Soft-touch hardening film

A hardening film and soft-touch technology, applied in the field of optical films, can solve the problems of affecting the visual effect and the decrease of the light transmittance of the hardened film, and achieve the effect of high light transmittance and improved elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

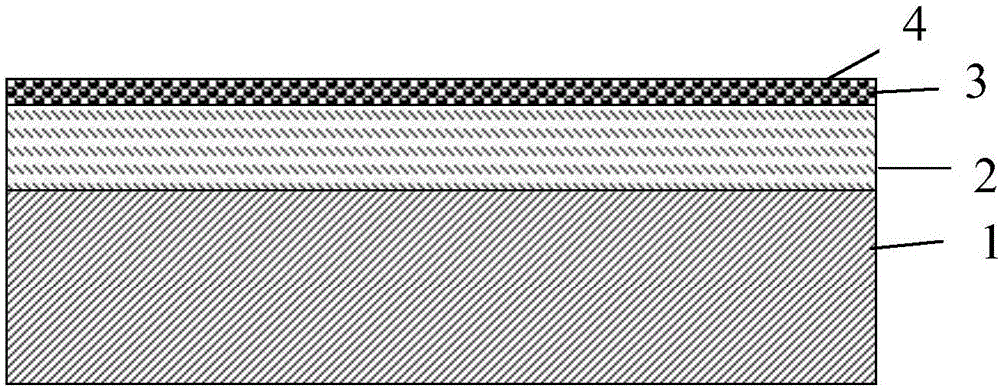

Image

Examples

Embodiment 1

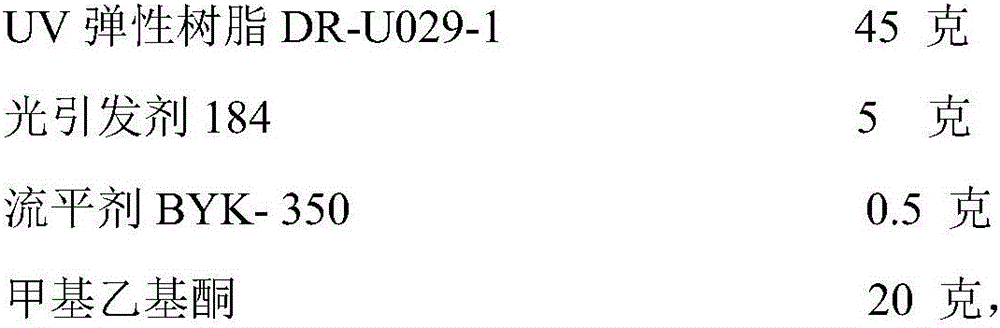

[0026] 1. Preparation of coating liquid for hand feeling layer

[0027]

[0028] Add 45 grams of UV elastic resin DR-U029-1 [Changxing Chemical], 5 grams of photoinitiator 184 [Tianjin Tianjiao Chemical Co., Ltd.], 0.5 grams of leveling agent BYK-350 [Bike], 20 gram of methyl ethyl ketone, stirred to obtain coating composition, stand-by.

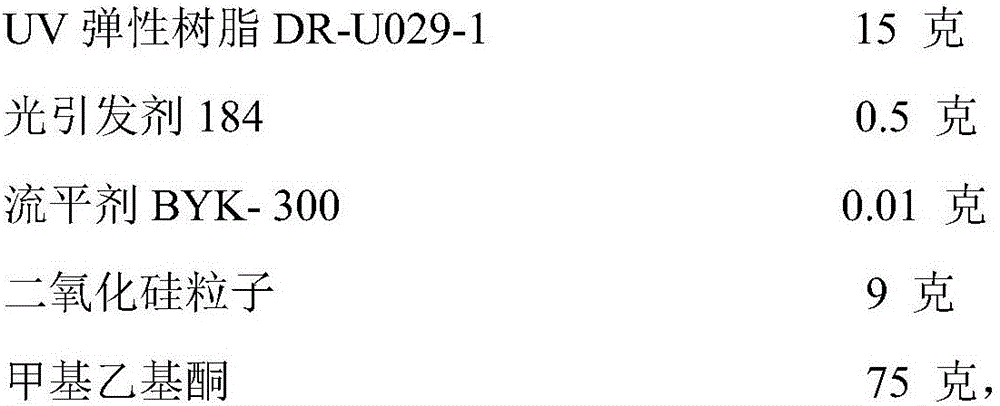

[0029] 2. Preparation of frosted layer coating solution:

[0030]

[0031] Add 15 grams of UV elastic resin DR-U029-1 [Changxing Chemical], 0.5 grams of photoinitiator 184 [Tianjin Tianjiao Chemical Co., Ltd.], 0.01 grams of leveling agent BYK-300 [Bike], 9 One gram of silicon dioxide particles [Degussa] with a particle size of 1 μm and 75 grams of methyl ethyl ketone were stirred to obtain a coating composition, which was ready for use.

[0032] 3. Preparation of soft-touch hardened film

[0033] On one optical surface of a polyethylene terephthalate film [PG52; Lucky] with a thickness of 25 μm, coat the coating solution for the ha...

Embodiment 2

[0036] 1. Preparation of coating liquid for hand feeling layer

[0037]

[0038] Add 37.5 grams of UV elastic resin CWD-52 [Gongyao International], 3.6 grams of photoinitiator TPO [Tianjin Tianjiao Chemical Co., Ltd.], 0.3 grams of leveling agent BYK-3560 [Bike], 30 grams ethyl acetate, stirred to obtain a coating composition, ready to use.

[0039] 2. Preparation of frosted layer coating solution:

[0040]

[0041]

[0042] Add 22.5 grams of UV elastic resin CWD-52 [Gongyao International], 1.3 grams of photoinitiator TPO [Tianjin Tianjiao Chemical Co., Ltd.], 0.13 grams of leveling agent BYK-331 [Bike], 15 grams PMMA particles with a particle size of 2 μm [Sekisui Chemical] and 67 grams of ethyl acetate were stirred to obtain a coating composition, which was set aside.

[0043] 3. Preparation of soft-touch hardened film

[0044] On one optical surface of a polyethylene terephthalate film [PG52; Lucky] with a thickness of 75 μm, coat the coating solution for the hand...

Embodiment 3

[0047] 1. Preparation of coating liquid for hand feeling layer

[0048]

[0049] Add 30 grams of UV elastic resin K-JA1553 [Zhide Chemical], 2.25 grams of photoinitiator 1173 [Tianjin Tianjiao Chemical Co., Ltd.], 0.25 grams of leveling agent BYK-394 [Bike], 40 grams of toluene, stirred to obtain a coating composition, and set aside.

[0050] 2. Preparation of frosted layer coating solution:

[0051]

[0052] Add 30 grams of UV elastic resin K-JA1553 [Zhide Chemical], 2.25 grams of photoinitiator 1173 [Tianjin Tianjiao Chemical Co., Ltd.], 0.25 grams of leveling agent Tech-206 [Tiger], 22.5 grams into the container Titanium dioxide with a particle size of 3 μm [Shanghai Edo Industry] and 60 grams of toluene were stirred to obtain a coating composition, which was set aside.

[0053] 3. Preparation of soft-touch hardened film

[0054] On one optical surface of a polyethylene terephthalate film [PG52; Lucky] with a thickness of 125 μm, coat the coating solution for the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com