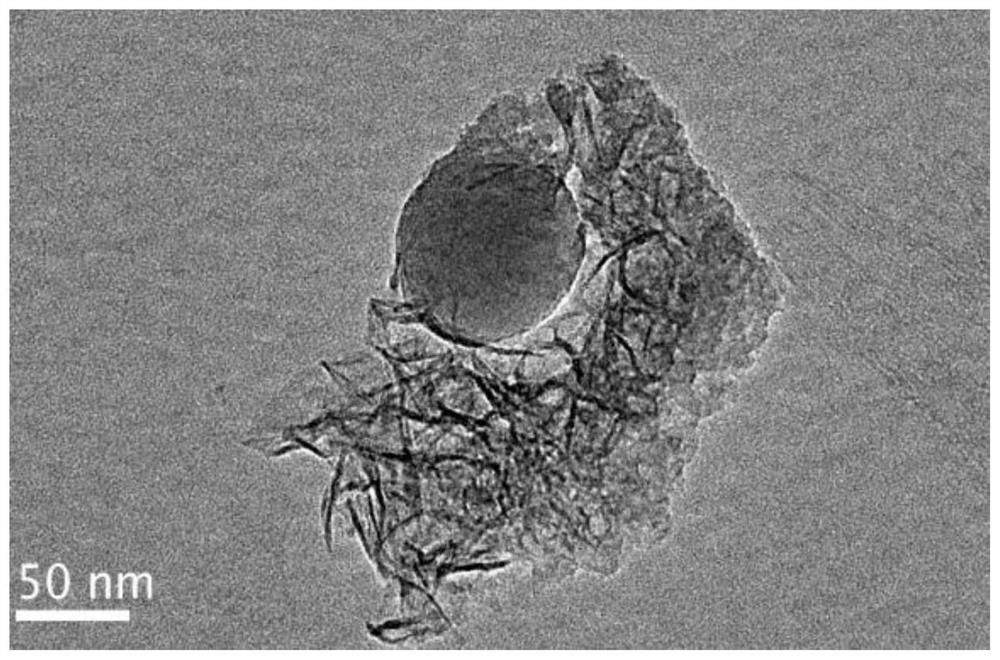

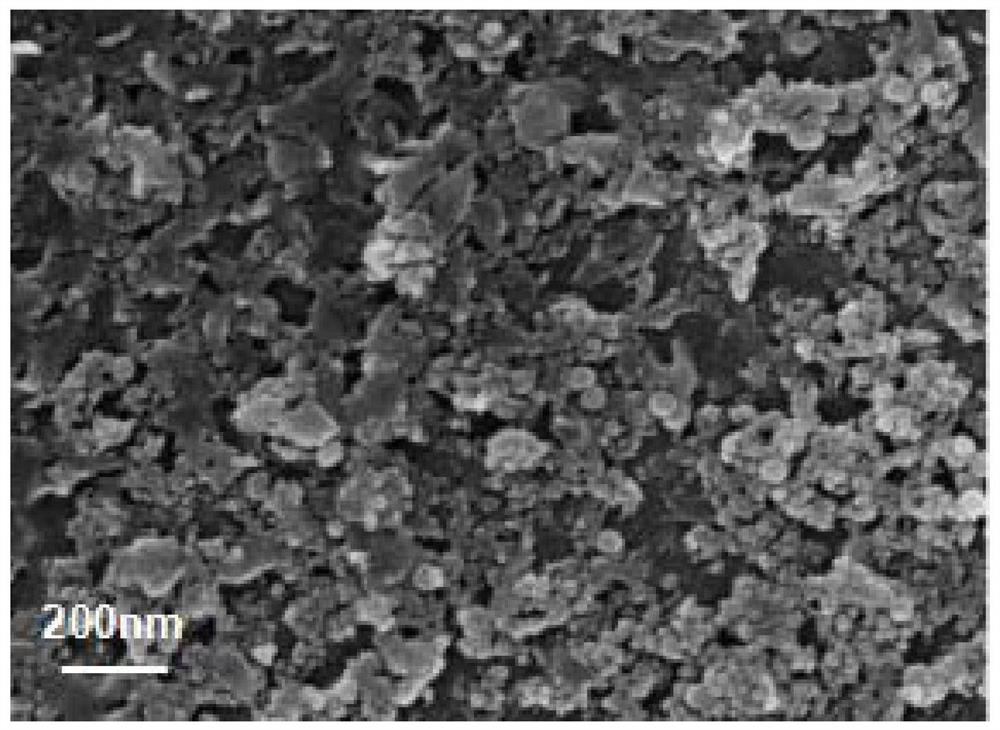

Preparation method of high-light-transmittance amphiphobic antireflection film

The invention belongs to the technical field of antireflection films, and particularly relates to a preparation method of a high-light-transmittance amphiphobic antireflection film. The method comprises the following steps: preparing grass-like alumina sol and silicon dioxide solid sphere sol by a sol-gel method, plating the mixed sol on a glass substrate by a dipping-pulling method, and modifying grass-like aluminum oxide and silicon dioxide solid spheres by using 1H,1H,2H,2H-perfluorodecyl triethoxy silane through chemical vapor deposition. The coating prepared by the method is high in light transmittance, and has excellent properties of super-hydrophobicity, oleophobicity, self-cleaning and the like. The sol-gel method is simple in process, extensible, low in cost and high in light transmittance by adopting a sol-gel method, and has a great prospect in solar energy, building glass, optical equipment and other applications.

Owner:CHANGZHOU UNIV

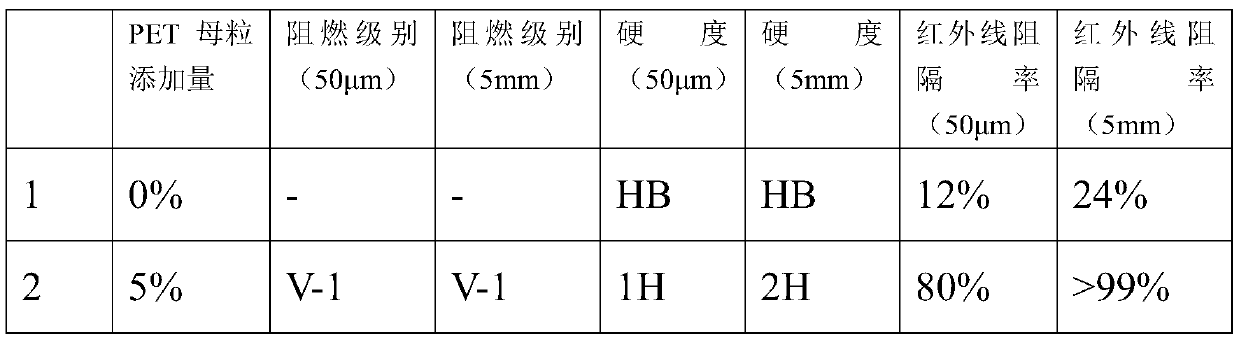

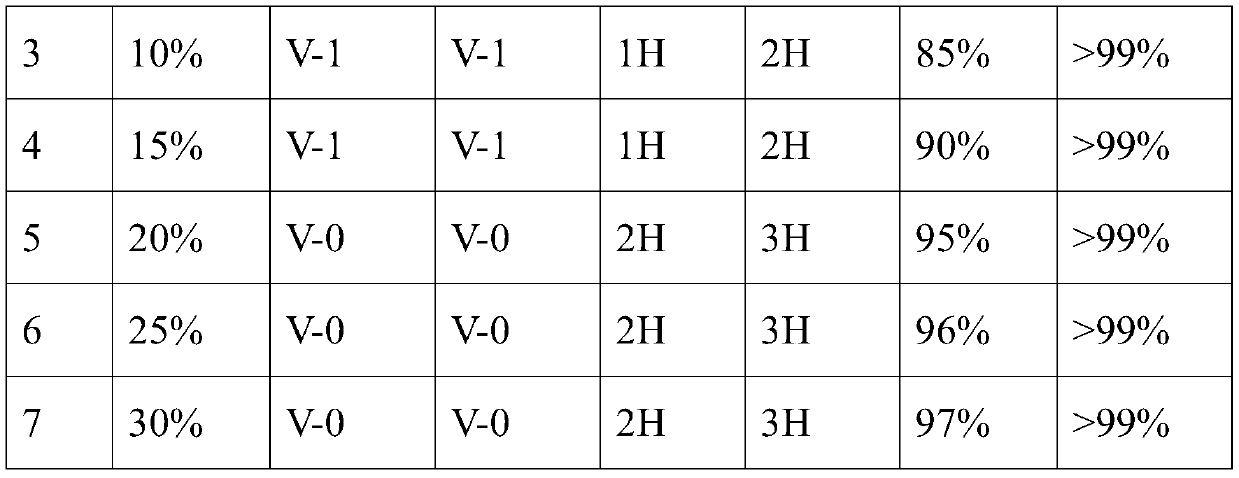

Hardened flame-retardant heat-insulating master batch and production method therefor

InactiveCN110157162ASimple preparation processLow costTransmittancePolyethylene terephthalate glycol

The invention discloses a hardened flame-retardant heat-insulating master batch and a production method therefor. The hardened flame-retardant heat-insulating master batch is prepared from the following raw materials in parts by weight: 50-70 parts of support resin polyethylene terephthalate (PET), 20-30 parts of polyethylene naphthalate (PEN), 5-10 parts of flame retardant, 5-10 parts of heat-insulating auxiliaries and 5-10 parts of dispersant. According to the hardened flame-retardant heat-insulating master batch and the production method therefor, after the PET master batch is added into aPET material product, a flame retardant rating of an obtained PET product can reach a level V0 (UL94), meanwhile, the infrared ray barrier rate reaches 60% to 99% (changing along with an addition level), and the influence on light transmittance of the product is relatively low. The PET master batch disclosed by the invention is prepared through subjecting various additives and the PET resin to mixing granulation, the preparation process is simple, and the cost is relatively low. The PEN resin is added into a formula of the PET master batch, so that mechanical properties and barrier performanceof the product can be improved, and thus, the field of application of the PET product is enlarged.

Owner:纳琳威纳米科技南通有限公司

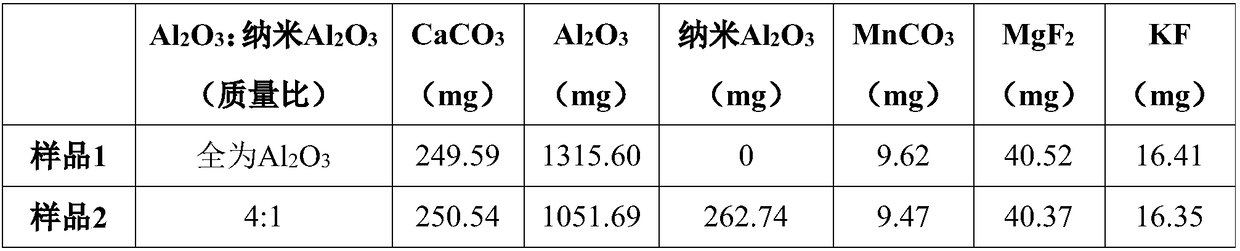

Ytterbium fluoride mixed coating material and preparation method thereof

ActiveCN111592231AInhibit sheddingImprove crack resistanceVacuum evaporation coatingSputtering coatingYtterbium fluorideRefractive index

The invention discloses an ytterbium fluoride mixed coating material and a preparation method thereof, and relates to the field of ytterbium fluoride mixed materials. The preparation method comprisesthe following steps: firstly, washing a quartz substrate, immersing the quartz substrate into tin dioxide sol containing potassium acetate, filtering and drying after the dipping to obtain a pretreated quartz substrate, mixing ytterbium fluoride with calcium fluoride, adding titanium dioxide, mixing and sintering, melting to obtain a mixed coating material, carrying out vacuum coating on the surface of the pretreated quartz substrate with the mixed coating material in a coating machine to obtain an ytterbium fluoride mixed coating material blank, and sintering the ytterbium fluoride mixed coating material blank to obtain the ytterbium fluoride mixed coating material. The ytterbium fluoride mixed coating material prepared by the invention has excellent anti-cracking performance, and has less influence on the optical refractive index of ytterbium fluoride.

Owner:南京睿扬光电技术有限公司

Transparent wood processing technology for manufacturing high-light-transmittance wooden crafts

InactiveCN113967953ADestruction will notCollapse will notPretreatment apparatusPressure impregnationPolymer sciencePolymer chemistry

The invention discloses a transparent wood processing technology for manufacturing high-light-transmittance wood crafts, and relates to the technical field of wood processing. The processing technology comprises the following steps: after lignin is removed from wood, the wood is placed in steeping liquor containing silver nanowires for steeping treatment, and then is steeped with transparent resin to obtain transparent wood. According to the method, before the delignified wood is filled with a polymer matrix, the silver nanowires with the length-diameter ratio are filled in the channels of the wood, the film channels constructed by the silver nanowire films are formed in the channels of the wood, and due to the fact that the silver nanowire films have good flexibility, the film channels formed in the wood channels have good stress dispersion functions, so that the polymer matrix is added to the wood channels, such that the film channels formed in the wood channels have the good stress dispersion effect so as to dissipate the stress generated during the curing expansion of the polymer matrix by the film channels so as to achieve the technical effects of no damage to the internal weak structure of the wood and no collapse of wood cells.

Owner:阜南县永盛工艺品有限公司

Transparent heat insulation film for building glass and preparation method of film

The invention relates to the technical field of heat insulation materials, and provides a transparent heat insulation film for building glass and a preparation method of the film. The method includesrespectively preparing a methyl ethyl ketone dispersion of indium tin oxide and lanthanum molybdate; then mixing the methyl ethyl ketone dispersion with polyvinylidene fluoride / polyvinyl butyral composite sol to prepare a heat insulation coating material; and forming a transparent heat insulation film on the surface of glass by dipping and pulling. Compared with the traditional method, the transparent heat insulation film not only has a good heat insulation effect and is beneficial to building energy conservation and emission reduction, but also has high visible light transmittance and littleinfluence on the light transmittance of glass.

Owner:成都其其小数科技有限公司

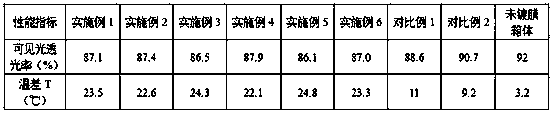

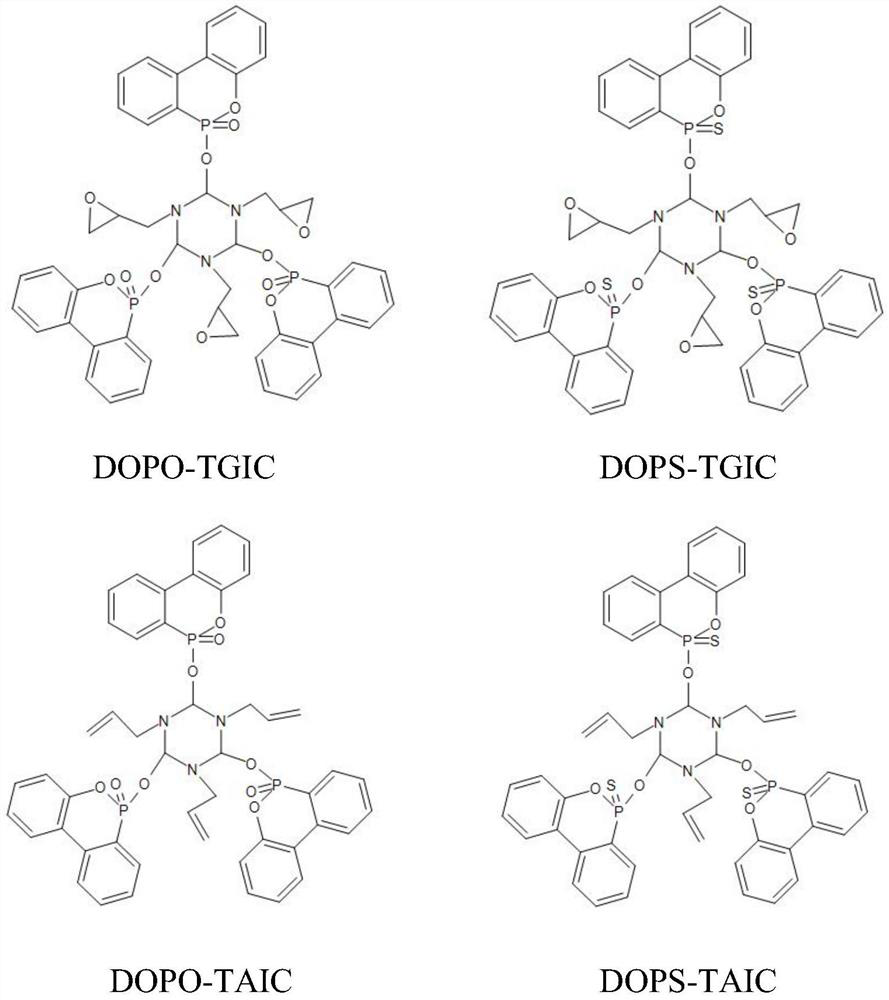

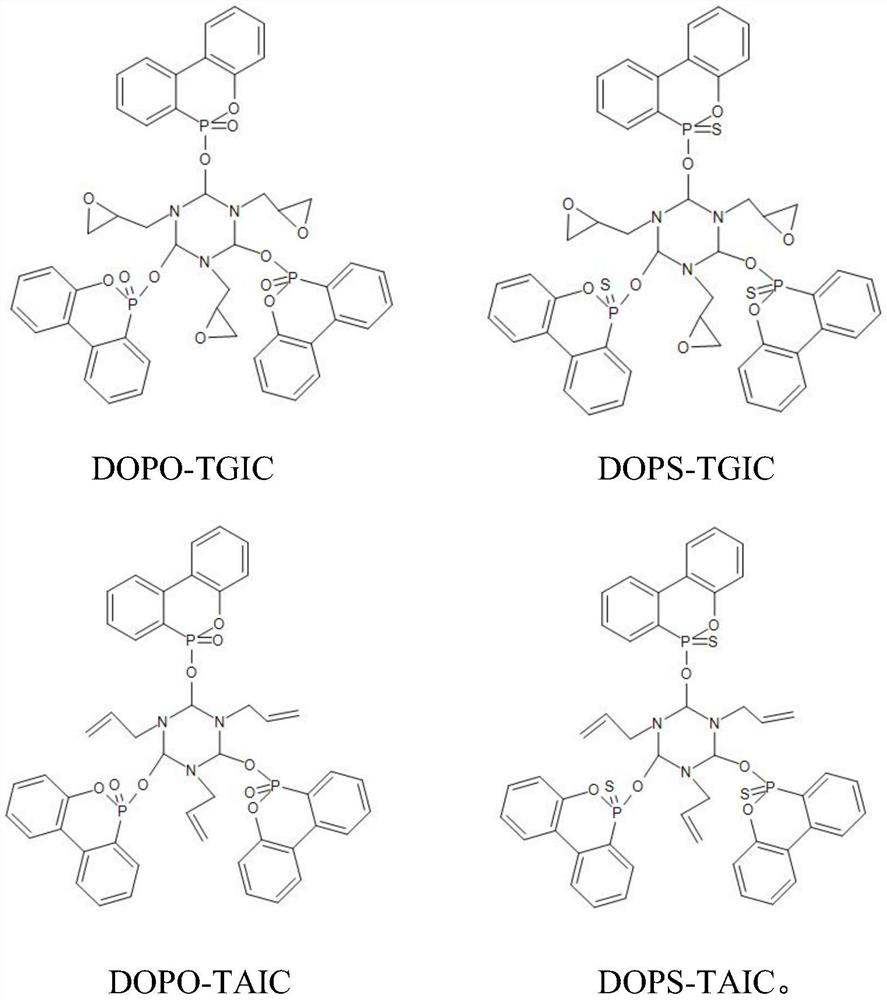

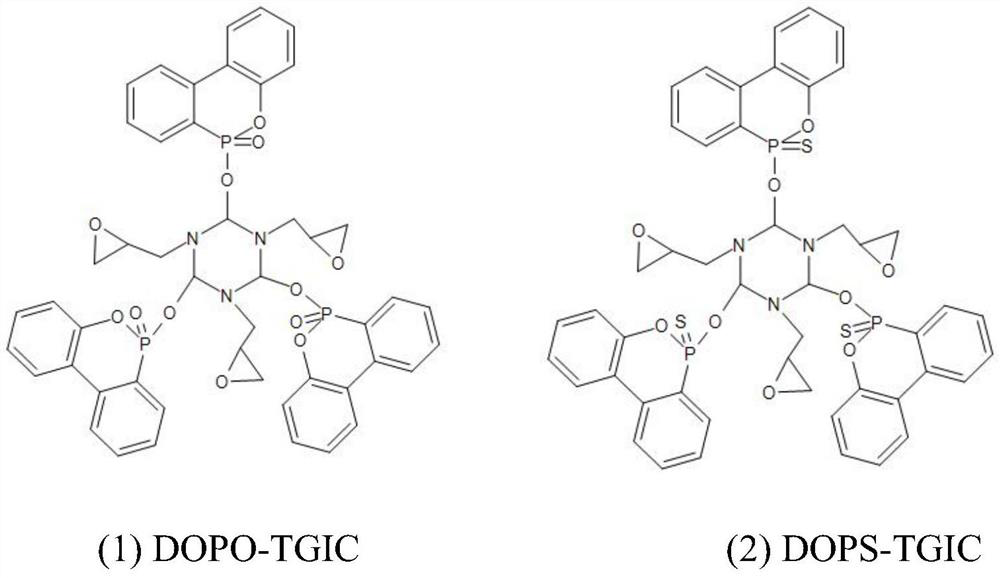

Environment-friendly flame-retardant transparent polyester material

The invention relates to an environment-friendly flame-retardant transparent polyester material, which is prepared from the following components in percentage by mass: 70 to 95 % of polyester resin, 4 to 30 % of DOPO derivative and 0.2 to 2 % of an antioxidant. The totaling is 100%. According to the environment-friendly flame-retardant transparent polyester material, the DOPO derivative is used, so that the synthesized flame retardant is halogen-free, smoke-free, non-toxic, free of migration and lasting in flame retardant property, and can be used for flame retardant treatment of various high polymer materials such as linear polyester, polyamide, epoxy resin and polyurethane.

Owner:ZHEJIANG XUSEN NON HALOGEN SMOKE FLAME RETARDANT CO LTD

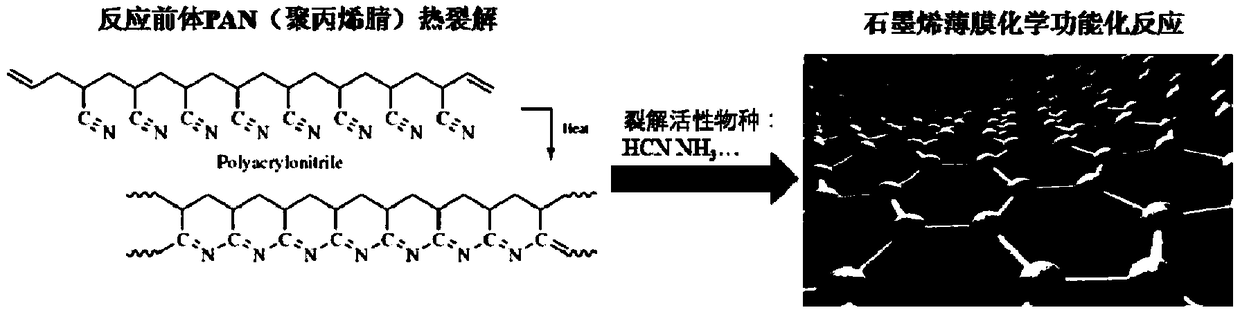

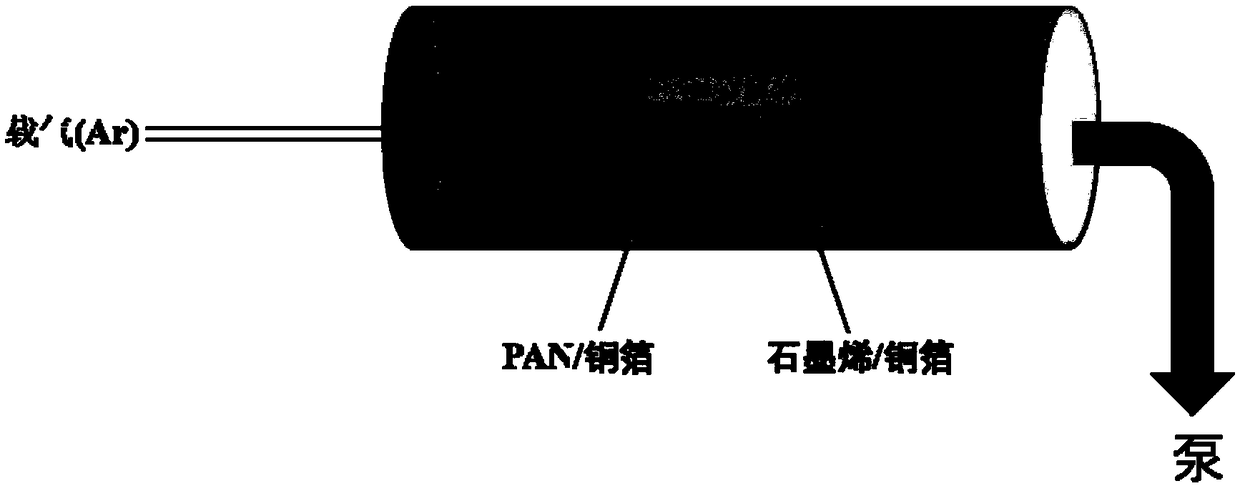

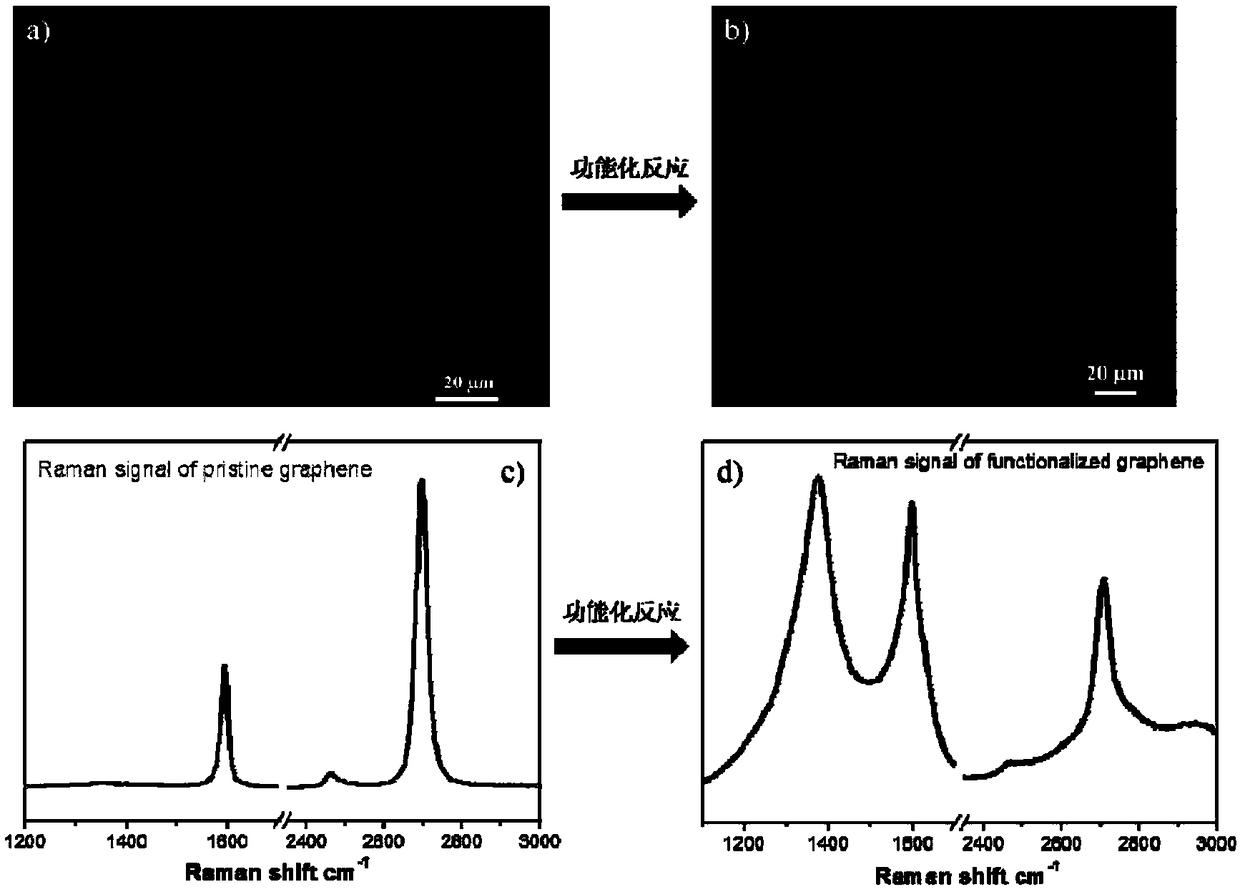

A kind of highly conductive graphene film and preparation method thereof

ActiveCN107403658BEfficient and uniform functionalizationSimple processConductive layers on insulating-supportsSynthetic resin layered productsComposite filmGas phase

The invention discloses a high-conductivity graphene thin film and a preparation method thereof. The preparation method comprises the following steps of sequentially arranging a graphene thin film / copper foil composite film structure and a polyacrylonitrile fiber film / copper foil composite film structure in a quartz cavity along an air flow direction of a carrier gas, introducing the carrier gas, rising a temperature, and performing gas-phase reaction under a vacuum condition, thereby obtaining the high-conductivity graphene thin film, wherein the graphene thin film / copper foil composite film structure is a composite structure of a copper foil and a graphene thin film coated on a surface of the copper foil, and the polyacrylonitrile fiber film / copper foil composite film structure is a composite structure of a copper foil and a polyacrylonitrile fiber film coated on a surface of the copper foil. The process is simple and practical, the related electrostatic spinning and low-voltage chemical vapor deposition (CVD) are mature technologies, and the function of gas-phase reaction on the graphene thin film is high-efficiency and uniform; and the conductivity of the functionalized graphene thin film is improved by 40% or above and is very remarkable, and the influence on the transmitting of the graphene thin film is very low.

Owner:PEKING UNIV

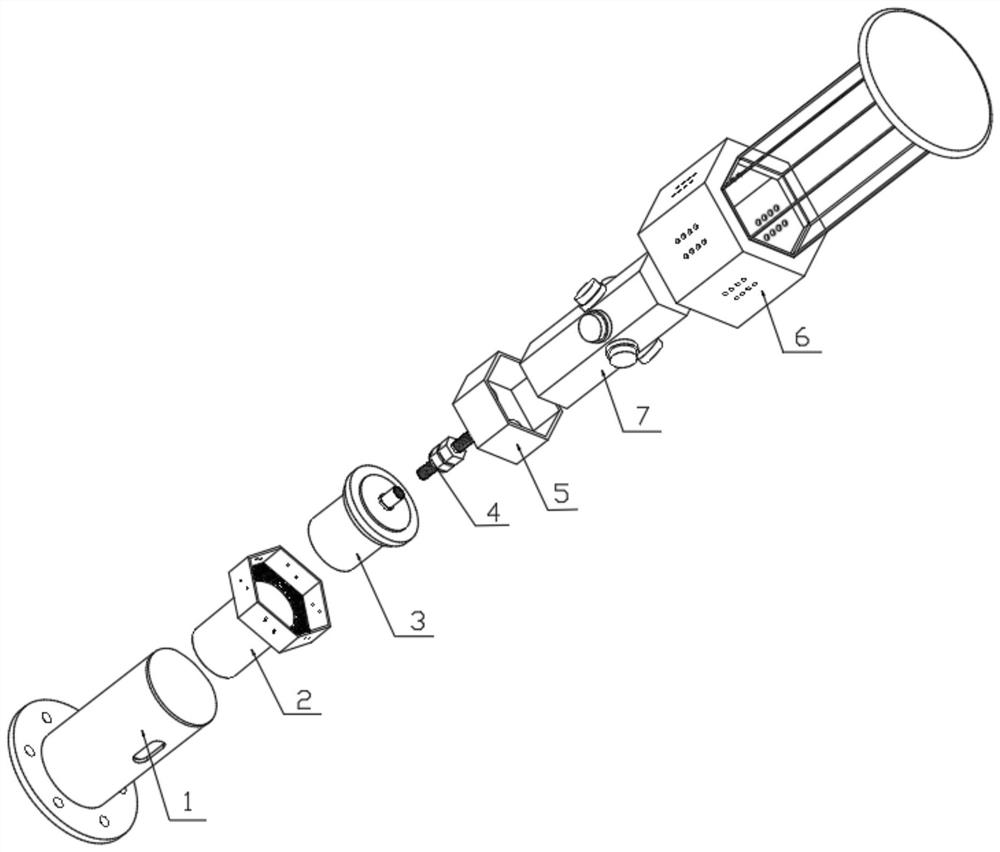

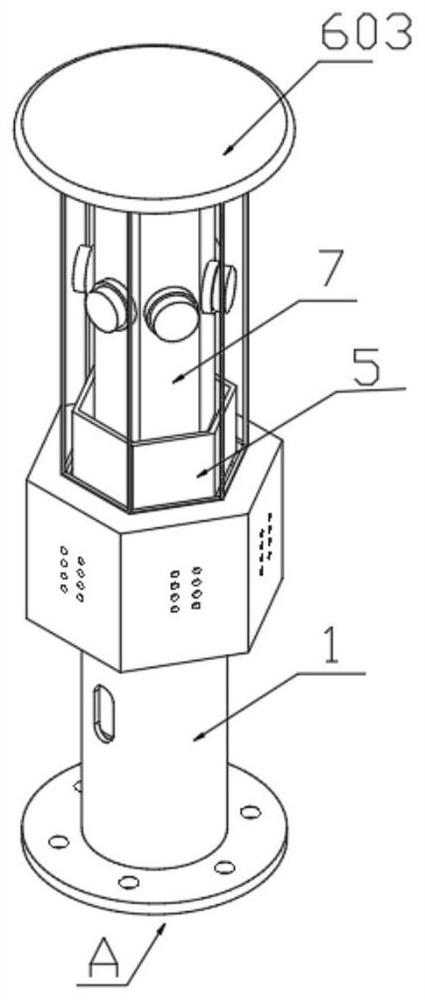

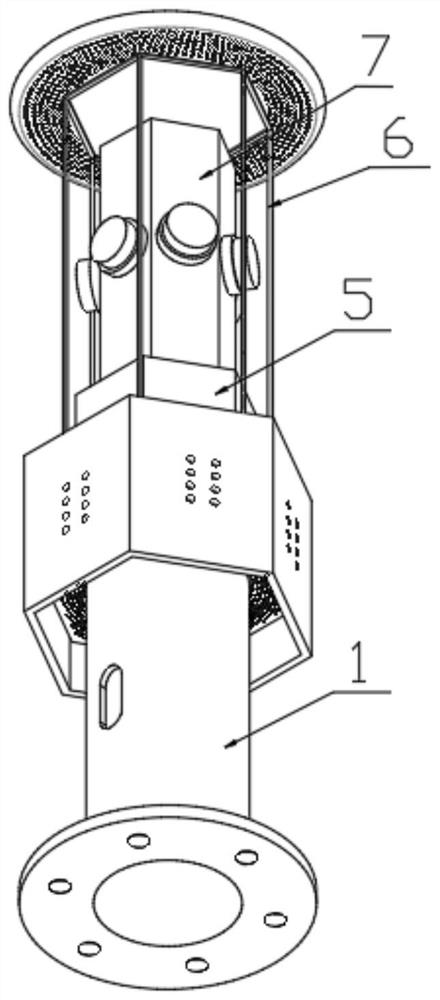

protective cover for panoramic camera

ActiveCN111897185BInstalled and disassembledEasy to carryPanoramic photographyCamera body detailsPanoramaEngineering

The invention discloses a protective cover for a panoramic camera and relates to the technical field of imaging equipment. The invention includes a base, a connecting seat, a counterweight support column, a panoramic camera mounting seat, a panoramic camera, and a cover body; a regular N-gon ring cover of the cover body, a regular N-gon transparent cover, and a circular transparent cover plate; the cover body sleeve After installation, the connecting plate between the ring cover and the regular N-shaped transparent cover is just pressed against the top surface of the first pallet, and the fine height adjustment is carried out through the first adjustment hole and the second adjustment hole with the pin; the whole mechanism passes through External air enters into the regular N-gon transparent cover through the first air hole and the flow hole on the surface of the second pallet, overflows through the second air hole, or circulates in reverse to maintain heat dissipation and air circulation in the cover. The invention can realize fast, efficient and stable installation and disassembly in the outdoor scene, can be disassembled and carried separately, is easy to carry and transport, and the height adjustment is accurate and efficient, ensuring the efficient work of the panoramic camera.

Owner:酷景传媒(上海)有限公司

Aluminate light conversion agent, preparation method thereof, and light conversion film containing the aluminate light conversion agent

ActiveCN106750520BHigh luminous intensityGood compatibilityLuminescent compositionsLuminous intensityCrucible

The invention discloses an aluminate light conversion agent and a preparation method thereof as well as a light conversion film containing the aluminate light conversion agent. The general formula of the aluminate light conversion agent is A1-xZnxAl12O19: Mn<4+>, wherein A is at least one of Ca<2+>, Sr<2+> and Ba<2+> and x is more than or equal to 0 and less than 1. The preparation method comprises the following steps: sufficiently grinding metal oxide, nano metal oxide, alkaline-earth salt, an activating agent and a fluxing agent, and uniformly mixing; adding a mixture into a crucible; putting the crucible into a high-temperature furnace; and carrying out program temperature rising and cooling to obtain the aluminate light conversion agent. The light conversion film containing the aluminate light conversion agent is prepared from the following raw materials in parts by mass: 100 parts of a thin film matrix, 8-45 parts of a master batch matrix, 0.5-10 parts of the aluminate light conversion agent, 0.15-0.3 part of a lubricating agent, 0.5-1.5 parts of a light stabilizer and 0.3-1.5 parts of an antioxygen. The aluminate light conversion agent disclosed by the invention has the advantages of high light emitting strength, high light conversion efficiency, good stability, long service life and simple preparation method; the adding amount in an agricultural thin film is small, and the aluminate light conversion agent has good compatibility with the thin film matrix and has less influences on light transmittance of the thin film.

Owner:SOUTH CHINA AGRI UNIV

Anti-PID effect assembly and preparation method and application thereof

PendingCN112820791AImprove performanceLight transmittance has little effectFinal product manufacturePhotovoltaic energy generationWeather resistanceTransmittance

The invention relates to the technical field of photovoltaics, and provides an anti-PID effect assembly. The anti-PID effect assembly comprises a glass substrate and a tin oxide layer arranged on any surface of the glass substrate. The ion radius of tin ions is smaller than that of sodium ions and calcium ions, so that the ion potential energy is higher, the binding capacity with oxygen atoms is higher, the tin ions have an obvious aggregation effect, and a glass network structure can be enhanced and is more compact, and accordingly migration of the sodium ions and the calcium ions is limited, carbonate containing the sodium ions and the calcium ions is not formed on the surface of the glass, the glass is protected from serious erosion, the weather resistance of the glass surface and a glass coating can be obviously improved, and the PID attenuation effect on the upper surface of the glass is effectively reduced. Meanwhile, the tin oxide layer has smaller influence on the light transmittance of the whole glass, so that the obtained assembly is stronger in PID effect resistance, excellent in overall performance and wide in application.

Owner:湖南旗滨光能科技有限公司

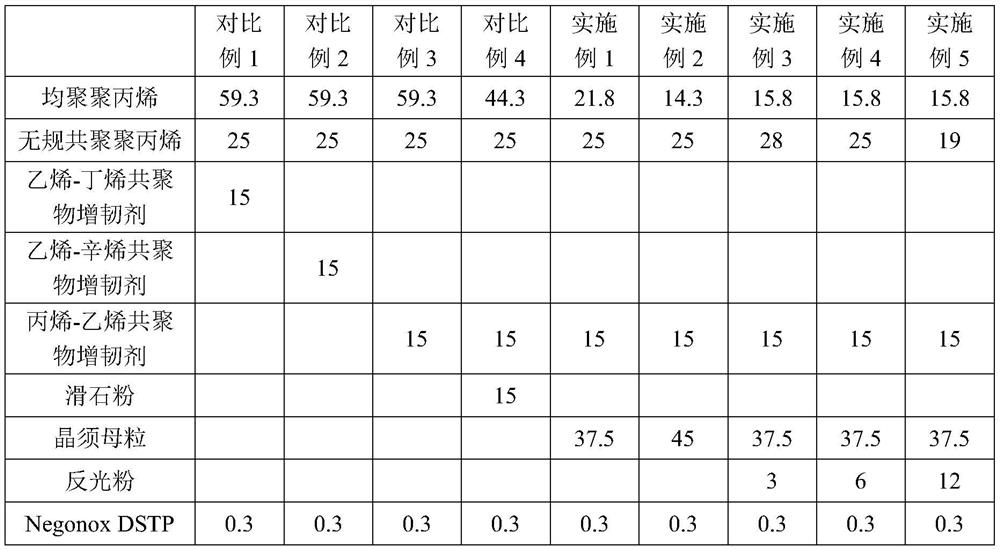

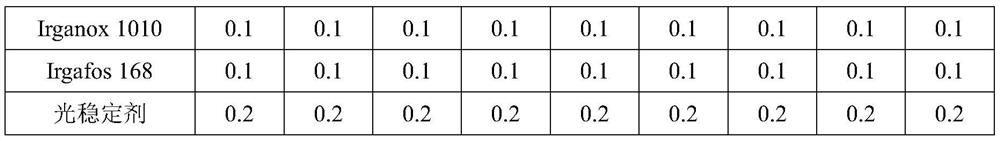

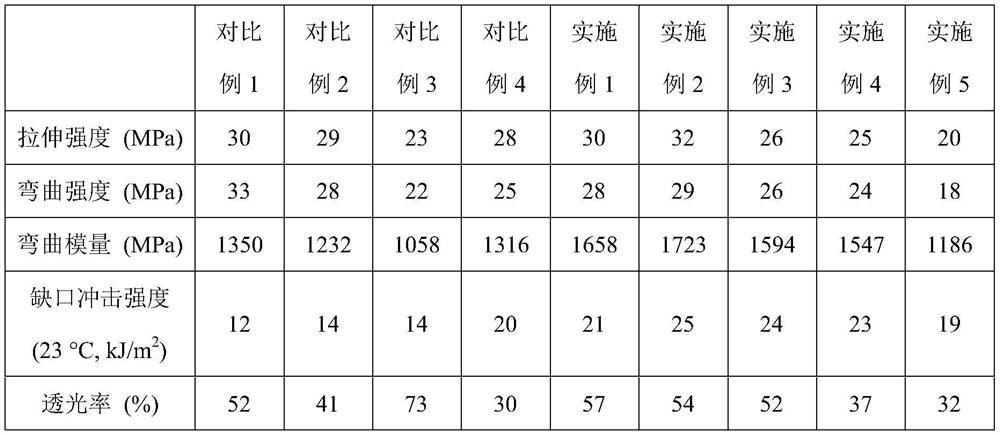

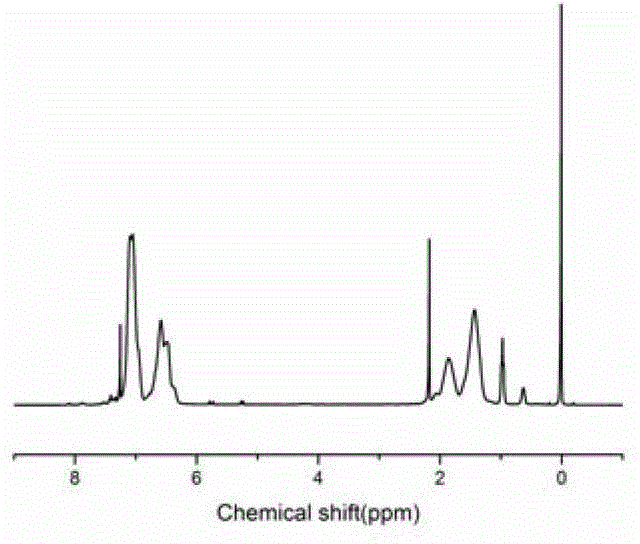

Reflective polypropylene composite material suitable for automotive trim and preparation method of reflective polypropylene composite material

The invention discloses a reflective polypropylene composite material suitable for automotive interiors and a preparation method of the reflective polypropylene composite material. The polypropylene composite material is composed of the following raw materials in percentage by weight: 10-70% of homo-polypropylene; 0-45% of polypropylene random copolymer; 5-25% of a propylene-ethylene copolymer toughening agent; 10-40% of whisker master batch; 1-10% of reflective powder; 0.1-2% of an antioxidant; and 0-5% of other additives. Compared with the conventional light-proof inorganic filler (such as talcum powder, calcium carbonate and the like), the light-transmitting whisker has the advantages that the loss of light transmittance of the material can be greatly reduced on one hand, and a better stiffening effect can be achieved on the other hand; compared with common light-transmitting filler glass fibers, the crystal whiskers can avoid the size control problem caused by height orientation during injection molding of the glass fibers. The high light transmittance of the material ensures that the reflective filler in the material can fully play a role, so that the use amount of the reflective filler can be remarkably reduced.

Owner:SHANGHAI PRET COMPOSITES +3

A kind of light diffusing agent and PMMA light diffusing plate and preparation method thereof

ActiveCN103193915BEvenly dispersedLight transmittance has little effectDiffusing elementsPolymethyl methacrylateRefractive index

The invention relates to a light diffusing agent, a PMMA (polymethyl methacrylate) light diffusing plate and a manufacturing method thereof. The light diffusing agent is a random copolymer of styrene (St) and methacryloxypropylisobutyl polyhedral oligomer silsesquioxane (MAiBuPOSS). The PMMA light diffusing plate comprises the following components in percentage by weight: 97.0-99.5% of polymethyl methacrylate and 0.5-3.0% of light diffusing agent. The refractive indexes of the styrene component and the MAiBuPOSS component in the light diffusing agent differ from the refractive index of PMMA; when passing through a material, a light ray is refracted for many times and becomes bright and soft after passing through a substrate. Meanwhile, the MAiBuPOSS component ensures that the dispersibility of PS (Poly Styrene) in PMMA is remarkably improved, excellent light transmission and light scattering are obtained, and the optical efficacy is high. The PMMA light diffusing plate manufactured by the invention can be used for LED (Light Emitting Diode) illumination lamps, such as a plate lamp, an advertising lamp box, a professional film viewer, a down lamp and the like.

Owner:石狮市天生化工有限公司 +1

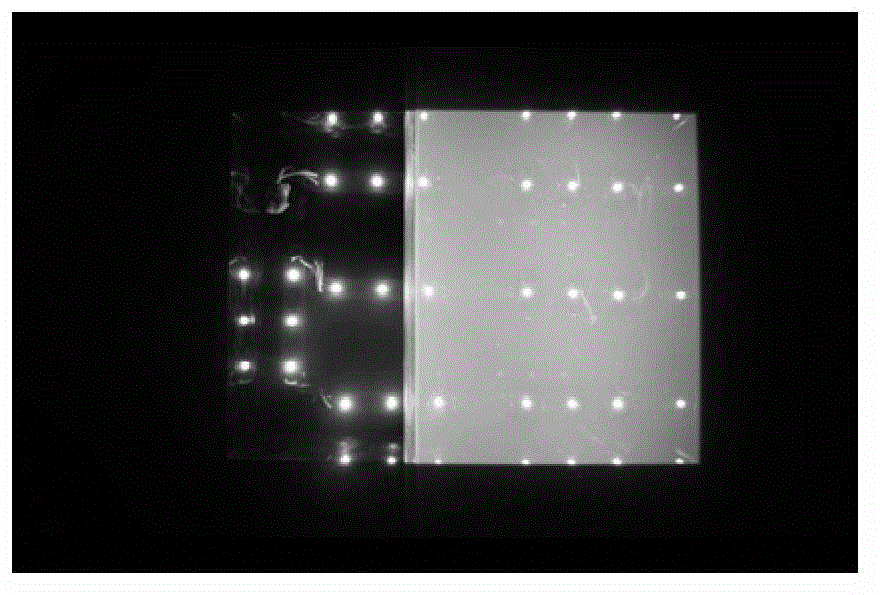

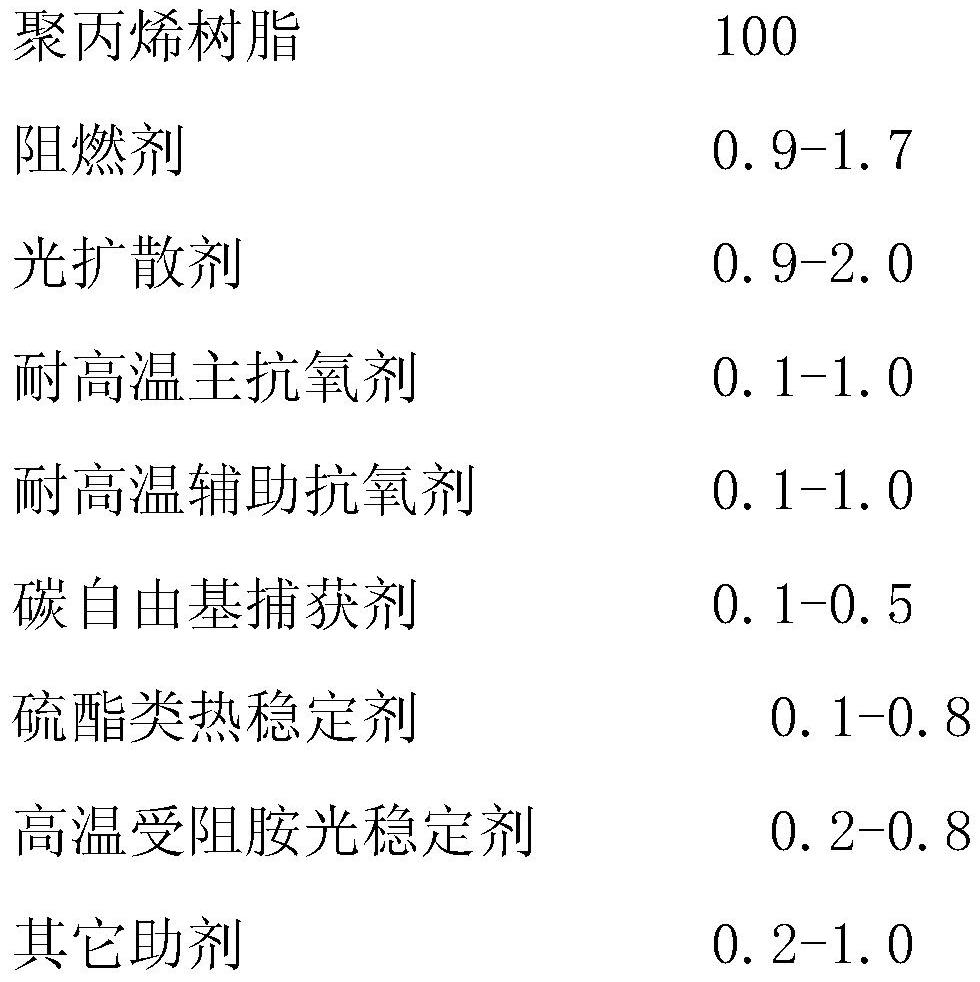

Flame-retardant light-diffusing PP material with anti-thermal oxygen aging function and preparation method thereof

ActiveCN110157094BLittle loss of mechanical propertiesSmall yellowing index changeLight fluxPhysical chemistry

The invention discloses a flame-retardant light-diffusing PP material with anti-thermal oxygen aging function and a preparation method thereof, comprising polypropylene resin, composite flame retardant, light diffusing agent, composite antioxidant, high-temperature heat-resistant heat stabilizer, anti- Composed of UV agent and other additives. The flame-retardant light-diffusing PP material produced by the invention has the characteristics of high luminous flux, good flame retardancy, no precipitation of flame retardant during use, and long service life.

Owner:NANTONG DONGFANG PLASTIC CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com