Conductive 3D printing material, and preparation method and application thereof

A 3D printing, nano-conductive technology, applied in the field of 3D printing, can solve the problems of poor light transmittance, limited functionalization effect, and slurry sedimentation of 3D printing parts, achieve good electrical conductivity and light penetration, improve electrical conductivity, The effect of relieving sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

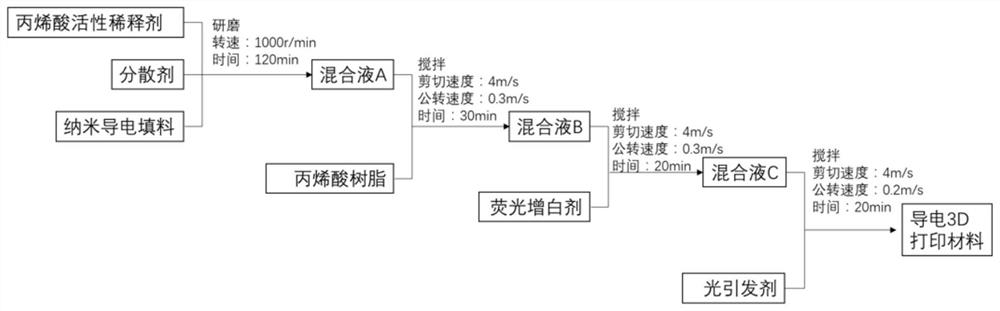

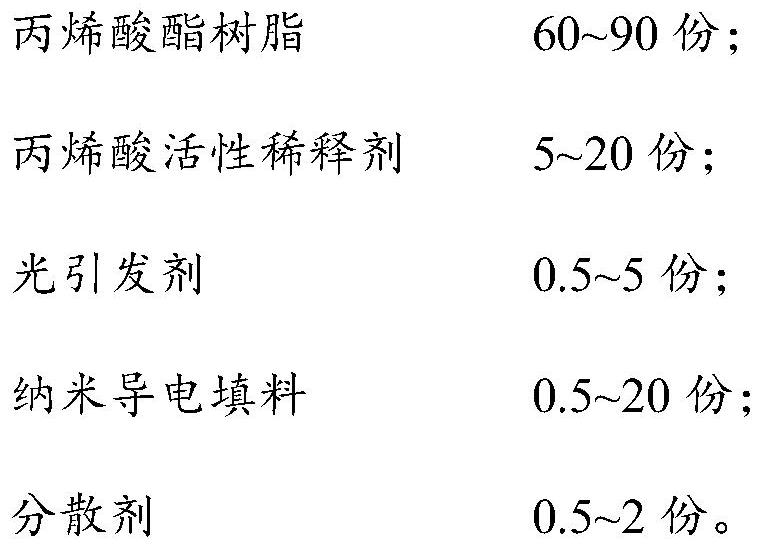

[0091] This example prepares a conductive 3D printing material. The specific raw material composition is shown in Table 1. The specific steps are as follows:

[0092] S1. After mixing the acrylic active diluent and dispersant, add the nano conductive filler three times (firstly mix the two nano conductive fillers evenly, and add the same mass each time), and grind; the grinding speed is 1000r / min, add the first time Grind for 20 minutes after the nano-conductive filler is added, grind for 40 minutes after adding the nano-conductive filler for the second time, and grind for 60 minutes after adding the nano-conductive filler for the third time. After the grinding is completed, the mixed solution A is obtained;

[0093] S2. Transfer the mixed liquid A to a double planetary stirring tank, add acrylate resin, and stir and mix for 30 minutes. During the stirring process, the shear speed is 4m / s, and the revolution speed is 0.3m / s. After the stirring is completed, the mixed liquid is ...

Embodiment 2

[0099] This example prepares a conductive 3D printing material. The specific difference from Example 1 is that the ratio of raw materials is different, and the specific raw material composition is shown in Table 1.

Embodiment 3

[0101] This example prepares a conductive 3D printing material. The specific difference from Example 1 is that the ratio of raw materials is different, and the specific raw material composition is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com