Preparation method of high-light-transmittance amphiphobic antireflection film

A technology of anti-reflection film and high light transmittance, applied in the direction of coating, etc., can solve the problems of low solid/liquid adhesion and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

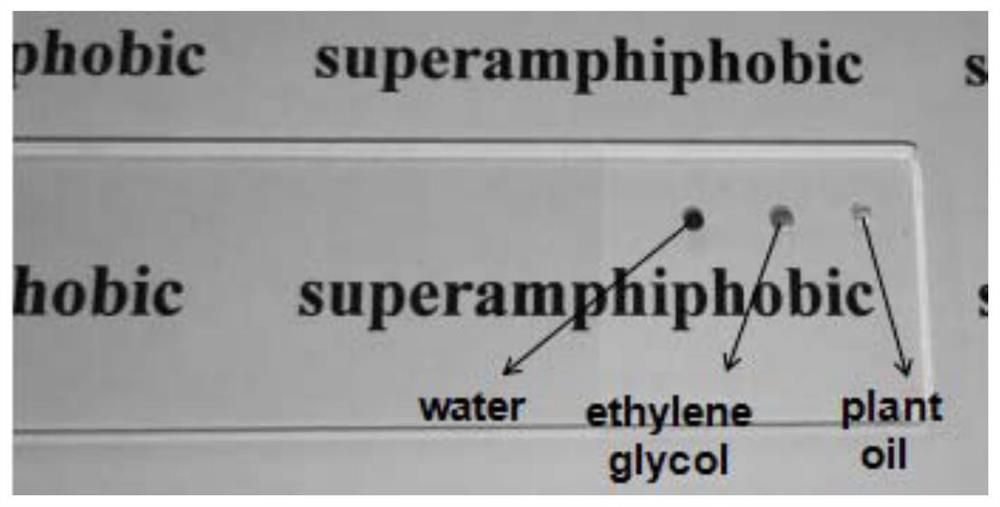

AI Technical Summary

Problems solved by technology

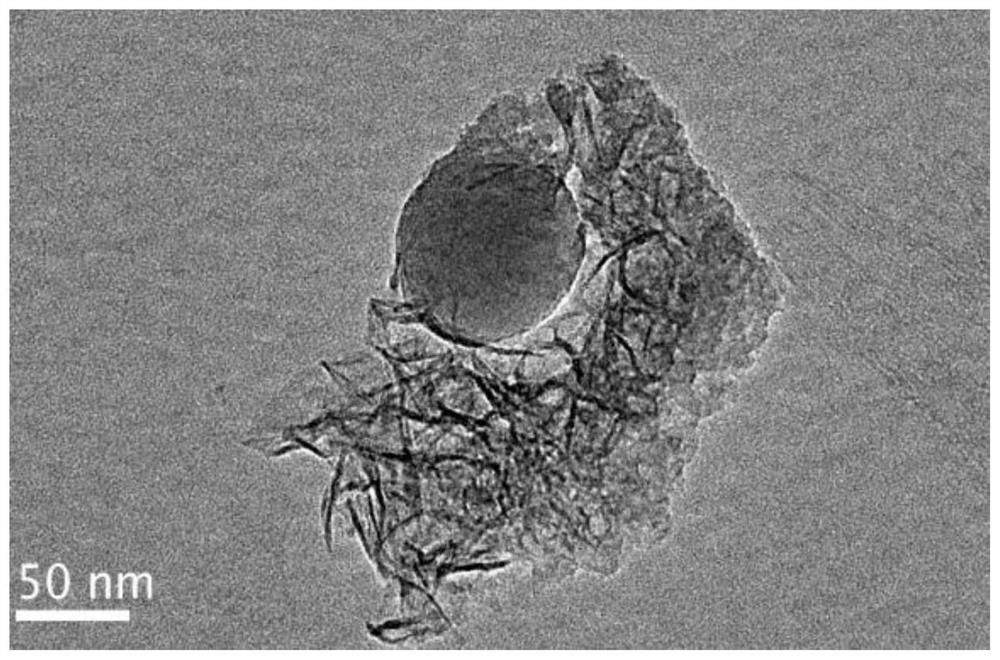

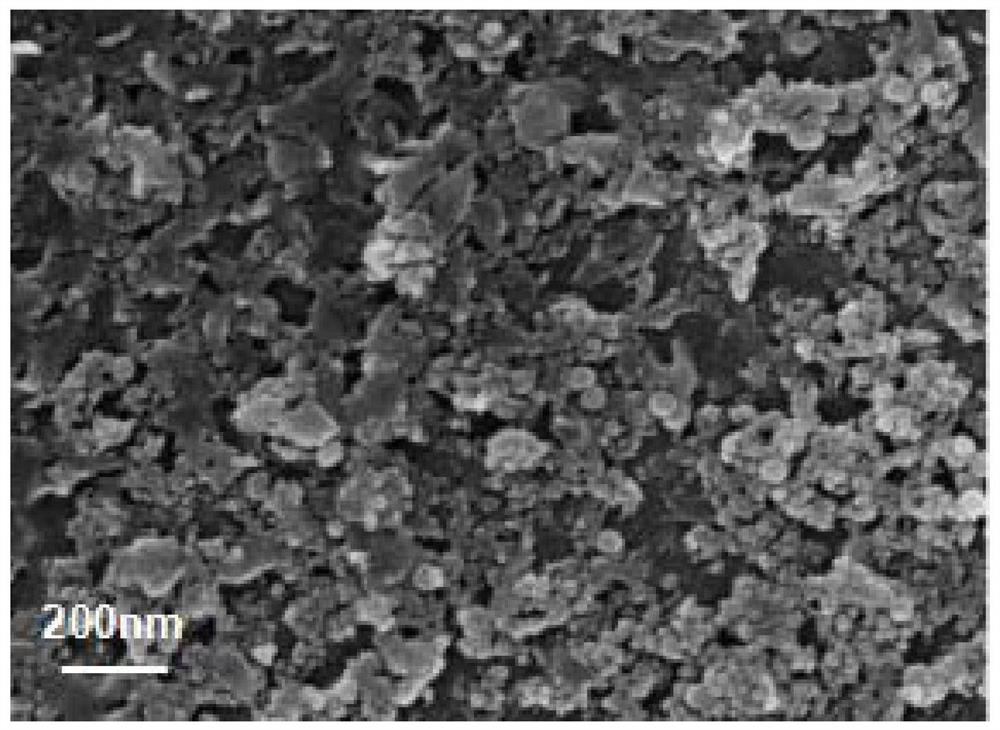

Method used

Image

Examples

Embodiment 1

[0025] (1) Aluminum nitrate is dissolved in 2-isopropoxyethanol, and then ethanolamine is added dropwise as a stabilizer. The resulting solution was stirred at room temperature for 1 hour to form a transparent aluminum sol;

[0026] Wherein, the mol ratio of aluminum nitrate and 2-isopropoxyethanol is 1:17, and the volume addition of ethanolamine is 3% of the volume addition of 2-isopropoxyethanol;

[0027] With ethanol (EtOH) as solvent, ammonia (NH 4 OH) as a catalyst, and tetraethyl orthosilicate (TEOS) as a silicon source, 20nm SiO was prepared by sol-gel method 2 Solid pellet sol;

[0028] Among them, EtOH, TEOS and NH 4 The molar ratio of OH is 114:3:5.4;

[0029] (2) 20nm SiO 2 Sol and Al 2 o 3 The sol is mixed at a mass ratio of 1:1 and dispersed ultrasonically to obtain uniform and stable SiO 2- al 2 o 3 Mixed sol.

[0030] (3) The dipping-pulling method is used to plate the coating, the pulling speed of the plated coating is 60mm / min, and the dipping time ...

Embodiment 2

[0033] Aluminum sol and SiO 2 The preparation of the solid bead sol is the same as in Example 1.

[0034] (1) 20nm SiO 2 Sol and Al 2 o 3 The sol is mixed at a mass ratio of 1:2 and dispersed ultrasonically to obtain uniform and stable SiO 2- al 2 o 3 Mixed sol.

[0035](2) The dipping-pulling method is used to plate the coating, the pulling speed of the plated coating is 60mm / min, and the dipping time is 360s. After the coated substrate was immediately cured at 100 °C for 5 min, it was calcined in a muffle furnace at 400 °C for 1 h to obtain Al 2 o 3 -SiO 2 membrane, and then immersed in deionized water at 90°C for 30 minutes to obtain a hydrophilic and lipophilic anti-reflective membrane.

[0036] (3) Put the plated film layer into a vacuum desiccator, drop 500 μL PFDTES into it, deposit it for 48 hours, and then put it into a 180° C. oven for curing for 30 minutes to prepare a double thinning anti-reflection film. The highest light transmittance of the coating is...

Embodiment 3

[0038] Aluminum sol and SiO 2 The preparation of the solid bead sol is the same as in Example 1.

[0039] (1) 20nm SiO 2 Sol and Al 2 o 3 The sol is mixed with a mass ratio of 1:3 and dispersed ultrasonically to obtain uniform and stable SiO 2- al 2 o 3 Mixed sol.

[0040] (2) The dipping-pulling method is used to plate the coating, the pulling speed of the plated coating is 60mm / min, and the dipping time is 360s. After the coated substrate was immediately cured at 100 °C for 5 min, it was calcined in a muffle furnace at 400 °C for 1 h to obtain Al 2 o 3 -SiO 2 membrane, and then immersed in deionized water at 90°C for 30 minutes to obtain a hydrophilic and lipophilic anti-reflective membrane.

[0041] (3) Put the plated film layer into a vacuum desiccator, drop 500 μL PFDTES into it, deposit it for 48 hours, and then put it into a 180° C. oven for curing for 30 minutes to prepare a double thinning anti-reflection film. The highest light transmittance of the coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com