Reflective polypropylene composite material suitable for automotive trim and preparation method of reflective polypropylene composite material

A technology for composite materials and automotive interiors, applied in the field of polypropylene composite materials and its preparation, can solve problems such as inability to highlight shapes or patterns, blurred boundaries of illuminated areas, loss of rigidity of PP materials, etc., and achieve refractive index matching , reduce the dosage, reduce the effect of rigidity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

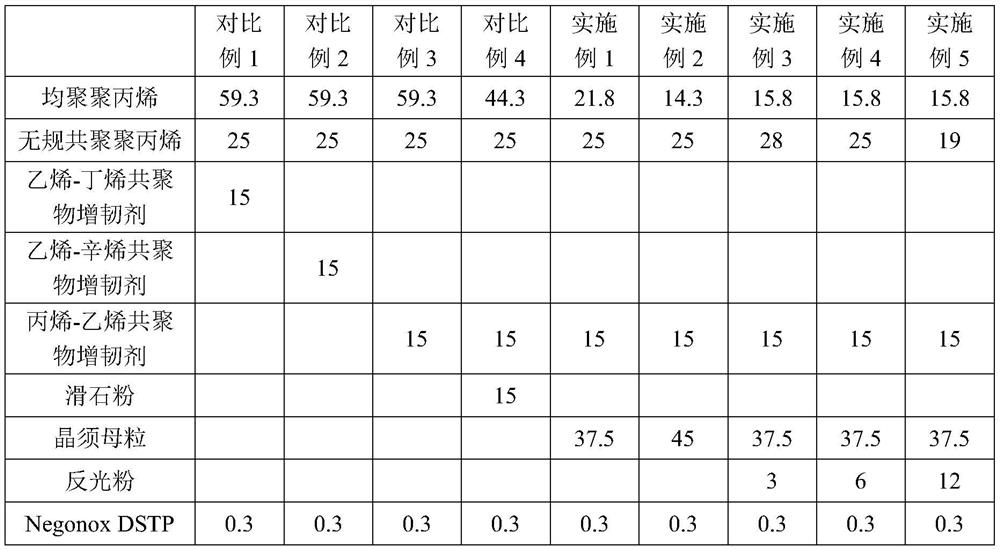

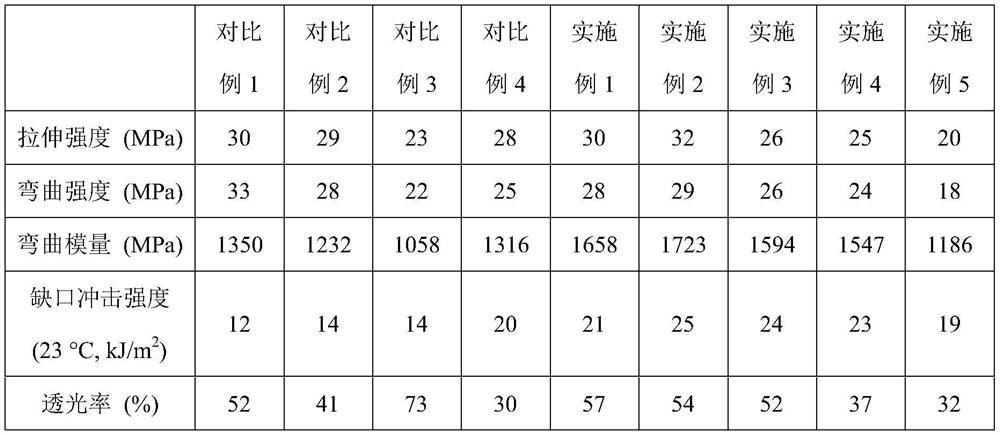

Embodiment 1

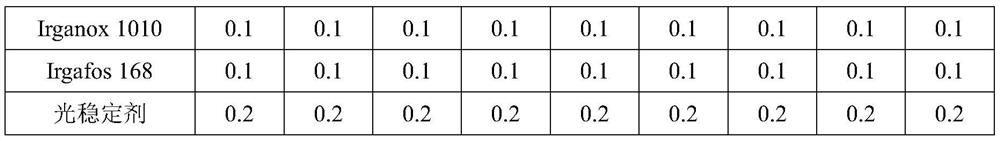

[0034] (1) Weigh 21.8% of homopolypropylene, 25% of random copolymerized polypropylene, 15% of propylene-ethylene copolymer toughening agent, 0.3% of Negonox DSTP, 0.1% of Irganox 1010, 0.1% of Irgafos 168, light 0.2% stabilizer was dry mixed in a high-speed mixer for 8 minutes to obtain a premix.

[0035] (2) Add the premix into the twin-screw extruder from the main feeding port of the screw, add the whisker masterbatch (37.5%) through the side feeding port, and cool and granulate after melting and extruding. The process is: one zone 190-200°C, second zone 200-210°C, third zone 210-220°C, fourth zone 205-215°C; residence time 1-2min, pressure 12-18MPa.

Embodiment 2

[0037] (1) Weigh 14.3% of homopolypropylene, 25% of random copolymerized polypropylene, 15% of propylene-ethylene copolymer toughening agent, 0.3% of Negonox DSTP, 0.1% of Irganox 1010, 0.1% of Irgafos 168, light 0.2% stabilizer was dry mixed in a high-speed mixer for 8 minutes to obtain a premix.

[0038] (2) Add the premix into the twin-screw extruder from the main feeding port of the screw, add the whisker masterbatch (45%) through the side feeding port, and cool and granulate after melting and extruding. The process is: one zone 190-200°C, second zone 200-210°C, third zone 210-220°C, fourth zone 205-215°C; residence time 1-2min, pressure 12-18MPa. Example 3

Embodiment 3

[0039](1) Weigh by weight 15.8% homopolypropylene, 28% random copolymer polypropylene, 15% propylene-ethylene copolymer toughening agent, 3% reflective powder, Negonox DSTP 0.3%, Irganox 1010 0.1%, Irgafos1680 .1% and 0.2% light stabilizer were dry mixed in a high-speed mixer for 8 min to obtain a premix.

[0040] (2) The premix is fed into the twin-screw extruder from the main feed port of the screw, the whisker masterbatch (37.5%) is added through the side feed port, and cooled and pelletized after being melted and extruded. The process is: one zone 190-200°C, 200-210°C in the second zone, 210-220°C in the third zone, 205-215°C in the fourth zone; residence time 1-2min, pressure 12-18MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com