Hardened flame-retardant heat-insulating master batch and production method therefor

A masterbatch and flame retardant technology, which is applied in the field of hardening, flame-retardant and heat-insulating masterbatch and its manufacturing field, can solve the problems of loss of life and property of the insulating film, the coating is easy to fall off, and the production cost is high, so as to improve the mechanical properties and The effect of barrier performance, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

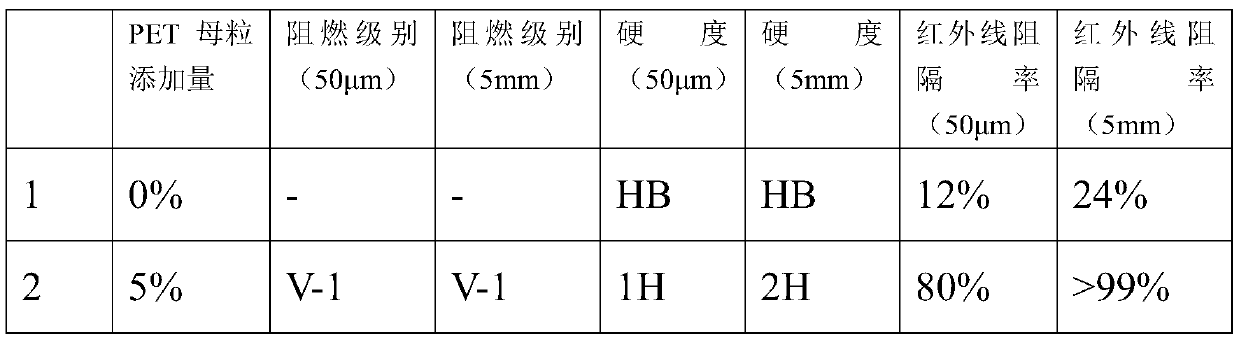

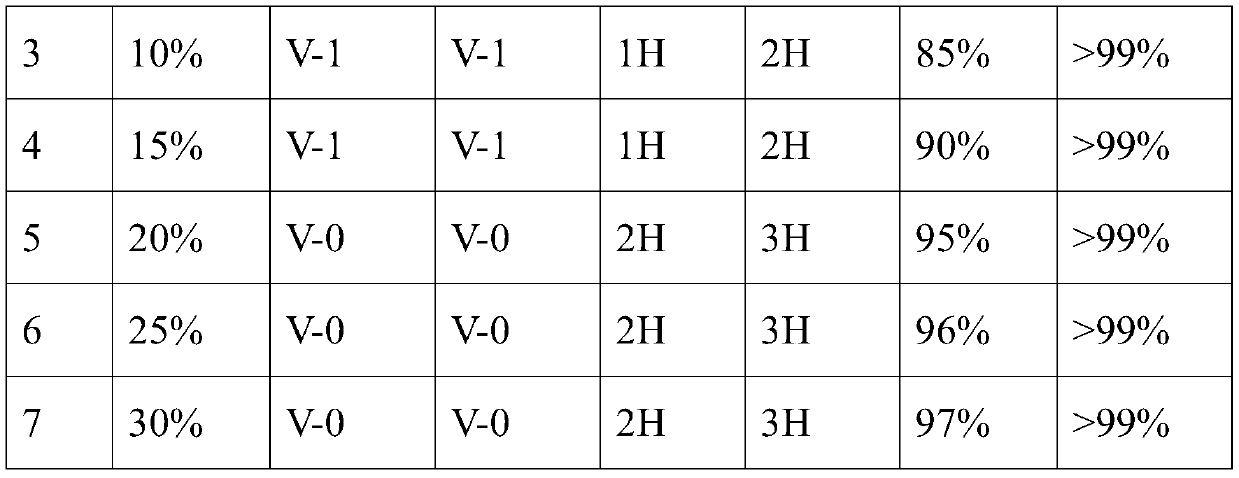

Examples

Embodiment 2

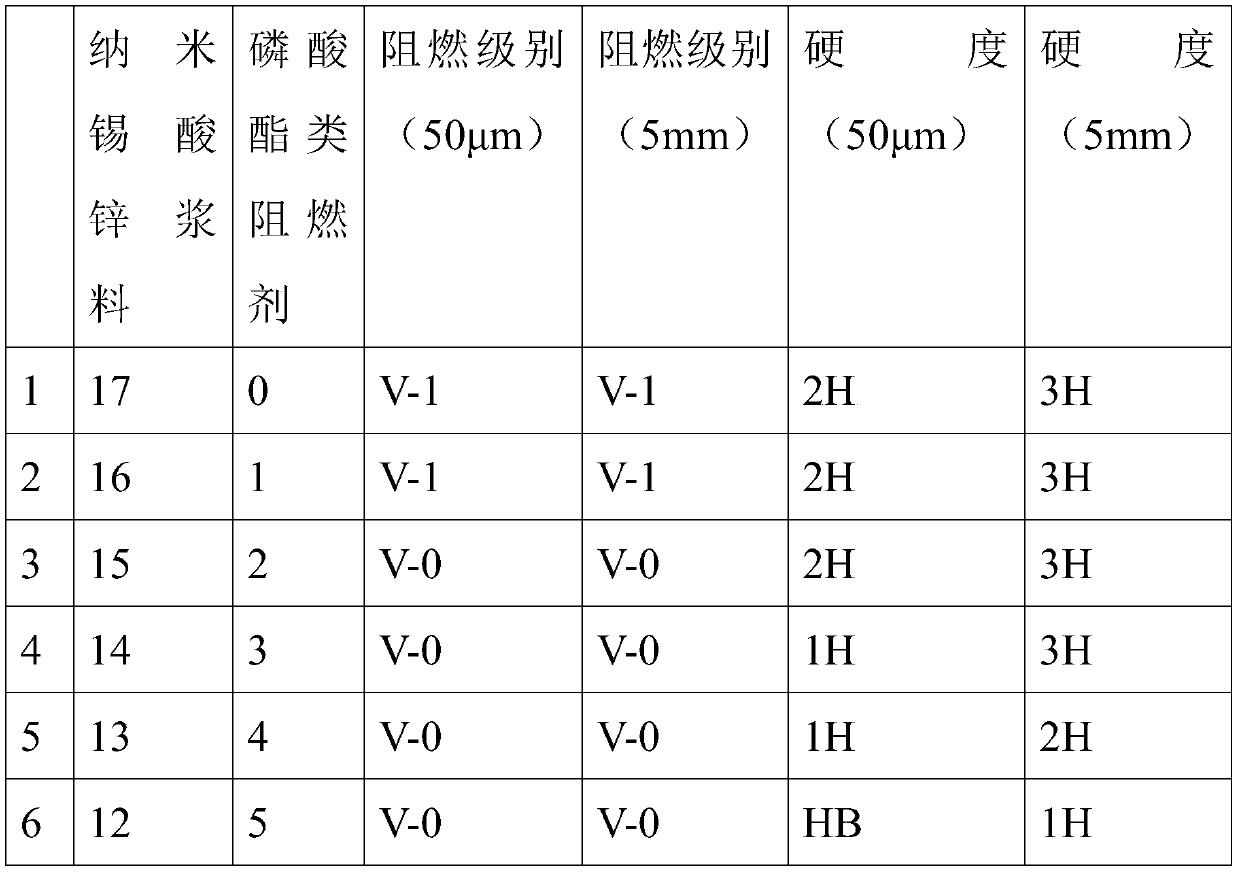

[0032] The steps of this embodiment are as follows:

[0033] S1: Disperse nano-zinc stannate in ethyl acetate solvent, configure a mixed dispersion with a mass fraction of 20%, then add 5% dispersant BYK110, put it into a grinder, and grind it through a high-speed grinder until the particle size is at 50nm, stop grinding, and discharge to obtain a nano-slurry with a solid content of 20%.

[0034] S2: Disperse nano-indium tin oxide in ethyl acetate solvent, configure a mixed dispersion with a mass fraction of 20%, then add 5% dispersant BYK110, put it into a grinder, and grind it through a high-speed grinder until the particle size is 50nm, stop grinding, and discharge to obtain a nano-slurry with a solid content of 20%.

[0035] S3: 15 parts of nano-zinc stannate slurry obtained from S1 and S2, 15 parts of nano-tungsten indium tin oxide, 50 parts of polyethylene terephthalate, 18 parts of PEN resin, 2 parts of phosphate flame retardant Parts were mixed in a high-speed mixer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com