PC material with high light transmittance and high haze and application of PC material

A technology with high light transmittance and high haze, which is applied in the field of PC materials, can solve the problems that the light transmittance of the material is greatly affected, the high light transmittance cannot be achieved, and the light transmittance of microcrystalline cellulose is low, so as to improve the The effects of PC haze, low light transmittance, and stable batch quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

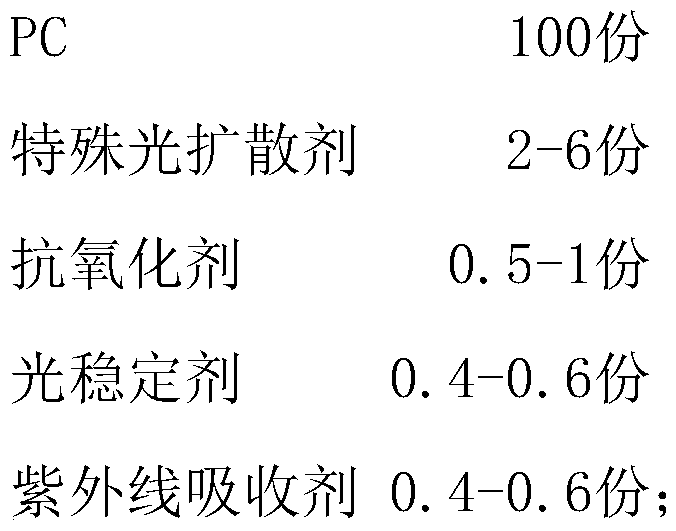

[0028] A PC material with high light transmittance and high haze, comprising the following raw materials in parts by weight:

[0029]

[0030]

[0031] Described special light diffusing agent is made through the following steps:

[0032] (1) Get 80 parts by weight of methyl methacrylate, 10 parts by weight of methyl acrylate, 40 parts by weight of nano silicon dioxide, 0.2 parts by weight of n-dodecyl mercaptan and join to 100 parts by weight of organic solvent , add 0.1 parts by weight of the first initiator during the stirring process, and then react at 40°C for 1 hour to obtain a pre-polymerization solution;

[0033] (2) Add 40 parts by weight of acrylonitrile and 5 parts by weight of methyl acrylate to the pre-polymerization solution, add 0.1 parts by weight of the second initiator during stirring, and then react at 40°C for 2 hours to obtain a polymerization liquid;

[0034] (3) Electrostatically spraying the polymer solution to obtain the special light diffusing ...

Embodiment 2

[0043] A PC material with high light transmittance and high haze, comprising the following raw materials in parts by weight:

[0044]

[0045] Described special light diffusing agent is made through the following steps:

[0046] (1) Get 100 parts by weight of methyl methacrylate, 20 parts by weight of methyl acrylate, 50 parts by weight of nano silicon dioxide, 0.4 parts by weight of n-dodecyl mercaptan and add to 100 parts by weight of organic solvent In the process of stirring, add 0.3 parts by weight of the first initiator, and then react at 50°C for 3 hours to obtain a pre-polymerization solution;

[0047] (2) Add 60 parts by weight of acrylonitrile and 10 parts by weight of methyl acrylate to the pre-polymerization solution, add 0.3 parts by weight of the second initiator during stirring, and then react at 50°C for 4 hours to obtain a polymerization liquid;

[0048] (3) Electrostatically spraying the polymer solution to obtain the special light diffusing agent.

[0...

Embodiment 3

[0057] A PC material with high light transmittance and high haze, comprising the following raw materials in parts by weight:

[0058]

[0059] Described special light diffusing agent is made through the following steps:

[0060](1) Get 90 parts by weight of methyl methacrylate, 15 parts by weight of methyl acrylate, 45 parts by weight of nano silicon dioxide, 0.3 parts by weight of n-dodecyl mercaptan and join to 100 parts by weight of organic solvent In the process of stirring, add 0.2 parts by weight of the first initiator, and then react at 45°C for 2 hours to obtain a pre-polymerization liquid;

[0061] (2) Add 50 parts by weight of acrylonitrile and 7.5 parts by weight of methyl acrylate to the pre-polymerization liquid, add 0.2 parts by weight of the second initiator during stirring, and then react at 45°C for 3 hours to obtain a polymerization liquid;

[0062] (3) Electrostatically spraying the polymer solution to obtain the special light diffusing agent.

[0063]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com